Industrial Swivel Plate Caster Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433338 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Industrial Swivel Plate Caster Market Size

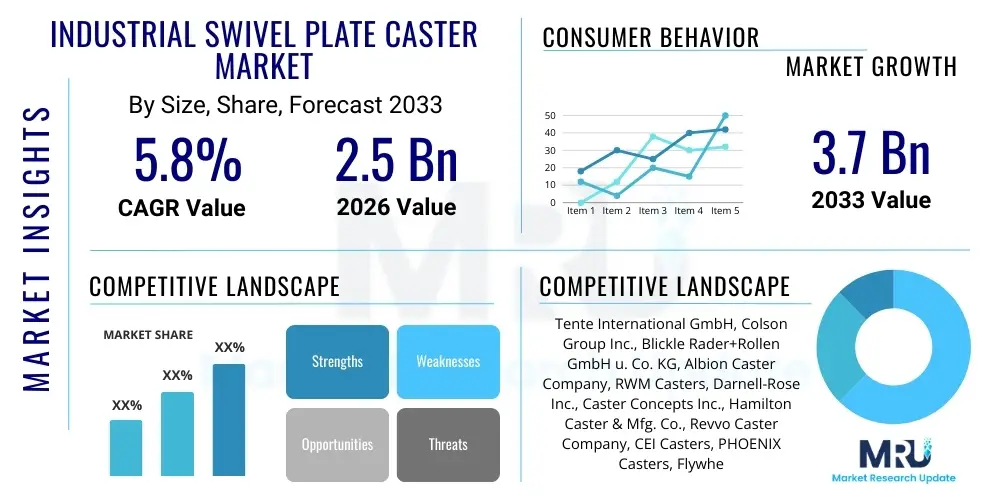

The Industrial Swivel Plate Caster Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 2.5 billion in 2026 and is projected to reach USD 3.7 billion by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the accelerated growth in automated material handling systems across various sectors, including logistics, automotive, and manufacturing. The increasing demand for efficiency and ergonomic solutions in workplace environments mandates the adoption of high-performance swivel plate casters capable of managing heavy loads and continuous operation cycles. Furthermore, significant infrastructure investments in emerging economies are bolstering the establishment of new production facilities and large-scale distribution centers, directly increasing the procurement volume for industrial casters.

The valuation reflects the increasing sophistication of caster technology, including the integration of specialized materials such as high-grade polyurethane, forged steel, and advanced composites designed for specific operational constraints like high temperature, corrosion resistance, or noise reduction. While traditional industrial sectors remain crucial consumption hubs, the rapid expansion of e-commerce and subsequent requirements for efficient warehousing and order fulfillment systems are creating new, high-volume opportunities for swivel plate caster manufacturers. This segment of the market demands durable, low-maintenance casters that minimize downtime and support high-speed material flow.

Market growth is also intrinsically linked to the regulatory landscape promoting workplace safety and ergonomics. Swivel casters equipped with advanced braking mechanisms, directional locks, and shock absorption features are increasingly preferred to mitigate risks associated with heavy load movement, thereby complying with stringent occupational health standards globally. This technological shift towards safety and performance enhancement contributes significantly to the overall average selling price (ASP) of industrial casters, propelling the market valuation upward during the forecast period.

Industrial Swivel Plate Caster Market introduction

The Industrial Swivel Plate Caster Market encompasses the manufacturing, distribution, and sale of mobility components characterized by a mounting plate designed for attachment to industrial equipment, carts, racks, and material transport platforms, alongside a swivel mechanism allowing 360-degree rotation. These products are crucial elements in facilitating smooth, efficient, and versatile movement within industrial, commercial, and institutional environments. Key applications span across heavy manufacturing, aerospace, healthcare, warehousing, automotive assembly lines, and food processing plants, where the reliable movement of heavy or sensitive materials is paramount. The primary benefit of employing industrial swivel plate casters lies in enhancing operational flexibility, reducing manual labor strain, and maximizing spatial utilization in high-density facilities. The market is driven by global trends in factory automation, the rise of mega-warehousing associated with e-commerce, and continuous efforts by industries to optimize internal logistics and material flow processes.

Industrial casters are engineered products, differing substantially from standard furniture casters due to their load-bearing capacity, operational endurance, and material composition. Swivel plate casters are particularly valued for their maneuverability in tight spaces and ability to change direction instantaneously, which is indispensable in dynamic assembly lines and complex inventory management systems. Their design typically includes specialized features such as precision ball bearings, heat-treated raceways, corrosion-resistant finishes, and specific wheel materials (e.g., nylon, rubber, polyurethane, cast iron) selected based on floor type, required noise level, and exposure to harsh chemicals or extreme temperatures. Product differentiation often centers on load rating capabilities, ranging from light-duty applications in retail environments to ultra-heavy-duty solutions handling loads exceeding 20,000 pounds in aerospace or shipbuilding.

Major applications influencing market dynamics include the automotive sector utilizing casters for conveyor dollies and parts carts; the aerospace industry demanding highly specialized, non-contaminating casters for cleanroom environments; and the general logistics sector requiring robust casters for pallet jacks and heavy storage racks. Driving factors for market growth include the global trend toward industrial automation, increasing investment in warehouse modernization, and the persistent need for durable, low-maintenance components that contribute to reduced operational costs. The fundamental requirement across all end-user segments is reliability under continuous, demanding usage conditions, ensuring minimal disruption to high-throughput operations.

Industrial Swivel Plate Caster Market Executive Summary

The Industrial Swivel Plate Caster Market is exhibiting strong positive momentum, characterized by a fundamental shift toward high-performance, specialized products over generic alternatives. Business trends indicate consolidation among mid-sized manufacturers seeking economies of scale and technological integration, particularly focusing on incorporating IoT capabilities into premium caster lines for predictive maintenance and asset tracking. Key industry players are increasingly investing in proprietary material science to develop lighter, stronger, and more resilient wheel and housing designs that withstand abrasive environments and extreme temperatures, thereby addressing niche demands from the heavy machinery and specialized chemical industries. Furthermore, the emphasis on sustainability is driving the development of recyclable materials and energy-efficient caster designs that minimize rolling resistance, thereby reducing the energy consumption required to move heavy apparatus, aligning with global corporate responsibility objectives.

Regional trends reveal Asia Pacific (APAC) as the fastest-growing market, primarily fueled by the massive expansion of manufacturing hubs in China, India, and Southeast Asian nations, alongside significant infrastructural development in logistics and automotive sectors. North America and Europe, while mature markets, maintain high revenue share due to the stringent demand for premium, high-load capacity casters integrated with advanced safety features and compliance with complex industry standards such as FDA regulations for food processing equipment. The European market, in particular, demonstrates a strong preference for ergonomic casters designed to minimize push/pull forces, reflecting robust occupational health regulations and sophisticated labor practices. Investment in automated storage and retrieval systems (AS/RS) across all regions further solidifies the demand for precision-engineered, high-tolerance casters capable of performing reliably within automated guidance pathways.

Segment trends underscore the dominance of the medium-to-heavy-duty category in terms of revenue, driven by pervasive use in general manufacturing and warehousing operations. The polyurethane wheel segment is experiencing rapid adoption due to its superior durability, noise dampening characteristics, and non-marking properties, offering a critical balance between load capacity and floor protection. Technologically, the segment is seeing an uptake in maintenance-free swivel plate casters, utilizing sealed precision bearings that eliminate the need for regular lubrication, drastically reducing lifecycle costs and contributing to enhanced overall equipment effectiveness (OEE). The demand for specialized stainless steel casters remains stable and high within the healthcare, pharmaceutical, and food and beverage sectors, where hygiene, wash-down capability, and corrosion resistance are non-negotiable operational requirements, ensuring robust market performance across specialized segments.

AI Impact Analysis on Industrial Swivel Plate Caster Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Industrial Swivel Plate Caster Market primarily center on three themes: how AI facilitates predictive failure analysis for critical caster components, its role in optimizing material flow within automated facilities that rely heavily on casters, and the potential for AI-driven design optimization. Users are keen to understand how sensor-enabled "smart casters" integrated with facility-wide AI systems can move beyond simple tracking to genuinely predict bearing failure, tire degradation, or structural stress before operational downtime occurs. Furthermore, there is significant interest in how AI algorithms optimize the dynamic routes of caster-equipped carts and movable fixtures in complex manufacturing environments, ensuring minimum travel time and avoiding bottlenecks, thus maximizing the utility of the underlying mobility infrastructure.

The core concern is shifting from traditional, scheduled maintenance to condition-based monitoring, driven by AI analysis of vibration, temperature, and load data streamed from embedded sensors. This transformation impacts the market by creating a premium segment for high-tech, IoT-enabled casters, moving the industry focus from purely mechanical reliability to integrated system performance. AI also influences inventory management for the casters themselves; by predicting the remaining useful life (RUL) of installed units, AI systems can automatically trigger replacement orders, reducing carrying costs for spare parts while eliminating unexpected equipment failures. This high-level data integration ensures that the physical infrastructure—the casters—is treated as a dynamic, monitored asset rather than a static consumable item, promising enhanced efficiency and lower total cost of ownership (TCO) for end-users.

Finally, AI is beginning to influence the design and manufacturing processes of casters. Generative design tools leveraging AI can rapidly iterate through thousands of material combinations and structural geometries to produce optimized swivel plate and fork designs that meet stringent load-to-weight ratios while minimizing material usage. This results in lighter, yet stronger casters tailored precisely to specific application demands (e.g., anti-shudder designs for robotic guidance systems), enhancing speed to market for custom solutions. While the industrial caster remains a fundamental mechanical component, its connectivity and lifecycle management are rapidly becoming digitized and governed by sophisticated AI methodologies, profoundly affecting procurement, maintenance protocols, and future design cycles.

- Integration of vibration and thermal sensors in casters for real-time performance monitoring.

- AI-driven predictive maintenance scheduling to anticipate and prevent bearing or wheel failure.

- Optimization of inventory routing and dynamic material flow using data from caster tracking systems.

- Generative design leveraging AI to create lighter, stronger, and more specialized caster structures.

- Enhanced supply chain management for caster manufacturers based on AI demand forecasting.

- Automated quality control checks in the manufacturing process using AI vision systems.

- Development of "Smart Casters" that communicate status and location to central facility management systems.

- Reduction of unexpected downtime by accurately forecasting the remaining useful life (RUL) of caster wheels and bearings.

DRO & Impact Forces Of Industrial Swivel Plate Caster Market

The Industrial Swivel Plate Caster Market is subject to a complex interplay of Drivers, Restraints, and Opportunities (DRO) that collectively determine its growth trajectory. The primary driver is the pervasive trend of industrial automation and the resultant proliferation of Automated Guided Vehicles (AGVs), material transport carts, and sophisticated assembly line fixtures, all requiring precision, reliable swivel casters. Concurrent with this, the explosive growth of global e-commerce has necessitated the development of massive, highly efficient warehousing and logistics facilities, creating unparalleled demand for medium-to-heavy-duty casters designed for continuous, high-speed operation. Furthermore, stringent regulatory standards focusing on ergonomic safety are driving demand for casters with low push/pull force requirements and advanced braking systems, compelling manufacturers to innovate beyond baseline mechanical specifications, thereby increasing market valuation.

However, the market faces significant restraints, notably the volatility in the price of key raw materials such as steel, iron, and specialized polymers, which directly impacts manufacturing costs and profit margins, making long-term pricing stability challenging. Another major restraint is the increasing prevalence of counterfeit or low-quality casters, particularly in price-sensitive emerging markets, which undermines the quality reputation of established brands and often leads to premature component failure, negatively affecting end-user trust and operational integrity. Furthermore, the specialized knowledge required for selecting the correct caster for complex environments—considering factors like extreme temperature, chemical exposure, and specific floor conditions—often leads to incorrect purchasing decisions, which can skew demand and maintenance patterns, inhibiting streamlined market growth.

These challenges present distinct opportunities for strategic expansion and differentiation. The foremost opportunity lies in the development and commercialization of IoT-enabled 'Smart Casters' capable of condition monitoring and seamless integration with Industrial Internet of Things (IIoT) frameworks, offering new revenue streams based on data services and predictive maintenance contracts. Secondly, the increasing global focus on sustainability provides an opportunity for manufacturers to innovate in eco-friendly materials and design for repairability, appealing to corporate clients committed to green supply chains. Finally, the underserved market for highly specialized, custom-engineered casters designed for ultra-heavy loads (e.g., aerospace tooling, nuclear components) or unique environmental challenges (e.g., cryogenic applications) offers lucrative margins and strengthens the competitive moat for technologically advanced market participants. These forces of demand and innovation ensure a dynamic and continually evolving market landscape.

Segmentation Analysis

The Industrial Swivel Plate Caster Market is comprehensively segmented based on material, load capacity, wheel diameter, braking mechanism, and end-use application, reflecting the diverse and specialized requirements of industrial operations globally. Analyzing the market through these segments reveals significant variance in growth potential and technological maturity. The Material segment, covering options like polyurethane, nylon, rubber, and steel/cast iron, dictates performance characteristics such as floor protection, noise level, and chemical resistance. Polyurethane wheels are currently experiencing the fastest growth due to their high load capacity relative to size and superior wear resistance, making them ideal for modern logistics centers. Conversely, segmentation by Load Capacity—categorized typically into light, medium, heavy, and super heavy-duty—demonstrates that the heavy-duty segment generates the highest revenue, driven by applications in general manufacturing and large-scale assembly lines where stability and durability are prioritized.

Further granularity is achieved through segmentation based on the Brake Type, which includes total lock, wheel brake, and directional lock mechanisms. Advanced braking systems are critical components, especially in high-traffic areas or on sloped surfaces, ensuring safety compliance and operational stability. The end-use application segment provides the deepest insights into demand drivers, grouping consumers such as the automotive industry (requiring anti-static and anti-shudder casters), logistics and warehousing (demanding high-throughput, non-marking casters), healthcare (requiring stainless steel, easy-clean models), and food and beverage processing (necessitating corrosion-resistant, wash-down compliant units). Each application segment has unique performance specifications that influence product design and pricing structure, driving specialization within the manufacturing base.

The strategic importance of segmentation lies in identifying high-growth niches and tailoring product development to meet precise industrial needs. For instance, the demand for ergonomic swivel plate casters that reduce initial push/pull force is growing rapidly in ergonomically conscious markets like North America and Western Europe, necessitating specific focus on bearing technology and wheel contour design. Similarly, the trend towards larger wheel diameters is evident in heavy-duty applications seeking easier rolling over uneven floors, minimizing user strain and maximizing equipment lifespan. The meticulous analysis of these segmentation trends enables manufacturers and distributors to optimize their product portfolios, ensuring alignment with accelerating industrial digitalization and automation demands across various global sectors.

- By Material:

- Polyurethane (PU)

- Nylon/Polyolefin

- Rubber (Thermoplastic, Solid)

- Cast Iron/Steel

- Phenolic

- By Load Capacity:

- Light Duty (Up to 300 lbs)

- Medium Duty (301 lbs to 1,000 lbs)

- Heavy Duty (1,001 lbs to 5,000 lbs)

- Super Heavy Duty (Over 5,000 lbs)

- By Wheel Diameter:

- Small (Under 4 inches)

- Medium (4 to 6 inches)

- Large (Over 6 inches)

- By Application:

- Automotive and Assembly

- Logistics and Warehousing

- Aerospace and Defense

- Healthcare and Pharmaceuticals

- Food and Beverage Processing

- General Manufacturing

- By Braking Mechanism:

- Total Lock Brake

- Wheel Brake

- Directional Lock Brake

- Central Locking System

Value Chain Analysis For Industrial Swivel Plate Caster Market

The value chain for the Industrial Swivel Plate Caster Market commences with the Upstream segment, dominated by the procurement and processing of fundamental raw materials. This includes high-grade steels (such as carbon and stainless steel) for the swivel housing, plate, and fork assembly; various polymers and chemical feedstocks (for polyurethane, nylon, and rubber production); and specialized bearing components (ball bearings, roller bearings). The stability and quality of the upstream supply chain are critical, as material consistency directly impacts the load rating, longevity, and structural integrity of the final product. Manufacturers often employ sophisticated sourcing strategies to mitigate exposure to volatile commodity prices, emphasizing long-term contracts with specialized metal foundries and chemical suppliers to ensure a steady, reliable input flow for mass production runs, thereby managing quality control from the foundational material level.

The Midstream phase involves the core manufacturing, which is highly technology-intensive, encompassing stamping, welding, forging, precision machining of raceways, injection molding of wheel cores and treads, and final assembly. Efficiency in this segment is achieved through advanced automation, robotic welding, and stringent quality assurance protocols to ensure precise alignment and smooth swivel action, which are crucial for performance under heavy load. The distinction between manufacturers often lies in proprietary swivel section designs and bearing technologies, differentiating high-performance (low-maintenance, precision bearing) casters from standard products. Distribution channels, a vital component of the value chain, are characterized by a dual approach: Direct sales to Original Equipment Manufacturers (OEMs) for integration into new machinery and Indirect sales through a robust network of specialized industrial distributors, MRO (Maintenance, Repair, and Operations) suppliers, and e-commerce platforms catering to replacement markets.

The Downstream segment involves the end-user deployment and after-sales support. Direct sales typically handle large volume orders for automotive assembly lines or large warehousing projects, requiring custom specifications and direct technical support. Indirect channels, often utilizing specialized industrial wholesalers, provide inventory access and localized service to smaller manufacturers and the vast replacement market. This distribution model ensures geographical reach and technical expertise close to the customer base. The success of the downstream segment is highly reliant on providing timely technical advice, ensuring the correct caster is selected for the floor surface and load conditions, and managing warranties. The evolving digitalization of industrial purchasing is increasingly shifting MRO sales towards dedicated B2B e-commerce platforms, optimizing the purchase process for replacement parts and standard catalogue items, thereby enhancing efficiency across the entire value chain.

Industrial Swivel Plate Caster Market Potential Customers

The potential customer base for Industrial Swivel Plate Casters is exceptionally diverse, spanning virtually every sector that requires internal movement of goods, machinery, or equipment. The primary customer segment comprises Original Equipment Manufacturers (OEMs) who integrate casters into their final products, such as industrial carts, mobile work platforms, conveyor system dollies, and medical equipment trolleys. Within the OEM space, the automotive industry represents a cornerstone, purchasing high volumes of casters for assembly line tooling, parts transport racks, and maintenance equipment. Logistics and Warehousing operations form another dominant customer group, driven by the ceaseless requirement to move inventory racks, specialized picking carts, and automated transport modules across expansive fulfillment centers, prioritizing durability and non-marking wheel materials to maintain facility integrity under constant use.

The secondary customer segment is the Maintenance, Repair, and Operations (MRO) market, which involves end-users purchasing casters for replacement, upgrade, or retrofit purposes on existing infrastructure. This segment includes general manufacturing facilities that utilize casters on movable machinery bases, service carts, and storage containers. The healthcare and pharmaceutical industries are also critical buyers, demanding stainless steel, high-hygiene casters for hospital beds, surgical carts, diagnostic equipment, and laboratory furnishings, often requiring specific certifications for cleanroom or wash-down environments. These customers prioritize corrosion resistance, ease of cleaning, and silent operation to maintain sanitary and patient-friendly conditions, driving demand for specialized, premium products.

Further niche markets include aerospace and defense, which require highly specialized, ultra-heavy-duty casters for handling massive tooling jigs, aircraft components, and specialized ground support equipment, often involving custom designs to manage extreme loads with minimal floor indentation. The food and beverage sector similarly acts as a dedicated niche, requiring casters resistant to frequent high-pressure steam cleaning, caustic chemicals, and temperature extremes (freezers and ovens). For all potential customers, the purchasing decision revolves around the total cost of ownership (TCO), balancing initial component cost against expected lifespan, maintenance requirements, and the impact of caster failure on operational efficiency, leading to a strong market preference for reliable, high-specification products that guarantee long-term performance under stress.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.5 billion |

| Market Forecast in 2033 | USD 3.7 billion |

| Growth Rate | CAGR 5.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Tente International GmbH, Colson Group Inc., Blickle Rader+Rollen GmbH u. Co. KG, Albion Caster Company, RWM Casters, Darnell-Rose Inc., Caster Concepts Inc., Hamilton Caster & Mfg. Co., Revvo Caster Company, CEI Casters, PHOENIX Casters, Flywheel Caster Manufacturing Co., Shepherd Caster Corporation, CasterMaster, Fairbanks Casters, Roll-Rite Casters, MedCaster, Ideal Caster, Darcor Casters, Vestil Manufacturing Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Swivel Plate Caster Market Key Technology Landscape

The technological landscape of the Industrial Swivel Plate Caster Market is continuously evolving, driven by the need for enhanced durability, reduced maintenance, and improved maneuverability. A primary technological focus lies in advanced bearing systems. The industry is rapidly adopting sealed precision ball bearings and maintenance-free swivel sections, which significantly increase the caster's lifespan and reduce the total cost of ownership (TCO) by eliminating the need for periodic lubrication and reducing frictional resistance. Furthermore, the engineering of the swivel raceway—the mechanism enabling 360-degree rotation—is crucial. Innovations here include heat-treated, forged steel raceways and specialized kingpinless designs for ultra-heavy-duty applications, preventing premature wear and failure under constant shock loading and heavy lateral forces prevalent in demanding industrial environments such as trailer towing and heavy tooling transport.

Another significant area of technological advancement involves specialized wheel materials and tread bonding techniques. Manufacturers are investing heavily in customized polyurethane formulations, tailored to offer specific attributes such as extreme chemical resistance, superior load deflection, non-marking characteristics, and enhanced dynamic capacity at high speeds. Advanced tread bonding methods, such as mechanical locking or highly durable chemical vulcanization, are essential to prevent tread separation, particularly in continuous-use, heavy-load environments. Moreover, the development of shock-absorbing and spring-loaded casters utilizing specialized elastomer compounds or adjustable internal springs represents a key technological segment. These features are vital for protecting sensitive equipment (e.g., electronic components, medical devices) during transport and reducing noise pollution, thereby complying with both product integrity and occupational safety standards.

The most transformative technology permeating the market is the integration of digital capabilities, leading to the emergence of IoT-enabled 'Smart Casters.' These units incorporate miniature sensors—accelerometers, temperature probes, and load cells—to collect real-time data on usage patterns, environmental conditions, and structural health. This data is transmitted wirelessly (via Bluetooth or low-power wide-area networks) to centralized maintenance systems, facilitating predictive failure analytics and asset tracking. While still nascent, this convergence of traditional mechanical components with embedded electronics is expected to redefine maintenance protocols, shifting them from reactive or scheduled intervention to proactive, condition-based servicing. This technological shift, coupled with continued material science improvements in corrosion resistance (e.g., specialized zinc coatings and comprehensive stainless steel construction), ensures the long-term reliability required by modern, high-throughput industrial settings.

Regional Highlights

The global Industrial Swivel Plate Caster Market exhibits substantial regional heterogeneity, shaped by differing levels of industrial maturity, regulatory environments, and investment priorities in automation infrastructure. North America represents a mature and high-value market, characterized by stringent safety regulations and a strong emphasis on ergonomic casters designed to minimize push/pull strain on workers. Demand in this region is driven primarily by the modernization of existing automotive and aerospace manufacturing facilities, coupled with the exponential construction and upgrading of logistics mega-centers necessitated by the robust e-commerce sector. Customers in the US and Canada typically demand premium, high-load capacity casters with advanced features like directional locks and sophisticated braking systems, favoring durability and low lifecycle cost over initial purchase price.

Europe, another highly established market, focuses heavily on specialization and sustainability. Western European nations, particularly Germany and the Nordic countries, show strong demand for casters engineered for quiet operation and extreme precision, aligning with highly regulated manufacturing environments and emphasis on occupational health. Furthermore, the European market is a leader in adopting specialized caster materials that comply with the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation. The primary growth drivers include the continued expansion of the pharmaceutical and high-tech manufacturing sectors, which require non-contaminating, wash-down casters, maintaining steady, albeit stable, growth rates.

Asia Pacific (APAC) stands out as the engine of global market growth, driven by aggressive industrialization and massive state-sponsored investment in infrastructure across China, India, and Southeast Asia. The rapid establishment of new automotive, electronics, and general assembly plants fuels extraordinary demand for all categories of industrial casters. While the market initially featured a strong bias toward cost-effective, standard models, there is a discernible shift towards higher quality and specialized casters as automation rates increase. The rapid expansion of logistics networks and warehousing capacity in populous nations makes APAC the highest volume market, often outpacing other regions in terms of new installations, making it critical for global manufacturers to establish robust local production and distribution capabilities to capitalize on this explosive demand.

- North America (US, Canada, Mexico): Focus on high-performance, ergonomic casters for automated logistics and modernized automotive manufacturing; strong MRO market.

- Europe (Germany, UK, France): Emphasis on precision engineering, compliance with strict environmental (REACH) and safety standards; strong demand from specialized sectors like pharmaceuticals.

- Asia Pacific (China, India, Japan, South Korea): Highest volume growth due to rapid industrialization, massive warehouse expansion, and rising factory automation adoption; increasing shift from low-cost to high-quality imports.

- Latin America (Brazil, Argentina): Growth tied to commodity exports and infrastructural projects; market characterized by demand for robust, medium-duty casters resilient to challenging floor surfaces.

- Middle East and Africa (MEA): Growth driven by large-scale oil and gas projects, infrastructure development, and nascent logistics hubs; demand for heavy-duty, temperature and corrosion-resistant casters.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Swivel Plate Caster Market.- Tente International GmbH (Germany)

- Colson Group Inc. (USA)

- Blickle Rader+Rollen GmbH u. Co. KG (Germany)

- Albion Caster Company (USA)

- RWM Casters (USA)

- Darnell-Rose Inc. (USA)

- Caster Concepts Inc. (USA)

- Hamilton Caster & Mfg. Co. (USA)

- Revvo Caster Company (UK)

- CEI Casters (USA)

- PHOENIX Casters (Germany)

- Flywheel Caster Manufacturing Co. (China)

- Shepherd Caster Corporation (USA)

- CasterMaster (China)

- Fairbanks Casters (USA)

- Roll-Rite Casters (USA)

- MedCaster (USA)

- Ideal Caster (India)

- Darcor Casters (Canada)

- Vestil Manufacturing Corporation (USA)

Frequently Asked Questions

Analyze common user questions about the Industrial Swivel Plate Caster market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors determine the correct load capacity selection for industrial swivel plate casters?

The primary factor for selecting load capacity is the total weight (equipment plus maximum payload) divided by the number of casters supporting the load, typically subtracting one caster (N-1 rule) to account for uneven floors or temporary load distribution imbalances. Additionally, the operational environment, including speed, shock loading (impact resistance), and whether the casters are required for continuous or intermittent use, necessitates factoring in safety margins, often ranging from 30% to 50% above the calculated static load requirement.

How does the adoption of automation and AGVs impact the design requirements of industrial casters?

Automation demands casters with higher precision, tighter tolerances, and specialized features such as directional stability and minimal rolling resistance to function effectively within pre-defined robotic pathways. AGVs specifically require heavy-duty kingpinless swivel sections to withstand torsional stress, combined with durable, non-marking polyurethane wheels that ensure longevity and traction necessary for automated guidance and braking systems.

Which wheel materials are best suited for environments with high exposure to chemicals and frequent wash-downs?

For chemical and wash-down environments, stainless steel casters equipped with high-grade Nylon (Polyolefin) or Polyurethane wheels are recommended. Nylon and specific high-chemical-resistant polyurethanes offer superior resistance to caustic cleaning agents, acids, and detergents compared to standard rubber. Stainless steel construction for the fork and plate ensures complete corrosion resistance, a critical requirement in food processing, pharmaceutical, and laboratory settings.

What are 'Smart Casters' and how are they improving operational efficiency in logistics?

Smart Casters are industrial swivel casters integrated with IoT technology, utilizing embedded sensors to measure operational parameters such as vibration, temperature, and load stress. By transmitting this data, they enable predictive maintenance systems to anticipate component failure (e.g., bearing degradation) before downtime occurs, significantly enhancing operational efficiency and reducing unexpected maintenance costs within large-scale logistics and warehouse operations.

What is the key technological difference between kingpin and kingpinless swivel plate casters?

Kingpin casters utilize a central bolt (the kingpin) to hold the swivel assembly together. Kingpinless casters, conversely, use a continuous, cold-formed inner and outer raceway that is designed to withstand heavy shock loading and constant swiveling without loosening or failure. Kingpinless designs are generally preferred for super heavy-duty, high-impact applications where the kingpin may eventually fail or require frequent maintenance due to wear and tear.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager