Induction Heating Roller Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432168 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Induction Heating Roller Market Size

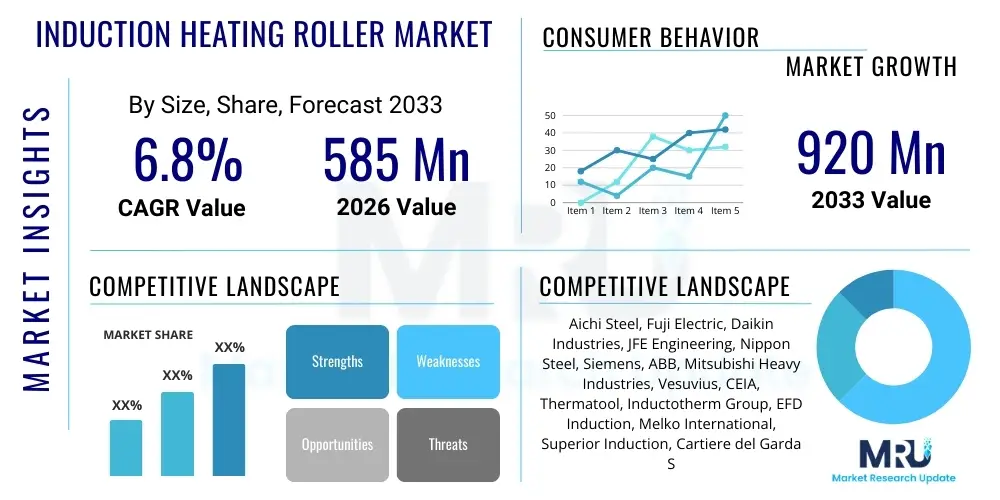

The Induction Heating Roller Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $585 Million USD in 2026 and is projected to reach $920 Million USD by the end of the forecast period in 2033. This robust expansion is primarily driven by the increasing global demand for high-precision thermal processing solutions across industries such as flexible packaging, non-woven textiles, and specialized printing, where precise temperature control and energy efficiency are paramount for material quality and operational cost reduction.

Induction Heating Roller Market introduction

The Induction Heating Roller Market encompasses advanced thermal processing equipment that utilizes electromagnetic induction principles to achieve rapid, highly uniform, and non-contact heating of roller surfaces. These specialized rollers are integral components in continuous web processing lines, offering significant advantages over traditional heating methods like hot oil circulation or electrical resistance heating by eliminating thermal inertia and enabling precise zone control. The core product provides a uniform temperature profile critical for sensitive material treatment, ensuring superior product quality, minimizing waste, and maximizing throughput in high-speed manufacturing environments. This technology is foundational in achieving the demanding specifications of modern flexible materials and composite structures.

Major applications of induction heating rollers span diverse industrial sectors, including plastic film stretching and calendering, high-speed textile lamination, specialized paper coating and drying, and the manufacture of battery separators and electronic films. The versatility and efficiency of induction heating rollers make them indispensable in processes requiring instantaneous temperature adjustments and high energy transfer rates. Furthermore, the inherent safety features associated with magnetic induction, combined with reduced maintenance requirements due to the absence of heating elements or circulating fluids, contribute significantly to their adoption. The market’s growth trajectory is strongly correlated with the rapid expansion of the global packaging industry and the stringent quality standards mandated in advanced materials manufacturing.

The primary driving factors propelling this market forward include the global push for enhanced manufacturing sustainability, necessitating energy-efficient heating technologies, and the relentless demand for higher quality and thinner materials, which requires absolute thermal precision. Induction rollers deliver superior energy efficiency, often exceeding 90%, compared to conventional systems, aligning perfectly with global decarbonization goals. Furthermore, the advancements in power electronics and control systems are making these rollers more accessible and easier to integrate into existing production lines. The shift towards Industry 4.0 principles also favors induction heating due to its inherent ability to provide real-time thermal monitoring and control, facilitating seamless integration into automated factory environments.

Induction Heating Roller Market Executive Summary

The Induction Heating Roller market is characterized by strong technological evolution and pronounced regional growth disparities, summarized by a persistent shift toward high-efficiency, multi-zone control systems. Business trends indicate an accelerated rate of strategic mergers and acquisitions among specialized component manufacturers and large industrial conglomerates aiming to consolidate expertise in power electronics and precision mechanics. Key players are heavily investing in developing smart rollers integrated with IoT capabilities to offer predictive maintenance services and enable remote performance diagnostics, transforming the product from a passive component into an active, data-generating asset within the production chain. Sustainability mandates are also driving innovation, with manufacturers focusing on lightweight designs and materials that further enhance operational efficiency and reduce the overall carbon footprint of web processing operations.

Regional trends reveal the Asia Pacific (APAC) region as the undisputed leader in market volume and growth potential, fueled by massive investment in flexible packaging, battery component manufacturing, and fast-growing non-woven industries, particularly in China, Japan, and South Korea. Conversely, mature markets in North America and Europe are focusing less on capacity expansion and more on technological upgrades and replacement cycles, emphasizing precision, energy savings, and adherence to stringent environmental regulations. European manufacturers, supported by robust engineering traditions, maintain a leading edge in high-specification, custom-engineered multi-zone roller solutions required for high-end applications like specialty films and technical textiles, commanding premium pricing and higher margins in these specialized segments.

Segment trends underscore the dominance of the Plastic & Film processing application segment, largely due to the escalating global demand for flexible packaging materials, driven by e-commerce expansion and changing consumer lifestyles. Within the product type segment, Multi-Zone Induction Heating Rollers are experiencing the fastest adoption rate. This trend is a direct response to the industry's need for longitudinal and lateral temperature gradient control across wide web materials, crucial for mitigating warping and ensuring homogenous quality during high-speed production. While the initial capital expenditure for multi-zone systems is higher, the superior process control and reduction in material waste provide a compelling return on investment, cementing their position as the future standard in high-precision thermal processing.

AI Impact Analysis on Induction Heating Roller Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Induction Heating Roller market commonly revolve around three core themes: predictive maintenance to eliminate unexpected downtime, optimization of energy consumption based on real-time production variables, and the ability of AI to ensure superior, consistent product quality by dynamically adjusting thermal profiles. Users are seeking assurances that AI integration can overcome the challenge of thermal drift caused by external factors (e.g., changes in ambient humidity or fluctuations in material thickness) which often plague traditional temperature control loops. The expectation is that AI algorithms will leverage historical operational data and real-time sensor feedback to model the complex thermal behavior of the roller and the processed web material, enabling proactive fine-tuning of the induction power to maintain a perfect, user-defined temperature gradient, thereby maximizing operational uptime and reducing material rejection rates substantially.

The integration of Machine Learning (ML) algorithms is rapidly moving from theoretical concept to practical application within high-end induction heating systems. These advanced algorithms analyze gigabytes of operational data, including current consumption, coil impedance, and surface temperature mapping, identifying subtle deviations that pre-empt component failure, such as bearing wear or minor electrical degradation, weeks before traditional diagnostics would flag an issue. This transition to predictive maintenance transforms maintenance schedules from reactive or time-based to condition-based, significantly increasing the effective operational lifespan of the rollers and minimizing total cost of ownership (TCO). Furthermore, AI is crucial for optimizing the heating process during material changeovers; instead of relying on fixed parameters, AI calculates the optimal ramp-up and stabilization profiles specific to the new material batch, cutting down non-productive setup time.

The highest value proposition of AI in this domain lies in process optimization for quality assurance. In processes like calendering or specialized film coating, maintaining a temperature uniformity within a fraction of a degree is mandatory. AI systems utilize sensor fusion—combining data from pyrometers, thermal cameras, and encoder feedback—to create a digital twin of the roller's thermal state. When a material characteristic shifts, potentially due to minor material inconsistency, the AI model instantaneously calculates the necessary micro-adjustments to the localized induction power supplied to specific zones. This dynamic, closed-loop thermal management system ensures that the output material consistently meets strict quality criteria, a level of precision unattainable by conventional PID controllers, thus fundamentally enhancing the reliability and performance of web processing machinery.

- AI enables predictive thermal drift compensation, ensuring precise temperature uniformity despite external variables.

- Machine Learning algorithms analyze operational data for predictive maintenance, significantly reducing unplanned downtime.

- IoT integration combined with AI facilitates real-time optimization of power consumption tailored to current production load.

- AI enhances quality control through sensor fusion, providing dynamic, closed-loop adjustment of multi-zone induction power.

- Smart rollers communicate performance metrics, allowing for remote diagnostics and rapid fault isolation, aligning with Industry 4.0 standards.

DRO & Impact Forces Of Induction Heating Roller Market

The Induction Heating Roller Market is being significantly driven by the imperative for operational efficiency, restrained primarily by high initial investment costs, and presents substantial opportunities rooted in technological diversification and geographical expansion. Drivers include the increasing global demand for high-performance composite materials and flexible packaging that require precise thermal treatment, coupled with regulatory pressures favoring energy-efficient manufacturing solutions. The induction process inherently offers faster ramp-up times and localized heating, leading to notable reductions in energy consumption compared to traditional thermal oil systems. This aligns directly with global industrial goals of reducing operational expenditure and environmental impact, thereby acting as a powerful market accelerator, especially in high-volume production environments where minute efficiency gains scale significantly.

The primary restraint challenging broader market adoption is the considerably high initial capital outlay required for induction heating roller systems and the associated specialized power supply electronics. The complexity of integrating these sophisticated systems, particularly the requirement for expert calibration and specialized maintenance knowledge, further complicates adoption for smaller and medium-sized enterprises (SMEs). Furthermore, while the operational costs are low, the dependence on highly skilled technical staff for maintenance and troubleshooting represents a barrier in regions with developing industrial labor markets. These restraints necessitate manufacturers to focus on modular, standardized designs that simplify integration and maintenance, thereby improving the long-term total cost of ownership (TCO) calculation for potential buyers.

Opportunities for growth are abundant, particularly in emerging applications such as the high-precision processing of battery electrodes, non-woven materials used in hygiene products, and specialized medical films, all requiring immaculate thermal precision. Geographical expansion into rapidly industrializing regions in Southeast Asia and Latin America represents a significant growth pathway, as these regions upgrade their manufacturing infrastructure to meet international quality standards. Furthermore, technological opportunities lie in developing hybrid heating systems that combine induction with other methods, optimizing performance for extremely specialized materials, and enhancing smart features through advanced IoT integration, further differentiating the induction roller solution in a competitive industrial machinery landscape. These market forces collectively shape the competitive dynamics, prioritizing technological superiority and application-specific engineering over sheer cost reduction.

Segmentation Analysis

The Induction Heating Roller Market segmentation provides a granular view of market dynamics, categorized fundamentally by Product Type, Application, and End-User Industry, reflecting the varying technological requirements and consumer demands across sectors. The segmentation by type—primarily Single-Zone versus Multi-Zone Rollers—highlights the growing technological sophistication, with multi-zone systems catering to applications requiring extremely high cross-web temperature uniformity, essential for wide-format, thin-gauge materials. Analyzing the application segment helps define the most lucrative revenue streams, where Plastic & Film processing traditionally dominates, but emerging areas like technical textiles and battery component manufacturing offer higher growth potential.

The performance differential between Single-Zone and Multi-Zone systems is critical for understanding adoption patterns. Single-Zone rollers, offering simplicity and lower cost, suffice for less stringent thermal applications or narrow web processing. However, the rise of Multi-Zone induction rollers, which utilize segmented coils and independent power supply channels to control temperature gradients along the width of the roller, is indicative of the industry's shift toward demanding higher quality output and tighter process control, especially in high-speed lamination and calender lines. This technological stratification allows manufacturers to tailor their product offerings precisely to specific application needs, ranging from basic drying tasks to complex thermal bonding processes.

End-user analysis demonstrates the cyclical demand patterns of heavy industrial buyers. Key end-user industries such as Flexible Packaging and Non-woven Textiles are characterized by high volume consumption and rapid adoption of new efficiency technologies. Conversely, specialized segments like Aerospace Composites, while low volume, demand highly customized, ultra-precise induction rollers, driving significant research and development efforts. Understanding these segment dynamics is vital for market participants to strategically allocate R&D resources, optimize production portfolios, and implement targeted sales strategies that address the specific performance requirements and regulatory landscapes of each industry sector.

- By Type:

- Single Zone Induction Heating Rollers

- Multi Zone Induction Heating Rollers

- By Application:

- Plastic and Film Processing (Calendering, Laminating, Stretching)

- Paper and Printing Industry (Coating, Drying)

- Textiles and Non-Wovens (Thermal Bonding, Finishing)

- Automotive Component Manufacturing

- Battery and Electronic Films Production

- Others (Medical Films, Specialty Coatings)

- By End-User Industry:

- Packaging Manufacturers

- Laminating and Converting Industries

- Calendering Equipment Users

- Technical Textile Producers

- Specialty Material Manufacturers

Value Chain Analysis For Induction Heating Roller Market

The value chain for the Induction Heating Roller Market is inherently complex, characterized by stringent requirements for specialized upstream components and highly technical downstream integration. Upstream activities involve the procurement and processing of specialized materials, including high-purity steel or advanced ceramics for the roller shells, sophisticated litz wire for the induction coils, and, critically, high-frequency Insulated Gate Bipolar Transistor (IGBT) power modules for the power supply unit. The precision required in coil winding and the engineering of the magnetic field structure are significant bottlenecks, demanding high intellectual property protection and specialized manufacturing expertise, often resulting in a consolidated supplier base for these core components.

Midstream activities focus on the core manufacturing process, which includes precision machining of the roller core, integration of the induction coil assembly, dynamic balancing, and meticulous integration of temperature sensing and control systems. This stage often involves highly customized engineering based on the specific web width, line speed, and material being processed by the end-user. Distribution channels vary significantly; highly specialized, custom-engineered rollers are typically sold through direct sales channels, involving extensive consultation and integration support provided by the roller manufacturer. Conversely, standardized, smaller induction heating units may be distributed via established industrial machinery distributors or system integrators who package the roller solution with broader web handling machinery.

Downstream analysis centers on the system integration and final application. Original Equipment Manufacturers (OEMs) of plastic film lines, calenders, and textile machinery are key consumers, integrating the rollers into their overall machine design. End-users receive the final product, and the value chain extends to include post-sales services such as commissioning, calibration, and long-term maintenance contracts, which often involve remote diagnostics and specialized technical support due to the complexity of induction technology. The preference for direct sales in complex projects highlights the necessity for manufacturers to maintain strong, technically competent sales and service teams capable of addressing precise client specifications and ensuring optimal system performance within the customer's production environment.

Induction Heating Roller Market Potential Customers

The primary customer base for Induction Heating Rollers consists of industrial entities engaged in continuous web-based material processing where uniform and highly controlled thermal input is non-negotiable for product quality. These end-users are typically characterized by high-volume production, stringent quality control standards, and a focus on maximizing energy efficiency and minimizing material waste. Key buyers include large multinational corporations specializing in flexible packaging production, such as producers of food wraps, medical sterilization pouches, and industrial shrink films, as they rely on lamination and sealing processes that demand exceptional thermal stability.

A significant segment of potential customers includes specialized producers within the textiles and non-wovens sector, particularly those manufacturing technical fabrics, hygiene components, and filtration media. In these applications, thermal bonding and calendering must be executed with superior precision to maintain material permeability, strength, and tactile properties without degradation. These customers often seek multi-zone rollers to handle wide, sensitive webs at high speeds. Furthermore, the burgeoning electric vehicle (EV) battery industry represents a high-growth customer segment, as manufacturers of lithium-ion battery separators and electrode foils require extremely accurate and reproducible heating cycles to ensure the electrochemical integrity and safety of the final product.

Finally, traditional paper and printing industries, particularly in high-end specialty coating and drying applications, continue to be stable consumers. However, the most compelling potential lies with system integrators and OEMs that specialize in providing turnkey web processing machinery. These companies act as intermediaries, specifying and procuring induction rollers based on the demanding requirements of their diverse client base. Targeting these integrators allows roller manufacturers to gain access to a broad range of end-user markets without the need for individual sales channels in every vertical, making them crucial strategic partners in market penetration efforts.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $585 Million USD |

| Market Forecast in 2033 | $920 Million USD |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Aichi Steel, Fuji Electric, Daikin Industries, JFE Engineering, Nippon Steel, Siemens, ABB, Mitsubishi Heavy Industries, Vesuvius, CEIA, Thermatool, Inductotherm Group, EFD Induction, Melko International, Superior Induction, Cartiere del Garda S.p.A., Andritz AG, IHI Corporation, Fives Group, SMS Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Induction Heating Roller Market Key Technology Landscape

The technological evolution of the Induction Heating Roller market is centered on enhancing thermal uniformity, boosting power efficiency, and improving system integration capabilities, largely driven by advancements in power electronics and sensor technology. Current cutting-edge systems utilize sophisticated multi-layer Litz wire coil designs engineered to create highly concentrated and uniform magnetic fields, minimizing edge effects and thermal inconsistencies across the roller surface, which is crucial for processing extra-wide web materials. Furthermore, the adoption of high-performance IGBT (Insulated Gate Bipolar Transistor) inverter technology allows for precise, ultra-fast control over the high-frequency current, facilitating instantaneous adjustment of heating power and enabling the rapid realization of complex, dynamic temperature profiles mandated by modern material science processes.

A critical area of innovation involves the implementation of advanced temperature sensing and feedback mechanisms. Traditional contact thermocouples are being superseded by non-contact technologies, primarily high-resolution infrared pyrometers and thermal imaging cameras, which provide real-time, comprehensive temperature maps of the roller surface. These precise readings feed into advanced proprietary control algorithms that use predictive models to compensate for variables like roller rotation speed and ambient temperature, maintaining stability within tighter tolerances (often ±0.5°C). The integration of robust shielding techniques and specialized materials (such as ceramic coatings or nickel alloys) for the roller surface also contributes to system longevity and efficiency by minimizing heat loss and resisting corrosion and abrasion in harsh industrial environments, extending the operational life between maintenance cycles.

The future technology landscape is heavily invested in digital integration and self-optimization. The increasing adoption of the Industrial Internet of Things (IIoT) is enabling induction heating rollers to become smart, interconnected devices capable of communicating performance data directly to centralized plant management systems. This facilitates remote monitoring, proactive diagnostics using cloud-based AI analytics, and seamless integration with broader Manufacturing Execution Systems (MES). Key players are developing modular power supply units and standardized communication protocols (such as OPC UA) to simplify retrofitting existing industrial lines and accelerate the deployment of these energy-efficient systems globally, ensuring the technology remains competitive against older, less controllable heating methods.

Regional Highlights

Asia Pacific (APAC) is recognized as the largest and fastest-growing market for Induction Heating Rollers, primarily driven by massive industrial capacity expansion in key economies like China, India, Japan, and South Korea. This region serves as the global hub for manufacturing high-volume goods, including flexible packaging, consumer electronics films, and, most significantly, EV batteries. The push for localized production of battery components, coupled with stringent quality requirements for separators and electrode foils, mandates the use of precision thermal control equipment, thereby driving high demand for Multi-Zone induction rollers. Government initiatives focused on industrial modernization and boosting energy efficiency across manufacturing sectors further underpin the robust growth observed across the APAC industrial corridor, often leading to rapid adoption of new, sophisticated thermal solutions.

Europe represents a mature but highly innovation-focused market, where growth is driven less by capacity expansion and more by the imperative for technological upgrade and adherence to stringent environmental and energy efficiency regulations, such as those related to the European Green Deal. European manufacturers are leaders in high-precision, customized engineering, dominating specialized niches like technical textiles, medical films, and high-security printing, where thermal tolerances are extremely narrow. The strong presence of major machinery manufacturers (OEMs) specializing in printing and converting equipment in countries like Germany and Italy ensures a consistent demand for advanced, smart induction rollers integrated with sophisticated control systems. The focus here is on lifetime operating costs and sustainability performance, rather than outright purchase price.

North America is characterized by a strong emphasis on automation and the replacement of aging infrastructure. The market is concentrated in high-value manufacturing segments such as aerospace composites, advanced materials processing, and specialized packaging for pharmaceutical and food industries. Demand is steady, fueled by the necessity for manufacturers to maintain competitiveness by reducing operational expenses and improving material throughput. Investment is focused on smart, IoT-enabled roller systems that offer predictive maintenance features and seamless data integration into existing SCADA systems. While the manufacturing base is smaller than APAC, the high average selling price (ASP) of sophisticated, large-format induction systems ensures the region maintains a significant market value share, often demanding highly durable, customized solutions tailored for demanding 24/7 operational cycles.

Latin America and Middle East & Africa (MEA) currently constitute smaller segments of the global market, but they exhibit nascent growth potential, particularly in specific industrial pockets. In Latin America, industrialization in Brazil and Mexico, especially within the automotive and packaging sectors, is stimulating demand for imported, energy-efficient processing equipment. For MEA, investment in specialized manufacturing—often tied to renewable energy (e.g., solar film production) and basic commodity processing—is slowly increasing the adoption of induction heating technologies. These regions are primarily price-sensitive, often preferring simpler, single-zone induction rollers, but they are increasingly recognizing the long-term cost benefits associated with precision thermal control and energy savings, indicating future opportunities for market expansion.

- APAC: Dominates in volume and growth, driven by flexible packaging, EV battery component manufacturing, and rapid industrialization in China and India.

- Europe: High-value, mature market focused on technological upgrades, energy efficiency, and precision engineering for specialty films and technical textiles.

- North America: Stable demand centered on replacing obsolete systems and integrating smart, automated induction rollers for high-end applications like aerospace and specialty packaging.

- MEA & Latin America: Emerging markets showing steady growth, driven by modernization efforts and increasing adoption of energy-efficient solutions in packaging and basic manufacturing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Induction Heating Roller Market.- Aichi Steel Corporation

- Fuji Electric Co., Ltd.

- Daikin Industries, Ltd.

- JFE Engineering Corporation

- Nippon Steel Corporation

- Siemens AG

- ABB Ltd.

- Mitsubishi Heavy Industries, Ltd.

- Vesuvius plc

- CEIA S.p.A.

- Thermatool Corp. (Inductotherm Group)

- EFD Induction Group

- Melko International Co., Ltd.

- Superior Induction, Inc.

- Cartiere del Garda S.p.A.

- Andritz AG

- IHI Corporation

- Fives Group

- SMS Group GmbH

Frequently Asked Questions

Analyze common user questions about the Induction Heating Roller market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary energy efficiency advantages of induction heating rollers compared to traditional systems?

Induction heating rollers offer superior energy efficiency, often exceeding 90% power-to-heat conversion, because they heat the roller surface directly via electromagnetic induction (non-contact), minimizing thermal losses associated with circulating fluids or indirect resistance heating. They also reduce energy consumption by providing faster startup times and highly localized heating only when necessary.

How does multi-zone induction technology improve product quality in web processing?

Multi-zone induction technology utilizes segmented coils and independent power controls to precisely manage temperature gradients across the width of the roller. This dynamic control eliminates thermal non-uniformity (hot spots or cold edges), which is critical for wide web materials like plastic films and laminates, ensuring consistent thickness, density, and adhesion, thereby significantly reducing material waste.

What is the typical lifespan and maintenance requirement for an induction heating roller system?

The typical operational lifespan of an induction heating roller system, excluding routine bearing and seal replacements, often exceeds 15-20 years. Maintenance requirements are low because there are no heating elements to replace and no thermal fluids to manage. Modern systems integrate AI-driven predictive maintenance, notifying operators of potential issues like bearing wear or coil degradation before catastrophic failure occurs.

Which industrial applications are driving the highest demand for advanced induction heating rollers?

The highest demand for advanced (multi-zone, high-precision) induction heating rollers is driven by the Flexible Packaging industry (for high-speed lamination and sealing), the Non-Woven Textiles sector (for precise thermal bonding), and, increasingly, the specialized manufacturing of components for Electric Vehicle (EV) batteries, particularly separators and electrode foils.

Is the high initial cost of induction heating rollers justified by long-term operational savings?

Yes, while the initial capital expenditure is higher than traditional heating methods, the long-term operational savings justify the investment. These savings stem from reduced energy consumption, minimal maintenance needs, decreased production downtime due to high reliability, and a significant reduction in material scrap rates enabled by superior process control and thermal uniformity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager