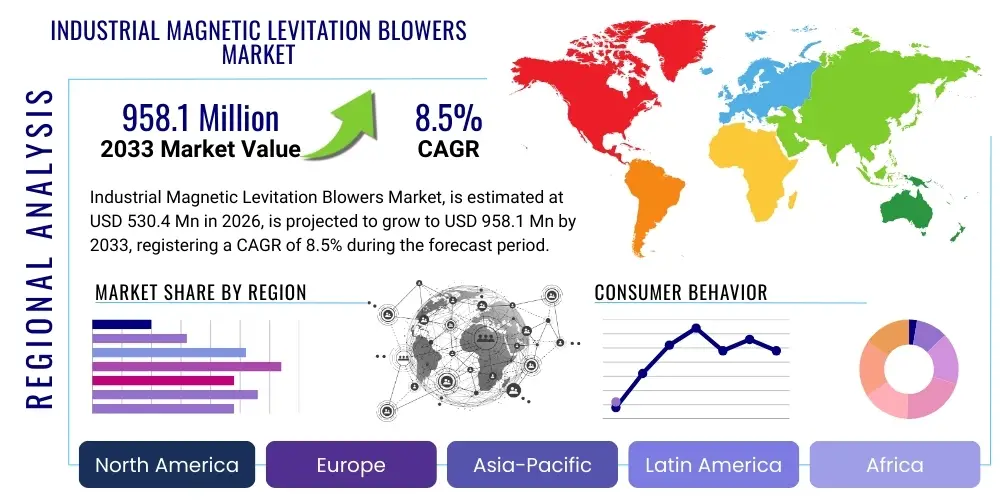

Industrial Magnetic Levitation Blowers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436241 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Industrial Magnetic Levitation Blowers Market Size

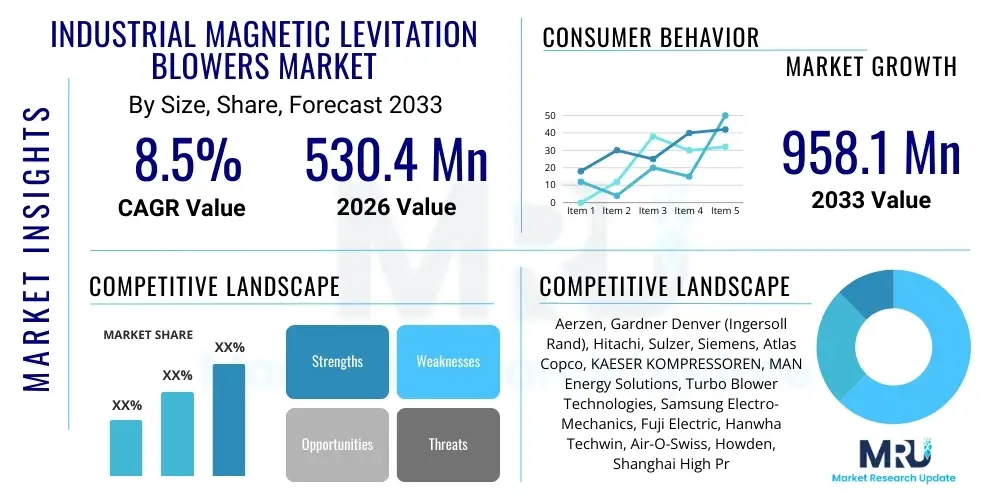

The Industrial Magnetic Levitation Blowers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 530.4 Million in 2026 and is projected to reach USD 958.1 Million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the global imperative for enhanced industrial efficiency, stringent environmental regulations necessitating oil-free compression solutions, and the superior energy-saving capabilities offered by magnetic levitation technology compared to conventional blower systems. The increasing adoption across high-demand sectors such as wastewater treatment, pharmaceuticals, and food and beverage processing, where reliability and purity are paramount, further accelerates market momentum. Furthermore, continuous advancements in active magnetic bearing (AMB) control systems are lowering maintenance costs and extending the operational lifespan of these units, making them a progressively attractive investment for large-scale industrial consumers seeking long-term operational expenditure reductions.

Industrial Magnetic Levitation Blowers Market introduction

The Industrial Magnetic Levitation Blowers Market encompasses specialized machinery designed for high-efficiency air and gas handling in industrial environments. These blowers utilize advanced magnetic bearing technology, which suspends the rotating shaft without physical contact, eliminating friction, wear, and the need for lubricating oils. This unique design translates directly into significantly higher energy efficiency—often yielding savings of 20% to 40% compared to traditional centrifugal or positive displacement blowers—and ensures a completely oil-free output, critical for processes sensitive to contamination. Major applications span municipal and industrial wastewater treatment (aeration tanks), chemical processing, power generation (flue gas desulfurization), and various manufacturing processes requiring precise, clean airflow. Key benefits include exceptionally low noise operation, reduced maintenance requirements, smaller footprints, and instantaneous performance monitoring capabilities. The market growth is principally driven by escalating global energy prices, government mandates promoting industrial decarbonization, and the technological maturity of sophisticated permanent magnet synchronous motor (PMSM) systems integrated with high-speed digital controllers.

Industrial Magnetic Levitation Blowers Market Executive Summary

The Industrial Magnetic Levitation Blowers Market exhibits robust growth, characterized by significant business trends favoring sustainability and automation. The primary business trend involves the shift from capital expenditure (CapEx) focus towards long-term operational expenditure (OpEx) savings, making the higher initial cost of magnetic levitation technology justifiable through decades of energy and maintenance savings. Technologically, integration with Industrial IoT (IIoT) platforms for predictive maintenance and remote diagnostics is becoming standard, enhancing reliability and reducing unplanned downtime. Regionally, Asia Pacific (APAC) dominates in terms of new installations, fueled by rapid industrialization, large-scale infrastructure projects, particularly in water treatment across China and India, and increasing government investments in environmental compliance technologies. North America and Europe, however, lead in technological maturity and adoption rates within existing facilities due to stringent energy efficiency standards and mature regulatory frameworks. Segment trends indicate that the wastewater treatment application segment retains the largest market share, while the pharmaceutical and food and beverage sectors are projected to register the fastest growth due to the critical requirement for uncontaminated, oil-free air supply throughout their sensitive production lines.

AI Impact Analysis on Industrial Magnetic Levitation Blowers Market

User queries regarding the impact of Artificial Intelligence (AI) on the Industrial Magnetic Levitation Blowers Market primarily revolve around optimizing operational efficiency, extending equipment lifespan, and reducing energy consumption unpredictability. Key themes often encountered include questions about AI’s role in predictive maintenance (forecasting magnetic bearing wear or surge conditions), real-time energy load balancing, and autonomous process control in complex aeration systems. Users are concerned with how AI integration might standardize operations across decentralized facilities and whether the investment in AI-driven control systems provides a measurable return on investment beyond standard digital controls. The consensus expectation is that AI will move magnetic levitation blowers from high-efficiency machines to intelligent assets capable of self-optimization, dynamically adjusting flow and pressure parameters based on anticipated load changes or external environmental factors, thereby maximizing uptime and minimizing energy waste throughout their lifecycle. This shift towards cognitive operation represents the next major technological leap for market stakeholders.

- AI enables highly precise predictive maintenance schedules by analyzing real-time vibration and temperature data, preventing catastrophic failures and minimizing unexpected downtime.

- Integration of machine learning algorithms optimizes the blower's energy consumption profile, matching airflow output exactly to process demand, leading to significant power savings beyond inherent magnetic efficiency.

- AI-driven control systems allow for self-diagnosis and autonomous optimization of magnetic bearing stiffness and damping parameters, ensuring stable, high-speed operation under varying industrial loads.

- Enhancement of surge and choke prevention through advanced pattern recognition and real-time kinetic model adjustments, improving operational safety and extending component life.

- Facilitation of remote monitoring and control capabilities through IIoT platforms, allowing operators to manage complex fleets of blowers across geographically dispersed industrial sites efficiently.

DRO & Impact Forces Of Industrial Magnetic Levitation Blowers Market

The dynamics of the Industrial Magnetic Levitation Blowers Market are shaped by powerful drivers related to sustainability and efficiency, moderated by notable restraints concerning capital investment and technological complexity, and propelled forward by significant market opportunities. The core driver is the escalating global focus on energy efficiency and reduction of carbon emissions, where magnetic levitation technology offers quantifiable, market-leading savings. Simultaneously, strict governmental and environmental regulations, particularly concerning wastewater discharge and industrial air quality, mandate the use of oil-free and high-reliability equipment. However, the market faces a significant restraint due to the high initial procurement and installation costs associated with sophisticated magnetic bearings and high-speed motor control systems, which can be prohibitive for smaller enterprises or those operating on tight CapEx budgets. Furthermore, the specialized nature of maintenance and repair requires highly trained technicians, adding complexity. The prevailing opportunities lie in the rapid expansion of industrial infrastructure in emerging economies, particularly in Asia, and the growing demand for integration of these blowers with smart factory ecosystems utilizing IIoT and cloud connectivity for enhanced operational visibility and predictive servicing. These forces collectively dictate the market adoption rate and the strategic focus of manufacturers on cost reduction and performance enhancement.

Segmentation Analysis

The Industrial Magnetic Levitation Blowers Market is strategically segmented based on crucial attributes including technology type, application area, and end-use industry, providing a detailed view of specific growth avenues and market penetration strategies. Segmentation by application, particularly the dominance of the wastewater treatment segment, reflects the significant and recurring demand for efficient aeration solutions in municipal and industrial facilities globally. Technology segmentation differentiates products based on bearing structure and control mechanisms, primarily categorizing the market into Active Magnetic Bearings (AMB) and Passive Magnetic Bearings (PMB), although AMB systems hold prominence due to their superior stability, controllability, and ability to handle high loads at variable speeds. End-use segmentation highlights varied requirements across industries, from the high-purity demands of pharmaceuticals and food processing to the high-volume, continuous operation required in chemical and power generation sectors, enabling suppliers to tailor solutions that meet specific operational benchmarks like noise reduction, flow consistency, and energy footprint.

- By Type:

- Active Magnetic Bearing (AMB) Blowers

- Passive Magnetic Bearing (PMB) Blowers

- By Flow Capacity:

- Low Capacity (Below 1,000 CFM)

- Medium Capacity (1,000 – 5,000 CFM)

- High Capacity (Above 5,000 CFM)

- By Application:

- Wastewater Treatment (Aeration)

- Chemical and Petrochemical Processing

- Pharmaceutical and Biotechnology

- Food and Beverage Processing

- Power Generation (Flue Gas Desulfurization)

- General Industrial Manufacturing

- By End-Use Industry:

- Municipal Sector

- Industrial Sector

Value Chain Analysis For Industrial Magnetic Levitation Blowers Market

The value chain for industrial magnetic levitation blowers is complex, starting with highly specialized component manufacturing and extending through intricate integration and after-sales service. Upstream analysis focuses on the sourcing of high-grade materials for Permanent Magnet Synchronous Motors (PMSMs), high-speed rotors, and crucially, the sophisticated sensor technology and power electronics necessary for the Active Magnetic Bearing (AMB) control systems. Key activities at this stage involve intensive R&D to enhance bearing control algorithms and improve motor efficiency, often requiring partnerships with specialized semiconductor and component suppliers. The manufacturing stage requires high precision machining and assembly, demanding rigorous quality control given the high rotational speeds of the equipment. Downstream analysis focuses on effective distribution channels, which are typically segmented into direct sales models for large-scale, customized industrial projects (e.g., municipal wastewater plants) and indirect sales through specialized industrial distributors and system integrators for standardized units. The after-market segment, encompassing maintenance, spare parts (especially controllers and sensors), and service contracts, constitutes a significant portion of the total value realization. Direct channels facilitate deep client engagement necessary for complex installations, while indirect channels provide wider geographical reach and localized support, ensuring prompt response to operational requirements.

Industrial Magnetic Levitation Blowers Market Potential Customers

Potential customers for Industrial Magnetic Levitation Blowers primarily comprise entities across sectors where high-volume, continuous, oil-free airflow, and minimized operational costs are critical operational benchmarks. The largest consumer base resides within the municipal sector, specifically organizations managing large sewage and wastewater treatment facilities, as aeration accounts for up to 60% of their total energy consumption; magnetic levitation blowers offer an immediate and massive reduction in this expenditure. Industrial end-users span sectors mandated by regulatory bodies to maintain product purity or those seeking competitive advantages through energy independence. This includes manufacturers of pharmaceuticals and biotechnology products that require sterile processing environments, food and beverage producers needing oil-free air for fermentation, conveying, and packaging, and chemical processing plants utilizing blowers for catalyst regeneration or pneumatic conveying systems. These buyers prioritize long-term Total Cost of Ownership (TCO) over initial price, making the efficiency, longevity, and low maintenance features of maglev blowers highly attractive investment criteria, particularly when integrating them into existing or new high-reliability operations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 530.4 Million |

| Market Forecast in 2033 | USD 958.1 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Aerzen, Gardner Denver (Ingersoll Rand), Hitachi, Sulzer, Siemens, Atlas Copco, KAESER KOMPRESSOREN, MAN Energy Solutions, Turbo Blower Technologies, Samsung Electro-Mechanics, Fuji Electric, Hanwha Techwin, Air-O-Swiss, Howden, Shanghai High Pressure Pump Factory. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Magnetic Levitation Blowers Market Key Technology Landscape

The technological landscape of the Industrial Magnetic Levitation Blowers market is dominated by the synergistic application of three core components: Active Magnetic Bearings (AMB), high-efficiency Permanent Magnet Synchronous Motors (PMSM), and advanced digital control systems. AMB technology is foundational, utilizing electromagnets controlled by sophisticated sensors and digital processors to suspend the rotor shaft completely without contact. This system requires real-time feedback and adjustment, typically executed tens of thousands of times per second, ensuring stability and precise positioning even at ultra-high rotational speeds. The integration of PMSM technology provides the highest possible motor efficiency and power density, allowing for smaller, lighter motors that can drive the impeller at speeds necessary to achieve required pressure and flow characteristics. Unlike traditional induction motors, PMSMs minimize energy losses associated with rotor currents, directly contributing to the blower’s overall efficiency gains. Moreover, the control infrastructure is transitioning towards powerful multi-core digital signal processors (DSPs) and Field-Programmable Gate Arrays (FPGAs) to manage complex magnetic bearing algorithms, motor speed, and simultaneous communication with external factory control systems (SCADA, PLC). This convergence of technologies facilitates superior performance, minimal friction losses, and robust integration into modern industrial automation environments, setting maglev blowers apart from legacy solutions.

Recent developments are heavily focused on enhancing the robustness and miniaturization of the control hardware, making the systems less susceptible to industrial noise and thermal fluctuations. Manufacturers are investing significantly in simplifying the control interface and integrating comprehensive diagnostic features directly into the blower's Human-Machine Interface (HMI), reducing the reliance on external commissioning tools and specialized programming knowledge. Furthermore, advancements in power electronics, specifically the use of Silicon Carbide (SiC) and Gallium Nitride (GaN) components in the motor drives, are enabling even higher switching frequencies and smaller inverters, contributing to better power factor correction and reducing overall system size and heat generation. This technological refinement is crucial for improving the return on investment (ROI) by enhancing long-term reliability and ensuring that the blower can maintain peak efficiency across wide operational turndown ranges—a critical requirement in applications like variable-load wastewater aeration basins where flow demand fluctuates dramatically throughout the day. The push towards standardization of communication protocols, such as OPC UA and MQTT, also streamlines the integration process, facilitating the creation of truly smart, interconnected blower fleets that communicate their health status and performance metrics seamlessly with central monitoring systems.

The future of the technology landscape centers around increased autonomy and reliability. Efforts are underway to incorporate self-learning control systems that can adapt to changing impeller conditions or minor component degradation over time, further extending maintenance intervals and predicting optimal service times with greater accuracy. This involves leveraging the data generated by the AMB sensors not just for immediate control but for long-term health trending and prognosis. Another critical area is the enhancement of auxiliary bearing technology—the physical backup bearings that engage only during power loss or significant system failure—ensuring that even in extreme events, the rotor can be safely brought to a halt without damage to the magnetic components or the impeller. The continuous reduction in component cost, particularly for high-speed electronics and advanced magnet materials, is expected to democratize the technology, making magnetic levitation blowers viable for a broader range of medium-sized industrial applications currently dominated by traditional, less efficient blower types. These technological vectors ensure that maglev blowers will remain at the forefront of industrial air and gas compression efficiency.

Regional Highlights

- Asia Pacific (APAC): APAC represents the fastest-growing and largest regional market, driven primarily by extensive infrastructure development, particularly in municipal wastewater treatment in densely populated nations like China and India, where governments are making massive investments to meet modern environmental standards. The region’s rapid industrialization, especially in sectors such as electronics manufacturing and petrochemicals, creates substantial demand for high-efficiency, continuous-operation blowers. Price sensitivity remains a factor, but the long-term cost benefits of energy efficiency are increasingly outweighing initial capital costs, leading to high adoption rates in large industrial clusters.

- North America: North America is characterized by high technological maturity and strict energy efficiency regulations (e.g., California’s energy standards). The market is driven by the replacement of aging infrastructure and a strong corporate focus on achieving sustainability goals. Adoption is high in the municipal sector and specialized industrial segments like pharmaceuticals and food processing, where the premium for oil-free operation is readily accepted. Key drivers include robust governmental incentives for energy-efficient equipment upgrades and the availability of sophisticated service and support networks.

- Europe: Europe exhibits strong growth rooted in its commitment to environmental sustainability and stringent EU directives on industrial emissions and energy consumption (e.g., the Energy Efficiency Directive). Germany, the UK, and Scandinavian countries are leaders in adopting magnetic levitation technology, often integrating these blowers as part of larger smart factory or Industry 4.0 initiatives. The region prioritizes operational lifetime and reliability, demanding highly customized solutions and comprehensive after-sales support from manufacturers. The prevalence of high energy costs further solidifies the economic argument for these high-efficiency systems.

- Latin America (LATAM): The LATAM market is emerging, demonstrating increasing adoption driven by urbanization and subsequent growth in municipal infrastructure projects, especially in countries like Brazil and Mexico. Economic volatility can constrain capital investment, positioning the market as more focused on phased implementation and smaller, highly critical applications initially. Market penetration is expected to accelerate as regional energy prices stabilize and operational budget constraints necessitate long-term cost-saving technologies.

- Middle East and Africa (MEA): Growth in the MEA region is segmented, with the Middle East focusing on large-scale petrochemical and desalination projects, requiring highly reliable, large-capacity blowers for continuous operation in challenging thermal environments. Africa’s adoption is concentrated around resource extraction industries and essential urban water infrastructure projects. The market here is highly dependent on foreign investment and technology imports, with key decisions driven by reliability under extreme operational conditions and long-term service contracts.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Magnetic Levitation Blowers Market.- Aerzen

- Gardner Denver (Ingersoll Rand)

- Hitachi

- Sulzer

- Siemens

- Atlas Copco

- KAESER KOMPRESSOREN

- MAN Energy Solutions

- Turbo Blower Technologies

- Samsung Electro-Mechanics

- Fuji Electric

- Hanwha Techwin

- Air-O-Swiss (KNF Group)

- Howden

- Shanghai High Pressure Pump Factory

- SKF Group (Supplier of Magnetic Bearing Systems)

- General Electric

- Mitsubishi Heavy Industries

- Xylem

- Ebara Corporation

Frequently Asked Questions

Analyze common user questions about the Industrial Magnetic Levitation Blowers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary energy efficiency benefit of magnetic levitation blowers compared to traditional blowers?

Magnetic levitation blowers eliminate mechanical friction by suspending the rotor using active magnetic bearings, resulting in energy savings typically ranging from 20% to 40% compared to conventional technologies like roots or centrifugal blowers, directly translating to lower operational costs over the equipment lifespan.

What are the typical maintenance requirements and lifespan of an industrial magnetic levitation blower?

These blowers require minimal routine maintenance due to their oil-free, non-contact operation. The primary components requiring checks are air filters and electronic control systems. Lifespan is significantly extended, often exceeding 20 years, with magnetic bearings themselves having theoretical near-infinite life, reducing downtime and service expenditure.

In which industrial application is the demand for magnetic levitation blowers highest globally?

The highest demand is consistently observed in the municipal and industrial wastewater treatment sector, specifically for aeration basins. Blowers are critical here, and their high efficiency is essential for minimizing the enormous electricity costs associated with continuous large-scale aeration processes.

Is the high initial cost of maglev blowers justifiable for small to medium-sized enterprises (SMEs)?

While the initial CapEx is higher, the investment is often justified even for SMEs due to the substantial reduction in operational expenditure (OpEx). Payback periods typically range from two to five years, primarily driven by dramatic energy savings and the virtual elimination of costs related to lubricants, belts, and frequent mechanical overhauls.

How does the integration of IIoT and AI enhance the performance of these blowers?

IIoT and AI enable real-time predictive maintenance, precise flow optimization based on variable demand, and remote diagnostics. This intelligence minimizes surge risks, optimizes energy consumption dynamically, and ensures maximum uptime by forecasting component wear before failure occurs.

The global market for industrial magnetic levitation blowers is undergoing a significant transformation, driven by a confluence of environmental pressures, technological advancements, and the relentless pursuit of operational efficiency across diverse industrial landscapes. The intrinsic design benefits—primarily the oil-free operation and the drastic reduction in energy consumption achieved through frictionless magnetic bearings—position this technology as a cornerstone of sustainable industrial air and gas handling. The market trajectory is not uniform; while mature markets in North America and Europe prioritize replacing existing, less-efficient equipment to meet stringent regulatory compliance and corporate sustainability targets, the rapid expansion in Asia Pacific is dictated by large-scale infrastructure buildout, particularly in water resource management and heavy manufacturing sectors. This dual mechanism of growth ensures sustained market momentum throughout the forecast period. Furthermore, the adoption curve is increasingly influenced by factors beyond mere efficiency. The enhanced precision, stability, and lower acoustic emissions of magnetic levitation systems are becoming non-negotiable requirements in sensitive environments like pharmaceutical cleanrooms and food production facilities, where minimizing contamination risks and optimizing process stability are paramount to compliance and product integrity. The integration of advanced digital controls, often featuring embedded AI capabilities for predictive maintenance and self-optimization, marks the transition of these blowers from sophisticated hardware into intelligent, networked assets within the broader framework of Industry 4.0. This digital convergence allows industrial operators to move from reactive maintenance scheduling to proactive, condition-based servicing, drastically lowering the total cost of ownership (TCO) and reinforcing the long-term economic argument for adopting this technology over traditional mechanical alternatives. The market competition remains intense, characterized by established industrial giants leveraging their extensive service networks and global footprint, while specialized technology firms focus on innovation in high-speed motors and magnetic bearing control algorithms to capture niche high-performance segments. The future growth hinges upon the manufacturers' ability to continuously reduce the initial capital investment barriers and provide seamless integration support for diverse and legacy industrial systems, thereby unlocking market potential across medium-sized enterprises previously reliant on lower-cost, conventional blower solutions. As global energy prices remain volatile and environmental scrutiny heightens, the magnetic levitation blower is poised to become the default standard for efficient industrial air compression.

In analyzing the strategic dynamics within the industrial magnetic levitation blower ecosystem, it is vital to acknowledge the role of standardization and regulatory harmonization. Efforts by international bodies to establish clearer performance benchmarks and energy efficiency classifications are crucial, as they provide end-users with a simplified framework for evaluating the long-term economic viability of these premium systems. Currently, market decisions are often complex, requiring deep technical analysis to fully appreciate the difference between static catalog efficiency ratings and real-world operational performance across variable load cycles. Magnetic levitation blowers excel under partial load conditions—a common scenario in many industrial processes, such as the fluctuating oxygen demands in biological wastewater treatment—where conventional blowers often suffer significant efficiency losses. This superior part-load performance is a key differentiator that manufacturers are increasingly highlighting in their competitive messaging, shifting the focus from peak efficiency to integrated, cycle-wide efficiency management. Furthermore, the robust nature of the active magnetic bearing system, which allows the blower to operate reliably across highly variable ambient temperatures and altitudes, expands its applicability into harsh operational environments previously dominated by more rugged, but less efficient, mechanical systems. The ongoing material science research aimed at developing more powerful, yet cost-effective, rare-earth magnets and sophisticated, high-temperature superconductors could potentially revolutionize the next generation of magnetic bearing design, reducing system size and further enhancing power density and efficiency. Strategic alliances between blower manufacturers and providers of industrial Internet of Things (IIoT) platforms are also defining the competitive landscape. These partnerships are essential for offering value-added services such as continuous remote diagnostics, performance benchmarking across global fleets, and secure, cloud-based data management, transforming the product offering into a comprehensive service solution. This transition to an ‘equipment-as-a-service’ model helps industrial consumers overcome the high upfront capital expenditure hurdle, allowing them to budget the cost of efficiency improvements as a predictable operating expense. Consequently, the ability of market players to successfully navigate the complex requirements of digital integration and service provisioning will increasingly determine their market share and competitive advantage in the coming decade.

The socio-economic impact of adopting industrial magnetic levitation blowers extends significantly beyond mere energy cost savings. By enabling cleaner, oil-free operations, these blowers directly contribute to higher product quality, particularly in sensitive sectors, minimizing the risk of expensive product recalls or batch contamination. This purity advantage is a non-negotiable value proposition in sectors governed by strict GMP (Good Manufacturing Practices) and HACCP (Hazard Analysis Critical Control Point) standards. Moreover, the characteristic low-noise profile of magnetic levitation systems is gaining prominence as global occupational safety standards evolve, addressing industrial noise pollution which is a pervasive health concern in manufacturing environments. The reduction in acoustic emissions improves workplace conditions and often simplifies compliance with local environmental noise ordinances, especially for facilities located near residential areas. From a strategic perspective, governmental policies, such as carbon pricing mechanisms and mandated energy audits, are increasingly externalizing the cost of inefficiency, thereby strengthening the economic case for magnetic levitation technology. Policymakers in leading industrial economies are recognizing that promoting the adoption of these best-available technologies is a powerful lever for achieving national climate targets without compromising industrial competitiveness. In response, manufacturers are focusing their R&D efforts not only on core efficiency metrics but also on modular designs that facilitate easier retrofitting into existing plant layouts. This focus on installability and scalability is critical for penetrating the vast installed base of older, lower-efficiency blowers. The overall market resilience is tied to fundamental global growth drivers: the need for clean water (wastewater treatment), reliable energy supply (power generation efficiency), and continuous growth in manufacturing output, all of which require consistent, high-quality air and gas compression. Therefore, the industrial magnetic levitation blowers market is structurally supported by enduring global macro trends toward sustainability and optimized resource management.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager