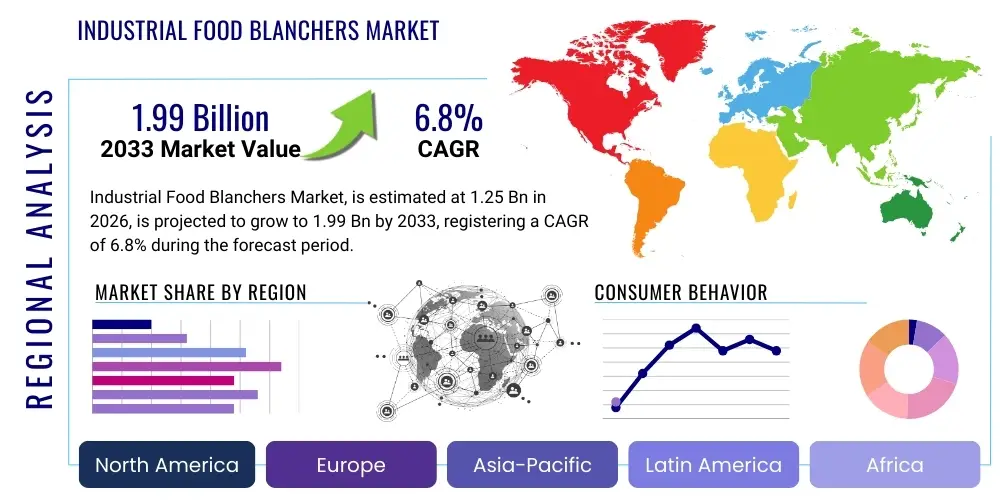

Industrial Food Blanchers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439575 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Industrial Food Blanchers Market Size

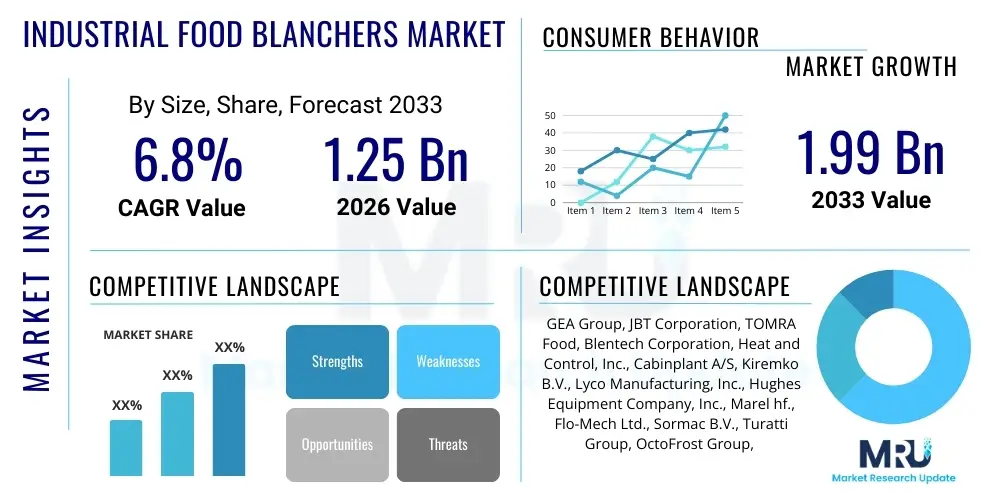

The Industrial Food Blanchers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 billion in 2026 and is projected to reach USD 1.99 billion by the end of the forecast period in 2033. This significant expansion is driven by the escalating demand for processed and convenience foods globally, coupled with increasingly stringent food safety regulations that mandate effective pre-treatment processes like blanching. Technological advancements aimed at enhancing energy efficiency, water conservation, and automation in blanching systems are further contributing to this upward trajectory, making modern blanching equipment an indispensable asset for food processors worldwide. The market's growth is also underpinned by the continuous innovation in food processing techniques and the expanding product portfolios of food manufacturers seeking to extend shelf life and preserve the nutritional integrity of their offerings.

Industrial Food Blanchers Market introduction

The Industrial Food Blanchers Market encompasses the global trade and deployment of specialized machinery designed for the thermal treatment of food products, primarily vegetables, fruits, and certain meat or seafood items, prior to further processing like freezing, canning, or dehydration. These sophisticated systems are crucial for inactivating enzymes responsible for spoilage, improving product texture, setting color, and significantly reducing microbial load, thereby extending shelf life and enhancing food safety. Industrial blanchers vary widely in design and operational principle, ranging from traditional hot water and steam blanchers to more advanced technologies such as microwave and ohmic blanchers, each offering distinct advantages in terms of efficiency, product quality preservation, and operational costs. Their application spans across a multitude of food processing sectors, from large-scale frozen food manufacturers to smaller specialized producers of organic or gourmet products, demonstrating their versatility and fundamental role in the modern food supply chain.

The primary function of an industrial food blancher is to expose food products to a controlled temperature for a specific duration, which serves multiple critical objectives. Beyond enzyme deactivation, blanching helps remove surface impurities, reduce peeling losses for certain vegetables, and can enhance the penetration of preserving agents in subsequent processing steps. For instance, in the preparation of frozen vegetables, blanching is indispensable for maintaining vibrant colors, desirable textures, and nutritional value that would otherwise degrade rapidly due to enzymatic activity. The benefits of using industrial food blanchers are extensive, including improved product quality, enhanced food safety through pathogen reduction, extended shelf life, and often, more efficient subsequent processing. These benefits collectively contribute to reduced food waste and greater consumer satisfaction, positioning blanchers as vital equipment in achieving high standards of food production.

Several driving factors are propelling the growth of this market. The global surge in demand for processed and ready-to-eat foods, driven by changing consumer lifestyles and urbanization, necessitates efficient and high-volume blanching solutions. Simultaneously, evolving food safety standards and regulations globally are compelling food manufacturers to invest in reliable blanching technologies to comply with statutory requirements and ensure public health. The continuous innovation in blancher design, focusing on energy efficiency, water recycling, and automation, also acts as a significant market driver, attracting food processors seeking to optimize operational costs and improve environmental sustainability. Furthermore, the increasing global trade of processed food products mandates robust preservation methods, with industrial blanching playing a pivotal role in maintaining product quality during extended transportation and storage periods, thus expanding its market reach.

Industrial Food Blanchers Market Executive Summary

The Industrial Food Blanchers Market is experiencing robust growth, driven by key business trends emphasizing efficiency, automation, and sustainability. Manufacturers are increasingly investing in continuous blanching systems over batch processes to achieve higher throughput and consistent product quality, aligning with the large-scale production demands of modern food processing. A significant trend is the integration of advanced sensors and control systems, enabling precise temperature and time management, which is crucial for optimizing blanching parameters and reducing energy and water consumption. Furthermore, there is a growing demand for customized blanching solutions tailored to specific product types and processing needs, reflecting the diverse and expanding product portfolios within the food industry. Businesses are also focusing on modular and scalable blancher designs that allow for easier upgrades and adaptation to changing production capacities, ensuring future-proof investments and operational flexibility.

Regional trends significantly shape the market landscape for industrial food blanchers. Asia Pacific is emerging as the fastest-growing region, fueled by rapid urbanization, increasing disposable incomes, and the consequent surge in demand for processed and convenience foods. This growth is paralleled by significant investments in new food processing plants and modernization of existing facilities across countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, continue to demonstrate strong demand for innovative, high-efficiency, and environmentally friendly blanching solutions, driven by stringent regulatory frameworks and a consumer preference for high-quality, sustainably produced food. Latin America and the Middle East & Africa regions are also witnessing gradual growth, propelled by the development of their local food processing industries and increasing adoption of international food safety standards, signaling long-term market potential in these developing economies.

Segmentation trends within the Industrial Food Blanchers Market highlight key areas of development and adoption. The continuous blanchers segment, encompassing technologies like belt and screw blanchers, is anticipated to maintain its dominance due to its superior efficiency, uniformity, and suitability for high-volume production. Among types, steam blanchers are projected to hold a substantial market share, primarily due to their effectiveness, lower water consumption compared to hot water blanchers, and ability to preserve nutrient content. However, emerging technologies such as ohmic and microwave blanchers are gaining traction, particularly for heat-sensitive products, offering faster processing times and enhanced quality retention. The application segment for fruits and vegetables continues to be the largest, reflecting the critical role of blanching in their preservation, although demand from seafood and poultry processing is also steadily increasing as these industries expand and seek to improve product quality and safety.

AI Impact Analysis on Industrial Food Blanchers Market

Common user questions regarding the impact of AI on the Industrial Food Blanchers Market often revolve around how artificial intelligence can enhance operational efficiency, improve product quality, and contribute to sustainability efforts. Users are keen to understand if AI can automate the complex process of blanching, optimize parameters in real-time to prevent over or under-blanching, and reduce costly downtime through predictive maintenance. There is also significant interest in AI's potential to analyze vast amounts of process data for actionable insights, leading to more informed decision-making and better overall process control. Furthermore, questions frequently arise about AI's role in ensuring compliance with evolving food safety regulations and its capacity to integrate seamlessly with existing food processing infrastructure. These inquiries underscore a collective anticipation for AI to transform blanching from a traditional thermal process into a smart, adaptive, and highly optimized operation.

Based on this analysis, the key themes, concerns, and expectations users have about AI's influence in this domain center on the desire for intelligent automation, predictive capabilities, and enhanced quality assurance. Users expect AI to move beyond basic process control to enable self-optimizing systems that can learn from historical data and adapt to varying raw material characteristics, thereby minimizing human intervention and operational errors. The concern about the initial investment and the complexity of implementing AI solutions is often balanced by the high expectation of significant returns through improved yield, reduced energy and water consumption, and superior end-product quality. The market anticipates AI to facilitate a paradigm shift towards highly efficient, data-driven blanching operations that are responsive to dynamic production environments and capable of achieving new benchmarks in food safety and resource optimization.

The integration of artificial intelligence within the industrial food blanchers market is poised to usher in a new era of precision, efficiency, and sustainability. AI algorithms can process real-time data from various sensors within blanching systems, including temperature, humidity, product flow, and even visual inspection systems, to make instantaneous adjustments to process parameters. This capability ensures optimal blanching conditions for every batch or continuous flow, preventing product degradation due to over-processing and ensuring thorough enzyme deactivation without compromising nutritional value or sensory attributes. Furthermore, AI can predict equipment failures by analyzing performance trends and flagging anomalies, thereby enabling proactive maintenance, reducing unscheduled downtime, and extending the operational lifespan of blanching machinery. This predictive power not only saves significant maintenance costs but also ensures consistent production schedules, a critical factor in high-volume food processing environments.

- Real-time Process Optimization: AI algorithms can continuously monitor and adjust blanching parameters (temperature, time, product speed) based on real-time data inputs from sensors, ensuring optimal processing for varying product characteristics and reducing energy waste.

- Predictive Maintenance: AI analyzes operational data to predict equipment failures before they occur, enabling proactive maintenance schedules, minimizing unplanned downtime, and extending the lifespan of blanching machinery components.

- Enhanced Quality Control: Machine vision systems powered by AI can inspect blanched products for consistency in color, texture, and detect foreign materials or defects, significantly improving product quality assurance and reducing manual inspection errors.

- Energy and Water Efficiency: AI can optimize energy consumption by precisely controlling heating elements and water usage based on current load and desired output, leading to significant reductions in operational costs and environmental impact.

- Automated Recipe Management: AI systems can store and manage an extensive database of blanching recipes for different products, automatically adjusting settings and ensuring consistent application of specific blanching protocols.

- Data-Driven Insights: AI collects and analyzes vast amounts of operational data, providing valuable insights into process bottlenecks, efficiency gaps, and opportunities for continuous improvement in blanching operations.

- Integration with Smart Factories: AI-powered blanchers can seamlessly integrate into broader smart factory ecosystems, communicating with other processing units to create a fully optimized and automated food production line.

- Adaptive Blanching: AI allows blanching systems to adapt dynamically to changes in raw material quality or environmental conditions, maintaining consistent output quality regardless of external variables.

DRO & Impact Forces Of Industrial Food Blanchers Market

The Industrial Food Blanchers Market is significantly influenced by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO), alongside various Impact Forces that shape its trajectory. A primary driver is the accelerating global demand for processed and convenience foods, driven by urbanization, busy lifestyles, and the need for longer shelf life products. This sustained consumer demand necessitates efficient and reliable pre-processing equipment like industrial blanchers to prepare food products for subsequent preservation methods such as freezing, canning, and dehydration. Complementing this, increasingly stringent food safety regulations and quality standards worldwide compel food manufacturers to adopt advanced blanching technologies to effectively reduce microbial load, inactivate spoilage enzymes, and ensure product safety and compliance. Furthermore, continuous technological advancements in blancher design, focusing on automation, energy efficiency, and water conservation, serve as a significant driver, encouraging processors to upgrade to more sustainable and cost-effective solutions. These advancements promise enhanced operational efficiency, reduced environmental footprint, and improved return on investment, making modern blanchers increasingly attractive to the industry.

However, several restraints challenge the market's full potential. The high initial capital investment required for purchasing and installing industrial blanching equipment can be a significant barrier, particularly for small and medium-sized enterprises (SMEs) with limited financial resources. This initial cost often includes not only the blancher itself but also auxiliary equipment, installation services, and necessary infrastructure modifications. Furthermore, the operational costs associated with energy consumption (for heating water or generating steam) and water usage (especially for hot water blanchers) present ongoing challenges, despite efforts towards more efficient designs. The complexity of maintenance for sophisticated systems and the need for skilled labor to operate and troubleshoot advanced blanchers also contribute to operational expenses and can be a limiting factor in regions with labor shortages or underdeveloped technical expertise. Moreover, blanching can lead to the leaching of water-soluble nutrients and changes in sensory attributes if not precisely controlled, requiring careful process optimization which can be challenging for diverse product portfolios.

Despite these restraints, the market presents considerable opportunities for growth and innovation. The emergence of developing economies, particularly in Asia Pacific and Latin America, represents vast untapped potential as their food processing industries expand and modernize. These regions are witnessing a rapid increase in processed food consumption and a growing focus on adopting international food safety standards, driving demand for new and upgraded blanching installations. Additionally, the development of smart blanching solutions incorporating IoT, AI, and advanced sensor technologies offers an opportunity for further optimization in terms of precision, efficiency, and resource utilization. These smart systems can provide real-time monitoring, predictive maintenance, and adaptive process control, transforming blanching into a more intelligent and responsive operation. Opportunities also lie in the customization of blanching solutions for niche markets and specialty products, such as organic produce or specific ethnic foods, requiring tailored approaches to preserve unique characteristics. Finally, advancements in waste heat recovery and water recycling technologies present significant opportunities for reducing the environmental impact and operating costs of blanching, aligning with global sustainability goals.

Impact forces acting on the Industrial Food Blanchers Market are multifaceted. Technological innovation is a paramount force, constantly pushing the boundaries of what blanchers can achieve in terms of speed, efficiency, and product quality. The regulatory landscape, particularly evolving food safety standards from bodies like the FDA, EFSA, and local authorities, directly impacts the design requirements and operational mandates for blanching equipment, driving manufacturers to innovate for compliance. Consumer preferences, with an increasing demand for minimally processed, natural, and nutritionally rich foods, influence the development of gentler blanching methods that minimize nutrient degradation and preserve sensory qualities. Supply chain dynamics, including raw material availability and logistics, can affect production costs and lead times for blanching equipment. Lastly, global economic conditions and geopolitical stability can influence investment decisions in food processing infrastructure, thereby impacting market demand and growth trajectories.

Segmentation Analysis

The Industrial Food Blanchers Market is meticulously segmented across various parameters to provide a comprehensive understanding of its structure and growth dynamics. These segments help in identifying key trends, understanding demand patterns, and strategizing market approaches effectively. The primary segmentation categories include the type of blancher technology employed, the mode of operation (batch versus continuous), the diverse applications across different food product categories, and the capacity of the blanching systems. Each segment reflects unique technological advancements, operational efficiencies, and suitability for specific processing requirements within the expansive food industry. Analyzing these segments individually and collectively offers insights into the market's evolving landscape, revealing areas of high growth potential and technological innovation, thereby guiding strategic investments and product development efforts across the value chain. Understanding these granular details is crucial for stakeholders to navigate the market effectively and capitalize on emerging opportunities.

- By Type:

- Steam Blanchers: Utilize steam for heating, known for preserving water-soluble nutrients, reducing water consumption, and offering quick heating.

- Hot Water Blanchers: Employ hot water immersion, often preferred for root vegetables and for achieving uniform heat distribution.

- Ohmic Blanchers: Use electrical resistance to generate heat directly within the food, providing rapid and uniform heating with minimal nutrient loss.

- Microwave Blanchers: Utilize microwave energy for rapid, volumetric heating, suitable for delicate products and reducing processing time.

- Others: Includes lesser-common or niche technologies like infrared blanchers and combined systems.

- By Mode of Operation:

- Batch Blanchers: Process food in distinct batches, suitable for smaller production volumes, specialized products, or when flexibility is required.

- Continuous Blanchers: Operate without interruption, ideal for large-scale production, offering high throughput and consistent processing.

- By Application:

- Fruits & Vegetables: The largest application segment, encompassing a wide array of produce for freezing, canning, and dehydration.

- Seafood: Used for pre-cooking shrimp, crab, and other seafood to improve texture, color, and remove impurities.

- Poultry: Employed for pre-cooking chicken or turkey pieces, often for ready-to-eat meals or further processing.

- Nuts & Seeds: Used to reduce microbial load and improve texture before roasting or other treatments.

- Pasta: Briefly blanched to prevent sticking and partially cook before final preparation.

- Others: Includes applications in pet food, specialty grains, and other processed food categories.

- By Capacity:

- Small Capacity: Designed for limited production, typically for artisanal producers or R&D facilities.

- Medium Capacity: Suitable for mid-sized food processors requiring moderate throughput.

- Large Capacity: Tailored for industrial-scale operations with high volume production demands.

Value Chain Analysis For Industrial Food Blanchers Market

A comprehensive value chain analysis for the Industrial Food Blanchers Market reveals a complex network of interconnected activities, commencing from raw material sourcing and extending to the ultimate end-user. The upstream segment of this value chain is critical, involving the procurement of essential components and raw materials required for manufacturing blanching equipment. This includes high-grade stainless steel for hygienic processing environments, sophisticated electronic components for control panels and automation systems, durable mechanical parts like conveyor belts, pumps, and motors, and specialized sensors for temperature and product monitoring. Suppliers in this segment are crucial in ensuring the quality, availability, and cost-effectiveness of these inputs, which directly influence the final product's performance and reliability. Strong relationships with reliable upstream suppliers are vital for blancher manufacturers to maintain production quality and control costs.

Moving further along the value chain, the core activity involves the design, manufacturing, and assembly of the industrial food blanchers themselves. This stage is dominated by specialized equipment manufacturers who integrate advanced engineering principles, hygienic design standards, and automation technologies to produce efficient and robust blanching systems. These manufacturers invest heavily in research and development to innovate new blanching methods, improve energy and water efficiency, and enhance the overall automation capabilities of their machinery. After manufacturing, the products enter the distribution channels, which typically involve a mix of direct sales and indirect channels. Direct sales are common for large-scale, customized projects, where manufacturers engage directly with major food processors, offering tailored solutions, installation services, and post-sales support. This approach allows for closer client relationships and deeper understanding of specific operational needs.

Indirect distribution channels involve distributors, agents, and system integrators who play a crucial role in reaching a broader customer base, especially small to medium-sized enterprises (SMEs) or regional markets. These intermediaries provide local market expertise, sales support, installation, and sometimes initial maintenance services, extending the manufacturer's reach without the need for extensive regional offices. The downstream segment of the value chain is composed of the diverse end-users of industrial blanchers, primarily large-scale food processing companies in sectors such as frozen foods, canned goods, prepared meals, and snack manufacturing. These end-users utilize blanchers as a critical pre-treatment step to ensure food safety, extend shelf life, and preserve the quality of their products. The effectiveness and efficiency of the blanching equipment directly impact their production output, product quality, and compliance with stringent food safety regulations. Therefore, the long-term success of blancher manufacturers is intrinsically linked to the satisfaction and operational success of their end-user customers.

Industrial Food Blanchers Market Potential Customers

The potential customers for industrial food blanchers represent a broad and diverse spectrum within the global food processing industry, each seeking to optimize their production processes, enhance food safety, and preserve product quality. These end-users are primarily organizations involved in large-scale food manufacturing that rely on thermal pre-treatment as a critical step before further processing, packaging, or distribution. A significant segment comprises companies in the frozen food industry, including producers of frozen vegetables, fruits, and ready-to-eat meals, where blanching is indispensable for enzyme inactivation, color setting, and texture preservation prior to freezing. Without proper blanching, these products would quickly degrade in quality and nutritional value during storage. The demand from this sector is consistently high, driven by changing consumer lifestyles and the growing preference for convenient, long-shelf-life food options, making them a primary target for blancher manufacturers and suppliers globally.

Another substantial customer base resides within the canning and bottling industry, where blanching is used for vegetables, fruits, and even some meats or seafood before sterilization. Blanching in this context helps to remove entrapped gases, reduce microbial load, and prepare the product for efficient filling and heat penetration during the canning process, ensuring both safety and quality. The snack food industry also represents a growing segment of potential customers, particularly for manufacturers of potato chips, vegetable crisps, and extruded snacks, where blanching can improve texture, reduce oil absorption, and enhance overall product appeal. Beyond these major segments, the seafood processing industry, poultry processors, and even nutraceutical companies that process botanical ingredients for health supplements, all constitute vital potential customers, each with specific blanching requirements to meet their product specifications and regulatory obligations.

Emerging markets and specialized food producers further expand the customer landscape. As developing economies expand their food processing infrastructure and adopt more advanced production techniques, the demand for industrial blanchers increases significantly. These regions are actively investing in modernizing their food supply chains to meet both domestic consumption and export demands. Furthermore, specialty food manufacturers focusing on organic products, gourmet ingredients, or specific dietary foods (e.g., gluten-free, plant-based) also seek advanced blanching solutions to preserve the unique characteristics and nutritional integrity of their niche offerings. These customers often require customizable blanching systems that can handle smaller batches with precision and gentleness, catering to the specific needs of their premium products. Overall, any food processing entity that requires enzyme deactivation, microbial reduction, texture improvement, or color stabilization as part of its production process stands as a potential customer for industrial food blanchers, underscoring the broad applicability and essential nature of this equipment across the food manufacturing landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.99 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GEA Group, JBT Corporation, TOMRA Food, Blentech Corporation, Heat and Control, Inc., Cabinplant A/S, Kiremko B.V., Lyco Manufacturing, Inc., Hughes Equipment Company, Inc., Marel hf., Flo-Mech Ltd., Sormac B.V., Turatti Group, OctoFrost Group, Tummers Food Processing Solutions, PROEX FOOD, Urschel Laboratories, Inc., FAM Stumabo, Wyma Solutions, FTC S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Food Blanchers Market Key Technology Landscape

The Industrial Food Blanchers Market is characterized by a dynamic and evolving technology landscape, constantly driven by the need for increased efficiency, improved product quality, reduced operational costs, and enhanced sustainability. A cornerstone of modern blanching technology is the shift towards continuous processing lines, which offer significantly higher throughput and more consistent product treatment compared to traditional batch systems. These continuous systems, often featuring conveyor belts or screw mechanisms, are integrated with advanced control systems such as Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems. These sophisticated controls enable precise management of critical parameters like temperature, dwell time, and product flow rate, ensuring optimal blanching conditions while minimizing human error and maximizing energy utilization. The integration of such automation technologies not only boosts productivity but also ensures traceability and adherence to strict food safety protocols, a paramount concern in the food processing industry.

Beyond traditional hot water and steam blanching, the market is witnessing growing adoption of more advanced and specialized technologies. Ohmic blanching, which utilizes electrical resistance to generate heat directly within the food product, offers rapid and uniform heating with minimal nutrient degradation, making it particularly suitable for delicate or viscous products. Similarly, microwave blanching systems provide swift volumetric heating, significantly reducing processing times and preserving a higher proportion of heat-sensitive nutrients and fresh-like sensory qualities. Furthermore, the development of energy-efficient designs is a major technological focus. This includes incorporating advanced heat recovery systems that capture waste heat from the blanching process to pre-heat incoming water or other process streams, thereby significantly reducing energy consumption. Enhanced insulation materials and optimized system layouts also contribute to minimizing heat loss, making modern blanchers far more environmentally friendly and economically viable than their predecessors.

The future of industrial food blanching is increasingly shaped by the integration of sensor technology and data analytics. Real-time sensors are deployed to continuously monitor product temperature, water quality, and other operational variables, providing instant feedback for process adjustments. This sensor data, when combined with advanced analytics and artificial intelligence (AI), enables predictive maintenance, anticipating equipment failures before they occur and minimizing costly downtime. AI also facilitates adaptive blanching, where parameters are automatically adjusted based on variations in raw material characteristics or ambient conditions, ensuring consistent product quality. Hygienic design principles are also paramount, with features like Clean-in-Place (CIP) systems and easy-to-disassemble components designed to minimize microbial contamination risks and facilitate thorough cleaning. Overall, the technology landscape is moving towards highly automated, intelligent, and sustainable blanching solutions that offer superior control, efficiency, and product integrity, addressing the evolving demands of the global food processing sector.

Regional Highlights

- North America: This region represents a mature yet highly innovative market for industrial food blanchers. Driven by stringent food safety regulations, a strong focus on automation to counteract labor costs, and a consistent demand for high-quality, processed convenience foods, North America continues to invest in advanced blanching technologies. Manufacturers here are keen on adopting energy-efficient and water-saving systems, often integrating smart technologies and AI for process optimization and predictive maintenance. The market is also influenced by consumer trends favoring organic and minimally processed foods, pushing for gentler blanching methods that preserve nutritional integrity and sensory attributes.

- Europe: The European market is characterized by a strong emphasis on sustainability, strict environmental regulations, and a demand for high-quality, traceable food products. This drives the adoption of blanchers that offer exceptional energy and water efficiency, alongside robust hygienic designs. Innovation in blanching technology is also a key feature, with significant research and development efforts aimed at developing novel blanching techniques that minimize nutrient loss and enhance product freshness. Countries like Germany, the Netherlands, and Italy are leading in blancher manufacturing and adoption, serving both local and international markets with sophisticated processing solutions.

- Asia Pacific (APAC): Positioned as the fastest-growing region, the APAC market for industrial food blanchers is experiencing rapid expansion due to burgeoning populations, increasing urbanization, rising disposable incomes, and the consequent surge in demand for processed and ready-to-eat foods. Significant investments in new food processing plants and the modernization of existing facilities, particularly in China, India, and Southeast Asian countries, are driving market growth. There is a strong demand for both cost-effective and high-capacity blanching solutions to meet the enormous production volumes required, alongside a growing focus on adopting international food safety standards, propelling the market forward.

- Latin America: This region is an emerging market for industrial food blanchers, with steady growth driven by the expansion of its domestic food processing industry and increasing exports of agricultural and processed food products. Countries such as Brazil, Mexico, and Argentina are investing in upgrading their food processing infrastructure to enhance efficiency and comply with international quality standards. While price sensitivity can be a factor, there is a growing recognition of the long-term benefits of investing in modern blanching equipment to improve product quality, extend shelf life, and open up new export opportunities.

- Middle East and Africa (MEA): The MEA region represents a nascent but developing market for industrial food blanchers. Growth is primarily attributed to the gradual industrialization of the food sector, increasing government initiatives to bolster local food production, and growing consumer demand for processed and packaged foods. Investments in food security and diversifying economies are also contributing factors. The adoption of blanching technology is crucial for preserving local produce and preparing food products for internal consumption and regional trade, offering significant long-term potential as food processing capabilities continue to evolve.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Food Blanchers Market.- GEA Group

- JBT Corporation

- TOMRA Food

- Blentech Corporation

- Heat and Control, Inc.

- Cabinplant A/S

- Kiremko B.V.

- Lyco Manufacturing, Inc.

- Hughes Equipment Company, Inc.

- Marel hf.

- Flo-Mech Ltd.

- Sormac B.V.

- Turatti Group

- OctoFrost Group

- Tummers Food Processing Solutions

- PROEX FOOD

- Urschel Laboratories, Inc.

- FAM Stumabo

- Wyma Solutions

- FTC S.p.A.

Frequently Asked Questions

Analyze common user questions about the Industrial Food Blanchers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is industrial food blanching and why is it essential?

Industrial food blanching is a thermal pre-treatment process where food products, primarily fruits and vegetables, are exposed to controlled temperatures for a short period. It is essential for inactivating enzymes that cause spoilage, improving color and texture, reducing microbial load, and removing entrapped gases, thereby extending shelf life and enhancing food safety and quality before further processing.

What are the main types of industrial blanchers available in the market?

The primary types include hot water blanchers, which immerse products in heated water; steam blanchers, utilizing steam for more controlled and water-efficient heating; and advanced technologies like ohmic blanchers (using electrical resistance) and microwave blanchers (using microwave energy) for rapid, volumetric heating, especially beneficial for delicate products or those requiring specific quality retention.

How do industrial blanchers contribute to food safety and quality?

Industrial blanchers significantly contribute to food safety by reducing surface microbial counts and inactivating harmful enzymes that could lead to spoilage or degradation. For quality, they set vibrant colors, firm textures, and help retain nutritional value, ensuring that processed foods meet consumer expectations and regulatory standards for both safety and sensory appeal.

What role does automation and AI play in modern industrial blanching systems?

Automation and AI in modern blanching systems enable precise control over processing parameters, higher throughput, and reduced manual intervention. AI-driven systems can optimize blanching conditions in real-time, predict equipment maintenance needs, and enhance quality control through machine vision, leading to greater efficiency, lower operational costs, and superior product consistency.

What are the key factors driving the growth of the Industrial Food Blanchers Market?

The market's growth is primarily driven by the increasing global demand for processed and convenience foods, stringent food safety regulations mandating effective pre-treatment, continuous technological advancements focused on energy and water efficiency, and the rising adoption of automation and smart processing solutions in the food industry. These factors collectively push manufacturers to invest in advanced blanching equipment.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager