Industrial Humidifiers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438983 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Industrial Humidifiers Market Size

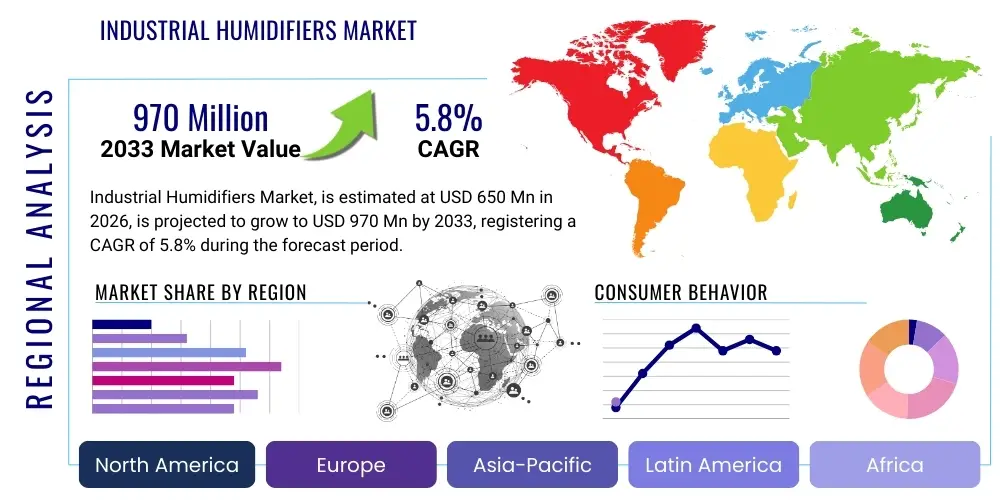

The Industrial Humidifiers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 970 Million by the end of the forecast period in 2033.

Industrial Humidifiers Market introduction

Industrial humidifiers are specialized systems designed to maintain precise humidity levels within large commercial and industrial environments, crucial for protecting sensitive materials, optimizing production processes, and ensuring employee health and safety. These systems are integral to sectors such as textiles, pharmaceuticals, food and beverage, cold storage, data centers, and specialized manufacturing where static electricity, material degradation, or microbial growth resulting from inadequate moisture content can severely compromise operational efficiency and product quality. The technology encompasses various types, including adiabatic (ultrasonic, compressed air, evaporative) and isothermal (steam) humidifiers, each selected based on specific application requirements, energy efficiency goals, and required level of humidity control precision.

The core product description centers on equipment that introduces controlled amounts of water vapor into the air. Major applications span climate control in cleanrooms, prevention of material shrinkage in wood processing, maintaining optimal paper quality in printing, and cooling heavy machinery in industrial halls. The inherent benefits of these systems include reduced production downtime due to material failure, enhanced energy savings through evaporative cooling effects, and compliance with stringent environmental health and safety regulations, particularly in pharmaceutical and healthcare settings. The accurate control provided by modern industrial humidification systems far surpasses residential or commercial-grade units in terms of output capacity, reliability, and integration capabilities with building management systems (BMS).

Driving factors for sustained market expansion include the global increase in stringent manufacturing standards across emerging economies, demanding precise climate control for high-value production processes. Furthermore, the rapid growth of the data center industry, where cooling and static charge mitigation are critical, significantly boosts demand for high-capacity adiabatic humidification solutions. Energy efficiency mandates, pushing manufacturers toward advanced technologies like ultrasonic and high-pressure fog systems which consume less power compared to traditional steam units, also contribute substantially to market adoption and technological evolution within the forecast period.

Industrial Humidifiers Market Executive Summary

The Industrial Humidifiers Market demonstrates robust growth driven primarily by technological advancements focused on energy efficiency, particularly the shift from steam-based isothermal systems to adiabatic technologies such as ultrasonic and high-pressure fogging. Business trends indicate a strong move toward integrated smart systems featuring IoT connectivity, allowing for predictive maintenance and remote monitoring, which appeals to large industrial facilities aiming for optimized uptime and reduced operational costs. The competitive landscape is characterized by consolidation and strategic partnerships aimed at broadening geographical reach and expanding product portfolios to cover niche applications, especially in precision manufacturing and specialized food storage environments.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, fueled by rapid industrialization, burgeoning manufacturing sectors in countries like China and India, and increasing investments in sophisticated infrastructure, including pharmaceutical production and advanced electronics fabrication. North America and Europe maintain stable demand, primarily driven by regulatory compliance requirements, retrofitting older HVAC systems with more energy-efficient humidification solutions, and sustained growth in the data center market. The Middle East and Africa (MEA) are emerging regions, seeing increased adoption in horticulture (greenhouses) and cold chain logistics sectors, though initial investment costs remain a moderate restraint.

Segment trends highlight the dominance of the Ultrasonic Humidifier segment within the technology type due to its superior energy efficiency and fine mist output, ideal for sensitive applications. The application segment sees the Pharmaceutical and Healthcare sector commanding significant revenue share, mandated by strict quality control standards for drug manufacturing and storage. The Textile industry also remains a fundamental consumer, relying on precise humidity control to maintain fiber integrity and minimize yarn breakage during high-speed production. Overall, market participants are heavily investing in R&D to deliver modular, scalable, and easy-to-integrate humidification solutions suitable for diverse industrial settings.

AI Impact Analysis on Industrial Humidifiers Market

User inquiries regarding the impact of Artificial Intelligence on the Industrial Humidifiers Market frequently center on how AI can enhance efficiency, reduce maintenance overhead, and optimize energy usage. Key themes emerging from these questions involve the integration of machine learning algorithms for predictive failure analysis, the potential for autonomous humidity control loops in complex cleanroom environments, and the optimization of multi-unit system orchestration across vast facilities. Users are particularly interested in minimizing water and energy waste, questioning how AI tools can model environmental variables (external weather, internal heat loads, occupancy) in real-time to adjust humidifier output proactively rather than reactively, thereby achieving unprecedented precision and substantial cost savings. The central expectation is that AI will transform industrial humidifiers from simple climate control devices into highly integrated, self-optimizing components of a larger smart building ecosystem, shifting maintenance paradigms from scheduled checks to condition-based interventions.

- AI algorithms enable predictive maintenance, anticipating component failure in pumps or nozzles based on operational data anomalies.

- Machine learning optimizes energy consumption by dynamically adjusting humidifier settings relative to immediate environmental requirements and predicted loads.

- AI-powered control systems allow for multi-zone orchestration, ensuring uniform humidity distribution across large, compartmentalized industrial spaces.

- Enhanced diagnostics through pattern recognition expedite troubleshooting, significantly reducing downtime and maintenance complexity.

- Generative AI tools assist in simulating complex airflow and moisture dispersion models during the design phase of large industrial HVAC installations.

DRO & Impact Forces Of Industrial Humidifiers Market

The Industrial Humidifiers Market dynamics are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO). Key drivers include the increasing global adoption of stringent quality control standards in sensitive industries like pharmaceuticals, electronics, and food processing, where precise humidity management is non-negotiable for product integrity. Simultaneously, the persistent need for energy-efficient operational solutions is fueling the transition toward advanced adiabatic technologies, offering lower power consumption than traditional steam systems. Restraints primarily involve the high initial capital investment required for installing industrial-grade systems and the complexity associated with integrating these advanced units into existing legacy HVAC infrastructure, especially in older industrial facilities. Water quality requirements and the associated cost of water treatment necessary to prevent scaling and microbial growth in humidifiers also act as significant barriers to entry for smaller enterprises.

Opportunities for market growth are vast, particularly stemming from the massive expansion of the global data center footprint, which requires highly controlled environments to prevent static discharge and optimize cooling efficiency. Furthermore, the growing trend toward precision agriculture and vertical farming presents a significant, untapped niche market, as controlled humidity is vital for crop yield optimization in indoor settings. The development of modular, scalable humidification solutions that are easier to install and maintain offers a pathway for manufacturers to address the investment cost restraint and broaden market access across mid-sized industrial users. The continuous push toward industrial IoT integration also provides opportunities for differentiation through software services and enhanced remote monitoring capabilities.

The impact forces driving the market are dominated by technological innovation in efficiency and precision, alongside regulatory pressures enforcing better environmental controls in workplaces and manufacturing settings. Economic feasibility is constantly being addressed by manufacturers developing products with lower total cost of ownership (TCO) over their lifespan. The societal need for cleaner, more controlled air environments, especially post-pandemic, has also subtly influenced demand, particularly in controlled production environments. Ultimately, the balance between regulatory push (mandating control) and technological pull (offering efficiency) dictates the velocity of market adoption, with major impacts currently stemming from the APAC region's intensive industrial development cycle.

Segmentation Analysis

The Industrial Humidifiers Market is comprehensively segmented based on technology, application, and output capacity, allowing for precise market sizing and strategic targeting across diverse industrial needs. The segmentation by technology differentiates between Isothermal (steam-based) and Adiabatic systems (ultrasonic, evaporative, high-pressure fog), highlighting the ongoing transition toward more energy-efficient adiabatic solutions. Application segmentation reveals the diverse end-use spectrum, ranging from critical infrastructure like data centers and pharmaceuticals to traditional high-volume manufacturing sectors such as textiles and pulp and paper. Capacity segmentation provides insights into the demands of small-scale industrial operations versus massive centralized HVAC systems found in large factories or power plants.

- By Technology: Isothermal (Steam Humidifiers, Gas-fired Humidifiers, Heated-element Humidifiers), Adiabatic (Ultrasonic Humidifiers, High-pressure Fog Humidifiers, Evaporative Humidifiers, Compressed Air Humidifiers)

- By Application: HVAC Systems, Pharmaceutical and Healthcare, Food and Beverage, Textile Industry, Data Centers and Server Rooms, Wood and Paper Industry, Cold Storage, Agriculture and Horticulture, Electronics and Semiconductor Manufacturing

- By Output Capacity: Below 100 kg/h, 100 kg/h – 500 kg/h, Above 500 kg/h

- By Component: Hardware (Pumps, Nozzles, Control Panels, Sensors), Software and Services

- By Region: North America, Europe, Asia Pacific (APAC), Latin America, Middle East and Africa (MEA)

Value Chain Analysis For Industrial Humidifiers Market

The value chain for the Industrial Humidifiers Market begins with upstream activities involving the sourcing of highly specialized components, including robust materials for enclosures, precision sensors, high-pressure pumps (for adiabatic systems), and heating elements (for isothermal systems). Key upstream suppliers are manufacturers of electronic control boards, specialized plastic and metal fabrication firms, and sensor technology providers. Quality control at this stage is crucial, as the performance and longevity of industrial humidifiers are directly dependent on the reliability of these core components, which must withstand harsh industrial environments, high flow rates, and continuous operation. Successful management of upstream logistics and material costs is a significant competitive advantage.

Midstream activities involve the design, manufacturing, assembly, and rigorous testing of the humidification units. Manufacturers focus on optimizing modular design for easier installation, reducing the manufacturing footprint, and integrating advanced control systems (often IoT-enabled). Distribution channels are highly varied; large, direct sales forces and specialized technical distributors handle complex, high-capacity installations (e.g., in data centers or pharma cleanrooms), requiring extensive pre-sale consultation and post-installation support. Indirect channels, such as HVAC wholesalers and authorized resellers, serve smaller industrial and commercial installations. The choice between direct and indirect distribution often hinges on the complexity and customization level required by the end-user.

Downstream analysis focuses on installation, commissioning, maintenance, and after-market services. Service provision, including water quality management advice, scheduled maintenance contracts, and spare parts supply, constitutes a critical revenue stream and source of customer retention. Potential customers are heavily influenced by the availability of rapid, competent local service, given that a failure in the humidification system can lead to substantial financial losses (e.g., ruined textile batches or server overheating). Effective downstream support ensures the long-term operational efficiency and adherence to warranties, making service excellence a crucial differentiator in the highly competitive industrial environment.

Industrial Humidifiers Market Potential Customers

Potential customers for industrial humidifiers are diverse, consisting of any large-scale industrial or highly controlled environment where air moisture content directly impacts product quality, process efficiency, or infrastructure longevity. The primary end-users or buyers of these specialized climate control systems are large manufacturing conglomerates, facility management companies overseeing critical infrastructure, and owners of specialized production environments. These buyers typically prioritize reliability, energy efficiency, ease of integration with existing Building Management Systems (BMS), and compliance with industry-specific certifications, such as ISO or GMP standards.

Key sectors driving demand include the pharmaceutical and biotech industries, which require validated humidity levels for production, storage, and testing areas (e.g., maintaining 40-60% relative humidity to prevent capsule degradation or static buildup). Data center operators are massive consumers, using high-pressure fog systems for adiabatic cooling and static electricity suppression to protect multi-million dollar server farms. Other crucial buyers are textile mills (to prevent fiber breakage and maintain strength), printing houses (to ensure paper dimensions remain stable), and food processing plants (to extend the shelf life of perishable goods in controlled cold environments). The purchasing decisions in these sectors are highly technical and often involve engineering consultants and facility directors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 970 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Condair Group AG, Carrier Global Corporation, Siemens AG, Spirax Sarco Engineering plc, H. IKEUCHI & CO., LTD., Nortec Humidity Inc., STULZ GmbH, Hygromatik GmbH, humidifgroup, Vaisala Oyj, Armstrong International, Inc., Pure Air Controls, LLC, Carel Industries S.p.A., Research Products Corporation (Aprilaire), Honeywell International Inc., Dri-Steem, LLC, Munters AB, Skatawa, Inc., Jiangsu Midea Group, FOGTEC Brandschutz GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Humidifiers Market Key Technology Landscape

The industrial humidifiers technology landscape is bifurcated primarily into Isothermal (steam-based) and Adiabatic (non-heating) methods, with the latter rapidly gaining dominance due to superior energy efficiency. Isothermal systems, which generate steam through electrical or gas heating, provide precise, hygienic humidification but incur high operating costs due to significant energy consumption. Conversely, adiabatic technologies, such as high-pressure fogging and ultrasonic humidifiers, atomize water into ultra-fine droplets that flash-evaporate, achieving cooling benefits alongside humidification with drastically reduced energy usage. Ultrasonic technology is particularly favored in cleanrooms and data centers for its fine particle size and quiet operation, demanding less energy than traditional evaporative cooling methods.

A significant technological advancement involves the integration of sophisticated controls and monitoring capabilities. Modern industrial humidifiers are increasingly equipped with IoT sensors, allowing for real-time remote diagnostics, performance tracking, and integration into facility-wide Building Management Systems (BMS). This connectivity facilitates predictive maintenance, where AI algorithms analyze operational data (e.g., vibration, water flow rate, energy draw) to predict potential component failures before they occur, drastically improving system reliability and reducing unexpected downtime. Manufacturers are focusing on developing highly resistant materials and advanced water treatment systems to cope with varying water hardness, minimizing maintenance burdens related to scaling and microbial proliferation (such as Legionella).

The innovation trajectory also emphasizes modularity and hybridization. Modular systems allow end-users to scale humidification capacity easily as their facility grows, reducing the complexity and cost of initial deployment. Hybrid systems that combine aspects of different technologies, leveraging the instantaneous output of steam when needed while relying on high-efficiency adiabatic methods for baseline control, offer greater flexibility and optimized operational expenditure. Furthermore, the development of specialized nozzles and dispersion units ensures uniform moisture distribution across vast industrial halls, mitigating the risk of localized saturation or inadequate coverage, which is essential for maintaining product quality in sectors like textiles and paper manufacturing.

Regional Highlights

- Asia Pacific (APAC): APAC is the fastest-growing region, driven by explosive growth in manufacturing (especially electronics, semiconductors, and pharmaceuticals) in China, India, South Korea, and Southeast Asian nations. Regulatory harmonization toward international quality standards, coupled with massive infrastructure investments in new data centers, positions this region as the major revenue contributor during the forecast period. The demand here is skewed toward high-efficiency adiabatic systems.

- North America: A mature market characterized by high awareness of energy efficiency and stringent workplace safety standards. Demand is steady, primarily fueled by the continuous expansion of hyperscale data centers, modernization of aging HVAC systems in commercial and industrial buildings, and robust consumption in the pharmaceutical and biotech industries. Focus is heavily on smart, networked humidification systems compliant with LEED standards.

- Europe: The European market demonstrates stable growth, strongly influenced by strict environmental regulations and the push for decarbonization. High penetration of advanced adiabatic technologies is observed, particularly in specialized manufacturing and museum/archival preservation. Germany, France, and the UK are key markets, emphasizing total cost of ownership (TCO) and long-term reliability over initial capital cost.

- Latin America (LATAM): An emerging market showing increasing adoption, particularly in the agricultural (horticulture) and food processing sectors in countries like Brazil and Mexico. Economic volatility and high initial investment costs are moderate restraints, but industrial expansion and foreign direct investment are slowly driving modernization projects requiring controlled environments.

- Middle East and Africa (MEA): This region is characterized by niche demand, mainly concentrated in oil and gas facilities, specialized cold chain logistics, and high-end commercial infrastructure. UAE and Saudi Arabia are making significant investments in climate-controlled mega-projects and data center hubs, requiring high-capacity humidification to combat the extreme arid climate challenges.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Humidifiers Market.- Condair Group AG

- Carrier Global Corporation

- Siemens AG

- Spirax Sarco Engineering plc

- H. IKEUCHI & CO., LTD.

- Nortec Humidity Inc.

- STULZ GmbH

- Hygromatik GmbH

- humidifgroup

- Vaisala Oyj

- Armstrong International, Inc.

- Pure Air Controls, LLC

- Carel Industries S.p.A.

- Research Products Corporation (Aprilaire)

- Honeywell International Inc.

- Dri-Steem, LLC

- Munters AB

- Skatawa, Inc.

- Jiangsu Midea Group

- FOGTEC Brandschutz GmbH

Frequently Asked Questions

What are the primary differences between Isothermal and Adiabatic industrial humidifiers?

Isothermal humidifiers (steam) heat water to create sterile vapor, offering precise control but consuming high energy. Adiabatic humidifiers (ultrasonic, fogging) atomize water without heating, offering significantly better energy efficiency and evaporative cooling benefits, making them the preferred choice for modern industrial and data center applications.

How does the growth of data centers influence the demand for industrial humidifiers?

Data centers are major drivers of demand, primarily for adiabatic systems. Humidifiers are essential in data centers to prevent static electricity (which damages sensitive electronics) and to utilize high-pressure fogging for highly efficient, low-energy evaporative cooling, which reduces operational expenditures compared to traditional chiller systems.

What are the main regulatory concerns impacting the industrial humidifiers market?

Key regulatory concerns revolve around water quality management and hygiene, specifically preventing the growth of harmful bacteria like Legionella. Compliance with standards such as GMP (Good Manufacturing Practice) in pharmaceuticals and strict health and safety standards necessitates the use of advanced, easily maintainable, and often sterile humidification technologies.

Which technology segment is expected to show the highest growth rate?

The Ultrasonic and High-Pressure Fogging sub-segments within the Adiabatic technology category are projected to exhibit the highest growth. This growth is directly attributable to their exceptional energy efficiency, low maintenance requirements, and the capability to provide the fine, consistent mist required by precision manufacturing and critical infrastructure like data centers.

What role does IoT integration play in the future of industrial humidification?

IoT integration is crucial for the market's evolution, enabling remote monitoring, real-time data analytics, and integration with Building Management Systems (BMS). This connectivity facilitates predictive maintenance, optimizes system performance based on environmental variables, and significantly improves the overall reliability and total cost of ownership (TCO) for large industrial users.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager