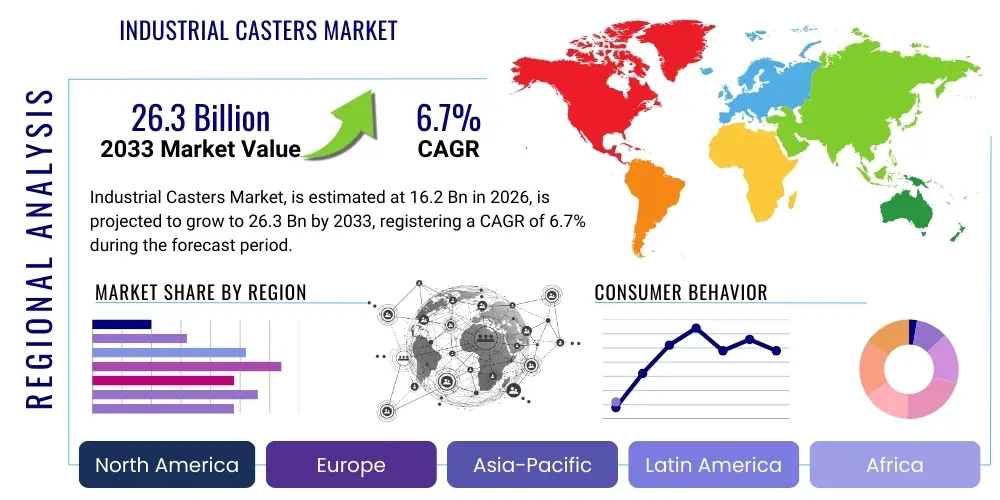

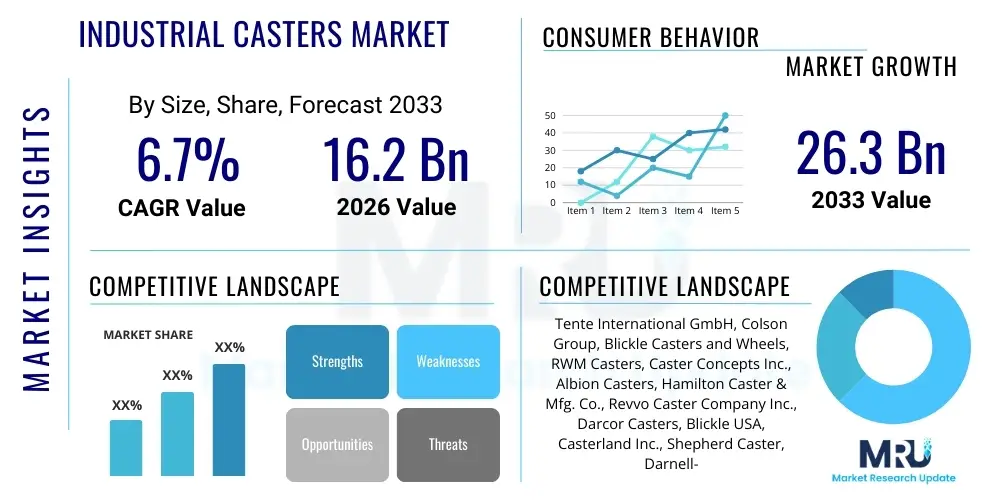

Industrial Casters Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439238 | Date : Jan, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Industrial Casters Market Size

The Industrial Casters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2026 and 2033. The market is estimated at USD 16.2 Billion in 2026 and is projected to reach USD 26.3 Billion by the end of the forecast period in 2033. This robust growth trajectory is underpinned by increasing industrial automation, the expansion of manufacturing facilities globally, and the rising demand for efficient material handling solutions across diverse sectors. The market's upward momentum is further supported by continuous technological advancements leading to the development of more durable, versatile, and application-specific casters that can withstand extreme conditions and heavy loads, catering to a broader spectrum of industrial requirements. This growth reflects a global shift towards optimizing operational workflows, enhancing worker safety, and investing in resilient infrastructure that depends on reliable mobility solutions, ensuring a sustained demand for high-performance industrial casters across the forecast period.

Industrial Casters Market introduction

The Industrial Casters Market encompasses the global production, distribution, and utilization of various types of wheels and their corresponding assemblies, specifically engineered for demanding applications within industrial, commercial, and institutional environments. These essential components provide mobility to a wide array of equipment, machinery, carts, dollies, and other heavy loads within critical operational settings such as manufacturing plants, expansive warehouses, sophisticated distribution centers, healthcare facilities, and various other institutional frameworks. Industrial casters are meticulously designed to not only offer foundational mobility but also to significantly enhance operational efficiency, improve workflow fluidity, and deliver substantial ergonomic benefits. Their implementation plays a pivotal role in mitigating manual labor requirements and substantially reducing the incidence of workplace injuries traditionally associated with the manual handling and repositioning of heavy items, thereby fostering safer and more productive work environments across diverse industries globally.

The product landscape within this highly specialized market is remarkably extensive and continuously evolving, featuring a broad spectrum of caster types engineered for distinct performance characteristics. This includes, but is not limited to, highly maneuverable swivel casters, steadfast rigid casters, advanced braking casters equipped with various locking mechanisms, sophisticated shock-absorbing casters designed to protect delicate loads, robust pneumatic casters for uneven terrain, and a variety of specialized casters crafted from diverse materials. These materials, such as durable polyurethane, resilient nylon, versatile rubber compounds, high-strength cast iron, and heat-resistant phenolics, are selected based on their specific properties to meet rigorous application requirements, including resistance to chemicals, extreme temperatures, abrasive surfaces, and heavy load-bearing capacities. The adaptability and material versatility ensure that an optimal caster solution is available for nearly every unique industrial challenge, from sterile cleanroom environments to rugged outdoor construction sites.

The major applications for industrial casters span an incredibly wide array of industry verticals, making them indispensable across sectors such as automotive manufacturing, aerospace engineering, complex logistics and warehousing operations, food and beverage processing, critical healthcare services, heavy construction, and the expansive retail sector. For instance, in modern logistics, casters are fundamental to the efficient operation of pallet jacks, material handling dollies, and mobile shelving units, directly optimizing warehouse space utilization and throughput. Within healthcare settings, specialized medical-grade casters are crucial for ensuring the silent, smooth, and precise movement of sensitive medical equipment, patient beds, and utility carts, which is paramount for maintaining patient comfort and facilitating critical care. The intrinsic versatility, robust design, and continuous technological innovation of industrial casters are therefore positioned as foundational elements of modern industrial infrastructure, driving efficiency and safety in a myriad of operational contexts and contributing significantly to the global supply chain's agility and resilience.

Industrial Casters Market Executive Summary

The Industrial Casters Market is currently experiencing a period of dynamic and sustained growth, primarily propelled by overarching business trends centered on the global acceleration of industrial automation and the pervasive digital transformation across manufacturing and logistics sectors. Enterprises across a broad spectrum of industries are making substantial investments in cutting-edge robotic systems, advanced automated guided vehicles (AGVs), and sophisticated smart material handling equipment. These technologies are inherently reliant on high-performance industrial casters to provide essential mobility, precision positioning, and consistent reliability. Furthermore, the exponential global expansion of the e-commerce sector has created an unprecedented demand for highly efficient and technologically advanced warehousing and fulfillment solutions. This surge mandates the widespread adoption of specialized casters in pallet trucks, utility trolleys, and flexible mobile storage systems, which are critical for optimizing spatial utilization and expediting order fulfillment. The pervasive global emphasis on implementing lean manufacturing principles and achieving superior operational efficiency further compels industries to upgrade to casters that offer exceptional durability, quieter operation, and significantly enhanced load capacities, thereby effectively minimizing operational downtime and reducing ongoing maintenance expenditures. This collective shift towards optimized, automated operational workflows represents a core and potent accelerator for the market's continued progression and expansion.

From a regional perspective, the market exhibits diverse growth patterns, each intricately influenced by varying levels of industrialization, technological adoption rates, and the robustness of infrastructure development across different geographies. The Asia Pacific (APAC) region unmistakably stands out as the most dominant and rapidly expanding market, a trend primarily attributed to the burgeoning manufacturing sectors in economic powerhouses such as China, India, Japan, and the dynamic economies of Southeast Asia. Substantial foreign direct investments flowing into manufacturing capabilities, coupled with an immense and growing consumer base and the rapid expansion of sophisticated logistics networks, are collectively fueling an insatiable demand for industrial casters throughout this region. North America and Europe, while generally considered mature markets, continue to demonstrate steady and resilient growth. This sustained momentum is largely driven by ongoing technological advancements, a consistent replacement demand for aging equipment, and the increasing adoption of highly specialized casters tailored for niche applications in high-value sectors such as aerospace, advanced automotive manufacturing, and the rapidly evolving healthcare industry. Concurrently, Latin America, the Middle East, and Africa are progressively emerging as significant growth frontiers, witnessing accelerating industrialization, burgeoning urbanization, and substantial investments in infrastructure development. These regions are poised to contribute considerably to overall market growth in the latter half of the forecast period as their industrial capacities mature and infrastructure projects proliferate.

Analysis of segmentation trends within the market reveals a distinct and growing inclination towards advanced materials and the integration of highly specialized functionalities. Casters fabricated from polyurethane and various nylon composites are experiencing burgeoning traction due to their excellent load-bearing capabilities, superior chemical resistance, and crucial non-marking properties, rendering them ideal for a wide spectrum of applications, from ultra-cleanroom environments to the most demanding heavy industrial settings. Concurrently, the heavy-duty casters segment is registering substantial demand, a direct consequence of the imperative to move increasingly heavier machinery, raw materials, and finished equipment in industries such as large-scale construction, defense manufacturing, and other forms of heavy fabrication. From an application standpoint, the logistics and automotive sectors remain the foremost consumers of industrial casters; however, the healthcare and food processing industries are demonstrating an accelerated rate of adoption, specifically for casters meticulously designed for stringent hygiene requirements, specific environmental controls, and quiet operation. The continuous innovation in advanced braking systems, sophisticated swivel mechanisms, and enhanced shock absorption technologies is also profoundly shaping segment preferences. End-users are increasingly seeking bespoke, custom-engineered solutions that are capable of addressing highly unique operational challenges, while simultaneously ensuring strict compliance with increasingly stringent safety regulations and performance benchmarks, driving further specialization and innovation across all market segments.

AI Impact Analysis on Industrial Casters Market

The integration of Artificial Intelligence (AI) and machine learning technologies within broader industrial operations is poised to significantly transform the industrial casters market, primarily through indirect yet profound influences on automation, efficiency, and maintenance strategies. Users frequently pose critical questions regarding how AI-driven predictive maintenance systems might influence the operational lifespan and optimal selection criteria for casters, the precise role of AI in dynamically optimizing material handling routes for Automated Guided Vehicles (AGVs) that intrinsically rely on casters, and the tangible potential for "smart casters" embedded with sophisticated sensors to provide real-time, actionable data for comprehensive operational analytics. Key concerns within the industry often revolve around the substantial initial cost implications associated with integrating such advanced technologies and the readiness of existing industrial infrastructure to seamlessly support AI-enhanced components. However, expectations are largely focused on achieving unparalleled increases in operational efficiency, substantial reductions in maintenance and operational costs through proactive preventative strategies, and the eventual development of more intelligent, fully autonomous material handling systems where high-performance casters will serve as an absolutely critical enabling component, providing the foundational mobility and data input for these advanced systems.

- AI-driven predictive maintenance platforms can significantly extend the operational lifespan of industrial casters by continuously monitoring and analyzing wear patterns, temperature fluctuations, and load stress, enabling early identification of potential failures and scheduling proactive maintenance, thereby reducing unexpected downtime.

- Optimization of AGV and robotic material handling operations through advanced AI algorithms leads to more efficient path planning, dynamic load balancing, and smoother movement trajectories, which collectively reduce mechanical stress on casters, enhance energy efficiency, and minimize wear and tear.

- The development of smart casters with integrated sensors (e.g., accelerometers, load cells, temperature sensors) allows for real-time collection of critical data on parameters such as load, speed, temperature, vibration, and travel distance, feeding into AI analytics for comprehensive performance monitoring and deeper operational insights.

- Enhanced material selection and innovative caster design processes are being revolutionized through AI simulations and generative design tools. These technologies allow engineers to rapidly model and test various material compositions and structural configurations, leading to the creation of casters optimally designed for specific extreme environments, unique load profiles, and extended durability.

- Improved inventory management and highly optimized warehouse logistics, powerfully driven by AI-powered systems, lead to more dynamic and agile material flow within facilities. This, in turn, increases the demand for high-performance, ultra-reliable, and highly adaptable casters capable of supporting complex, intelligent material movement strategies.

- Automation of various stages within the caster manufacturing processes, leveraging AI and robotics, has the potential to lead to more consistent product quality, increased production throughput, reduced manufacturing defects, and greater capabilities for highly customized production runs, meeting niche industrial requirements with unprecedented precision and efficiency.

DRO & Impact Forces Of Industrial Casters Market

The Industrial Casters Market is profoundly influenced by a complex and dynamic interplay of strategic drivers, significant restraints, nascent and established opportunities, and broader external impact forces. A primary and overwhelmingly powerful driver is the accelerating global trend of industrial automation and the pervasive proliferation of robotics across all major sectors, including advanced manufacturing, sophisticated logistics, and expansive warehousing operations. As industries worldwide relentlessly pursue higher levels of productivity, precision, and reduced reliance on manual labor, the widespread adoption of Automated Guided Vehicles (AGVs), Autonomous Mobile Robots (AMRs), and other sophisticated material handling equipment becomes not just beneficial but absolutely crucial. All these advanced mobile systems critically depend on the seamless integration of high-performance industrial casters to achieve their foundational mobility, directional control, and operational stability. Furthermore, the relentless and exponential expansion of the e-commerce industry necessitates the establishment of vast, highly efficient, and technologically advanced warehousing and distribution networks, within which industrial casters play an indispensable role in ensuring the smooth, rapid, and precise movement of goods, thereby creating a sustained and escalating demand for robust caster solutions. The global imperative for fostering ergonomic workplaces and significantly enhancing worker safety also acts as a substantial driver, as modern, well-designed casters inherently reduce manual strain, prevent musculoskeletal injuries, and minimize accidents associated with the manual repositioning of heavy loads. Additionally, continuous and significant innovation in caster materials science and design methodologies, leading to solutions offering superior load capacity, extended durability, and highly specialized functionalities, consistently stimulates and propels overall market growth and evolution.

Despite the strong growth drivers, the industrial casters market concurrently faces several inherent restraints that could potentially impede its otherwise robust growth trajectory. One significant challenge is the relatively high initial cost associated with acquiring premium, highly specialized industrial casters, particularly those meticulously designed for extreme operating environments, ultra-heavy loads, or specific high-performance applications. This cost factor can often present a substantial financial barrier for small and medium-sized enterprises (SMEs) operating with more constrained capital budgets, potentially leading them to opt for less sophisticated, lower-cost alternatives. Price sensitivity, especially prevalent in fiercely competitive global markets, frequently results in a preference for cheaper caster options, which regrettably often compromises long-term performance, durability, and overall operational safety. Moreover, the inherent volatility and unpredictable fluctuations in the prices of critical raw materials, such as various grades of steel, diverse rubber compounds, and a range of specialized polymers (e.g., polyurethane, nylon), which are all indispensable for caster manufacturing, can directly impact production costs, erode profit margins, and introduce supply chain instabilities for manufacturers. Furthermore, a persistent lack of widespread awareness among some end-users regarding the profound long-term benefits and total cost of ownership advantages of investing in high-quality casters, versus the short-term savings from opting for inferior alternatives, contributes to suboptimal purchasing decisions. This is often coupled with insufficient or inadequate maintenance practices in certain industrial settings, which can lead to premature caster failures and foster a detrimental perception of casters as merely disposable components rather than critical, long-term operational assets. The intense competitive pressure from a fragmented landscape of unorganized local manufacturers, frequently offering significantly lower-cost products (albeit often of demonstrably lower quality and reliability), also poses a considerable challenge to established, quality-focused industry players, impacting market share and pricing stability.

Notwithstanding these complex challenges, the industrial casters market is replete with substantial and attractive opportunities that promise to drive future expansion and innovation. The burgeoning demand emanating from rapidly developing economies, particularly across the dynamic regions of Asia Pacific, Latin America, and emerging parts of Africa, driven by aggressive industrialization, large-scale infrastructural development, and increasing urbanization, presents vast untapped market potential. These regions are witnessing significant investment in new manufacturing facilities, logistics hubs, and commercial infrastructure, all of which require extensive caster solutions. Another significant opportunity lies in the growing global focus on developing sustainable and environmentally friendly caster solutions. This includes pioneering the use of recycled and bio-based materials, implementing energy-efficient manufacturing processes, and designing casters with extended lifecycles and enhanced recyclability, which opens lucrative new avenues for market differentiation and caters to environmentally conscious enterprises. Furthermore, the increasing adoption of highly specialized casters in niche yet high-growth applications such as advanced medical equipment (e.g., MRI machines, patient transport), stringent cleanroom environments, specialized material handling for renewable energy components (e.g., wind turbine blades, solar panels), and the demanding requirements of the entertainment industry (e.g., stage sets) offers significant expansion prospects. The accelerating advent of smart manufacturing paradigms and the broader Industry 4.0 movement creates immense opportunities for integrating casters with advanced IoT sensors for real-time predictive maintenance, dynamic operational monitoring, and intelligent route optimization for AGVs. This integration offers substantial value-added services, transforms operational efficiency, and significantly expands the market's technological frontier. Strategic partnerships, collaborative ventures, and targeted mergers and acquisitions represent powerful tools for market players to expand their product portfolios, geographical reach, and technological capabilities, enabling them to effectively capitalize on these diverse and evolving opportunities. The collective impact forces, therefore, lean decisively towards continued positive growth, contingent upon manufacturers' ability to adeptly navigate cost sensitivities, proactively address supply chain complexities, and maintain a relentless focus on innovation to meet evolving industrial demands and critical sustainability goals.

Segmentation Analysis

The Industrial Casters Market is meticulously segmented based on a comprehensive array of critical factors to provide a granular and nuanced understanding of its diverse components, underlying dynamics, and varied demand patterns. These highly specific segmentation approaches empower manufacturers, suppliers, and end-users to precisely identify distinct product types, specific application niches, and unique regional demands, thereby facilitating the development and execution of highly targeted market strategies and agile product development initiatives. Key segmentation dimensions include the fundamental material composition of the caster wheel, its meticulously engineered load-bearing capacity, the specific application industry, the precise type of caster assembly, and broad geographical regions. This multi-faceted segmentation framework is instrumental in delineating distinct market niches, enabling a precise and quantitative assessment of market size, the identification of primary growth drivers, and a detailed analysis of the competitive landscapes prevailing within each individual sub-segment. The inherent diversity in industrial mobility needs, ranging from the ultra-hygienic requirements of medical environments to the extremely heavy-duty and rugged demands of outdoor construction sites, inherently necessitates this extensive and granular product differentiation. This ensures that a highly optimized and suitable caster solution is available for virtually every conceivable industrial mobility requirement, underscoring the market's vast scope and specialized nature.

- By Material

- Polyurethane: Known for high load capacity, floor protection, and chemical resistance. Widely used across industries for versatile performance.

- Nylon: Offers high strength, chemical inertness, and impact resistance. Ideal for heavy loads and harsh environments where abrasion is a concern.

- Rubber: Includes Solid Rubber (durability, floor protection), Thermoplastic Rubber (non-marking, quiet), and Mold-on Rubber (shock absorption, grip). Favored for noise reduction and cushioning.

- Cast Iron: Excellent for extreme heavy loads and high temperatures. Highly durable but can mark floors and requires lubrication.

- Phenolic: High load capacity, very hard, and resistant to chemicals and high temperatures. Often used in ovens or foundries.

- Polyolefin: Lightweight, non-marking, and resistant to water and many chemicals. Cost-effective for medium-duty applications.

- Steel: Offers superior strength and temperature resistance. Suitable for extremely heavy-duty and rugged industrial applications, often paired with steel or iron wheels.

- High-Temperature Materials: Specialized composites or alloys designed to perform in environments exceeding 250°C, found in baking, automotive paint lines, and ovens.

- By Load Capacity

- Light-Duty Casters (up to 200 lbs per caster): Typically for office furniture, small carts, and display units. Focus on maneuverability and quietness.

- Medium-Duty Casters (200 - 1,000 lbs per caster): Commonly used in institutional settings, material handling carts, and lighter industrial equipment. Balance of strength and agility.

- Heavy-Duty Casters (1,000 - 5,000 lbs per caster): Essential for industrial machinery, heavy-duty carts, aerospace ground support, and automotive assembly lines. Prioritize strength and durability.

- Super Heavy-Duty Casters (above 5,000 lbs per caster): Designed for extreme loads such as large machinery, construction equipment, and specialized industrial transport. Feature robust construction and specialized bearings.

- By Caster Type

- Swivel Casters: Allow 360-degree rotation, providing maximum maneuverability for precise positioning.

- Rigid Casters: Fixed direction, used for straight-line tracking and stability for heavy loads.

- Brake Casters: Include Total Lock (locks both wheel and swivel), Top Lock (locks wheel only), and Side Lock (locks wheel via side lever). Crucial for safety and stability.

- Kingpinless Casters: Eliminate the kingpin, reducing swivel play and improving durability under heavy impact loads.

- Shock Absorbing Casters: Incorporate springs or elastomers to cushion loads from impacts and vibrations, protecting sensitive items.

- Pneumatic Casters: Air-filled tires provide excellent cushioning and traction on uneven or outdoor surfaces.

- Spring-Loaded Casters: Similar to shock-absorbing, they use springs for damping and maintaining contact on uneven floors, often self-leveling.

- Custom Casters: Engineered for unique, highly specialized applications with specific environmental, load, or mobility requirements not met by standard products.

- By Application

- Material Handling Equipment: Dollies, hand trucks, carts, pallet jacks, and shelving units for warehouse and logistics operations.

- Industrial Machinery and Equipment: Mobility solutions for manufacturing equipment, workbenches, and assembly line tooling.

- Medical Equipment: Hospital beds, medical carts, diagnostic machines, operating room equipment requiring quiet, hygienic, and smooth movement.

- Food Service Equipment: Bakery racks, ovens, refrigerated carts, utility trolleys needing resistance to heat, moisture, and washdowns.

- Automotive Industry: Casters for assembly line fixtures, engine stands, tool carts, and paint booths.

- Aerospace Ground Support Equipment: Specialized casters for moving aircraft components, service platforms, and maintenance tools.

- Retail Display Racks and Shopping Carts: Durable and smooth-rolling casters for commercial and customer-facing environments.

- Waste Management Bins: Robust casters for large, heavy refuse containers requiring outdoor durability.

- Scaffolding and Construction Equipment: Heavy-duty casters for mobile scaffolding, work platforms, and portable generators.

- Furniture and Fixtures (Industrial Grade): Casters for heavy-duty tables, chairs, and modular workstations in industrial settings.

- By Industry Vertical

- Manufacturing: General manufacturing, heavy fabrication, light manufacturing, and assembly operations.

- Logistics and Warehousing: Distribution centers, fulfillment centers, freight terminals, and storage facilities.

- Automotive: Car and truck manufacturing, component suppliers, repair shops.

- Aerospace: Aircraft manufacturing, MRO (Maintenance, Repair, and Overhaul) facilities.

- Healthcare: Hospitals, clinics, laboratories, nursing homes, medical device manufacturing.

- Food and Beverage: Processing plants, commercial kitchens, catering services, cold storage.

- Construction: Building sites, equipment rental, scaffolding companies.

- Retail: Supermarkets, department stores, retail backrooms, e-commerce fulfillment.

- Pharmaceuticals: Drug manufacturing, research labs, cleanroom environments.

- Textiles: Fabric mills, garment manufacturing, dyeing facilities.

- Chemicals: Processing plants, storage facilities, requiring chemical-resistant casters.

- Heavy Industry: Mining, steel mills, foundries, requiring super heavy-duty solutions.

- By Distribution Channel

- Direct Sales: Manufacturers selling directly to large OEMs or industrial enterprises for custom or bulk orders.

- Distributors/Wholesalers: Intermediaries providing regional reach, inventory, and technical support to a wide range of customers.

- Online Retail: E-commerce platforms catering to smaller businesses or individual purchases, offering convenience and broad product access.

Value Chain Analysis For Industrial Casters Market

The value chain for the Industrial Casters Market constitutes a complex and highly integrated network of interdependent activities, meticulously designed to transform raw materials into finished caster products and deliver them efficiently to diverse end-users. The initial stage, critical upstream analysis, commences with the rigorous procurement of essential raw materials. This typically involves sourcing various high-grade steel alloys for robust housing components, precision bearings, and axles; a wide array of rubber compounds for resilient tires; versatile polyurethane for durable tread materials; diverse nylon grades for both wheels and structural components; and other specialized plastics and metallic alloys depending on the caster's specific application requirements. Manufacturers often engage with a sophisticated global network of specialized suppliers, prioritizing critical factors such as uncompromising material quality, competitive cost-effectiveness, and the unwavering reliability of the supply chain to ensure consistent production. The subsequent design and engineering phase, frequently leveraging advanced CAD/CAM software, finite element analysis (FEA), and sophisticated simulation tools, is paramount at this stage. This phase intensively focuses on cutting-edge material science, intricate load dynamics, ergonomic considerations, and environmental resistance, ensuring that each component, from the smallest bearing to the largest bracket, is optimized for peak performance and longevity. This foundational upstream phase also critically includes the manufacturing of intricate components like high-precision bearings, robust axles, and sturdy brackets, all of which are integral to the final caster assembly, ensuring that every individual component adheres to stringent industrial standards for unparalleled durability, unwavering performance, and absolute safety.

Industrial Casters Market Potential Customers

The industrial casters market caters to an exceptionally broad and highly diverse spectrum of potential customers spanning virtually every sector that necessitates efficient and reliable mobility for equipment, heavy machinery, or various types of goods. These crucial end-users, or buyers, represent a vast continuum, ranging from multinational manufacturing conglomerates with sprawling global operations to small, specialized local workshops, each presenting a unique set of requirements predicated on their specific operational environment, precise load specifications, and adherence to stringent regulatory compliance standards. Manufacturers of industrial casters primarily target companies that are deeply involved in material handling, intricate logistics, and complex production processes, where the efficient, safe, and controlled movement of raw components, work-in-progress materials, and finished goods is absolutely critical for achieving optimal productivity, maintaining stringent quality standards, and ensuring robust workplace safety. This extensive customer base explicitly includes entities such as advanced automotive assembly plants that require heavy-duty, impact-resistant casters for their high-speed production lines, aerospace manufacturing facilities needing specialized non-marking and anti-static casters for handling sensitive and valuable equipment, and large-scale warehousing operations that deploy thousands of casters for pallet trucks, dollies, and mobile shelving units to maximize storage space utilization and optimize workflow efficiency within their vast facilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 16.2 Billion |

| Market Forecast in 2033 | USD 26.3 Billion |

| Growth Rate | 6.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Tente International GmbH, Colson Group, Blickle Casters and Wheels, RWM Casters, Caster Concepts Inc., Albion Casters, Hamilton Caster & Mfg. Co., Revvo Caster Company Inc., Darcor Casters, Blickle USA, Casterland Inc., Shepherd Caster, Darnell-Rose Inc., Pemco Casters, Durastar Casters, Flexello Casters, Roll-Rite LLC, Steinco GmbH, TELLURE ROTA SpA, Suzhou Rida Caster Co. Ltd., Keystone Caster Corp., Globe Caster Manufacturing Company, Nutting Casters, Wagner System GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Casters Market Key Technology Landscape

The industrial casters market is currently undergoing a rapid and transformative evolution, primarily driven by relentless advancements in materials science, sophisticated manufacturing processes, and the strategic integration of smart technologies. These innovations are all meticulously aimed at significantly enhancing caster performance, extending durability, and optimizing operational efficiency across a myriad of demanding applications. One of the foremost technological focuses is directed towards the development of highly advanced wheel materials meticulously engineered to withstand increasingly extreme operational conditions. These conditions encompass not only exceptionally heavy loads but also highly abrasive surfaces, persistently high temperatures, and intensely corrosive chemical environments. This drive for innovation involves pioneering new formulations of specialized polyurethanes, developing high-grade nylons with superior mechanical properties, and creating advanced composite materials that collectively offer unparalleled wear resistance, superior shock absorption capabilities, and crucial non-marking properties. For instance, new generations of polyurethane wheels are being specifically developed to deliver higher load capacities while simultaneously exhibiting significantly reduced rolling resistance, a critical factor for both manual handling applications and the battery-powered automated systems prevalent in modern industrial settings. Concurrently, high-temperature phenolic resins and advanced metallic alloys are being precisely engineered for highly specialized applications in demanding environments such as industrial ovens, high-heat kilns, or heavy foundries, continually pushing the boundaries of traditional caster performance and operational envelopes.

Regional Highlights

- North America: This region represents a highly mature and technologically advanced market, distinguished by a very high adoption rate of automation across both manufacturing and logistics sectors. There is a robust and consistent demand for industrial casters emanating from critical industries such as automotive, aerospace, healthcare, and general manufacturing. The market here places a significant emphasis on high-quality, specialized casters equipped with advanced features such as intelligent sensors for predictive maintenance, ergonomic designs, and superior load-bearing capacities. The region benefits from a significant presence of long-established, innovative manufacturers and a continuous focus on research and development aimed at enhancing efficiency, safety, and operational performance. Replacement demand also contributes substantially to market stability and growth, alongside new installations driven by modernization efforts.

- Europe: Similar to North America, Europe is a highly mature and sophisticated market for industrial casters, characterized by a strong emphasis on high-performance, precision-engineered, and ergonomically superior caster solutions. The region is governed by some of the world's most stringent safety regulations and environmental standards, which inherently drive the demand for casters with advanced braking systems, superior shock-absorbing capabilities, and non-toxic, eco-friendly materials. Key contributing countries include Germany, the United Kingdom, France, and Italy, which are leaders in the automotive, industrial machinery, and medical equipment manufacturing sectors. There is a growing interest and investment in sustainable and recyclable caster materials, reflecting the region's broader commitment to environmental stewardship and circular economy principles.

- Asia Pacific (APAC): Positioned as the largest and most rapidly growing market globally for industrial casters, the APAC region's expansion is fundamentally propelled by unprecedented levels of industrialization, massive manufacturing sector expansion, and the burgeoning growth of e-commerce across its diverse economies. China and India are at the forefront of this growth, supported by substantial governmental and private investments in infrastructure, advanced logistics, and new manufacturing capacities. The region exhibits a highly diverse demand profile, ranging from cost-effective standard caster options for emerging businesses to high-performance, specialized units required by advanced manufacturing and high-tech industries. The scale of manufacturing output and the rapid development of warehousing and logistics networks make APAC a critical growth engine.

- Latin America: This region is an emerging market for industrial casters, demonstrating consistent and promising growth fueled by increasing foreign direct investment in manufacturing capabilities, significant infrastructure development projects, and a growing consumer base driving industrial expansion. Brazil and Mexico are particularly key players within this region, experiencing escalating demand from the automotive sector, ongoing construction projects, and the expanding food processing industries. Opportunities exist for a broad spectrum of casters, encompassing both standard, cost-effective solutions and moderately specialized units, as the region's industrial capabilities and technological adoption continue to mature and expand. The focus is often on durability and cost-efficiency to meet the demands of developing industrial landscapes.

- Middle East and Africa (MEA): Also an emerging market, the MEA region is witnessing notable growth in the industrial casters sector. This growth is primarily driven by strategic diversification efforts away from traditional oil-based economies, leading to increased industrialization, substantial investments in logistics and transportation infrastructure, and a boom in construction and urban development projects. Countries like the UAE, Saudi Arabia, and South Africa are investing heavily in large-scale infrastructure and industrial zones, which consequently creates a strong demand for durable, robust, and often heavy-duty casters capable of performing reliably in harsh climatic conditions. Due to a relatively limited local manufacturing base for casters, the region remains largely reliant on imports from established global manufacturers, presenting significant opportunities for international market players.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Casters Market.- Tente International GmbH

- Colson Group

- Blickle Casters and Wheels

- RWM Casters

- Caster Concepts Inc.

- Albion Casters

- Hamilton Caster & Mfg. Co.

- Revvo Caster Company Inc.

- Darcor Casters

- Blickle USA

- Casterland Inc.

- Shepherd Caster

- Darnell-Rose Inc.

- Pemco Casters

- Durastar Casters

- Flexello Casters

- Roll-Rite LLC

- Steinco GmbH

- TELLURE ROTA SpA

- Suzhou Rida Caster Co. Ltd.

- Keystone Caster Corp.

- Globe Caster Manufacturing Company

- Nutting Casters

- Wagner System GmbH

Frequently Asked Questions

What is an industrial caster and what are its primary uses?

An industrial caster is a specialized wheel and its complete assembly, meticulously engineered for heavy-duty applications within industrial, commercial, and institutional environments. Its fundamental purpose is to facilitate the efficient, controlled, and safe movement of various types of equipment, heavy machinery, utility carts, dollies, and other substantial loads. Primary uses span critical sectors such as manufacturing, large-scale warehousing, healthcare facilities, food service operations, and the automotive industry, thereby significantly enhancing operational mobility, improving workflow efficiency, and contributing substantially to overall workplace safety by reducing manual strain and enabling easy transport of heavy items across facilities.

What are the key factors driving the growth of the Industrial Casters Market?

The Industrial Casters Market's robust growth is primarily propelled by several interconnected key factors. These include the accelerating global trend of industrial automation and the widespread proliferation of robotics in various sectors, the unprecedented expansion of the e-commerce industry which necessitates advanced logistics and warehousing solutions, a heightened global emphasis on workplace safety and ergonomic design to prevent injuries, and continuous, rapid technological advancements in caster materials and intricate designs that consistently offer superior performance, enhanced durability, and greater specialization for diverse applications, all of which fuel sustained market demand.

Which regions are expected to show the most significant growth in the Industrial Casters Market?

The Asia Pacific (APAC) region is unequivocally projected to exhibit the most significant growth in the Industrial Casters Market. This is largely driven by its extensive industrialization initiatives, the monumental expansion of its manufacturing sector, and the booming e-commerce activities prevalent in economic powerhouses like China and India, alongside other rapidly developing economies. While North America and Europe are mature markets, they will continue to experience steady growth, primarily attributed to ongoing automation efforts and a sustained demand for highly specialized, high-performance casters that meet stringent industry standards and replace aging infrastructure.

What types of materials are commonly used for industrial caster wheels?

A diverse range of materials is commonly employed for industrial caster wheels, each selected for specific performance characteristics. These include polyurethane, valued for its high load capacity, excellent floor protection, and chemical resistance; nylon, chosen for its strength, chemical inertness, and impact resistance; various types of rubber (such as solid, thermoplastic, and mold-on) for superior shock absorption, quiet operation, and floor protection; cast iron, utilized for extreme heavy loads and high-temperature applications; phenolic, known for its high load capacity and chemical/heat resistance; and polyolefin, favored for its lightweight, non-marking, and moisture-resistant properties. The optimal material selection is always contingent upon the specific application's load requirements, environmental conditions, and desired operational characteristics.

How is technology, such as AI and IoT, impacting the Industrial Casters Market?

Technology, particularly Artificial Intelligence (AI) and the Internet of Things (IoT), is profoundly impacting the Industrial Casters Market by ushering in an era of "smart casters." This involves integrating sophisticated sensors into casters to collect real-time data on parameters such as load distribution, temperature, speed, and vibration. This data then feeds into AI analytics for highly accurate predictive maintenance, proactively identifying potential failures and extending caster lifespan. Furthermore, AI optimizes material handling routes for Automated Guided Vehicles (AGVs) that rely on these casters, significantly enhancing operational efficiency, providing deeper operational insights, and contributing to the development of more intelligent and autonomous material handling systems across various industrial landscapes, fundamentally transforming industrial mobility solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager