Industrial MRO Adhesives Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432256 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Industrial MRO Adhesives Market Size

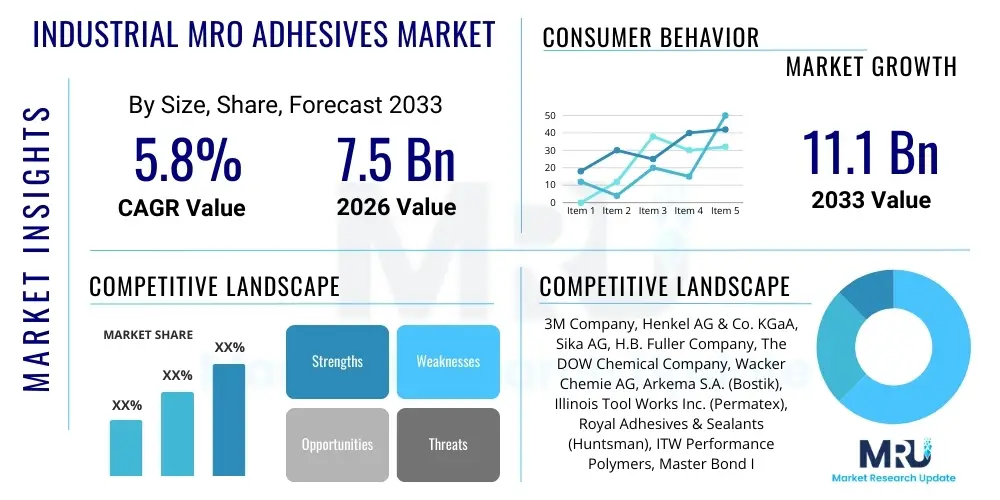

The Industrial MRO Adhesives Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 7.5 Billion in 2026 and is projected to reach USD 11.1 Billion by the end of the forecast period in 2033.

Industrial MRO Adhesives Market introduction

The Industrial Maintenance, Repair, and Operations (MRO) Adhesives Market encompasses specialized chemical compounds utilized across various heavy and light industries for routine maintenance, emergency repair, and operational continuity of machinery, infrastructure, and components. Unlike assembly line adhesives, MRO adhesives are primarily designed for field application, quick curing, and superior durability, often required to bond dissimilar substrates, fill voids, and withstand harsh environmental conditions such as extreme temperatures, chemical exposure, and high vibration. These products are crucial for minimizing downtime, extending the operational lifespan of assets, and ensuring worker safety in sectors ranging from automotive and aerospace to energy and general manufacturing. Key product types include epoxies, polyurethanes, cyanoacrylates, anaerobics, and silicones, each formulated to address specific operational challenges related to sealing, gasketing, locking, and structural bonding during maintenance activities.

The increasing focus on predictive maintenance and the shift towards sophisticated asset management strategies are significantly driving the demand for high-performance industrial MRO adhesives. Modern manufacturing environments rely heavily on continuous operation, making prompt and durable repairs indispensable. These adhesives offer significant advantages over traditional mechanical fastening methods, such as bolts and welding, by providing improved stress distribution, lighter weight solutions, and enhanced resistance to fatigue and corrosion. Furthermore, the development of sustainable and low-VOC (Volatile Organic Compound) adhesive formulations is becoming a major trend, driven by stringent environmental regulations and corporate sustainability mandates across North America and Europe. This evolution caters to industries seeking safe and environmentally compliant repair solutions without compromising performance or speed of application.

Major applications of industrial MRO adhesives span critical areas like threadlocking to prevent fastener loosening in vibrating equipment, gasketing for fluid sealing in pumps and compressors, retaining for securing cylindrical parts, and structural bonding for fixing cracks or broken machinery components. The utility of these products is diversified across heavy machinery, pipelines, structural elements, and electronic assemblies. The growing complexity of industrial equipment, coupled with the necessity for highly reliable repair solutions in remote or challenging operating environments (such as offshore platforms or wind turbines), underscores the essential nature of specialized MRO adhesive chemistries. This market segment is characterized by technical expertise, product customization, and a strong reliance on specialized distribution channels to reach maintenance professionals directly.

Industrial MRO Adhesives Market Executive Summary

The Industrial MRO Adhesives Market demonstrates robust expansion driven primarily by the global emphasis on extending equipment lifespan and optimizing total cost of ownership (TCO) in industrial settings. Business trends indicate a strong move toward advanced, high-strength formulations, particularly two-component epoxies and specialized anaerobic sealants, which offer rapid repair capabilities and long-term durability, minimizing costly production interruptions. Key manufacturers are focusing on integrating smart technologies, such as condition monitoring and digital dispensing systems, into MRO workflows, enhancing the precision and efficiency of adhesive application. Furthermore, the competitive landscape is shifting towards providers who can offer comprehensive training and technical support alongside their product portfolio, catering to the highly specific needs of industrial maintenance professionals.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market segment, fueled by rapid industrialization, expansion of the manufacturing base in China and India, and significant investments in infrastructure and energy sectors requiring intensive MRO activities. North America and Europe maintain a mature yet high-value market, characterized by stringent regulatory standards favoring environmentally friendly, solvent-free adhesives and a high demand for premium, specialized solutions used in aerospace, medical device manufacturing, and high-tech automotive facilities. The adoption of predictive maintenance protocols globally necessitates continuous consumption of reliable MRO consumables, ensuring stable revenue streams for market players across all geographical zones.

In terms of segment trends, the repair and structural bonding application segment dominates the market due to the constant need for emergency fixes and component overhaul in capital-intensive industries. Technology-wise, anaerobic adhesives and modified acrylics are experiencing accelerated adoption owing to their quick-curing properties suitable for minimizing machinery downtime. End-use segmentation reveals the significant contribution of the automotive and heavy machinery sectors, where MRO activities are continuous and critical for safety and efficiency. The market structure is undergoing consolidation, with larger chemical companies acquiring specialized adhesive manufacturers to bolster their comprehensive MRO product offerings and gain deeper penetration into specialized maintenance niches.

AI Impact Analysis on Industrial MRO Adhesives Market

User inquiries regarding AI's impact on the Industrial MRO Adhesives Market predominantly center on optimization, predictive failure analysis, and material innovation. Users frequently ask if AI can predict when and where adhesive failure might occur in critical assets, how machine learning can optimize the selection and application parameters for specific MRO tasks, and if AI algorithms can accelerate the discovery and formulation of new high-performance, sustainable adhesive chemistries. The key themes revolve around achieving predictive maintenance accuracy, automating quality control during repair, and ultimately enhancing the efficacy and reliability of MRO adhesive usage to reduce overall maintenance costs and downtime.

The core expectation is that AI integration will transform MRO from reactive or scheduled maintenance to a truly predictive model, directly influencing adhesive consumption patterns. By analyzing historical performance data, environmental conditions, and sensor inputs (vibration, temperature), AI models can precisely pinpoint components requiring preventative repair, thereby increasing the proactive application of MRO adhesives like structural epoxies or high-temperature sealants before catastrophic failure occurs. This leads to more strategic inventory management of adhesives and optimized application techniques, ensuring the right product is used at the right time with maximum effectiveness, reducing material waste and application errors typically associated with manual processes.

Furthermore, AI and machine learning are poised to revolutionize adhesive formulation and quality control. Computational chemistry and AI-driven simulation tools can rapidly evaluate thousands of chemical combinations, accelerating the development cycle for specialized MRO adhesives tailored for extreme environments or novel material bonding. In the operational phase, AI-powered vision systems are already being deployed to verify the quality and uniformity of adhesive beads or coatings during complex repair procedures, ensuring compliance with strict industrial standards, particularly in demanding sectors like aerospace and nuclear energy, thereby significantly boosting the perceived reliability and value proposition of high-end MRO adhesive products.

- AI enables predictive adhesive failure analysis, optimizing scheduled maintenance cycles.

- Machine learning algorithms enhance the selection of optimal adhesive chemistries for specific operational stressors (e.g., temperature, vibration).

- AI-driven robotics and dispensing systems ensure precise and automated adhesive application, minimizing human error in complex repairs.

- Computational chemistry, supported by AI, accelerates the R&D of novel, sustainable, and high-performance MRO formulations.

- Integration of AI with IIoT sensors allows real-time monitoring of bonded joints, predicting the remaining useful life of MRO repairs.

DRO & Impact Forces Of Industrial MRO Adhesives Market

The Industrial MRO Adhesives Market is significantly influenced by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO), which collectively shape the market's trajectory and profitability. A primary driver is the pervasive necessity across all capital-intensive industries to maintain operational continuity and minimize unplanned downtime, which mandates the use of reliable, quick-curing repair materials. This is coupled with the structural shift towards lighter materials (like composites and advanced plastics) in manufacturing, which often require adhesive bonding for effective repair, as traditional welding or mechanical fastening methods are unsuitable. However, the market faces restraints such as the perceived high initial cost of specialized chemical adhesives compared to conventional mechanical fixes, and the need for highly skilled technicians to ensure proper surface preparation and application, which is a barrier in certain less developed industrial regions.

Opportunities for growth are abundant, particularly in the realm of advanced product development. The push for sustainability presents a major opportunity for manufacturers focusing on bio-based MRO adhesives, low-VOC formulations, and non-toxic materials that comply with increasingly strict global health and safety standards. Furthermore, the expansion of renewable energy infrastructure, specifically wind and solar farms, provides a new, high-growth segment requiring constant MRO activities using specialized structural adhesives designed to endure outdoor exposure and extreme weather. Digitalization in MRO, including the use of augmented reality (AR) for application training and AI for material selection, represents another avenue for market participants to add value and enhance product adoption rates.

Impact forces acting on this market include high regulatory scrutiny regarding hazardous materials, which dictates product formulation and supply chain complexity, and the cyclical nature of industrial spending, where economic downturns can lead to delays in major equipment overhauls, temporarily dampening MRO expenditure. However, the long-term impact force remains overwhelmingly positive, driven by the global aging infrastructure in key sectors like oil and gas, utilities, and transportation, all demanding constant maintenance and refurbishment using advanced bonding and sealing solutions. The performance gap between generic, commodity adhesives and high-specification MRO adhesives is widening, allowing specialized manufacturers to command higher price points based on superior longevity and reduced total lifecycle costs for the end-user.

Segmentation Analysis

The Industrial MRO Adhesives Market segmentation provides a granular view of product usage, application type, and end-user demands, enabling market stakeholders to tailor their strategies effectively. The market is primarily segmented based on Resin Type (Epoxy, Polyurethane, Cyanoacrylate, Silicone, Acrylic, etc.), which dictates the strength, curing speed, and chemical resistance of the product. Further segmentation includes Application Method (Manual, Automated/Dispensing Equipment), which is critical for understanding adoption in high-volume versus field repair scenarios, and Functionality (Sealing, Bonding, Gasketing, Threadlocking, Retaining), representing the core purpose of the adhesive in MRO activities. This structural division helps in identifying high-growth niches like specialized sealing in corrosive environments or high-strength bonding in structural repairs.

From an end-user perspective, the segmentation across major industrial categories—such as Automotive & Transportation, General Manufacturing, Energy & Utilities, Aerospace & Defense, and Marine—is crucial. Each segment possesses distinct requirements; for instance, Aerospace MRO demands specialized fire-retardant and certified materials, while the Energy sector prioritizes chemical resistance and temperature stability for pipeline and valve maintenance. The trend shows that while General Manufacturing accounts for the largest volume due to breadth of activity, high-value growth is often concentrated in highly regulated industries that require premium, engineered adhesive solutions and strict documentation regarding repair materials.

The ongoing analysis of these segments reveals that Cyanoacrylates and Epoxies remain dominant due to their versatility and proven efficacy, though Polyurethane and Modified Acrylics are rapidly gaining ground, particularly in applications requiring flexibility and rapid strength build-up. Regional segmentation also plays a pivotal role, with varying environmental standards and maintenance practices influencing product preference. For example, North America shows higher penetration of UV-curing adhesives for streamlined repair processes, while developing markets may rely more heavily on traditional, multi-purpose epoxy systems. Strategic segmentation allows vendors to optimize their supply chain and R&D focus toward the most profitable and fastest-evolving segments globally.

- Resin Type:

- Epoxy

- Polyurethane

- Cyanoacrylate

- Silicone

- Acrylic

- Anaerobic

- Application:

- Structural Bonding & Repair

- Sealing & Gasketing

- Threadlocking & Retaining

- Surface Protection

- End-Use Industry:

- Automotive & Transportation

- Heavy Machinery & Equipment

- Energy & Utilities (Oil & Gas, Power Generation)

- Aerospace & Defense

- Marine

- General Manufacturing & Fabrication

Value Chain Analysis For Industrial MRO Adhesives Market

The value chain for the Industrial MRO Adhesives Market begins with upstream activities involving the sourcing and processing of specialized raw materials, primarily polymers, resins (such as epoxies, acrylics, and silicones), curing agents, fillers, and various performance additives. Key suppliers include major chemical and petrochemical companies. Performance optimization in this upstream segment is critical, as the quality and purity of base resins directly determine the final MRO adhesive characteristics, such as durability, temperature resistance, and curing time. Manufacturers often engage in long-term contracts with specialized raw material suppliers to ensure supply stability and maintain proprietary formulation integrity, which is essential for specialized MRO products.

The midstream stage involves manufacturing and formulation, where core chemical companies convert raw materials into finished MRO adhesive products. This stage is highly research and development intensive, focusing on proprietary chemical synthesis, quality control, and testing to meet stringent industrial specifications (e.g., military standards, ISO certifications, industry-specific approvals). Effective production relies on scaled-up blending and mixing processes, coupled with advanced packaging designed for industrial environments, ensuring product stability and ease of application in the field. Differentiation at this stage often comes from patent-protected technologies like advanced primer-less adhesion systems or fast-setting chemistries that provide competitive advantages in emergency repair scenarios.

The downstream segment encompasses distribution and end-user application. Due to the diverse and urgent nature of MRO demands, the distribution channel is complex, involving both direct sales to large industrial customers (Direct Channel) and sales through specialized industrial distributors, MRO supply houses, and online platforms (Indirect Channel). Industrial distributors play a vital role, maintaining large inventories, providing localized technical support, and offering just-in-time delivery for maintenance teams. Potential customers, or end-users, value technical service, training on application methods, and readily available product inventory. The final value added lies in the successful application of the adhesive, which ensures equipment reliability and operational uptime, linking the product's performance directly to the customer's operational efficiency and cost savings.

Industrial MRO Adhesives Market Potential Customers

Potential customers for Industrial MRO Adhesives span the entire spectrum of capital-intensive industries where equipment degradation and mechanical failures are constant threats to productivity and safety. These end-users are characterized by a high reliance on complex machinery and infrastructure that requires continuous preventative and corrective maintenance. The primary buyers are typically Maintenance Managers, Chief Engineers, Procurement Specialists, and MRO Inventory Controllers who prioritize product reliability, speed of repair, and compliance with operational safety standards. These decision-makers seek adhesives that guarantee minimal downtime and maximum lifespan extension for high-value assets, often necessitating long-term contracts for specialized product supply and technical service packages.

The automotive manufacturing and heavy equipment sectors represent significant customer bases, constantly requiring threadlockers for engine assemblies, gasketing materials for fluid systems, and structural repair epoxies for tooling and machinery. Similarly, the Energy and Utilities sector—including oil refineries, natural gas pipelines, and power generation plants—is a massive consumer of high-temperature, chemical-resistant sealants and bonding agents for mission-critical infrastructure maintenance. The purchasing behavior in these industries is driven by factors such as regulatory compliance, certifications (e.g., ASME, API), and the ability of the adhesive to withstand extreme operating conditions, prioritizing performance over low cost.

Furthermore, specialized industries like Aerospace & Defense and Marine engineering are rapidly growing customer segments, where the use of high-performance, lightweight composite materials necessitates specialized bonding solutions for repair. These customers require materials with precise specifications, traceability, and often require unique packaging formats for field repairs. Other significant buyers include general fabrication shops, food and beverage processing plants (requiring food-grade sealants), and municipal water treatment facilities. The common thread among all potential customers is the need for industrial-grade reliability and prompt delivery of technical MRO solutions that directly contribute to asset health and operational longevity, positioning the adhesive as an essential strategic consumable rather than a mere commodity item.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 7.5 Billion |

| Market Forecast in 2033 | USD 11.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Henkel AG & Co. KGaA, Sika AG, H.B. Fuller Company, The DOW Chemical Company, Wacker Chemie AG, Arkema S.A. (Bostik), Illinois Tool Works Inc. (Permatex), Royal Adhesives & Sealants (Huntsman), ITW Performance Polymers, Master Bond Inc., Delo Industrial Adhesives, Ashland Global Holdings Inc., Cytec Solvay Group, Scigrip Adhesives. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial MRO Adhesives Market Key Technology Landscape

The technological landscape of the Industrial MRO Adhesives Market is characterized by continuous innovation focused on enhancing speed, durability, and ease of application, directly addressing the core MRO objective of minimizing downtime. One of the most significant advancements is the proliferation of high-performance, two-part structural acrylics and epoxies that achieve handling strength rapidly, often within minutes, which is critical for emergency field repairs. Furthermore, research is focused on developing hybrid chemistries, such as silyl modified polymers (SMPs) and hybrid polyurethanes, that combine the best properties of different chemical bases—offering elasticity, high shear strength, and excellent environmental resistance without the need for complex surface preparation or high VOC content.

Another major technological driver is the integration of advanced curing mechanisms. UV-curing adhesives are gaining traction in controlled MRO environments, offering instant cure times upon exposure to specific light wavelengths, thereby accelerating assembly and repair processes significantly. While UV curing is limited by shadow areas, newer LED-curable formulations are expanding the scope of applicability. For anaerobic adhesives, which are essential for threadlocking and retaining, innovation involves developing formulations with enhanced oil tolerance and varied viscosities, allowing them to cure reliably even on slightly contaminated or passive metal surfaces, a common challenge in real-world MRO scenarios.

Beyond the chemical formulation itself, technology in dispensing and application equipment is transforming MRO practices. Precision metering, mixing, and dispensing systems, often computer-controlled, ensure the correct ratio of multi-component adhesives is maintained, reducing waste and guaranteeing optimal material performance. Furthermore, the adoption of specialized packaging, such such as dual cartridges and pre-measured systems, facilitates use by maintenance technicians in challenging environments. The future technology trajectory points toward "smart adhesives" incorporating elements like color-changing indicators for proper curing status or integrating micro-sensors capable of signaling the onset of bond degradation, linking the adhesive directly into the broader Industrial Internet of Things (IIoT) framework.

Regional Highlights

Geographically, the Industrial MRO Adhesives Market exhibits varied growth patterns driven by regional industrial maturity, regulatory environment, and infrastructure investment levels. North America remains a highly lucrative market characterized by early adoption of advanced adhesive technologies and a strong presence of critical industries like aerospace, complex automotive assembly, and oil & gas. The region’s strict occupational safety and environmental regulations drive high demand for low-VOC, non-hazardous, and high-specification MRO products, favoring premium suppliers. Continuous investment in upgrading aging manufacturing infrastructure further solidifies steady demand for structural repair solutions.

Europe represents a mature market focusing heavily on sustainability and precision engineering. Demand here is strongly influenced by EU directives related to chemical usage (e.g., REACH), leading to a high penetration of bio-based, solvent-free, and high-performance engineered adhesives used extensively in automotive repairs, renewable energy (particularly wind turbine maintenance), and high-value machinery overhaul. Germany, the UK, and France are the key consumers, driven by their robust manufacturing bases and a strong cultural emphasis on preventative maintenance schedules which ensures sustained consumption of MRO consumables.

Asia Pacific (APAC) is projected to be the fastest-growing region, primarily fueled by the rapid expansion of industrial manufacturing capacities in China, India, South Korea, and Southeast Asian nations. Massive infrastructure projects, coupled with burgeoning automotive production and subsequent aftermarket activities, create immense demand for MRO adhesives across all performance grades. While price sensitivity can be higher in certain APAC sub-regions, the sheer volume of new factories and ongoing maintenance requirements translate into substantial market opportunities. Investment in modern MRO practices, moving away from reactive fixes to scheduled preventative work, is accelerating the adoption of specialized adhesive systems across the region.

- Asia Pacific (APAC): Dominates growth due to rapid industrialization, infrastructure development, and expanding automotive and electronics manufacturing base; high potential for volume consumption.

- North America: High-value market focused on premium, certified, and specialized adhesives for aerospace, complex machinery, and advanced manufacturing MRO; stringent regulatory compliance drives innovation.

- Europe: Mature market characterized by strong regulatory compliance (low-VOC, REACH), high demand from the renewable energy sector, and advanced manufacturing (e.g., automotive repair and precision machinery).

- Latin America (LATAM): Growth driven by mining, oil and gas, and increasing local manufacturing operations; market size is smaller but shows potential for standardized, robust MRO products.

- Middle East and Africa (MEA): Demand heavily concentrated in the energy (oil and gas exploration and refining) and infrastructure sectors; focus on high-temperature and chemical-resistant sealing and bonding products for harsh operating environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial MRO Adhesives Market.- Henkel AG & Co. KGaA

- 3M Company

- H.B. Fuller Company

- Sika AG

- The DOW Chemical Company

- Wacker Chemie AG

- Arkema S.A. (Bostik)

- Illinois Tool Works Inc. (Permatex)

- ITW Performance Polymers (Devcon, Plexus)

- Master Bond Inc.

- Huntsman Corporation (Royal Adhesives & Sealants)

- DELO Industrial Adhesives

- Ashland Global Holdings Inc.

- Cytec Solvay Group

- Scigrip Adhesives (A Weld-On Company)

- PPG Industries, Inc.

- Momentive Performance Materials Inc.

- Chemetall GmbH (BASF Group)

- Permabond LLC

- Kao Corporation

Frequently Asked Questions

Analyze common user questions about the Industrial MRO Adhesives market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers accelerating the growth of the Industrial MRO Adhesives Market?

The primary drivers are the imperative to minimize industrial downtime, the aging of global industrial infrastructure requiring increased repair activities, and the growing adoption of lightweight materials (composites, plastics) in manufacturing that necessitate specialized adhesive-based repair methods over traditional mechanical fasteners. Furthermore, the push for preventative and predictive maintenance strategies increases the systematic consumption of MRO consumables.

How does the shift towards sustainable practices influence the formulation of MRO adhesives?

The shift towards sustainability mandates the development of low-VOC (Volatile Organic Compound), solvent-free, and bio-based adhesive formulations. Regulatory pressures, especially in Europe and North America, compel manufacturers to innovate products that reduce environmental impact while maintaining high performance, focusing on user safety and reduced hazardous material exposure during application.

Which end-use industry represents the largest consumer segment for specialized MRO adhesives?

The General Manufacturing and Fabrication sector historically represents the largest volume consumer due to the sheer diversity and scale of its maintenance activities. However, the Automotive & Transportation sector, followed closely by the Energy & Utilities sector (Oil & Gas, Power Generation), are the largest consumers of high-performance, critical MRO adhesives due to the need for extreme durability, temperature stability, and resistance to harsh operational fluids.

What is the significance of anaerobic adhesives in industrial maintenance operations?

Anaerobic adhesives are critical for MRO because they cure only in the absence of oxygen and in contact with active metal surfaces, making them ideal for locking threaded fasteners, retaining cylindrical parts (bearings, sleeves), and gasketing metal flanges. Their primary significance lies in preventing equipment failure caused by vibration loosening, leakage, and corrosion, thereby ensuring machine reliability and operational safety.

What role does digitalization or AI play in the future application of MRO adhesives?

Digitalization enables advanced predictive maintenance models, where AI analyzes asset condition data to forecast potential component failures, optimizing the timing and type of adhesive repair needed proactively. It also facilitates precise application through automated dispensing robotics and provides AR-supported training for technicians, ensuring consistent quality and reduced reliance on manual, often error-prone, application techniques in complex MRO procedures.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager