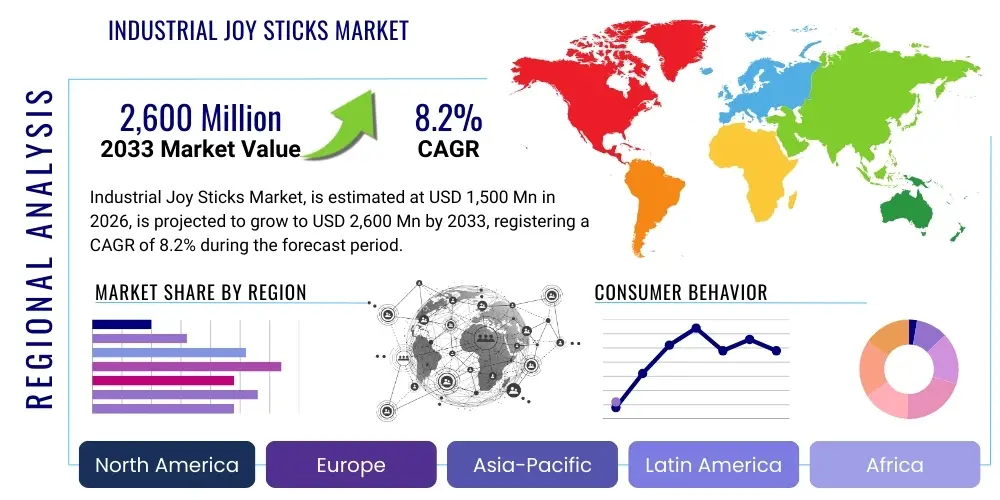

Industrial Joy Sticks Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438246 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Industrial Joy Sticks Market Size

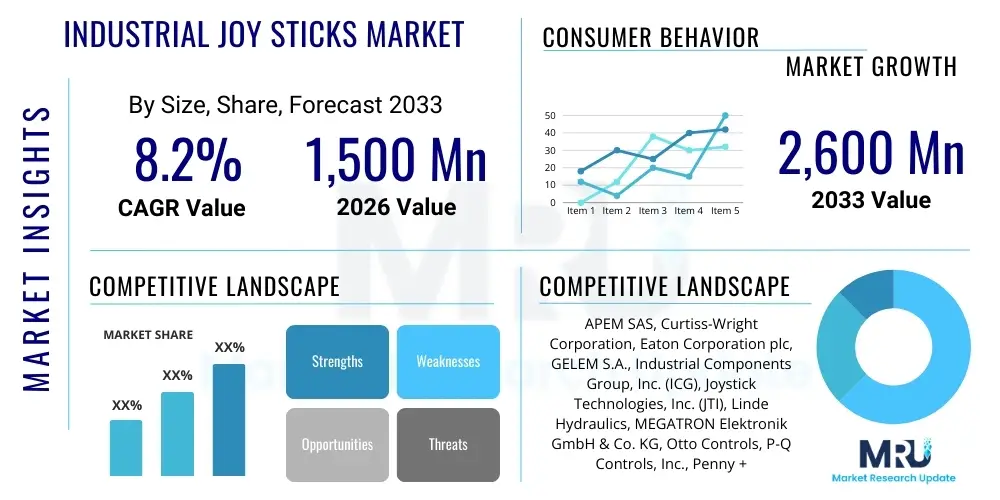

The Industrial Joy Sticks Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.2% between 2026 and 2033. The market is estimated at USD 1,500 Million in 2026 and is projected to reach USD 2,600 Million by the end of the forecast period in 2033.

Industrial Joy Sticks Market introduction

The Industrial Joysticks Market encompasses specialized human-machine interface (HMI) devices engineered for precision control and durability in demanding operational environments. Unlike consumer-grade joysticks, industrial variants are built to withstand extreme temperatures, vibrations, dust, and continuous heavy usage, making them essential components in machinery across sectors like construction, material handling, marine operations, and medical imaging. These devices translate physical movements—often 1D, 2D, or 3D translations—into electronic signals that command complex machinery, requiring high reliability and customization regarding grip, actuation force, and communication protocols (such as CAN bus or Ethernet).

Key applications for these robust control mechanisms span heavy equipment control, including cranes, excavators, and aerial work platforms (AWPs), where precise load manipulation and maneuverability are paramount for safety and efficiency. Furthermore, they are vital in automated manufacturing systems, remotely operated vehicles (ROVs) used in underwater or hazardous environments, and specialized medical equipment, particularly robotic surgery systems where tactile feedback and minimal latency are non-negotiable requirements. The versatility of industrial joysticks, configurable with numerous buttons, detents, and safety interlocks, drives their indispensable role in modern industrial automation.

The market growth is primarily driven by the global expansion of automation technologies, the increasing complexity of machinery requiring intuitive control, and stringent safety regulations demanding fail-safe HMI solutions. Benefits include enhanced operator ergonomics, reduced reaction time, and improved precision during intricate tasks, directly correlating to higher productivity and lower operational errors. Furthermore, the shift towards proportional control systems and feedback mechanisms within joysticks allows operators to achieve smoother, more controlled movements, optimizing the performance of high-value industrial assets.

Industrial Joy Sticks Market Executive Summary

The Industrial Joy Sticks Market is experiencing robust expansion driven by global infrastructure development and the pervasive trend toward Industry 4.0 adoption, particularly within emerging economies seeking to modernize manufacturing and logistics infrastructure. Business trends indicate a strong move toward developing non-contact sensing technologies, such as Hall effect sensors, which offer superior longevity and reliability compared to traditional potentiometers, thus reducing maintenance downtime. Furthermore, customization remains a critical differentiator, with manufacturers offering modular designs that allow end-users to tailor grip types, switch configurations, and mounting options to specific machinery ergonomics and operational requirements.

Regionally, Asia Pacific is anticipated to be the fastest-growing market, propelled by massive investments in construction, factory automation, and rapid urbanization, particularly in China, India, and Southeast Asian nations. North America and Europe maintain dominance in terms of technological sophistication, focusing on integrating advanced communication interfaces like CANopen and J1939 protocols for seamless integration into sophisticated vehicle control systems and autonomous platform interfaces. These regions are also leading the demand for safety-critical joysticks compliant with functional safety standards (e.g., ISO 13849).

Segment trends highlight the dominance of the non-contact technology segment (Hall effect and inductive sensors) due to its enhanced reliability and lifespan. In terms of application, material handling equipment (cranes, forklifts) and construction machinery continue to hold the largest market shares, reflecting the essential nature of precise control in these heavy-duty sectors. Emerging segments showing high growth potential include surgical robotics and high-end simulation systems, which require ultra-precise force feedback and haptic technologies embedded within the joystick mechanism, signaling a trend toward advanced, immersive control solutions.

AI Impact Analysis on Industrial Joy Sticks Market

Common user questions regarding AI's impact on industrial joysticks often revolve around the potential for complete displacement by autonomous systems, the role of predictive maintenance using AI algorithms, and how AI can enhance the user experience through adaptive control interfaces. Users are keenly interested in understanding if AI-driven autonomy will render human operators obsolete, or if, conversely, AI integration will create smarter joysticks that assist human control rather than replace it entirely. Key themes emerging from this inquiry include the development of human-in-the-loop systems, the need for standardized data protocols for sensor fusion, and the integration of machine learning (ML) for optimized force feedback and reduced operator fatigue.

The integration of Artificial Intelligence primarily affects the industrial joystick market by shifting the device's function from purely mechanical input to an intelligent control interface that processes contextual data. AI algorithms are increasingly being used within control systems to interpret nuanced human input, filter out unintended movements (tremors, fatigue), and provide dynamic assistance based on the operational context. For instance, in a large crane operation, an AI-enhanced joystick can automatically limit speed or adjust trajectory if the system detects proximity hazards or instability, thereby augmenting operator safety and precision, rather than fully automating the task.

Furthermore, AI significantly enhances the lifecycle management of industrial joysticks. Embedded sensors within high-end joysticks collect vast amounts of usage data—such as force applied, frequency of use, and temperature variances—which are then analyzed by ML models. This predictive maintenance capability allows operators to anticipate component failure (like potentiometers or springs) before critical failure occurs, maximizing machine uptime and minimizing unplanned downtime, which is crucial in high-capital industries. This shift towards smart, data-generating input devices represents a significant value addition fueled directly by AI analytics.

- AI-driven predictive maintenance based on usage data analysis, extending joystick lifespan.

- Implementation of adaptive control logic to filter operator error and enhance precision in complex maneuvers.

- Facilitation of Human-in-the-Loop (HIL) systems, enabling seamless handover between manual and autonomous control modes.

- Optimization of haptic feedback mechanisms based on real-time environmental and load conditions.

- Integration of neural networks to interpret complex gesture inputs beyond simple translational movements.

DRO & Impact Forces Of Industrial Joy Sticks Market

The Industrial Joy Sticks Market is primarily propelled by the relentless demand for higher productivity and operator safety in industrial and off-highway vehicle (OHV) sectors, balanced against the constraint of high initial capital expenditure associated with specialized, ruggedized components. The growth is fueled by regulatory mandates enforcing safer operational parameters for heavy machinery, compelling manufacturers to upgrade legacy HMI systems with modern, ergonomic, and functionally safe joysticks. Opportunities arise from the proliferation of remotely operated vehicles (ROVs) and surgical robotics, which require bespoke, highly sensitive control mechanisms capable of operating under extreme precision demands, creating lucrative niche markets beyond traditional construction and material handling sectors. These forces collectively shape the competitive and technological landscape, demanding continuous innovation in sensor technology and ergonomic design.

Drivers: A principal driver is the increasing adoption of factory automation and connected equipment within the framework of Industry 4.0, where precise, reliable input devices are foundational to efficient machine operation. The growing trend of machine electrification, particularly in construction and agricultural equipment, necessitates advanced electronic control interfaces compatible with battery management systems and electric motor controls. Furthermore, operator comfort and reduced fatigue are now critical design considerations, prompting demand for advanced ergonomic features, leading to higher-value joystick sales. The replacement cycle of aging equipment, particularly in mature markets like North America and Europe, also provides a consistent demand floor for modern, standards-compliant joysticks.

Restraints: Significant restraints include the high initial cost of ruggedized, high-specification industrial joysticks compared to standard commercial alternatives, which can deter adoption in price-sensitive markets or for low-capital machinery. Technical complexities related to integration with legacy machinery and diverse proprietary communication protocols pose integration challenges for end-users. Moreover, the market faces potential threats from the long-term trend toward full autonomy in certain industrial applications (e.g., autonomous mining trucks), which could eventually suppress the demand for human-operated HMI devices, although this transition is expected to be gradual and partial.

Opportunities: Opportunities are strong in developing advanced haptic and force feedback technologies for simulation and training systems, allowing operators to safely practice complex maneuvers. The expansion into emerging applications such as precision agriculture (using joysticks for advanced sprayer control and implement guidance) and renewable energy maintenance (controlling robotic arms for turbine inspection) offers diversified revenue streams. Furthermore, the development of wireless and portable industrial controllers that offer the same robust performance as wired versions presents a key avenue for market expansion, enhancing flexibility in dynamic work environments.

Impact Forces: The impact forces are characterized by a medium to high influence from regulatory standards (e.g., functional safety certifications IEC 61508, ISO 13849), which directly increase the barrier to entry and drive up the cost of compliant products. Technological obsolescence, driven by rapid advancements in sensor and communication technologies (e.g., the shift from analog potentiometers to Hall effect sensors), is another powerful force requiring continuous R&D investment. Finally, consolidation among major industrial equipment OEMs dictates the purchasing power and technical specifications demanded from joystick suppliers, influencing pricing and customization requirements.

Segmentation Analysis

The Industrial Joy Sticks Market segmentation provides a granular view of device types, sensor technologies, end-use applications, and geographical regions, reflecting the diverse and specialized nature of industrial control requirements. The differentiation across these segments is crucial for manufacturers to tailor their product offerings—ranging from basic single-axis controllers used in simple valve actuation to complex multi-axis grips featuring integrated CAN bus communication and advanced tactile feedback used in critical heavy machinery operations. Understanding these segments is key to identifying high-growth pockets and adapting to specific regulatory or operational demands across industries.

Segmentation by sensing technology remains a primary differentiator, as reliability and lifespan are non-negotiable for industrial applications. While potentiometers are cost-effective, the higher durability and reduced need for calibration offered by Hall effect and inductive sensors are rapidly capturing market share, especially in harsh or continuously operating environments where device failure results in significant financial losses. The axis configuration segment—1-axis, 2-axis, 3-axis, and multi-axis—is directly correlated to the complexity of the machine being controlled, with 2-axis (X-Y plane) being standard for directional control, and multi-axis devices being reserved for complex robotic arms or sophisticated camera/sensor systems.

The application segment clearly illustrates the market's reliance on heavy-duty sectors, where industrial joysticks are indispensable safety and operational components. Material handling and construction continue to dominate due to the sheer volume of equipment requiring proportional control. However, the fastest growth is often observed in precision-driven, high-value sectors such as military/aerospace (simulation, UAV control) and medical equipment (robotic surgery consoles), which require ultra-low latency, customized ergonomics, and stringent component tracing and quality standards. This diversification underscores the market's resilience and adaptability to emerging technological demands.

- By Technology:

- Potentiometer-based Joysticks

- Hall Effect Joysticks (Non-Contact)

- Inductive Joysticks

- By Mechanism Type:

- Finger-Operated Joysticks

- Hand-Operated Joysticks (Grip Joysticks)

- Thumb-Tip Joysticks

- By Axis Configuration:

- 1-Axis

- 2-Axis

- 3-Axis (including Z-axis rotation/plunge)

- Multi-Axis (4+ axes)

- By Application:

- Construction Machinery

- Material Handling Equipment (Cranes, Forklifts)

- Agricultural Machinery

- Military and Aerospace (Simulation & UAVs)

- Mining Equipment

- Medical Equipment (Surgical Robotics, Imaging)

- Factory Automation & Robotics

- By End-Use Industry:

- OEMs (Original Equipment Manufacturers)

- Aftermarket

Value Chain Analysis For Industrial Joy Sticks Market

The value chain for industrial joysticks is characterized by a specialized and rigorous progression, starting from the sourcing of high-reliability electronic components and advanced materials, through specialized manufacturing and rigorous certification, culminating in direct or integrated distribution to large industrial OEMs and aftermarket end-users. Upstream activities are heavily focused on securing precision components, including Hall effect sensors, high-durability polymers (for grips and casings), specialized metal alloys, and advanced wiring and connector systems designed to meet IP ratings (Ingress Protection) and withstand harsh operational conditions. Key challenges at this stage include managing the supply chain volatility for specialized semiconductor components and ensuring materials meet functional safety standards.

The midstream phase involves the core manufacturing process, which includes injection molding of ergonomic grips, precision machining of metal bases, and the intricate assembly of sensor electronics, mechanical springs, and internal circuitry. A critical element here is the robust Quality Assurance (QA) and testing regime, which must validate the device's lifespan (measured in millions of cycles), its environmental resistance (vibration, temperature shock), and compliance with industrial communication standards (CAN bus, Ethernet). Manufacturers often invest heavily in clean-room assembly for high-precision components, differentiating themselves based on customization capabilities and functional safety certification levels (e.g., PLd, SIL 2).

Downstream activities center on distribution, which is often bifurcated into direct sales channels targeting large Original Equipment Manufacturers (OEMs) and indirect sales through specialized industrial distributors and system integrators serving the aftermarket and smaller industrial users. Direct relationships with OEMs (e.g., manufacturers of cranes or excavators) are essential, as joysticks are often co-designed and deeply integrated into the machine's control architecture. Indirect distribution relies on partners with strong technical knowledge to provide installation support and local inventory. The final link involves technical support and maintenance services, which are critical given the demanding applications and the high cost associated with equipment downtime.

Industrial Joy Sticks Market Potential Customers

The primary potential customers and end-users of industrial joysticks are defined by industries that rely on heavy, precise, and complex machinery requiring human control input under challenging environmental or performance conditions. The largest consumer base comprises Original Equipment Manufacturers (OEMs) specializing in industrial machinery. These manufacturers, such as those producing construction equipment (Caterpillar, Komatsu), material handling systems (Liebherr, Konecranes), and agricultural machinery (John Deere, CNH Industrial), integrate joysticks directly into their control cabins during the design phase. For these customers, reliability, functional safety certification, and seamless communication protocol integration are the paramount purchasing criteria.

A second significant customer segment involves the Maintenance, Repair, and Overhaul (MRO) sector, which drives aftermarket demand. This includes fleet operators, mining companies, and large logistics hubs that require replacement joysticks due to wear and tear on existing equipment. These buyers prioritize product compatibility, immediate availability, and cost-effectiveness, often seeking alternatives or upgrades to improve the durability of their current systems. The aftermarket demand is generally less sensitive to bespoke customization but highly sensitive to longevity improvements, often favoring non-contact Hall effect technology for replacement parts.

Emerging high-value customers include specialized robotics companies and medical device manufacturers. In surgical robotics, the end-user is the hospital or medical institution, but the buyer is typically the robotics platform developer (e.g., Intuitive Surgical). These clients demand joysticks with exceptional tactile feedback, minimal drift, and compliance with strict medical device regulations (FDA, CE Mark). Additionally, defense and aerospace contractors purchasing for military simulators, unmanned aerial vehicle (UAV) ground control stations, and ship bridge control systems represent a high-specification segment where extreme reliability and specialized environmental ruggedization are mandatory purchase specifications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1,500 Million |

| Market Forecast in 2033 | USD 2,600 Million |

| Growth Rate | 8.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | APEM SAS, Curtiss-Wright Corporation, Eaton Corporation plc, GELEM S.A., Industrial Components Group, Inc. (ICG), Joystick Technologies, Inc. (JTI), Linde Hydraulics, MEGATRON Elektronik GmbH & Co. KG, Otto Controls, P-Q Controls, Inc., Penny + Giles Controls Ltd., R. F. I. Electronics, SAUER-DANFOSS (Danfoss Power Solutions), Sensor-Technik Wiedemann GmbH (STW), Spohn & Burkhardt GmbH & Co. KG, Sure Grip Controls Inc., Technolab Devices Pvt. Ltd., The Gessmann Group, WIKA Alexander Wiegand SE & Co. KG, ZF Friedrichshafen AG. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Joy Sticks Market Key Technology Landscape

The industrial joystick market is technologically defined by a continuous push toward non-contact sensing, advanced communication protocols, and enhanced human factors engineering (HFE). The shift from traditional potentiometric sensing, which suffers from mechanical wear and drift, to non-contact technologies like the Hall effect and inductive sensing is the most critical technological trend. Hall effect sensors measure magnetic fields and offer virtually infinite rotational life and superior accuracy because there is no physical contact between the moving parts, translating directly into reduced maintenance and increased reliability, vital for mission-critical applications in mining and defense.

Communication technology integration is another defining feature of the modern industrial joystick. The prevalence of CAN bus (Controller Area Network) protocols, including specific variants like CANopen and SAE J1939 (common in commercial and off-highway vehicles), allows joysticks to communicate digitally with the main vehicle or machine control unit, reducing wiring complexity and improving diagnostics capabilities. Advanced devices are now featuring Ethernet-based communication (such as EtherCAT or PROFINET), enabling real-time data exchange for highly synchronized systems, pushing the joystick beyond a simple input device into a sophisticated sensor node within a larger industrial network.

Ergonomics and functional safety represent key areas of development. Manufacturers are heavily investing in modular design architectures, allowing for quick customization of grips, handles, and switch layouts to maximize operator comfort and reduce the risk of repetitive strain injuries. Crucially, the functional safety landscape requires embedded electronics to conform to standards like ISO 13849 (Performance Level) and IEC 61508 (Safety Integrity Level), leading to the development of redundant sensor circuits and self-diagnostic features within the joystick itself. The incorporation of proportional control mechanisms, providing variable output based on displacement, has also matured, offering finer command over hydraulic and electric actuators in high-precision tasks.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand, technology adoption, and competitive intensity within the Industrial Joy Sticks Market. Each region exhibits unique characteristics based on industrial base, regulatory environment, and pace of automation.

- North America: This region is characterized by high demand for technologically advanced and functionally safe joysticks, particularly within the aerospace, defense, and oil and gas sectors. The market is mature, with a strong emphasis on integrating HMI devices with IoT platforms and implementing advanced telematics. Key drivers include rigorous safety standards for heavy equipment (especially in construction and mining) and substantial investment in defense simulation and training systems.

- Europe: Europe is a leader in adopting stringent functional safety standards (e.g., machinery directive compliance), driving the demand for high-specification, certified Hall effect joysticks. Germany, France, and the UK are primary markets due to strong automotive manufacturing, advanced factory automation, and heavy material handling industries. The region also hosts major global players, fostering innovation in modular design and CAN bus integration.

- Asia Pacific (APAC): APAC is the fastest-growing market, primarily fueled by rapid industrialization, massive infrastructure projects (especially in China and India), and the expansion of the manufacturing sector. While the market initially utilized cost-effective potentiometric solutions, there is a swift transition towards Hall effect technology driven by increasing labor costs and the need for improved equipment uptime in new factories and modern construction fleets.

- Latin America: This region presents moderate growth, largely driven by investments in mining, agriculture (precision farming), and port modernization. The market relies heavily on imports from North America and Europe. Price sensitivity remains a factor, but regulatory pushbacks toward safer machinery operation are slowly increasing the demand for certified, higher-quality control devices, particularly in Brazil and Mexico.

- Middle East and Africa (MEA): Growth in MEA is highly concentrated in GCC countries, propelled by large-scale construction, infrastructure development, and substantial investments in the energy sector (oil and gas, renewables). Demand is specific, requiring joysticks engineered to withstand extremely high temperatures, dust, and sand, placing a premium on robust ingress protection (IP ratings) and thermal stability.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Joy Sticks Market.- APEM SAS

- Curtiss-Wright Corporation

- Eaton Corporation plc

- GELEM S.A.

- Industrial Components Group, Inc. (ICG)

- Joystick Technologies, Inc. (JTI)

- Linde Hydraulics

- MEGATRON Elektronik GmbH & Co. KG

- Otto Controls

- P-Q Controls, Inc.

- Penny + Giles Controls Ltd.

- R. F. I. Electronics

- SAUER-DANFOSS (Danfoss Power Solutions)

- Sensor-Technik Wiedemann GmbH (STW)

- Spohn & Burkhardt GmbH & Co. KG

- Sure Grip Controls Inc.

- Technolab Devices Pvt. Ltd.

- The Gessmann Group

- WIKA Alexander Wiegand SE & Co. KG

- ZF Friedrichshafen AG

Frequently Asked Questions

Analyze common user questions about the Industrial Joy Sticks market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the key difference between industrial and commercial joysticks?

Industrial joysticks are engineered for extreme durability, long cycle life (often millions of cycles), environmental resistance (high IP ratings for dust/water), and adherence to strict functional safety standards (e.g., ISO 13849), critical for heavy machinery control.

Why are Hall Effect sensors becoming dominant in industrial joystick technology?

Hall effect sensors are non-contact, meaning they use magnetic fields to detect position rather than mechanical sliding components like potentiometers. This eliminates wear and tear, vastly improving the device's lifespan, reliability, and precision, particularly in continuous-use environments.

Which industrial application drives the highest demand for specialized joysticks?

The Material Handling Equipment and Construction Machinery segments currently represent the largest volume of demand, as cranes, forklifts, and excavators critically depend on high-precision, robust multi-axis joysticks for safe and proportional load manipulation.

How does functional safety impact the design and cost of industrial joysticks?

Functional safety requirements (like achieving SIL 2 or PL d) necessitate redundancy in sensor systems, continuous self-diagnostics, and certified component materials. This stringent compliance significantly increases the complexity and thus the final cost of the joystick, ensuring fail-safe operation.

What role does CAN bus communication play in modern industrial joysticks?

CAN (Controller Area Network) bus protocols allow the joystick to communicate digitally and reliably with the main machine controller, simplifying wiring harnesses, enabling advanced diagnostics, and facilitating seamless integration into complex electronic vehicle architectures.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager