Industrial Pump Control Cabinet Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432723 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Industrial Pump Control Cabinet Market Size

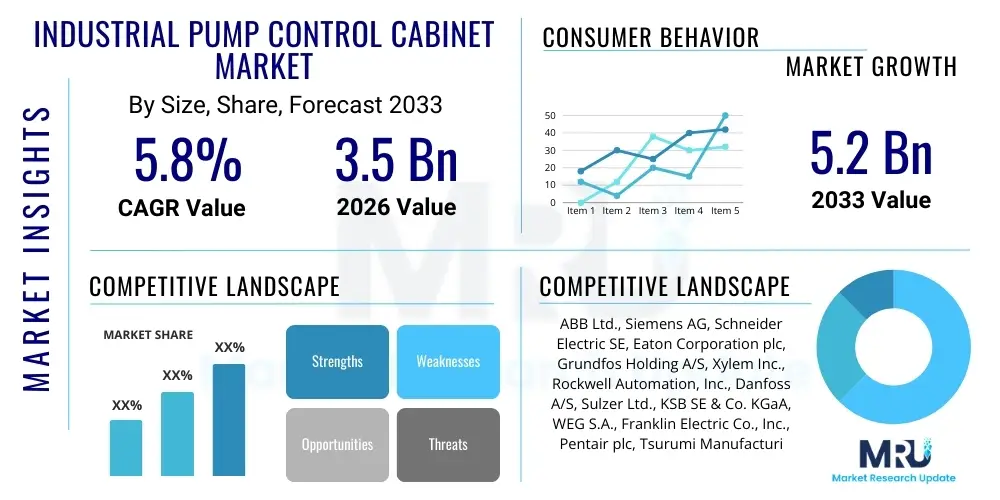

The Industrial Pump Control Cabinet Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 3.5 Billion in 2026 and is projected to reach USD 5.2 Billion by the end of the forecast period in 2033.

Industrial Pump Control Cabinet Market introduction

The Industrial Pump Control Cabinet Market encompasses essential electrical and electronic assemblies designed to manage, protect, and automate industrial pumping systems across diverse sectors such as water treatment, oil and gas, manufacturing, and chemical processing. These cabinets house sophisticated components including Variable Frequency Drives (VFDs), motor starters, protection relays, programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Their primary function is to optimize pump performance, ensuring efficiency, preventing equipment damage due to operational anomalies like dry run or overcurrent, and facilitating seamless integration into larger Supervisory Control and Data Acquisition (SCADA) systems. The shift towards energy efficiency and the stringent regulatory environment governing industrial water and wastewater management are central to the increasing adoption of modern control cabinets.

The core product, the industrial pump control cabinet, serves as the central nervous system for fluid management applications. It offers critical features such as remote monitoring capabilities, automated fault diagnostics, and multi-pump coordination logic, which are indispensable in environments requiring continuous, reliable operation. Modern cabinets often leverage connectivity features, enabling industrial internet of things (IIoT) integration for predictive maintenance scheduling and real-time operational adjustments. Major applications span municipal water supply, agricultural irrigation, power generation cooling systems, and specialized processes within the chemical industry where precise flow control is mandatory. The technological evolution has shifted focus from traditional direct-on-line (DOL) starting mechanisms to advanced VFD-based systems that significantly reduce energy consumption and mechanical stress on pumps.

The market growth is primarily driven by global infrastructure development, particularly in emerging economies, necessitating robust water and sanitation facilities. Furthermore, the increasing need for optimizing industrial process efficiency and reducing operational expenditure acts as a significant catalyst. Benefits derived from deploying these systems include enhanced pump longevity, substantial energy savings due to optimized speed control, minimized downtime through proactive fault detection, and compliance with increasingly strict environmental and safety standards. These compelling benefits ensure that control cabinets remain a vital investment component in any capital expenditure related to fluid handling infrastructure globally.

Industrial Pump Control Cabinet Market Executive Summary

The Industrial Pump Control Cabinet market is experiencing robust expansion driven by critical business trends centered around industrial digitalization, stringent energy efficiency mandates, and the rising global demand for processed water resources. A major business trend involves the rapid integration of smart control technologies, specifically emphasizing IoT-enabled controllers and advanced predictive maintenance software embedded within the cabinets. This shift moves the market beyond basic motor protection towards comprehensive asset management solutions, offering significant value addition to end-users by minimizing unexpected failures and maximizing system throughput. Consolidation among key players and strategic partnerships focusing on software integration capabilities are defining the competitive landscape, pushing innovation in modular design and user-friendly interfaces.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, fueled by massive urbanization, large-scale industrialization in countries like China and India, and significant government investments in water infrastructure projects. North America and Europe, while mature markets, emphasize replacement and retrofit cycles, driven predominantly by compliance requirements related to ISO 50001 (Energy Management) and modernization of aging infrastructure, often favoring highly efficient, decentralized control architectures. The Middle East and Africa (MEA) region is exhibiting strong potential, particularly in the oil and gas sector and desalination projects, requiring extremely rugged and reliable control solutions capable of operating in harsh environmental conditions. Infrastructure gaps in Latin America present both challenges and opportunities for suppliers capable of providing cost-effective, durable control solutions.

Segment-wise, the market is witnessing heightened demand for Variable Frequency Drive (VFD) cabinets, owing to their unparalleled energy saving capabilities compared to fixed-speed starters. The wastewater treatment segment continues to be a dominant application area, driven by global population growth and increasing regulatory oversight of effluent quality. Furthermore, the low voltage segment dominates the market in terms of volume, catering to general industrial and municipal applications, although the high voltage segment (critical for power generation and large-scale oil pumping stations) commands a higher average selling price and requires specialized technical expertise. Customization and modularity are key segment trends, allowing manufacturers to quickly deploy solutions tailored to specific process requirements without excessive lead times.

AI Impact Analysis on Industrial Pump Control Cabinet Market

Common user questions regarding AI's impact on the Industrial Pump Control Cabinet Market revolve primarily around how AI enhances operational predictability, whether existing infrastructure can be retrofitted with AI capabilities, and the implications for energy optimization and security. Users are concerned with the practical applications of AI algorithms for detecting anomalies that precede equipment failure, seeking confirmation that AI can transition the industry from scheduled maintenance to true predictive maintenance. There is also significant interest in AI's role in optimizing pump duty cycles based on real-time process variables, load forecasting, and dynamic pricing models for electricity, aiming to minimize total cost of ownership (TCO). Furthermore, questions often address data security and the necessary computational infrastructure required at the edge or cloud level to support complex machine learning models efficiently within industrial environments.

The integration of Artificial Intelligence (AI) algorithms profoundly affects the functionality and value proposition of modern industrial pump control cabinets. AI models are trained on historical performance data, vibrational analysis, pressure readings, and current consumption to establish baseline operating profiles. When deviations occur, the AI system inside or connected to the control cabinet can issue alerts or autonomously adjust pump parameters (such as VFD output frequency) to prevent catastrophic failures or optimize energy usage. This transition from reactive troubleshooting to proactive management minimizes unplanned downtime, which is often the largest operational cost factor in industrial fluid handling systems. AI transforms the control cabinet from a protective device into a predictive asset manager.

Moreover, AI contributes significantly to complex system optimization in multi-pump installations, such as large municipal booster stations or complex chemical dosing systems. Machine learning determines the most efficient sequencing and staggering of multiple pumps to meet variable demand while ensuring minimum wear and tear distribution across the assets. This capability, often integrated through sophisticated PLCs and edge gateways within the cabinet, provides tangible improvements in overall system efficiency and lifecycle management. The application of AI also extends to cybersecurity, where pattern recognition algorithms monitor network traffic and control inputs for unusual or malicious activities, securing the critical infrastructure managed by the cabinet.

- AI enables predictive maintenance by analyzing sensor data for anomaly detection.

- Optimized energy consumption through dynamic pump speed adjustment based on load forecasting.

- Enhanced multi-pump system coordination and load balancing via machine learning algorithms.

- Improved fault diagnostics, providing root cause analysis instantaneously.

- Automated tuning of control loops (PID adjustments) for instantaneous process optimization.

- Increased system cybersecurity through AI-driven intrusion detection within the control network.

- Facilitation of digital twin modeling for virtual simulation and testing of cabinet performance.

- Reduced reliance on highly specialized technicians for routine operational adjustments.

DRO & Impact Forces Of Industrial Pump Control Cabinet Market

The dynamics of the Industrial Pump Control Cabinet market are shaped by a powerful interplay of drivers, restraints, and opportunities, all underscored by significant impact forces related to technological progression and environmental regulation. Key drivers include the global mandate for industrial energy efficiency, driven by escalating energy costs and government incentives for adopting VFD-based control systems. The continuous expansion and upgrade of municipal water and wastewater infrastructure across emerging and developed regions necessitate reliable control solutions. Furthermore, the increasing complexity of industrial processes requires highly automated and interconnected control cabinets capable of integrating seamlessly into Industry 4.0 frameworks, compelling industries to modernize their older fixed-speed pump systems.

However, the market faces notable restraints. High initial capital expenditure associated with advanced, VFD-equipped, and IoT-enabled control cabinets presents a barrier to entry, particularly for Small and Medium Enterprises (SMEs) in price-sensitive markets. Another significant constraint is the complexity of integrating diverse control platforms and communication protocols (such as Modbus, Profibus, and Ethernet/IP) across multi-vendor environments, leading to installation and commissioning challenges. Furthermore, a shortage of skilled personnel capable of installing, maintaining, and programming sophisticated PLC and HMI systems within these cabinets slows down adoption rates, necessitating increased reliance on vendor support and training programs.

Opportunities for market expansion are abundant, particularly in leveraging the transition towards edge computing and hybrid cloud architectures for remote monitoring and data analysis. The refurbishment and modernization segment offers significant potential, as countless legacy pump systems worldwide are due for efficiency upgrades. Furthermore, the growing adoption of modular and standardized control cabinet designs can reduce customization costs and lead times, broadening market accessibility. The principal impact forces shaping the market trajectory are the pervasive influence of the Industrial Internet of Things (IIoT), which drives demand for networked components, and increasingly rigorous global standards for water quality and effluent discharge, mandating precise, documented process control that only modern cabinets can provide.

Segmentation Analysis

The Industrial Pump Control Cabinet market is highly segmented based on critical factors such as product type, voltage range, component, industry application, and control method, reflecting the diverse operational requirements across the industrial landscape. Analyzing these segments provides strategic insights into high-growth areas and technological preference shifts. The segmentation by control method, particularly between Variable Frequency Drives (VFDs) and traditional fixed-speed starters, is pivotal, with VFDs gaining substantial market share due to their superior energy efficiency and ability to provide soft starting, thereby extending motor life. Regional analysis of segment performance is crucial, as requirements for cabinet protection ratings (e.g., NEMA or IP ratings) differ significantly based on local environmental conditions and industry concentration.

Segmentation by voltage reveals a dominant market share held by Low Voltage (up to 1000V) cabinets, which serve the vast majority of municipal, HVAC, and light industrial applications. However, the High Voltage segment (above 1000V) commands a significant portion of the revenue, driven by specialized, high-power applications in mining, oil and gas pipelines, and large utility-scale power plants where robustness and complex redundancy protocols are paramount. The component segment highlights the increasing value contribution of smart components, notably PLCs, dedicated motor protection relays, and sophisticated communication modules, signaling a shift in manufacturing focus toward digital capability rather than purely mechanical robustness.

Furthermore, application-based segmentation clearly indicates the resilience and size of the Water and Wastewater Treatment sector, which remains the single largest consumer of industrial pump control cabinets globally, driven by continuous infrastructure investment. The Oil and Gas sector, particularly upstream and midstream operations, requires highly explosion-proof and certified cabinets, commanding a premium price point. This detailed segmentation allows manufacturers to tailor their product development and marketing strategies, focusing resources on emerging control technologies like wireless monitoring modules and certified solutions for hazardous area classifications, thus maximizing market penetration.

- By Control Method:

- Variable Frequency Drive (VFD) Control Cabinets

- Fixed Speed (Direct-on-Line and Star-Delta) Control Cabinets

- Soft Starter Control Cabinets

- By Component:

- Programmable Logic Controllers (PLCs)

- Variable Frequency Drives (VFDs)

- Contactors and Starters

- Relays and Overload Protection Devices

- Human-Machine Interfaces (HMIs)

- Switchgear and Circuit Breakers

- By Voltage Range:

- Low Voltage (Below 1000V)

- Medium Voltage (1000V to 6000V)

- High Voltage (Above 6000V)

- By Application/End-Use Industry:

- Water and Wastewater Treatment

- Oil and Gas (Upstream, Midstream, Downstream)

- Chemical and Petrochemical

- Power Generation (Thermal, Nuclear, Renewable)

- HVAC and Building Services

- Mining and Metallurgy

- Food and Beverage Processing

- Pulp and Paper

Value Chain Analysis For Industrial Pump Control Cabinet Market

The value chain for the Industrial Pump Control Cabinet Market begins with the upstream suppliers responsible for providing critical raw materials and specialized electronic components. Upstream activities involve sourcing high-grade sheet metal (steel or aluminum) for cabinet enclosures, and securing specialized electrical and electronic components such as semiconductors for VFDs, microprocessors for PLCs, and high-quality switchgear. The efficiency and reliability of these upstream suppliers directly influence the final product quality and the manufacturer's lead times. Strong relationships with reliable component vendors, especially those providing advanced automation components, are crucial for managing technological obsolescence and ensuring supply chain resilience against geopolitical disruptions.

Midstream activities involve the core manufacturing and assembly processes. Cabinet manufacturers focus on design engineering, software development for control logic, panel wiring, integration of VFDs and PLCs, and rigorous testing and quality assurance procedures, often adhering to standards like UL, CE, or regional electrical codes. Customization is a key aspect of this stage, as many industrial projects require cabinets tailored to specific pump specifications, hazardous area classifications (e.g., ATEX or IECEx), and unique communication protocols. The ability to offer modular and highly configurable designs minimizes engineering costs and accelerates deployment time, offering a significant competitive advantage in the midstream segment.

Downstream activities involve distribution, installation, commissioning, and post-sales service. Distribution channels are typically a mix of direct sales to large Engineering, Procurement, and Construction (EPC) firms, and indirect sales through specialized industrial distributors and system integrators. Direct channels ensure better control over complex projects, while indirect channels provide wider market reach, especially for standardized products and replacement units. The final stage involves commissioning—the crucial process of programming and verifying the cabinet's operation on-site—and ongoing maintenance, predictive diagnostics, and spare parts supply, which increasingly relies on remote monitoring capabilities integrated into the cabinet’s design to maintain long-term customer relationships and capture recurring service revenue.

Industrial Pump Control Cabinet Market Potential Customers

The primary customers for Industrial Pump Control Cabinets are large-scale infrastructure operators, industrial manufacturers, and utilities that rely heavily on controlled fluid movement for core operations. The end-user segment is highly diverse, ranging from municipal authorities managing public services to multinational corporations operating complex manufacturing plants. Municipal water utilities are perhaps the most consistent and largest buyers, requiring cabinets for pumping stations that manage raw water intake, filtration, distribution (booster stations), and highly regulated wastewater collection and treatment facilities. Their purchasing decisions are primarily influenced by reliability, regulatory compliance, and lifecycle energy efficiency, often procuring through public tenders that mandate adherence to strict technical specifications and long-term service contracts.

The second major group includes heavy process industries such as the Oil and Gas, Chemical, and Power Generation sectors. In these environments, pump control cabinets are integral to safety and process integrity, handling highly volatile, corrosive, or high-temperature fluids. Customers in the Oil and Gas sector, for instance, demand explosion-proof enclosures (NEMA 7 or equivalent) and certified components, leading to higher price points and specialized vendor relationships. The focus here shifts from pure energy savings to operational safety, reliability under extreme conditions, and minimizing the risk of environmental incidents, leading to significant investment in redundant and fail-safe control architectures.

Finally, a significant customer base resides in general manufacturing and commercial building sectors, including Food and Beverage processing, HVAC systems for large commercial facilities, and general light industrial assembly. These buyers typically opt for more standardized, low-voltage control cabinets, focusing on ease of installation and maintenance. For the Food and Beverage industry, specialized wash-down enclosures and materials (often stainless steel) are required to meet hygiene standards. Purchasing decisions in this segment are often decentralized and driven by system integrators who specify cabinets based on cost, integration ease, and local service availability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.5 Billion |

| Market Forecast in 2033 | USD 5.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ABB Ltd., Siemens AG, Schneider Electric SE, Eaton Corporation plc, Grundfos Holding A/S, Xylem Inc., Rockwell Automation, Inc., Danfoss A/S, Sulzer Ltd., KSB SE & Co. KGaA, WEG S.A., Franklin Electric Co., Inc., Pentair plc, Tsurumi Manufacturing Co., Ltd., Flowserve Corporation, Teco Electric & Machinery Co., Ltd., Nidec Corporation, Vacon (now part of Danfoss), Allied Flow Specialists, Inc., Integrated Flow Solutions. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Pump Control Cabinet Market Key Technology Landscape

The technology landscape of the Industrial Pump Control Cabinet Market is rapidly evolving, driven primarily by the transition toward smart, interconnected, and highly efficient control architectures. Variable Frequency Drives (VFDs) remain the foundational technology, providing precise speed and torque control to optimize pump performance and achieve significant energy savings, often justifying the cabinet's cost through reduced operational expenditure alone. However, the innovation curve is centered on integrating advanced connectivity features using industrial Ethernet protocols (like PROFINET and EtherNet/IP) and wireless communication modules (5G, LoRaWAN), enabling seamless data exchange between the cabinet, the cloud, and enterprise resource planning (ERP) systems. This focus on seamless integration is mandatory for participation in modern Industry 4.0 environments, requiring control cabinets to function as intelligent nodes rather than isolated control units.

The adoption of advanced Programmable Logic Controllers (PLCs) and dedicated Pump Controllers with built-in specialized function blocks is crucial. Modern PLCs offer greater processing power, supporting complex control algorithms, sophisticated data logging capabilities, and the deployment of edge computing applications, allowing real-time data analysis and decision-making directly at the pump station without reliance on continuous cloud connectivity. Furthermore, the shift towards Human-Machine Interfaces (HMIs) featuring high-resolution touchscreens and intuitive graphical user interfaces simplifies commissioning, diagnostics, and routine operator interaction. These HMIs often incorporate web server functionalities, allowing technicians to remotely access and configure the system via standard web browsers, significantly enhancing efficiency and reducing site visits.

Material science and protective technologies also form a critical part of the technological landscape. The use of advanced enclosure materials, such as non-metallic (fiberglass or polycarbonate) or high-grade stainless steel, is vital for cabinets deployed in harsh, corrosive, or outdoor environments, ensuring longevity and protection against dust and moisture ingress (high IP/NEMA ratings). Furthermore, safety technologies, including advanced motor protection relays that monitor winding temperature, vibration, and phase loss, are becoming standard features, ensuring compliance with strict safety regulations and maximizing asset lifespan. The convergence of these hardware advancements with sophisticated cybersecurity protocols is essential, as networked control cabinets become potential vectors for industrial cyber threats, mandating robust embedded security features.

Regional Highlights

Regional dynamics play a significant role in shaping the demand, technology preferences, and regulatory environment of the Industrial Pump Control Cabinet Market. Asia Pacific (APAC) is projected to be the fastest-growing region, primarily due to unprecedented investment in infrastructure modernization, rapid urbanization, and significant government spending on establishing new water and wastewater treatment plants, particularly in populous nations like China, India, and Southeast Asia. While price sensitivity remains a factor in certain sub-regions, the overall shift towards high-efficiency VFD-based systems is strong, driven by new governmental energy-saving initiatives and the massive scale of new industrial facilities being constructed.

North America and Europe represent mature markets characterized by replacement demand, strict regulatory environments, and a high uptake of premium, digitally integrated control solutions. In North America, the emphasis is on cybersecurity compliance, standardized NEMA ratings, and the integration of control cabinets into existing SCADA networks, particularly within the oil and gas and municipal utility sectors. European growth is sustained by the stringent implementation of the EU Water Framework Directive and energy efficiency regulations, fostering a market environment highly receptive to advanced, decentralized, and environmentally certified control systems that prioritize modularity and lifecycle efficiency.

The Middle East and Africa (MEA) region presents a highly specialized market, dominated by large-scale capital projects in desalination, petrochemicals, and oil infrastructure. Demand is concentrated on extremely durable, often high-voltage, explosion-proof (ATEX/IECEx certified) cabinets capable of withstanding high temperatures and corrosive atmospheres. Latin America is characterized by slower, yet steady, growth driven by mining and municipal water infrastructure improvements, where the market often favors a balance between advanced functionality and cost-effectiveness, leading to strong demand for locally assembled or customized solutions with robust local service support.

- North America: Focus on retrofit projects, smart city initiatives, cybersecurity standards, and strong demand from the oil and gas midstream sector.

- Europe: Driven by strict energy efficiency mandates (e.g., IE4 motor standards), high adoption of IoT connectivity, and modernization of aging utility networks.

- Asia Pacific (APAC): Leading market growth due to massive infrastructure expansion, particularly in water treatment and manufacturing sectors; increasing adoption of VFDs replacing traditional starters.

- Middle East and Africa (MEA): High demand for specialized, rugged, and explosion-proof cabinets for desalination plants and large oil and gas production facilities.

- Latin America: Growth sustained by investments in mining operations, agriculture, and essential utility upgrades, balancing cost optimization with technological reliability.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Pump Control Cabinet Market.- ABB Ltd.

- Siemens AG

- Schneider Electric SE

- Eaton Corporation plc

- Grundfos Holding A/S

- Xylem Inc.

- Rockwell Automation, Inc.

- Danfoss A/S

- Sulzer Ltd.

- KSB SE & Co. KGaA

- WEG S.A.

- Franklin Electric Co., Inc.

- Pentair plc

- Tsurumi Manufacturing Co., Ltd.

- Flowserve Corporation

- Teco Electric & Machinery Co., Ltd.

- Nidec Corporation

- Vacon (now part of Danfoss)

- Allied Flow Specialists, Inc.

- Integrated Flow Solutions

Frequently Asked Questions

Analyze common user questions about the Industrial Pump Control Cabinet market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the adoption of VFD-based pump control cabinets?

The primary drivers are substantial energy savings (often 30-50% compared to fixed-speed starters), reduced mechanical stress on pump components leading to longer asset life, and the necessity for precise flow and pressure control mandated by modern industrial processes and environmental regulations.

How does IIoT integration enhance the performance of industrial pump control cabinets?

IIoT integration allows cabinets to become smart nodes, enabling real-time remote monitoring, predictive diagnostics using cloud or edge analytics, seamless communication with SCADA/ERP systems, and over-the-air firmware updates, significantly reducing downtime and maintenance costs.

Which end-use industry represents the largest market share for industrial pump control cabinets?

The Water and Wastewater Treatment industry consistently holds the largest market share, driven by continuous global infrastructure investments required for treating and distributing potable water and managing municipal and industrial wastewater effluent compliance.

What certifications or protective ratings are most critical for pump control cabinets deployed in hazardous areas?

Cabinets deployed in environments prone to explosive gas or dust (Oil & Gas, Chemical) require stringent certifications such as ATEX (Europe), IECEx (Global), or specific NEMA ratings (e.g., NEMA 7 or NEMA 9) to ensure the enclosure prevents ignition and maintains operational safety.

What is the current trend regarding the voltage range segment in new industrial installations?

While Low Voltage systems dominate in volume, there is a rising trend in complex installations, particularly in large utility and mining sectors, towards Medium Voltage and High Voltage VFD cabinets, as these systems offer better efficiency for controlling very large horsepower industrial pumps over extended distances.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager