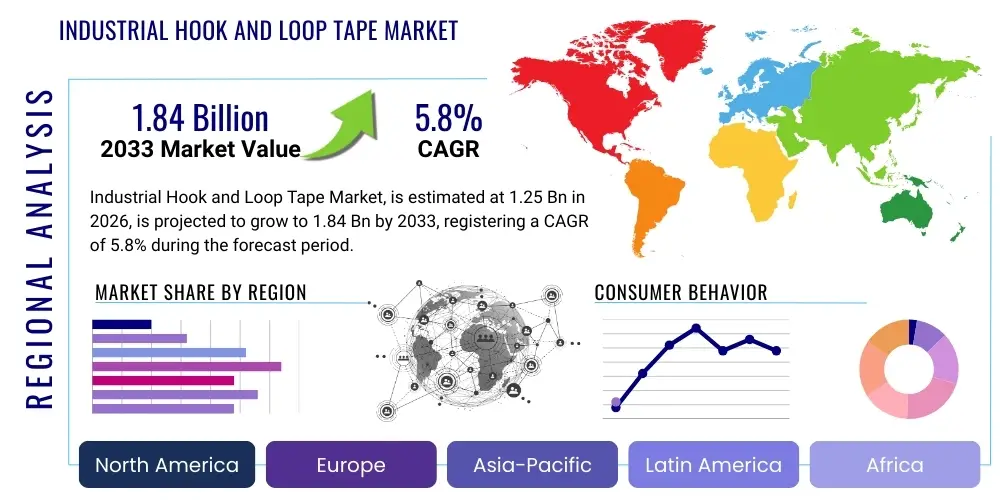

Industrial Hook and Loop Tape Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439272 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Industrial Hook and Loop Tape Market Size

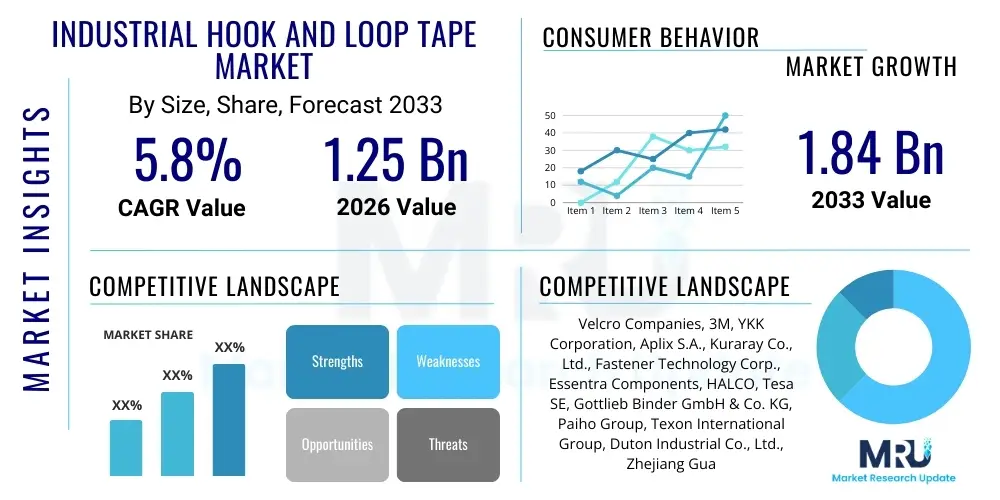

The Industrial Hook and Loop Tape Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.84 Billion by the end of the forecast period in 2033.

Industrial Hook and Loop Tape Market introduction

The industrial hook and loop tape market encompasses a diverse range of fastening solutions designed for robust, reusable, and secure applications across various sectors. These versatile tapes, characterized by their two components—a 'hook' side and a 'loop' side—offer a reliable and adjustable alternative to traditional fasteners like zippers, buttons, and adhesives. Their ease of use, durability, and ability to withstand repeated opening and closing cycles make them indispensable in demanding industrial environments. Key applications span automotive interiors, medical devices, aerospace components, construction materials, military equipment, and heavy-duty packaging, where quick assembly, secure attachment, and maintenance accessibility are paramount.

The primary benefits of industrial hook and loop tapes include their exceptional strength, flexibility, resistance to various environmental factors such as temperature extremes and moisture, and their capacity for repeated engagement and disengagement without significant loss of fastening integrity. They facilitate modular design, simplify assembly processes, and allow for easy repair or replacement of components. Driving factors for market expansion include the increasing demand for lightweight and customizable fastening solutions in the automotive and aerospace industries, the growing need for sterile and reusable fasteners in healthcare, and the accelerating adoption of modular construction techniques. Furthermore, advancements in material science are continuously enhancing the performance characteristics of these tapes, leading to specialized products tailored for extreme conditions and specific industrial requirements, thereby solidifying their market position as a critical component in modern manufacturing and assembly processes.

Industrial Hook and Loop Tape Market Executive Summary

The Industrial Hook and Loop Tape Market is experiencing robust growth, driven by an escalating demand for versatile, durable, and reusable fastening solutions across a multitude of industrial sectors. Business trends indicate a significant shift towards customized and high-performance tapes, with manufacturers focusing on developing products resistant to extreme temperatures, chemicals, and heavy loads to meet stringent industry standards. There is also a notable emphasis on automation in production processes and the integration of advanced adhesive technologies to enhance product efficacy and application ease. Emerging markets, particularly in Asia Pacific, are showcasing accelerated adoption rates due to rapid industrialization and expansion in manufacturing capabilities, while established regions continue to innovate in specialized high-value applications. The competitive landscape is marked by continuous product development and strategic collaborations aimed at expanding market reach and technological superiority.

Regional trends highlight Asia Pacific as the dominant and fastest-growing market segment, primarily propelled by flourishing automotive production, a burgeoning electronics sector, and significant investments in infrastructure development. North America and Europe maintain strong market shares, driven by advanced manufacturing industries, a strong focus on medical and aerospace applications, and strict regulatory frameworks demanding high-quality fastening solutions. Segment trends reveal an increasing preference for adhesive-backed hook and loop tapes due to their ease of application and strong bonding capabilities, along with a rising demand for heavy-duty and fire-retardant variants in sectors like construction and defense. Furthermore, the push for sustainable manufacturing practices is fostering innovation in eco-friendly material compositions, influencing product development across all segments and shaping future market dynamics towards more environmentally responsible solutions.

AI Impact Analysis on Industrial Hook and Loop Tape Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Industrial Hook and Loop Tape Market frequently center on enhancing manufacturing efficiency, improving product quality control, optimizing supply chain logistics, and facilitating the development of advanced materials. There is a strong expectation that AI can revolutionize production processes through predictive maintenance, thereby minimizing downtime and reducing operational costs. Users are also keen on understanding how AI can enable hyper-personalization of tape solutions for niche industrial applications and contribute to more sustainable manufacturing practices. Concerns often revolve around the initial investment costs for AI integration, the need for skilled labor to manage AI systems, and the potential impact on traditional manufacturing roles, alongside the benefits of increased precision and speed in product development cycles.

- AI-driven predictive maintenance systems can monitor manufacturing equipment in real-time, forecasting potential failures and scheduling proactive maintenance, which significantly reduces unexpected downtimes and optimizes production throughput for hook and loop tape manufacturers.

- Enhanced quality control through AI-powered visual inspection systems ensures consistent product specifications, detecting even minute defects in tape construction, adhesive application, and hook-loop integrity, leading to higher-quality outputs and reduced waste.

- Supply chain optimization benefits from AI algorithms that provide advanced demand forecasting, inventory management, and route optimization, ensuring timely delivery of raw materials and finished products, which is crucial for a global market.

- AI-assisted material science research accelerates the development of novel polymers and adhesives for industrial hook and loop tapes, allowing for the creation of products with superior resistance to chemicals, temperature, and UV radiation, tailored for specific demanding applications.

- Intelligent automation and robotic integration, guided by AI, can streamline the complex processes of weaving, coating, cutting, and packaging industrial hook and loop tapes, improving overall operational efficiency and consistency while reducing labor-intensive tasks.

DRO & Impact Forces Of Industrial Hook and Loop Tape Market

The Industrial Hook and Loop Tape Market is influenced by a dynamic interplay of drivers, restraints, opportunities, and pervasive impact forces that collectively shape its growth trajectory and competitive landscape. Key drivers include the escalating demand for secure and reusable fastening solutions across diverse industrial applications, particularly within the automotive, medical, and aerospace sectors where durability and ease of assembly are paramount. The continuous innovation in material science leading to high-performance tapes, coupled with the increasing adoption of modular design principles in manufacturing, further propels market expansion. However, the market faces restraints such as the volatile pricing of raw materials, primarily polymers and adhesives, which can impact production costs and profit margins. Intense competition from alternative fastening methods like zippers, snaps, and conventional adhesives also poses a challenge, requiring continuous product differentiation and value addition from hook and loop tape manufacturers. Opportunities abound in the development of specialized tapes for extreme environmental conditions, the expansion into emerging economies with rapid industrialization, and the integration of sustainable and eco-friendly manufacturing processes to meet evolving regulatory and consumer demands for green products.

The impact forces within the market structure further define its dynamics. The bargaining power of buyers is moderate to high, as end-users, especially large industrial clients, often seek cost-effective solutions without compromising quality, driving intense price competition among suppliers. Conversely, the bargaining power of suppliers, particularly for specialized raw materials, can be significant due to patented technologies or limited sources, influencing input costs. The threat of substitutes remains a constant factor, pushing manufacturers to innovate and demonstrate the superior long-term value and reusability of hook and loop systems compared to single-use fasteners. The threat of new entrants is relatively low due to the high capital investment required for manufacturing infrastructure and the need for established distribution networks and brand recognition. However, niche players with innovative technologies or specialized product offerings can disrupt specific segments. Lastly, the intensity of rivalry among existing competitors is high, characterized by continuous product development, competitive pricing strategies, and aggressive marketing efforts to capture and retain market share, fostering a dynamic and innovative environment.

Segmentation Analysis

The Industrial Hook and Loop Tape Market is comprehensively segmented across various dimensions to provide a detailed understanding of its structure, dynamics, and growth opportunities. These segmentations are critical for identifying target markets, developing tailored product strategies, and forecasting future trends. The market is primarily categorized by product type, material composition, application area, and end-use industry, reflecting the diverse requirements and functional specificities demanded by industrial clients. Each segment reveals unique growth drivers and competitive landscapes, from specialized high-performance tapes to standard solutions, and from automotive applications to the rapidly evolving medical and defense sectors. Understanding these granular divisions allows stakeholders to pinpoint areas of high potential and strategic focus within the broader market, ensuring optimized resource allocation and impactful market penetration strategies.

- By Product Type:

- Standard Hook and Loop Tapes: General-purpose solutions for various industrial applications.

- Heavy-Duty Hook and Loop Tapes: Designed for high-stress applications requiring superior tensile strength and shear resistance.

- Adhesive-Backed Hook and Loop Tapes: Feature pressure-sensitive adhesive for easy application to various surfaces.

- Sew-On Hook and Loop Tapes: Integrated into textiles and fabrics, offering maximum durability and washability.

- Fire-Retardant Hook and Loop Tapes: Engineered to meet specific fire safety standards for critical environments.

- Specialized Hook and Loop Tapes: Include high-temperature resistant, chemical-resistant, and UV-resistant variants.

- By Material:

- Nylon: Known for its strength, abrasion resistance, and excellent loop cycle life.

- Polyester: Offers superior UV resistance, water resistance, and stability in outdoor environments.

- Polypropylene: Lightweight, cost-effective, and resistant to certain chemicals.

- Blends and Composites: Customized combinations of materials to achieve specific performance characteristics.

- By Application:

- Automotive: For interior trim, seating, wiring harnesses, and component fastening.

- Medical & Healthcare: Used in patient restraints, orthotics, prosthetics, and disposable medical garments.

- Aerospace & Defense: For interior panels, cable management, equipment mounting, and uniform components.

- Industrial & Manufacturing: Fastening machine guards, tool organization, and temporary fixtures.

- Building & Construction: For insulation, signage, temporary flooring, and access panel attachments.

- Packaging: Reusable closures for boxes, bags, and protective covers.

- Others: Marine, Recreation, Sports Equipment.

- By End-Use Industry:

- Original Equipment Manufacturers (OEMs): For integration into new products and assemblies.

- Aftermarket/Maintenance, Repair, and Operations (MRO): For replacement, repair, and ongoing operational needs.

Value Chain Analysis For Industrial Hook and Loop Tape Market

The value chain for the Industrial Hook and Loop Tape Market begins with the upstream analysis, which involves the sourcing and processing of raw materials. This stage is dominated by suppliers of various polymers such as nylon, polyester, and polypropylene, along with adhesive manufacturers and textile producers who provide the foundational fabrics. Key activities at this stage include polymerization, extrusion of plastic filaments, and the weaving or knitting of fabric substrates, all of which are crucial for determining the quality and performance characteristics of the final hook and loop product. Innovation in raw material science, focusing on enhanced durability, environmental resistance, and sustainability, plays a significant role in differentiating upstream suppliers. The cost and availability of these raw materials directly impact the manufacturing costs and pricing strategies of the tape producers, making strong supplier relationships and diverse sourcing strategies essential for maintaining competitive advantage.

Moving downstream, the value chain encompasses the manufacturing, distribution, and eventual end-use of industrial hook and loop tapes. Manufacturers convert raw materials into finished tapes through processes involving hook and loop formation, coating with specialized adhesives, and cutting into various forms. Distribution channels are typically a mix of direct and indirect approaches. Direct sales involve manufacturers selling directly to large Original Equipment Manufacturers (OEMs) or key industrial accounts, often with customized solutions and technical support. Indirect channels include distributors, wholesalers, and specialized industrial supply retailers who cater to a broader range of smaller businesses, MRO (Maintenance, Repair, and Operations) markets, and niche applications. The effectiveness of the distribution network is crucial for market penetration and accessibility. The final stage involves the application of these tapes by end-users across diverse industries such as automotive, medical, aerospace, and construction, where their functionality in assembly, secure fastening, and reusability provides significant value. After-sales support, technical assistance, and product customization services further enhance customer value throughout the value chain.

Industrial Hook and Loop Tape Market Potential Customers

The potential customers for industrial hook and loop tape are highly diverse, spanning a wide array of end-use industries that require reliable, reusable, and efficient fastening solutions. Key segments include the automotive sector, where these tapes are extensively utilized for interior trim, seating arrangements, cable management, and headliners due to their lightweight properties and ease of assembly and disassembly for maintenance. Manufacturers of medical devices and healthcare products represent another significant customer base, employing hook and loop tapes in patient strapping, orthotics, prosthetics, surgical drapes, and adjustable garments, where sterility, skin compatibility, and repeated usage are critical. The aerospace and defense industries also represent high-value customers, using these tapes for interior paneling, insulation attachment, wiring bundles, equipment mounting, and military uniforms, valuing their fire-retardant properties, strength-to-weight ratio, and vibration resistance. These industries often demand highly specialized and certified products tailored for extreme operational conditions and stringent performance requirements.

Beyond these primary sectors, the industrial and manufacturing industry as a whole constitutes a vast customer base, utilizing hook and loop tapes for securing machine guards, organizing tools, temporary fixtures, and material handling applications where quick adjustments are necessary. The building and construction sector uses them for fastening insulation, temporary signage, carpet tiles, and access panels, appreciating their ease of installation and removal. Additionally, the packaging industry leverages reusable hook and loop closures for specialty bags, protective covers, and industrial containers, offering convenience and reducing waste. Other niche markets include marine applications for boat covers and upholstery, sports and recreation equipment for straps and closures, and electronics for cable management. The common thread among these potential customers is the need for a versatile, durable, and reliable fastening system that offers advantages over traditional methods in terms of cost-effectiveness, reusability, modularity, and simplified assembly or maintenance, driving continuous demand across the industrial landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.84 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Velcro Companies, 3M, YKK Corporation, Aplix S.A., Kuraray Co., Ltd., Fastener Technology Corp., Essentra Components, HALCO, Tesa SE, Gottlieb Binder GmbH & Co. KG, Paiho Group, Texon International Group, Duton Industrial Co., Ltd., Zhejiang Guangli Textile Co. Ltd., Heyi Holdings Co., Ltd., Shin Sung Co. Ltd., Arow Holdings Limited, Hoook. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Hook and Loop Tape Market Key Technology Landscape

The Industrial Hook and Loop Tape Market is characterized by a dynamic and evolving technology landscape, with continuous advancements aimed at enhancing product performance, durability, and application versatility. A primary area of technological innovation lies in material science, focusing on the development of advanced polymers and fiber formulations that offer superior strength-to-weight ratios, increased resistance to extreme temperatures, UV radiation, and various chemicals. For instance, specialized resins and coatings are being engineered to create tapes suitable for high-heat environments like engine compartments in automotive or aerospace applications, while flame-retardant additives are crucial for meeting stringent safety standards in construction and defense. Furthermore, there is significant research into incorporating recycled and bio-based materials to address sustainability concerns, pushing the market towards more environmentally friendly fastening solutions that do not compromise on performance.

Another critical aspect of the technology landscape involves manufacturing processes and adhesive technologies. Modern production techniques, including advanced weaving and knitting machinery, allow for greater precision in hook and loop formation, optimizing engagement strength and cycle life. Laser cutting and ultrasonic welding are increasingly employed for precision customization and secure attachment to various substrates, enhancing efficiency and reducing waste. In terms of adhesives, the focus is on developing high-performance, pressure-sensitive adhesives (PSAs) that offer robust bonding to a wide range of surfaces, including low surface energy plastics, metals, and composites, while maintaining resistance to moisture and industrial solvents. Smart manufacturing technologies, including automation, robotics, and integrated sensor systems, are also becoming integral to improving production consistency, throughput, and quality control, thereby driving operational efficiencies and fostering innovation within the industrial hook and loop tape manufacturing sector.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market and is projected to exhibit the highest growth rate due to rapid industrialization, burgeoning manufacturing sectors in countries like China, India, Japan, and South Korea, and significant investments in infrastructure, automotive, and electronics industries, driving immense demand for industrial fasteners.

- North America: A mature market characterized by robust demand from the automotive, aerospace, defense, and medical sectors. Innovation in specialized, high-performance tapes and a strong emphasis on research and development drive market growth, particularly in customized and certified fastening solutions for demanding applications.

- Europe: Exhibits steady growth, fueled by stringent regulatory standards for safety and quality in industries such as automotive, construction, and healthcare. Countries like Germany and France are key contributors, focusing on advanced manufacturing techniques and sustainable product development, enhancing the market for high-value industrial hook and loop tapes.

- Latin America: An emerging market with growing industrial activities and expanding manufacturing bases, particularly in Mexico and Brazil. Increasing foreign investments and a rising demand for reliable industrial fasteners in construction and automotive sectors are key growth drivers, albeit from a smaller base compared to other regions.

- Middle East and Africa (MEA): Shows promising growth potential, driven by significant investments in infrastructure development, construction projects, and diversifying economies. The rising demand for versatile fastening solutions in oil and gas, automotive assembly, and general industrial applications contributes to market expansion in the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Hook and Loop Tape Market.- Velcro Companies

- 3M

- YKK Corporation

- Aplix S.A.

- Kuraray Co., Ltd.

- Fastener Technology Corp.

- Essentra Components

- HALCO

- Tesa SE

- Gottlieb Binder GmbH & Co. KG

- Paiho Group

- Texon International Group

- Duton Industrial Co., Ltd.

- Zhejiang Guangli Textile Co. Ltd.

- Heyi Holdings Co., Ltd.

- Shin Sung Co. Ltd.

- Arow Holdings Limited

- Hoook

Frequently Asked Questions

What are the primary advantages of industrial hook and loop tape over traditional fasteners?

Industrial hook and loop tapes offer significant advantages due to their reusability, adjustability, and rapid engagement/disengagement capabilities. Unlike permanent fasteners, they allow for quick assembly, disassembly, and maintenance, reducing labor costs and time. They also provide a smooth, flexible closure that minimizes abrasion and noise, are resistant to vibration, and can conform to irregular shapes, making them ideal for applications requiring frequent access or modular design without compromising secure attachment.

Which industries are the largest end-users of industrial hook and loop tapes?

The largest end-users are primarily the automotive, medical and healthcare, aerospace and defense, and general industrial and manufacturing sectors. The automotive industry utilizes them for interior components and cable management; medical for patient restraints and disposable medical devices; aerospace and defense for interior panels and equipment mounting; and general industrial for securing machine guards and material handling, all demanding durable and reliable fastening solutions for high-performance applications.

How do advancements in material science impact the industrial hook and loop tape market?

Advancements in material science are crucial for market growth, enabling the development of tapes with enhanced performance characteristics. This includes new polymer formulations that offer superior resistance to extreme temperatures, chemicals, UV radiation, and moisture. Innovations also extend to flame-retardant properties, antimicrobial treatments, and the integration of recycled or bio-based materials, expanding the range of applications and meeting increasing demands for specialized and sustainable industrial fastening solutions.

What role does customizability play in the industrial hook and loop tape market?

Customizability is a significant differentiator, allowing manufacturers to tailor tapes to specific industrial requirements. This includes variations in material (nylon, polyester, polypropylene), adhesive types (rubber, acrylic, hot melt), hook/loop configurations, widths, lengths, and specialized treatments (fire-retardant, high-temperature resistant, conductive). This flexibility ensures optimal performance for diverse applications, from heavy-duty industrial fastening to delicate medical device assembly, meeting precise functional and aesthetic needs.

What are the key factors driving the growth of the Industrial Hook and Loop Tape Market?

Key growth drivers include the increasing demand for lightweight and modular designs in industries such as automotive and aerospace, the rising need for reusable and hygienic fastening solutions in the medical sector, and the growth of automation in manufacturing processes. Additionally, continuous product innovation leading to high-performance tapes, coupled with expanding industrialization in emerging economies and a focus on sustainable manufacturing practices, are all contributing significantly to market expansion.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager