Industrial Tugger Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439044 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Industrial Tugger Market Size

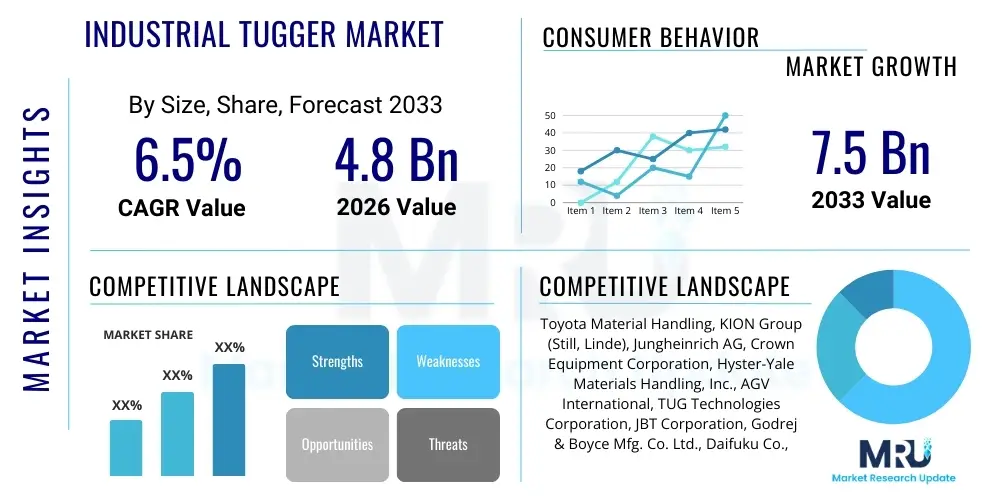

The Industrial Tugger Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.5 Billion by the end of the forecast period in 2033. This robust expansion is primarily attributed to the increasing emphasis on automation in warehouse and manufacturing environments globally, particularly driven by the rise of e-commerce and the need for optimized material flow logistics. The adoption of electric and autonomous tuggers is a major contributor to this valuation increase, providing efficient, sustainable, and scalable solutions for intra-logistics operations across diverse industries.

Market valuation reflects the cumulative demand for various types of industrial tuggers, including manually operated, rider tuggers, and increasingly, automated guided vehicle (AGV) tuggers. While traditional internal combustion engine (ICE) models are witnessing phased replacement due to stringent environmental regulations, the shift towards lithium-ion powered electric tuggers is accelerating market expansion. Geographically, Asia Pacific remains a high-growth region, fueled by rapid industrialization and the establishment of massive logistics hubs, necessitating high-capacity material handling solutions to manage substantial throughput.

Industrial Tugger Market introduction

The Industrial Tugger Market encompasses the production, distribution, and utilization of specialized electric or internal combustion vehicles designed to tow multiple trailers or carts carrying materials across warehouses, factories, airports, and distribution centers. These devices, integral to efficient lean manufacturing and logistics systems, replace traditional forklift dependency for long-distance horizontal transport of consolidated loads, significantly improving safety and operational throughput. The core function of an industrial tugger is to facilitate the "train" concept, where a single operator or automated unit can move a large quantity of goods simultaneously, thus maximizing labor utilization and reducing congestion within operational aisles.

Major applications of industrial tuggers span the automotive assembly lines, where they deliver components like seats or engines on a synchronized schedule; general manufacturing, where they move sub-assemblies between production stages; and the burgeoning e-commerce fulfillment sector, where they manage inbound and outbound logistics for high-volume goods. The primary benefits include enhanced operational efficiency, reduced manual handling labor costs, improved workplace safety due to designated transport routes, and greater energy efficiency compared to repeatedly running forklifts for similar tasks. These systems are essential for optimizing the flow of goods in complex, large-scale industrial environments, aligning material flow with production requirements.

Key driving factors accelerating the market growth include the global trend toward warehouse automation, the necessity for efficient just-in-time (JIT) material delivery systems, and technological advancements that allow for the integration of tuggers with sophisticated Warehouse Management Systems (WMS). Furthermore, increasing labor costs and a continuous push for higher environmental standards are compelling organizations to invest in electric and potentially autonomous tugger solutions. This convergence of operational needs and technological maturity is positioning the industrial tugger as a cornerstone of modern intra-logistics infrastructure.

Industrial Tugger Market Executive Summary

The Industrial Tugger Market is characterized by robust growth, propelled primarily by the paradigm shift towards digitized and automated material handling processes across global industrial sectors. Business trends indicate a significant consolidation among major Original Equipment Manufacturers (OEMs), coupled with an intensified focus on developing modular, interoperable automated guided vehicle (AGV) tugger solutions. Manufacturers are heavily investing in lithium-ion battery technology to extend operational range and reduce charging downtime, positioning sustainability and total cost of ownership (TCO) as critical competitive differentiators. Furthermore, the expansion of global third-party logistics (3PL) providers and the exponential growth of e-commerce warehousing are creating sustained demand for flexible, high-capacity towing solutions.

Regionally, Asia Pacific is maintaining market dominance and demonstrating the fastest growth trajectory, driven by massive investments in new factory builds, particularly in China, India, and Southeast Asian nations establishing themselves as global manufacturing hubs. North America and Europe, while mature markets, are experiencing high replacement rates, driven by the conversion from legacy internal combustion engine (ICE) models to advanced electric and autonomous systems, often spurred by strict emissions standards and smart factory initiatives. These regions prioritize integration with advanced industrial IoT (IIoT) frameworks and cybersecurity measures for their connected fleets.

Segment trends reveal a significant preference shift toward electric-powered tuggers, projected to capture the largest market share due to their suitability for indoor operations and lower maintenance requirements. Load capacity segmentation highlights increasing demand for models capable of towing between 5,000 kg and 10,000 kg, reflecting the trend toward moving larger, consolidated material trains. In terms of navigation technology, laser guidance and vision-based systems are rapidly displacing magnetic tape guidance, especially in environments requiring dynamic routing and quick layout adjustments, signifying a market preference for flexibility and advanced autonomy features.

AI Impact Analysis on Industrial Tugger Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Industrial Tugger Market generally revolve around how AI enhances route optimization, predictive maintenance capabilities, and the overall intelligence of Automated Guided Vehicle (AGV) tuggers. Users frequently inquire about the feasibility of dynamic, real-time rerouting based on facility congestion, the accuracy of AI-driven battery life predictions, and the integration level necessary for tuggers to interact seamlessly with other automated warehouse systems like robotic arms or storage and retrieval systems (AS/RS). The underlying theme is the expectation that AI will transform tuggers from simple transport vehicles into fully cognitive, self-managing assets, capable of contributing actively to holistic operational efficiency rather than merely executing predefined movements. Concerns often focus on the complexity and cost of implementing AI infrastructure and the necessary skills gap mitigation required for maintenance personnel.

AI's primary influence is moving autonomous tuggers beyond fixed-path navigation into environments requiring complex decision-making and dynamic path planning. Machine learning algorithms analyze vast datasets related to traffic patterns, order fulfillment priorities, and unexpected obstacles to calculate the most efficient path in real-time, drastically improving throughput and reducing idle time. Furthermore, AI is central to developing robust fleet management software, ensuring load distribution is optimized and reducing energy consumption by intelligently managing acceleration and braking profiles. This layer of intelligence ensures the entire fleet operates as a highly synchronized, adaptive system.

The long-term impact of AI involves enhancing predictive failure analysis. By continuously monitoring hundreds of operational parameters—motor temperature, battery cell degradation, tire pressure, and suspension load—AI models can predict component failure days or weeks in advance. This transition from reactive or scheduled maintenance to highly accurate predictive maintenance minimizes unplanned downtime, extends the useful life of the equipment, and lowers the overall maintenance expenditure, thus improving the total cost of ownership for end-users relying on continuous operation.

- AI-driven real-time path optimization and dynamic congestion management for AGV fleets.

- Enhanced predictive maintenance algorithms analyzing sensor data to preempt component failures.

- Improved battery life management and energy consumption optimization through machine learning.

- Seamless integration of tugger decision-making with WMS and MES for synchronous material delivery.

- Vision-based AI enables advanced obstacle detection and classification in complex operational areas.

DRO & Impact Forces Of Industrial Tugger Market

The Industrial Tugger Market is fundamentally shaped by a confluence of driving forces, restraining factors, and emerging opportunities, collectively exerting a significant impact on market trajectory and investment decisions. The key Driver is the persistent global trend toward automation and lean manufacturing principles, which demand precise, scheduled material flow solutions to minimize waste and optimize production cycles. Restraints primarily involve the high initial capital expenditure associated with advanced electric and autonomous tugger systems, alongside the technical complexity and integration challenges when retrofitting existing, legacy infrastructure. Conversely, the principal Opportunity lies in the rapid technological advancement of battery storage, coupled with the expansion of Robotics-as-a-Service (RaaS) business models, making advanced solutions more accessible to Small and Medium-sized Enterprises (SMEs).

Key drivers include regulatory pressures favoring electric vehicles (EVs) over internal combustion engine (ICE) models, particularly in confined indoor spaces where emissions are a concern. The continuous growth of the e-commerce sector, necessitating larger and more complex distribution centers operating around the clock, mandates highly efficient and scalable intra-logistics solutions like tugger trains. Furthermore, the consistent increase in labor costs and the difficulty in securing specialized manual material handling personnel are accelerating the return on investment (ROI) for autonomous tugger solutions, thereby strengthening their adoption across high-wage economies in North America and Europe.

The most significant impact force currently influencing the market is technological innovation, specifically the maturity of simultaneous localization and mapping (SLAM) technologies and vision-based navigation systems. These advancements allow tuggers to operate without fixed infrastructure modifications, enhancing flexibility and reducing deployment time. However, market adoption faces resistance from established operational inertia, where transitioning from long-standing manual processes to fully integrated automation requires significant internal organizational restructuring and employee training. Addressing cybersecurity vulnerabilities associated with interconnected fleet management systems also acts as an underlying impact force influencing buyer hesitation and vendor design protocols.

Segmentation Analysis

The Industrial Tugger Market is comprehensively segmented based on Power Source, Load Capacity, Navigation Technology, and Application, providing a clear framework for understanding market dynamics and targeted deployment strategies. Power Source segmentation distinguishes between the dominant Electric segment, driven by sustainability and indoor use, and the declining but still relevant Internal Combustion Engine (ICE) segment, primarily used in heavy-duty outdoor applications. Load Capacity segregation addresses various industrial needs, ranging from lighter loads suitable for cleanrooms and textile facilities to heavy-duty models necessary for automotive and steel industries. Navigation Technology determines the level of autonomy and complexity, moving from simple manned operation to highly sophisticated SLAM-based autonomous tuggers, reflecting the overall shift towards smart factory integration.

The dominance of the Electric segment is critical, as OEMs prioritize energy efficiency and the integration of advanced battery management systems (BMS). The market for electric tuggers is further refined by battery type, with lithium-ion rapidly replacing lead-acid due to superior energy density, faster charging cycles, and longer lifespan, directly addressing the core industrial requirement for continuous 24/7 operation. Furthermore, the application segmentation highlights sectors like Automotive and Manufacturing as primary consumers due to their high volume, repetitive material transport needs, while Airports and Healthcare facilities represent emerging, high-value niches focused on specialized material transport.

Understanding these segments is crucial for strategic planning. For instance, companies targeting high-mix, low-volume production environments often require versatile tuggers utilizing vision-based navigation for rapid reconfiguration, whereas large-scale, high-volume production facilities, like automotive stamping plants, prioritize heavy-duty electric tuggers optimized for fixed routes and maximum payload. The intersection of these segment factors defines product development roadmaps and competitive positioning within the global industrial material handling landscape, ensuring solutions are tailored precisely to specific operational demands and facility types.

- By Power Source:

- Electric

- Internal Combustion Engine (ICE)

- By Load Capacity:

- Up to 5,000 kg

- 5,001 kg to 10,000 kg

- Above 10,000 kg

- By Navigation Technology:

- Manned/Manual Tuggers

- Automated Guided Vehicle (AGV) Tuggers (Laser, Vision/SLAM, Magnetic Tape)

- By Application:

- Manufacturing

- Warehouse and Logistics (E-commerce Fulfillment)

- Automotive

- Aviation/Airport

- Healthcare and Pharmaceutical

- Others (Textiles, Food & Beverage)

Value Chain Analysis For Industrial Tugger Market

The value chain for the Industrial Tugger Market begins with upstream activities, dominated by the procurement of essential raw materials and specialized components. Key upstream elements include high-grade steel and aluminum for chassis construction, sophisticated electronic components such as sensors, controllers, and specialized navigation systems (LiDAR, cameras), and, crucially, battery components, where sourcing of lithium-ion cells and battery management systems is paramount. Efficient management of the supply chain for these high-technology components is vital for controlling manufacturing costs and ensuring product performance, particularly battery longevity and charging speed, which are major differentiators in the electric segment. OEMs often forge strategic alliances with technology providers for navigation and control systems to maintain a competitive edge.

Midstream activities encompass the manufacturing, assembly, and quality control processes. This stage involves the design and engineering of the tugger platform, integration of power source technologies, and installation of advanced software for fleet management and autonomy. Distribution channels play a critical role, segmenting into direct and indirect routes. Direct sales are common for large-scale, complex autonomous fleet deployments where customization, integration, and post-sales service contracts are negotiated directly between the OEM and the large industrial end-user (e.g., major automotive companies). This direct interaction ensures precise alignment of the product with the facility’s specific WMS/MES requirements.

The downstream segment involves product installation, integration services, maintenance, and technical support. Indirect distribution, leveraging authorized dealers, local distributors, and third-party logistics providers (3PLs) specialized in material handling equipment, is crucial for reaching SMEs and geographically dispersed markets. These intermediaries provide localized support, spare parts, and essential maintenance services, which are critical given the demanding operational schedules of industrial environments. The RaaS model is emerging as a critical downstream component, offering financing flexibility and bundled maintenance, fundamentally altering how customers acquire and utilize advanced industrial tugger technology, shifting the focus from capital expenditure to operational efficiency.

Industrial Tugger Market Potential Customers

The core customer base for the Industrial Tugger Market spans several high-volume, efficiency-driven industrial sectors where the movement of materials between fixed points is constant and repetitive. The largest and most demanding customer segment is the Automotive industry, particularly vehicle assembly plants and Tier 1 and Tier 2 suppliers, which rely on tuggers for synchronized, just-in-time delivery of components (kits, engines, seats) to precise line-side locations. These customers require highly reliable, heavy-duty tuggers, increasingly demanding integrated autonomous capabilities to maintain synchronized production cycles and reduce errors in complex assembly sequences.

The second major segment includes large-scale Warehouse and Logistics operations, significantly fueled by the exponential growth of e-commerce and the rise of mega-distribution centers operated by both retailers and 3PLs. These customers use tuggers for bulk material handling, moving pallets from receiving docks to storage areas, or transporting consolidated orders to shipping zones. Their primary needs center around operational flexibility, high energy efficiency for 24/7 use, and seamless integration with existing warehouse management systems (WMS). The demand here leans heavily towards AGV tuggers to mitigate labor dependency and scale operations rapidly during peak seasons.

Beyond these primary sectors, potential customers include airports and ground support operators, utilizing specialized tuggers for baggage handling and aircraft positioning; general manufacturing facilities (e.g., metal fabrication, electronics assembly) needing point-to-point material transfer; and the Healthcare and Pharmaceutical sector, where specialized, often smaller, electric tuggers are used for transporting sensitive materials, linen, and food trays within controlled hospital environments, prioritizing quiet operation and high maneuverability. The common denominator across all these end-users is the fundamental need to streamline repetitive internal transport tasks, improve safety, and achieve higher throughput efficiency.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.5 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Toyota Material Handling, KION Group (Still, Linde), Jungheinrich AG, Crown Equipment Corporation, Hyster-Yale Materials Handling, Inc., AGV International, TUG Technologies Corporation, JBT Corporation, Godrej & Boyce Mfg. Co. Ltd., Daifuku Co., Ltd., Schaefer Systems International, Inc. (SSI Schaefer), Konecranes, Doosan Corporation, Mitsubishi Logisnext Co., Ltd., Combilift Ltd., PalletTrucks UK, Aisle-Master, Clark Material Handling Company, EZGO Textron, Alke Electric Vehicles |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Industrial Tugger Market Key Technology Landscape

The technological landscape of the Industrial Tugger Market is rapidly evolving, driven by the convergence of electrification, advanced sensing, and artificial intelligence, moving the technology away from simple motorized carts toward complex, cognitive mobile robots. The most crucial technological shift is the widespread adoption of lithium-ion (Li-ion) batteries, replacing traditional lead-acid systems. Li-ion technology offers significant operational advantages, including opportunity charging capability, extended run times, and zero maintenance, drastically improving utilization rates in continuous operation environments. Furthermore, advanced Battery Management Systems (BMS) are becoming standard, utilizing sophisticated software to optimize charging profiles and monitor cell health, thereby extending the battery lifecycle and ensuring peak performance.

In terms of guidance and autonomy, the market has transitioned significantly from basic magnetic tape guidance to more flexible, infrastructure-light navigation solutions. Simultaneous Localization and Mapping (SLAM) technology, often utilizing LiDAR sensors combined with computer vision systems, is now a key differentiator for Automated Guided Vehicle (AGV) tuggers. SLAM allows tuggers to map and navigate complex, dynamic environments without fixed guidance paths, enabling real-time rerouting around unexpected obstacles or traffic congestion. This flexibility is essential for modern, high-mix logistics operations where floor layouts and material demands frequently change. Sensor fusion, combining data from LiDAR, ultrasonic sensors, and vision cameras, is enhancing safety and precision, meeting the stringent regulatory requirements for human-robot interaction in collaborative workspaces.

Connectivity and fleet management software represent the critical layer enabling efficient operation of large tugger fleets. Modern industrial tuggers are integrated into the Industrial Internet of Things (IIoT), allowing them to communicate continuously with Warehouse Management Systems (WMS) and Manufacturing Execution Systems (MES) via Wi-Fi or 5G networks. This integration facilitates optimal task assignment, route scheduling, and preventative maintenance alerts based on real-time operational data. The continued development of standardized interfaces (e.g., VDA 5050 protocols in Europe) is crucial for promoting interoperability between different vendors' tuggers and central fleet controllers, simplifying the integration process for end-users seeking mixed-fleet solutions and driving further adoption of autonomous technologies.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to maintain the highest growth rate, driven by accelerated industrialization, the establishment of large-scale manufacturing bases (especially in electronics, textiles, and automotive sectors in China, India, and Vietnam), and massive investment in e-commerce fulfillment infrastructure. Government initiatives supporting domestic manufacturing and the rapid adoption of factory automation technologies are key contributors. This region is witnessing strong demand for both heavy-duty rider tuggers and sophisticated AGV solutions tailored for newly built, highly integrated facilities.

- North America: North America represents a mature, high-value market characterized by high labor costs and a strong focus on maximizing operational efficiency. Growth here is primarily driven by the need for replacement of older fossil-fuel-based fleets with advanced electric and fully autonomous AGV tuggers. The e-commerce explosion necessitates robust intralogistics solutions, leading to rapid adoption of RaaS models and heavy investment in integration technologies that link tugger fleets with AI-driven WMS platforms.

- Europe: Europe is a key market propelled by stringent environmental regulations and aggressive smart factory (Industry 4.0) initiatives. There is a strong preference for electric-powered tuggers and highly automated solutions that meet strict safety standards. Germany and Scandinavia are leaders in adopting AGV tuggers, focusing heavily on sustainability and energy efficiency metrics. The region is also at the forefront of establishing interoperability standards (like VDA 5050) for autonomous material handling systems, fostering market integration.

- Latin America (LATAM): The LATAM market is characterized by moderate growth, primarily centered in industrially active countries such as Brazil and Mexico, which serve as manufacturing and assembly hubs for global corporations. Demand is concentrated in the automotive and general manufacturing sectors. While budgetary constraints often limit widespread adoption of highly expensive autonomous systems, there is a steady transition towards reliable, high-capacity electric rider tuggers to improve manual transport efficiency.

- Middle East and Africa (MEA): The MEA market, while currently smaller, is expanding due to substantial investments in logistics infrastructure (ports, mega-warehouses) in the GCC countries (Saudi Arabia, UAE). The focus is often on large-scale logistics and construction projects. Demand is increasing for durable, high-performance tuggers capable of operating reliably in harsh environmental conditions. Infrastructure development surrounding trade hubs is the primary driver of market interest in efficient material flow solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Industrial Tugger Market.- Toyota Material Handling

- KION Group (Still, Linde)

- Jungheinrich AG

- Crown Equipment Corporation

- Hyster-Yale Materials Handling, Inc.

- AGV International

- TUG Technologies Corporation

- JBT Corporation

- Godrej & Boyce Mfg. Co. Ltd.

- Daifuku Co., Ltd.

- Schaefer Systems International, Inc. (SSI Schaefer)

- Konecranes

- Doosan Corporation

- Mitsubishi Logisnext Co., Ltd.

- Combilift Ltd.

- Alke Electric Vehicles

- Taylor-Dunn Manufacturing (Polaris Inc.)

- Clark Material Handling Company

- EZGO Textron

- Cushman (Textron)

Frequently Asked Questions

Analyze common user questions about the Industrial Tugger market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of Autonomous Tuggers (AGVs) over traditional manned tuggers?

AGV tuggers offer superior operational consistency, operate 24/7 without requiring breaks, minimize human error, and enhance workplace safety by adhering strictly to pre-programmed or dynamically calculated routes. They also integrate seamlessly with WMS, optimizing material flow and reducing overall labor costs, yielding a better ROI in high-volume environments.

How is the adoption of lithium-ion batteries affecting the Industrial Tugger Market?

Lithium-ion adoption is accelerating the shift from ICE and lead-acid models by providing longer runtimes, maintenance-free operation, and significantly faster opportunity charging, enabling continuous operation. This improves fleet utilization, lowers the total cost of ownership (TCO), and aligns with corporate sustainability mandates, particularly in Europe and North America.

Which industry application accounts for the largest market share for industrial tuggers?

The Automotive Industry, encompassing both assembly and component manufacturing, holds the largest market share. Tuggers are essential for complex just-in-time (JIT) and kitting operations, ensuring synchronized delivery of thousands of components to the assembly line, minimizing inventory holding costs and maximizing production flow.

What is SLAM technology and why is it important for modern tugger navigation?

Simultaneous Localization and Mapping (SLAM) is a navigation technology utilizing sensors (LiDAR, vision) to allow autonomous tuggers to build a map of their environment while simultaneously locating themselves within that map. SLAM is crucial because it eliminates the need for physical infrastructure (like magnetic tape), offering unparalleled flexibility and ease of deployment and allowing for dynamic path planning in changing environments.

What major regulatory factors influence the industrial tugger market growth?

Stricter global environmental regulations, particularly regarding indoor air quality and carbon emissions, strongly favor the replacement of diesel and LPG-powered tuggers with electric models. Additionally, increasing workplace safety standards globally drive demand for automated solutions that reduce collision risks associated with manual material handling.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager