Induction Sealing Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431888 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Induction Sealing Machine Market Size

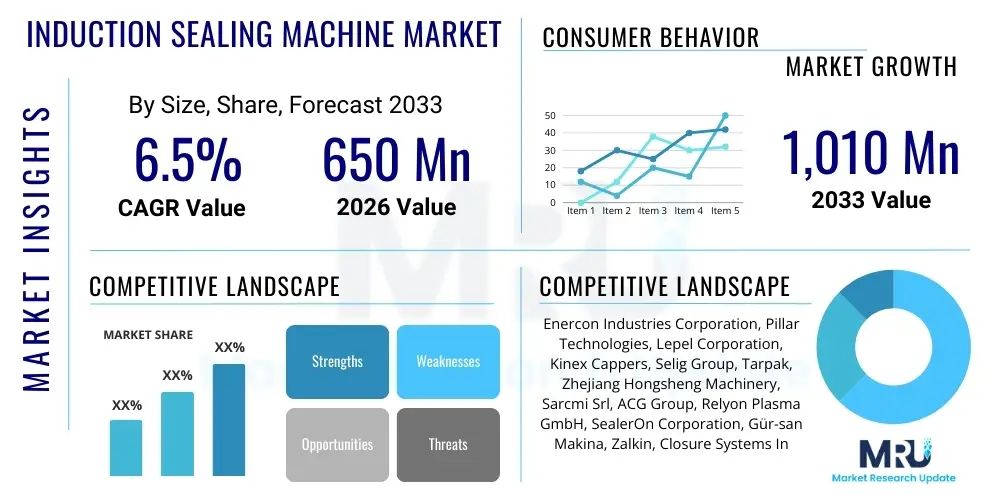

The Induction Sealing Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 1,010 Million by the end of the forecast period in 2033.

Induction Sealing Machine Market introduction

The Induction Sealing Machine Market encompasses equipment used to create hermetic seals on containers, typically utilizing aluminum foil liners activated by electromagnetic induction. This non-contact sealing process is critical for preserving product freshness, preventing leakage, and offering tamper evidence across various packaging industries. Induction sealing equipment operates by generating an electromagnetic field that heats a conductive aluminum foil liner placed within the container cap. The heat melts the polymer coating on the liner, bonding it securely to the container lip, resulting in a reliable and airtight barrier essential for product integrity and consumer safety.

These machines are broadly categorized based on their level of automation, including manual, semi-automatic, and high-speed automatic systems, catering to diverse production volumes ranging from small-scale operations to large pharmaceutical and food processing plants. Major applications span the Food and Beverage sector (sauces, beverages, dairy), Pharmaceuticals (medicines, supplements), Cosmetics (creams, lotions), and Chemical industries (agrochemicals, lubricants). The primary benefits derived from utilizing induction sealing technology include extended shelf life, enhanced security against counterfeiting, superior leak prevention, and compliance with stringent international packaging standards, making it indispensable for modern manufacturing lines.

Driving factors for market expansion include the increasing global demand for packaged food and beverages, driven by urbanization and changing consumer lifestyles, necessitating robust sealing solutions for extended transit and storage. Furthermore, growing regulatory emphasis on tamper-evident packaging, particularly in the pharmaceutical and nutraceutical sectors, mandates the adoption of induction sealing technology. Technological advancements focused on increasing sealing efficiency, reducing energy consumption through solid-state designs, and integrating machine vision systems for quality control are also significant propellers of market growth, offering higher throughput and reduced operational costs to end-users globally.

Induction Sealing Machine Market Executive Summary

The Induction Sealing Machine Market is characterized by robust growth, primarily fueled by stringent global regulations mandating tamper-evident packaging and the expansion of the Food and Beverage (F&B) industry in emerging economies. Current business trends indicate a shift towards highly automated, high-speed induction sealers that integrate seamlessly with existing filling and capping lines, prioritizing efficiency and minimal footprint. There is a notable trend in adopting advanced technologies such as water-cooled, solid-state induction generators which offer superior power density and reliability compared to traditional air-cooled systems, thereby driving down maintenance costs and improving overall equipment effectiveness (OEE).

Regionally, the Asia Pacific (APAC) stands out as the fastest-growing market due to rapid industrialization, burgeoning pharmaceutical manufacturing bases in countries like India and China, and increasing consumer spending on packaged goods. North America and Europe, while mature, maintain strong market share, primarily driven by the replacement of older machinery with IoT-enabled, high-precision models capable of handling complex materials and specialized container shapes. Regulatory bodies, particularly the FDA and EMA, continue to influence procurement decisions globally, forcing manufacturers to invest in verifiable sealing processes to ensure consumer safety and product quality.

In terms of segmentation, automatic, high-power induction sealing machines are expected to dominate the market share, reflecting the industry's continuous drive toward mass production efficiency, especially within the liquid packaging segment. The pharmaceutical segment remains a high-value growth area, demanding specialized, validated sealing equipment that meets Good Manufacturing Practice (GMP) standards, often requiring integrated non-destructive seal integrity testing. Furthermore, the consumables side, specifically the conductive liners and seals, is experiencing innovation, focusing on sustainable, bio-degradable materials and specialized barriers for aggressive chemical products, ensuring comprehensive market expansion across the entire value chain.

AI Impact Analysis on Induction Sealing Machine Market

User inquiries regarding the integration of Artificial Intelligence (AI) in induction sealing primarily center on predictive maintenance capabilities, enhanced quality assurance, and optimization of machine parameters for diverse packaging materials. Users are seeking to understand how Machine Learning (ML) algorithms can predict component failure (such as generator overheating or coil degradation) before it leads to costly downtime, moving from reactive or preventative maintenance to truly predictive strategies. A significant concern revolves around using AI-powered vision systems for real-time, non-destructive seal integrity checks, ensuring 100% quality compliance without slowing down high-speed production lines. Furthermore, end-users are keen on leveraging AI to automatically adjust the sealing time and power level based on ambient temperature, conveyor speed fluctuations, and minor variations in cap material, thus optimizing energy usage and maximizing seal consistency across long production runs.

AI's primary influence is enabling smart manufacturing within the induction sealing domain. By collecting vast amounts of operational data—including power consumption curves, temperature profiles, and throughput rates—ML models can identify anomalies indicative of imminent equipment failure, offering precise maintenance scheduling. This shift dramatically reduces unplanned downtime, a critical factor in high-volume industries like beverages and pharmaceuticals. AI also enhances efficiency by facilitating autonomous process optimization, where the machine learns the optimal sealing parameters for new product changeovers faster and more reliably than manual human adjustment, leading to faster setup times and reduced material waste during commissioning.

The integration of deep learning algorithms with high-resolution cameras allows for sophisticated inspection far beyond simple presence detection. AI can detect microscopic faults, incomplete seals, or material inconsistencies on the foil liner or container lip that would be undetectable by traditional sensors. This superior level of quality control ensures compliance with stringent regulatory requirements while simultaneously building a robust data history that supports continuous process improvement and regulatory audits. Ultimately, AI elevates induction sealing machines from simple mechanical devices to integral, intelligent components of a fully networked, smart packaging line, ensuring unprecedented levels of reliability, efficiency, and compliance.

- Predictive Maintenance (P-M) utilizing ML to forecast coil or generator failures.

- Real-time Seal Integrity Verification via AI-powered vision systems for non-destructive testing.

- Automated Parameter Optimization for sealing power and duration based on material variations.

- Enhanced Energy Efficiency through algorithmic adjustment of power output.

- Improved Root Cause Analysis by correlating sealing failures with operational data patterns.

- Autonomous Changeover Management reducing manual calibration time for different container formats.

DRO & Impact Forces Of Induction Sealing Machine Market

The Induction Sealing Machine Market is primarily driven by the escalating demand for tamper-evident packaging mandated across global supply chains, coupled with the inherent benefits of extended shelf life, which is critical for perishable goods and international distribution. A major restraint, however, involves the high initial capital investment required for high-speed, fully automatic induction sealing systems, especially for smaller and medium-sized enterprises (SMEs). This barrier to entry is compounded by the need for specialized consumables, namely the aluminum foil liners, which add recurring operational costs and complexity in sourcing. Opportunities are vast, focused on developing sustainable, non-metallic induction-compatible sealing solutions to meet growing environmental standards and expanding the application scope into niche markets like cannabis-infused products and specialized industrial chemicals that require highly robust, chemical-resistant seals. The prevailing impact forces are technological innovation, pushing towards solid-state, energy-efficient designs, and regulatory harmonization, demanding consistent sealing quality across all geographic regions.

Driving factors are inherently linked to consumer safety and market expansion. The rapid growth of e-commerce necessitates highly reliable, leak-proof packaging to withstand complex logistics and handling, boosting demand for induction sealing in categories like household cleaning products and cosmetics shipped directly to consumers. Furthermore, the global proliferation of counterfeiting activities, particularly affecting high-value pharmaceutical brands, accelerates the adoption of robust, verifiable tamper-proof solutions like induction seals. Technological advancements, such as the development of wider sealing heads and multi-lane systems, enable higher production throughput, directly addressing the scaling needs of large manufacturing operations in APAC.

Conversely, market restraints include the technical challenge of sealing containers made from recycled plastics or materials with high variation in wall thickness, which can lead to inconsistent heat transfer and seal failure. Economic volatility in certain regions can also impact capital expenditure budgeting, delaying the adoption of new machinery. The primary opportunities lie in capitalizing on the shift toward sustainability, developing liners that are easily separable from the cap material to facilitate recycling, and integrating IoT capabilities for remote diagnostics and maintenance, improving overall global service delivery. Impact forces necessitate that manufacturers continuously innovate to improve sealing consistency (a major pain point for users) and adhere strictly to global food contact material regulations, demanding detailed material traceability and process validation.

Segmentation Analysis

The Induction Sealing Machine Market is comprehensively segmented across several dimensions, including the type of machine automation, the power output of the induction generator, the cooling mechanism employed, and the primary end-user industry. This granular segmentation is crucial for understanding specific market dynamics, regional adoption patterns, and technological preferences. The core differentiators lie between low-speed, manual systems suitable for pilot projects or small-scale operations and high-speed, fully automatic systems integral to pharmaceutical and high-volume food production lines. End-user classification is arguably the most influential segment, as regulatory compliance and packaging requirements differ dramatically between sectors like pharmaceuticals, which demand validation, and the beverage sector, which prioritizes speed and throughput efficiency.

Segmentation by technology type, specifically focusing on cooling mechanisms (Air-Cooled vs. Water-Cooled), highlights the industry's move toward higher reliability and denser power packages. Water-cooled systems, while requiring complex infrastructure, offer superior power consistency and are essential for continuous, high-duty cycle applications commonly found in automated lines. Conversely, air-cooled, often handheld or semi-automatic units, prioritize portability and ease of installation, dominating the lower power spectrum of the market. Understanding this segmentation helps manufacturers tailor power capacity and cooling solutions to match specific industrial environments and production rate requirements globally.

Furthermore, segmentation by sealing head design—flat heads, tunnel heads, or custom heads for specialized necks—reflects the growing complexity in container geometry and material science. The trend towards lightweight packaging and sustainable bottle designs often necessitates customized sealing solutions that can adapt to thin-walled containers without deformation while ensuring perfect seal integrity. The detailed analysis of these segments is key to identifying niche high-growth areas, such as the demand for sealing equipment compatible with high-barrier plastic resins like PET and HDPE, which are crucial for oxygen-sensitive products in the food and nutraceutical industries.

- By Automation Type:

- Handheld Induction Sealing Machines (Portable)

- Semi-Automatic Induction Sealing Machines (Batch Production)

- Automatic In-Line Induction Sealing Machines (High Volume)

- By Power Output:

- Low Power (500W - 2kW)

- Medium Power (2kW - 6kW)

- High Power (6kW and Above)

- By Cooling Mechanism:

- Air-Cooled Systems

- Water-Cooled Systems

- By End-Use Industry:

- Food and Beverage (F&B)

- Pharmaceutical and Nutraceutical

- Cosmetics and Personal Care

- Chemical and Petrochemical

- Others (e.g., Agrochemicals, Lubricants)

- By Sealing Head Type:

- Flat Sealing Heads

- Tunnel Sealing Heads (Deep caps)

- Custom and Specialized Heads

Value Chain Analysis For Induction Sealing Machine Market

The Induction Sealing Machine market value chain begins with the upstream suppliers of critical raw materials, primarily electronic components such as high-frequency transistors (IGBTs), power supply units, and specialty copper coils used in the induction generator and sealing head. This stage is crucial, as the performance and reliability of the final machine are directly dependent on the quality and robustness of these sophisticated electronic parts, demanding stringent quality control from component manufacturers. Suppliers of control systems, including PLCs and human-machine interfaces (HMIs), also form a vital part of the upstream segment, dictating the machine's user-friendliness and integration capabilities within smart factory environments. Price volatility and supply chain resilience for semiconductors are ongoing factors influencing upstream costs and lead times for machine manufacturers.

The midstream involves the core activities of induction sealing machine manufacturers. This stage includes sophisticated R&D for developing efficient solid-state generators, precision engineering for mechanical integration (conveyor systems, height adjustment), and software development for advanced control and diagnostics. Key activities involve assembly, rigorous testing, and compliance certification (CE, UL, FDA validation readiness). Distribution channels facilitate the movement of the finished equipment to end-users. Direct distribution is common for high-value, complex automated systems requiring specialized installation and ongoing maintenance contracts, allowing manufacturers to maintain tight control over customer relationships and service quality. Indirect channels, involving authorized distributors and regional agents, are often employed for simpler, standardized, or handheld models, particularly in fragmented or geographically dispersed markets like APAC.

Downstream activities center on installation, commissioning, training, and extensive after-sales service, which includes supplying spare parts, conducting routine maintenance, and providing performance upgrades. The downstream segment also heavily interacts with suppliers of consumables—the actual aluminum foil seals and liners—which must be perfectly matched to the sealing machine specifications and the container material. End-users (e.g., pharmaceutical companies) demand comprehensive validation documentation (IQ/OQ/PQ) and long-term service agreements, making post-sale support a critical differentiator. The downstream success is measured by minimizing downtime and maximizing the OEE of the installed machinery, ensuring the sustained value delivery to the packaging operation.

Induction Sealing Machine Market Potential Customers

Potential customers for induction sealing machines represent a diverse global cohort of manufacturing entities whose products require guaranteed freshness, extended shelf life, or tamper-evident features. The largest segment of buyers consists of multinational corporations and high-volume regional players within the Food and Beverage (F&B) industry, including manufacturers of dairy products, bottled water, juices, edible oils, sauces, and condiments. These entities utilize automatic in-line systems, prioritizing speed (caps per minute) and reliability to maintain continuous production cycles. Their purchasing decisions are driven by the need for regulatory compliance regarding food safety and the imperative to reduce product recalls resulting from packaging failure.

The pharmaceutical and nutraceutical sectors constitute another high-value customer base, characterized by stringent regulatory oversight (FDA, EMA). These buyers, including generic drug manufacturers, specialized biotech firms, and vitamin/supplement producers, demand validated sealing equipment that adheres to Good Manufacturing Practices (GMP). Their focus is less on sheer speed and more on precise control, data logging capabilities, and the integration of non-destructive seal integrity testing mechanisms to ensure dosage integrity and prevent contamination. They frequently purchase water-cooled, high-precision automatic systems suitable for sensitive and high-cost products.

Furthermore, the chemical and industrial sectors, including producers of engine lubricants, agrochemicals, specialized solvents, and household cleaners, are significant end-users. Their requirement centers on creating chemical-resistant, leak-proof seals that can withstand corrosive contents and harsh transport conditions. For these customers, reliability under extreme operating conditions and compatibility with challenging cap and bottle materials (such as fluorinated plastics) are key purchasing criteria. The cosmetics industry, encompassing personal care and beauty product manufacturers, increasingly relies on induction sealing to ensure product quality, prevent leakage during travel, and provide a premium, tamper-evident consumer experience.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 1,010 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Enercon Industries Corporation, Pillar Technologies, Lepel Corporation, Kinex Cappers, Selig Group, Tarpak, Zhejiang Hongsheng Machinery, Sarcmi Srl, ACG Group, Relyon Plasma GmbH, SealerOn Corporation, Gür-san Makina, Zalkin, Closure Systems International (CSI), KWT Induktionstechnik GmbH, Suresafe Industries, Alfa-Laval, PDC International, Ecomac, Induction Cap Sealing Systems (ICSS). |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Induction Sealing Machine Market Key Technology Landscape

The technological evolution within the Induction Sealing Machine market is predominantly focused on transitioning from older vacuum tube and SCR-based generators to advanced solid-state induction technology. Solid-state generators, utilizing high-frequency insulated-gate bipolar transistors (IGBTs), offer substantially higher energy conversion efficiency, reduced operational noise, and exceptional sealing consistency, particularly critical in high-speed applications where minute power fluctuations can lead to seal defects. These modern systems are considerably more compact and require less maintenance than their predecessors, contributing directly to a smaller equipment footprint and lower total cost of ownership (TCO). Furthermore, the precise digital control afforded by solid-state technology allows for immediate feedback and modulation of the output frequency and power, enabling accurate sealing across varied cap sizes and container materials without extensive manual tuning.

A crucial technological advancement involves the integration of the Industrial Internet of Things (IIoT) and sophisticated Human-Machine Interfaces (HMIs). Modern induction sealing machines are equipped with onboard diagnostic systems that monitor key parameters such as generator temperature, coil current, line speed, and power input in real-time. This data is transmitted via secure industrial protocols to plant-wide Manufacturing Execution Systems (MES) or cloud platforms, enabling remote monitoring, performance analysis, and predictive maintenance alerts. The HMIs are evolving into large, touch-sensitive displays with intuitive, recipe-driven controls, allowing operators to save and instantly recall validated sealing profiles for hundreds of different product SKUs, drastically reducing changeover time and minimizing operator error.

Another significant area of innovation is in the sealing head design and ancillary quality control systems. New coil designs, including specialized tunnel and segmented heads, are being developed to handle containers with complex, non-standard neck finishes, ensuring uniform heating and sealing integrity across difficult geometries. Complementing the sealing process are integrated quality inspection technologies, such as high-resolution vision systems that verify cap presence, alignment, and seal integrity (via thermal imaging or spectral analysis) immediately post-sealing. Non-destructive seal integrity testing (NDSIT) based on pressure decay or vacuum testing is becoming standard on high-end pharmaceutical equipment, ensuring regulatory compliance and providing absolute certainty regarding the hermeticity of the final package.

Regional Highlights

The regional dynamics of the Induction Sealing Machine Market reflect disparate levels of industrial maturity, regulatory enforcement, and consumer demand for packaged goods. Asia Pacific (APAC) currently dominates the market in terms of volume growth and is projected to exhibit the highest Compound Annual Growth Rate (CAGR) throughout the forecast period. This growth is attributable to rapid urbanization, the massive expansion of the middle-class population increasing demand for convenience foods, and the establishment of large-scale manufacturing hubs for pharmaceuticals and consumer products in countries like China, India, and Southeast Asian nations. Regulatory harmonization efforts and increased foreign direct investment (FDI) in manufacturing further boost the demand for automated sealing solutions in this region.

North America and Europe represent mature, high-value markets characterized by early adoption of induction sealing technology and stringent quality control standards. In these regions, the market is primarily driven by replacement demand for older machinery, technological upgrades (shifting to IoT-enabled and solid-state equipment), and the continuous innovation required to handle highly specialized, custom packaging formats for premium products. European markets, in particular, show a strong emphasis on sustainable packaging materials and high energy efficiency standards, pushing manufacturers toward advanced water-cooled and optimized power delivery systems. The presence of major pharmaceutical giants ensures sustained investment in validated sealing technologies.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging markets experiencing steady growth. In LATAM, market growth is fueled by expanding local food and beverage processing industries and increasing penetration of international consumer packaged goods (CPG) companies. In the MEA region, investments in infrastructure, particularly in the Arabian Gulf states, and growing hygiene awareness post-pandemic are driving the adoption of induction sealing equipment, especially for liquid packaging and bottled water. However, market penetration in these regions can be volatile, often constrained by complex import duties and the reliance on semi-automatic or handheld equipment due to capital limitations among smaller local producers.

- Asia Pacific (APAC): Highest growth market driven by large manufacturing output, pharmaceutical expansion in India and China, and booming F&B consumption. Key countries include China, India, Japan, and South Korea.

- North America: Mature market focusing on technology replacement, advanced automation, and high regulatory standards for pharmaceuticals and nutraceuticals. Dominant areas are the US and Canada.

- Europe: Strong demand driven by sustainability mandates, focus on energy efficiency, and stringent European Medicines Agency (EMA) regulations impacting sealing validation. Key markets include Germany, France, and the UK.

- Latin America (LATAM): Emerging market growth fueled by domestic F&B processing and expanding consumer markets in Brazil and Mexico.

- Middle East and Africa (MEA): Steady adoption rate, primarily for bottled water, cosmetics, and chemical packaging; growth influenced by infrastructure investment and urbanization in the GCC nations and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Induction Sealing Machine Market.- Enercon Industries Corporation

- Pillar Technologies

- Lepel Corporation

- Kinex Cappers

- Selig Group

- Tarpak

- Zhejiang Hongsheng Machinery

- Sarcmi Srl

- ACG Group

- Relyon Plasma GmbH

- SealerOn Corporation

- Gür-san Makina

- Zalkin

- Closure Systems International (CSI)

- KWT Induktionstechnik GmbH

- Suresafe Industries

- Alfa-Laval

- PDC International

- Ecomac

- Induction Cap Sealing Systems (ICSS)

Frequently Asked Questions

Analyze common user questions about the Induction Sealing Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of solid-state induction sealers over traditional vacuum tube models?

Solid-state induction sealers utilize modern components (IGBTs) providing superior energy efficiency, requiring less cooling, and delivering precise, digitally controlled power output, which significantly improves sealing consistency and reduces overall maintenance requirements and equipment footprint compared to older vacuum tube systems.

How is the Induction Sealing Market addressing the increasing demand for sustainable packaging?

The market is innovating by developing specialized induction liners made from more sustainable or bio-degradable polymer coatings and focuses on creating peelable seals that allow for easier separation of the aluminum foil and the plastic cap, thereby simplifying the container recycling process for end-users and achieving circular economy goals.

What is the typical lifespan and required maintenance frequency for an automatic induction sealing machine?

The typical operational lifespan of a high-quality automatic induction sealing machine can exceed 15 years with proper care. Maintenance typically involves quarterly checks of the cooling system and power components, annual calibration verification, and replacement of high-wear items like conveyor belts, largely depending on the operating duty cycle and adherence to the manufacturer's predictive maintenance schedules.

In which end-use industry is the implementation of non-destructive seal integrity testing (NDSIT) most critical?

NDSIT is most critical within the Pharmaceutical and Nutraceutical industries. Regulations mandate high assurance of seal integrity for patient safety and product efficacy, making integrated testing systems (such as pressure decay or thermal analysis) essential for validating the hermetic seal without compromising product quality or slowing high-speed production lines.

What factors determine the optimal power output (kW) required for an induction sealing system?

The optimal power output is primarily determined by three factors: the line speed (caps per minute), the diameter of the cap being sealed, and the composition of the cap/liner material. Higher line speeds and larger diameter caps generally necessitate higher kilowatt generators (typically 4kW to 10kW or more) to ensure sufficient heat transfer and sealing dwell time within the constraints of the production line.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager