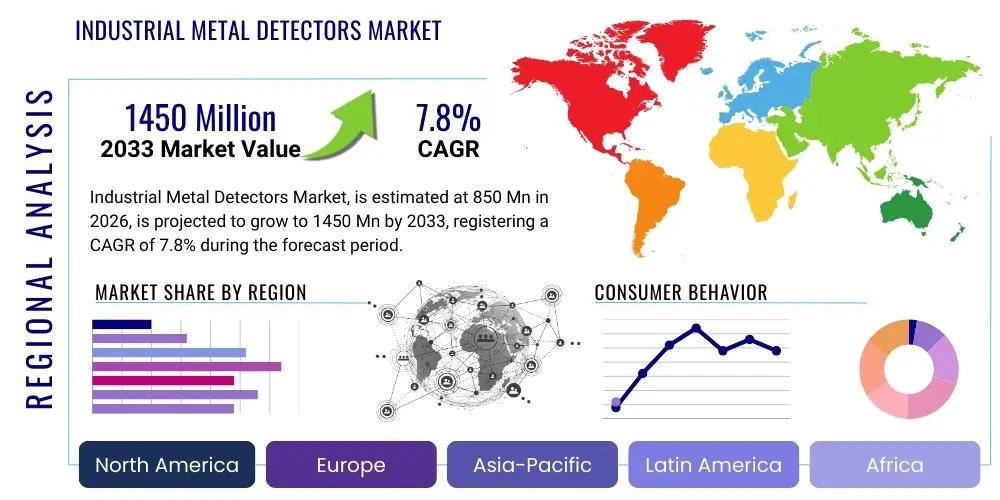

Industrial Metal Detectors Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439881 | Date : Jan, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Industrial Metal Detectors Market Size

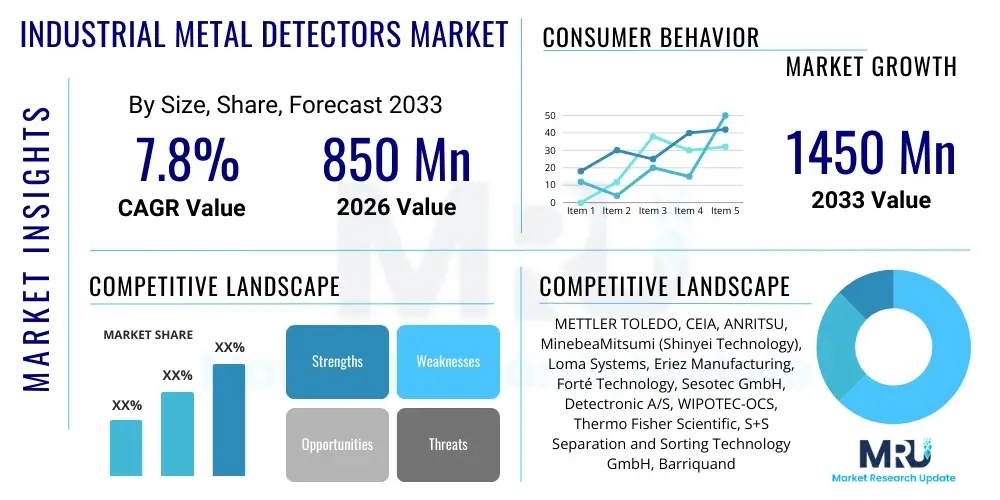

The Industrial Metal Detectors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 850 million in 2026 and is projected to reach USD 1450 million by the end of the forecast period in 2033. This growth is driven by increasing emphasis on product safety and quality across various manufacturing sectors, coupled with stringent regulatory standards worldwide. Advancements in sensor technology and integration with automated production lines are further contributing to the market expansion. The demand for industrial metal detectors is particularly robust in industries such as food processing, pharmaceuticals, and packaging, where contaminant detection is critical for consumer health and brand reputation.

Industrial Metal Detectors Market introduction

The industrial metal detectors market encompasses a range of sophisticated equipment designed to identify and remove metallic contaminants from various product streams and industrial processes. These devices utilize electromagnetic fields to detect the presence of ferrous, non-ferrous, and stainless steel particles, ensuring product integrity and operational safety. Major applications span food and beverage processing, pharmaceuticals, textiles, plastics, mining, and recycling, where they prevent costly machinery damage, protect consumers from contaminated products, and ensure compliance with global safety standards like HACCP and FDA regulations. The primary benefits include enhanced product safety, reduced recall risks, improved brand reputation, increased operational efficiency by preventing equipment downtime, and adherence to rigorous quality control protocols. Key driving factors contributing to market growth include the escalating consumer demand for safer products, increasingly stringent international food and pharmaceutical safety regulations, the rising trend of automation and smart manufacturing (Industry 4.0), and the growing need to protect expensive production machinery from metallic foreign objects.

Industrial Metal Detectors Market Executive Summary

The Industrial Metal Detectors Market is experiencing significant momentum, propelled by robust business trends centered on automation, digitization, and a heightened focus on product quality and safety across global industries. Manufacturers are increasingly integrating advanced detection systems into their production lines to meet stringent regulatory requirements and safeguard their brands. Regionally, Asia Pacific is emerging as a dominant force due to rapid industrialization, expansion of the food and pharmaceutical sectors, and increasing adoption of manufacturing best practices, while North America and Europe continue to hold substantial market shares driven by well-established regulatory frameworks and technological advancements. Segment-wise, conveyor-fed systems remain a cornerstone due to their versatility and efficiency in high-volume production, but specialized detectors for gravity-fed, pipeline, and pharmaceutical applications are also witnessing strong growth. The market is further characterized by a trend towards multi-frequency and digital signal processing technologies, aiming for higher detection accuracy and fewer false positives, indicating a dynamic landscape shaped by both traditional needs and innovative solutions.

AI Impact Analysis on Industrial Metal Detectors Market

Users frequently inquire about how Artificial Intelligence (AI) will revolutionize industrial metal detection, focusing on its potential to enhance accuracy, reduce false positives, and streamline operational efficiency. Common questions revolve around the integration of AI with existing systems, the development of predictive analytics for maintenance, and AI's ability to adapt to diverse product matrices and novel contaminants. There's significant interest in AI's role in real-time data interpretation, self-optimization of detection parameters, and improved connectivity within Industry 4.0 ecosystems. Users expect AI to minimize human intervention, offer more intelligent decision-making capabilities, and ultimately deliver a higher level of product safety and quality assurance with reduced operational costs.

- Enhanced detection accuracy and reduced false positives through pattern recognition and machine learning algorithms.

- Predictive maintenance capabilities, enabling detectors to self-diagnose and flag potential issues before failures occur.

- Real-time data analysis and processing optimization for continuous improvement of production lines.

- Adaptive learning for new product variations, contaminant types, and environmental changes, reducing recalibration needs.

- Seamless integration with broader Industry 4.0 and IoT frameworks for centralized monitoring and control.

- Automated setup and optimization of detection parameters, minimizing manual intervention and operator error.

- Improved traceability and audit capabilities through advanced data logging and anomaly detection.

DRO & Impact Forces Of Industrial Metal Detectors Market

The industrial metal detectors market is significantly influenced by a confluence of driving factors, restraints, opportunities, and broader impact forces. Key drivers include the increasingly strict regulatory compliance, such as HACCP and FDA standards, demanding higher levels of product safety, along with the global surge in automation and smart manufacturing initiatives across various industries. The inherent benefits of metal detectors in preventing machinery damage and reducing product recalls also fuel their adoption. However, the market faces restraints such as the relatively high initial capital investment required for advanced systems, the technical complexities associated with integrating these detectors into existing production lines, and the challenge of minimizing false rejection rates without compromising detection sensitivity. Opportunities abound with the integration of cutting-edge technologies like AI and IoT for enhanced performance and predictive capabilities, the development of more portable and compact solutions, and the untapped potential in emerging economies with nascent industrial sectors. These elements collectively shape a dynamic market landscape, where technological innovation and regulatory pressures play crucial roles in defining growth trajectories.

Segmentation Analysis

The industrial metal detectors market is broadly segmented to provide a granular understanding of its diverse applications, technologies, and end-user requirements. This segmentation allows for precise market analysis, identifying key growth areas and specific demand patterns across different industrial verticals and product types. Understanding these segments is crucial for strategic planning, product development, and targeted marketing efforts, enabling stakeholders to cater to specific needs within the highly specialized landscape of industrial safety and quality control.

- By Product Type:

- Conveyor-fed Metal Detectors

- Gravity-fed (Free-fall) Metal Detectors

- Pipeline Metal Detectors (Pumped Products)

- Pharmaceutical Metal Detectors (Tablet/Capsule)

- Walk-through Metal Detectors (Personnel Screening)

- Handheld Metal Detectors (Spot Checking)

- Tunnel Metal Detectors

- By Application:

- Food & Beverage Industry

- Pharmaceutical Industry

- Packaging Industry

- Textile Industry

- Mining & Quarrying

- Plastics & Rubber Industry

- Recycling Industry

- Wood & Paper Industry

- Chemical Industry

- By Technology:

- Balanced Coil Technology

- Ferrous-in-foil Technology

- Multi-frequency Technology

- Digital Signal Processing (DSP) Technology

- AI-integrated Detection Systems

- By End-Use Industry:

- Food Processing Plants

- Pharmaceutical Manufacturing Facilities

- Mining Operations

- Plastic & Rubber Product Manufacturing

- Textile & Apparel Production

- Waste Management & Recycling Centers

- Wood & Furniture Manufacturing

- Chemical Processing Plants

Value Chain Analysis For Industrial Metal Detectors Market

The value chain for the industrial metal detectors market begins with upstream activities encompassing the procurement of critical raw materials such as specialized metals, electronic components, sensors, and microprocessors from various suppliers. Research and development efforts are paramount at this stage, focusing on advancing detection capabilities, improving software algorithms, and enhancing connectivity features. Moving downstream, manufacturing processes involve assembly, calibration, and quality control of the detectors, often tailored to specific industry requirements. Distribution channels are diverse, including direct sales from manufacturers, a network of specialized distributors and resellers, and integrators who combine metal detectors with other inspection and automation equipment. Direct channels allow for closer customer relationships and custom solutions, while indirect channels provide broader market reach and localized support, ensuring the products reach end-users efficiently for installation, maintenance, and ongoing technical support.

Industrial Metal Detectors Market Potential Customers

The primary potential customers and end-users of industrial metal detectors span a wide array of manufacturing and processing industries that prioritize product safety, quality control, and operational integrity. This includes large-scale food processing companies involved in baked goods, meat, dairy, and confectionery, where even minute metal contaminants can lead to severe health risks and costly recalls. Pharmaceutical manufacturers are also crucial customers, utilizing these detectors to ensure their tablets, capsules, and powders are free from metallic impurities, adhering to stringent good manufacturing practices (GMP). Furthermore, the mining and quarrying sector relies on industrial metal detectors to protect expensive crushing and grinding machinery from tramp metal damage, significantly reducing downtime and maintenance costs. Other key buyers include manufacturers in plastics, textiles, recycling, and packaging, all seeking to maintain product purity, protect equipment, and comply with industry-specific safety standards. The expanding focus on consumer protection and regulatory compliance continues to broaden the customer base for these essential safety devices.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 million |

| Market Forecast in 2033 | USD 1450 million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | METTLER TOLEDO, CEIA, ANRITSU, MinebeaMitsumi (Shinyei Technology), Loma Systems, Eriez Manufacturing, Forté Technology, Sesotec GmbH, Detectronic A/S, WIPOTEC-OCS, Thermo Fisher Scientific, S+S Separation and Sorting Technology GmbH, Barriquand, CASSEL Inspection, Eagle Product Inspection, Ishida Co. Ltd., A&D Company, Bunting Magnetics, Sartorius AG, Fortress Technology Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Metal Detectors Market Key Technology Landscape

The industrial metal detectors market is characterized by a continuously evolving technological landscape, driven by the demand for higher sensitivity, greater accuracy, and enhanced operational efficiency. Traditional balanced coil technology remains a cornerstone, offering robust and reliable detection for a wide range of applications. However, advancements in digital signal processing (DSP) have significantly improved the ability to filter out electrical interference and product effects, leading to fewer false rejections and increased detection stability, particularly with challenging products. Multi-frequency technology allows detectors to operate at various frequencies simultaneously or sequentially, optimizing detection for different types of metals and product characteristics. Furthermore, the integration of artificial intelligence (AI) and machine learning algorithms is emerging as a transformative trend, enabling predictive maintenance, adaptive learning for new contaminants, and real-time self-optimization of detection parameters. These technologies, coupled with improved connectivity through IoT and Industry 4.0 protocols, are paving the way for more intelligent, automated, and seamlessly integrated metal detection solutions within modern manufacturing environments.

Regional Highlights

- North America: A mature market driven by stringent food safety regulations (FDA, USDA) and pharmaceutical standards. High adoption of advanced technologies and automation. Significant presence of key market players and strong R&D investments.

- Europe: Characterized by robust regulatory frameworks (HACCP, BRC) and a strong emphasis on product quality. Germany, UK, and France are key contributors, focusing on innovative solutions for food, pharmaceutical, and recycling industries.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, expanding food and beverage, and pharmaceutical manufacturing sectors in China, India, and Southeast Asian countries. Increasing awareness of product safety and growing foreign investments are key drivers.

- Latin America: Emerging market with increasing industrialization and a rising focus on food safety standards, particularly in Brazil and Mexico. Adoption is growing as industries modernize their production facilities.

- Middle East & Africa (MEA): A developing market with growth driven by investments in the food processing and packaging sectors, alongside an increasing focus on improving industrial safety standards. Saudi Arabia and UAE are leading the adoption curve.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Metal Detectors Market.- METTLER TOLEDO

- CEIA

- ANRITSU

- MinebeaMitsumi (Shinyei Technology)

- Loma Systems

- Eriez Manufacturing

- Forté Technology

- Sesotec GmbH

- Detectronic A/S

- WIPOTEC-OCS

- Thermo Fisher Scientific

- S+S Separation and Sorting Technology GmbH

- Barriquand

- CASSEL Inspection

- Eagle Product Inspection

- Ishida Co. Ltd.

- A&D Company

- Bunting Magnetics

- Sartorius AG

- Fortress Technology Inc.

Frequently Asked Questions

Analyze common user questions about the Industrial Metal Detectors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What industries benefit most from industrial metal detectors?

Industries such as food and beverage, pharmaceuticals, textiles, plastics, mining, and recycling benefit significantly, primarily for product safety, quality control, and machinery protection. These sectors rely on precise detection to prevent contamination and damage.

How do industrial metal detectors ensure product safety?

They ensure product safety by detecting and rejecting ferrous, non-ferrous, and stainless steel contaminants that could inadvertently enter products during manufacturing. This compliance with standards like HACCP and FDA protects consumers and brand reputation.

What are the primary types of industrial metal detectors?

The primary types include conveyor-fed for packaged goods, gravity-fed for free-falling products, pipeline for pumped liquids, pharmaceutical for tablets, and specialized detectors for unique applications. Each type is designed for specific product handling and operational environments.

How is AI impacting the future of metal detection?

AI is transforming metal detection by improving accuracy, reducing false rejections, enabling predictive maintenance, and optimizing system performance through machine learning. It allows for adaptive detection, real-time data analysis, and seamless integration with Industry 4.0 automation.

What are the key factors driving market growth?

Key drivers include stringent global regulatory mandates for product safety, increasing automation in manufacturing processes, a rising consumer demand for high-quality and safe products, and the need to prevent costly machinery damage from metallic foreign objects. These factors collectively push for greater adoption of advanced detection systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Industrial Metal Detectors Market Size Report By Type (Rectangular Aperture Metal Detectors, Gravity Fall Metal Detectors, Pipeline Liquid, Paste and Slurry Metal Detectors, Metal Detectors with Conveyor), By Application (Mining and Plastic Industry, Textiles Industry, Pharmaceutical Industry, Food Industry), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Industrial Metal Detectors Market Statistics 2025 Analysis By Application (Food Industry, Pharmaceutical Industry, Textiles Industry, Mining and Plastic Industry), By Type (Metal Detector with Conveyor, Rectangular Aperture Metal Detector, Gravity Fall Metal Detector, Pipeline Liquid, Paste and Slurry Metal Detector), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Industrial Metal Detectors Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Hand-held Metal Detectors, Ground-search Metal Detectors, Walk-through Metal Detectors), By Application (Food Industry, Pharmaceutical Industry, Textiles Industry, Mining and Plastic Industry, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager