Infrared Rapid Coal Quality Analyzer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432131 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Infrared Rapid Coal Quality Analyzer Market Size

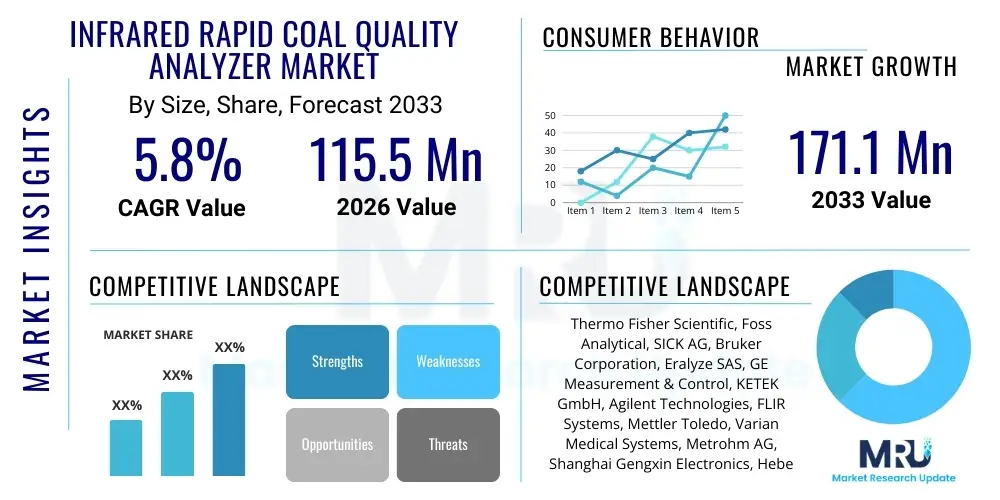

The Infrared Rapid Coal Quality Analyzer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $115.5 Million in 2026 and is projected to reach $171.1 Million by the end of the forecast period in 2033.

The growth trajectory of the Infrared Rapid Coal Quality Analyzer Market is fundamentally driven by the increasing global demand for energy coupled with stringent regulatory frameworks concerning environmental emissions and fuel efficiency. Traditional methods of coal analysis are time-consuming and labor-intensive, often delaying critical operational decisions in power generation and metallurgy. The shift towards infrared technology addresses this core inefficiency by providing rapid, non-destructive, and highly accurate analysis of key coal parameters such as ash content, moisture, volatile matter, and calorific value, enabling quicker material sorting and process optimization.

Furthermore, operational efficiencies mandated by competitive energy markets necessitate real-time quality monitoring. Infrared analyzers, particularly those leveraging Near-Infrared (NIR) and Fourier-Transform Infrared (FTIR) spectroscopy, integrate seamlessly into existing conveyor belt systems or laboratory automation workflows, minimizing human error and maximizing throughput. The significant initial capital expenditure associated with these sophisticated devices is increasingly justified by the substantial long-term savings realized through improved combustion efficiency, reduced maintenance costs stemming from consistent fuel quality, and minimized contractual penalties related to substandard coal deliveries. This favorable cost-benefit analysis accelerates adoption across major coal-consuming industries globally.

Infrared Rapid Coal Quality Analyzer Market introduction

The Infrared Rapid Coal Quality Analyzer Market encompasses advanced analytical instruments designed to determine the physical and chemical properties of coal in near real-time, relying primarily on infrared spectroscopic principles. These analyzers measure the absorption or reflection of infrared radiation by coal samples, quickly correlating the spectral data with established quality metrics critical for end-users such as power generation utilities, steel manufacturers, and mining operations. The core product provides instantaneous results regarding parameters like calorific value, ash content, moisture level, and sulfur content, which are essential for quality control, blending optimization, and transactional validation in the coal supply chain.

Major applications of these analyzers span across the entire coal utilization spectrum, from the mine face—where rapid analysis informs excavation and blending decisions—to the power plant or coke oven, where continuous monitoring ensures optimal combustion and operational safety. A key benefit driving market growth is the substantial improvement in operational response time; results that historically took hours using conventional laboratory methods (such as bomb calorimetry or proximate analysis) are delivered in minutes or seconds, allowing for immediate process adjustments. This speed minimizes inventory holding times and reduces the risk associated with processing non-compliant fuel.

Key driving factors include the global push for cleaner coal technologies requiring tighter control over input quality to reduce harmful emissions, the inherent economic advantage of optimizing fuel blending for maximum efficiency, and the geographical expansion of coal trading, necessitating standardized and rapid quality certification. The market is also heavily influenced by the transition from batch testing to continuous, inline monitoring, requiring rugged, robust, and highly automated infrared analysis solutions capable of operating in harsh industrial environments with minimal recalibration and maintenance requirements.

Infrared Rapid Coal Quality Analyzer Market Executive Summary

The Infrared Rapid Coal Quality Analyzer Market is characterized by intense focus on digitalization and automation, with business trends leaning towards solutions that offer cloud-based data management and remote diagnostics, moving beyond mere measurement tools to comprehensive quality management systems. Major vendors are prioritizing the development of robust calibration models and advanced chemometrics to enhance accuracy across diverse coal types and moisture variations, directly addressing historical limitations associated with spectral analysis in complex matrices. Strategic partnerships between instrument manufacturers and major industrial automation firms are becoming prevalent, aiming to create seamlessly integrated, end-to-end quality control platforms that standardize data outputs and facilitate enterprise-wide decision-making regarding fuel procurement and usage.

Regionally, the Asia Pacific (APAC) stands as the dominant market, propelled by the high volume of coal consumption in rapidly industrializing economies like China and India, where significant investments are being made in power generation infrastructure and cleaner combustion technologies. North America and Europe, while seeing slower growth in coal consumption, represent mature markets focused on replacing older, less efficient analytical equipment with advanced NIR and FTIR systems for enhanced environmental compliance and cost-efficiency. Latin America and the Middle East and Africa (MEA) are emerging growth regions, driven by new mining projects and the need to establish reliable quality control protocols for export purposes and nascent domestic power sectors.

Segment trends reveal a strong preference for high-throughput, inline (on-belt) systems within the power generation and bulk material handling sectors, maximizing the advantage of real-time analysis for large volumes. Conversely, portable and benchtop analyzers maintain significant relevance in mining exploration, smaller laboratories, and contractual validation points where flexibility and ease of transport are paramount. Technology-wise, the adoption of Near-Infrared Spectroscopy (NIRS) is accelerating due to its balance of cost, robustness, and suitability for continuous monitoring of key compositional parameters, although mid-infrared (MIR) techniques, such as FTIR, continue to dominate laboratory-grade, high-precision applications requiring detailed structural information.

AI Impact Analysis on Infrared Rapid Coal Quality Analyzer Market

User inquiries regarding AI's role in the Infrared Rapid Coal Quality Analyzer Market frequently center on three critical areas: enhanced prediction accuracy, autonomous operation, and predictive maintenance. Users are keenly interested in how Artificial Intelligence and Machine Learning (ML) can overcome the current challenge of spectral drift and improve the robustness of calibration models across highly variable coal feeds. They anticipate AI algorithms moving beyond simple regression to complex pattern recognition, allowing the system to automatically compensate for minor sample presentation inconsistencies or environmental changes, thereby minimizing the need for frequent, expensive manual recalibrations and maximizing instrument uptime.

Furthermore, there is significant user expectation for AI-driven data fusion. Current analyzers generate vast amounts of spectroscopic data, often siloed from other process data (e.g., boiler temperature, flow rates, pulverizer settings). Users seek AI systems capable of integrating and interpreting these disparate datasets in real-time, providing holistic process optimization advice rather than just isolated quality metrics. This capability transforms the analyzer from a simple measurement device into an intelligent process control nexus. Concerns often revolve around data security, the ethical implications of autonomous decision-making in high-stakes operational environments, and the availability of skilled personnel capable of managing and tuning these advanced, AI-powered systems.

The overarching theme is the transition toward 'smart' coal quality management. AI's ability to analyze historical spectral data, maintenance logs, and environmental conditions allows for the prediction of component failure, enabling just-in-time servicing. It also facilitates superior outlier detection and quality anomaly flagging, moving human operators into supervisory roles focused on strategic decision-making rather than continuous manual monitoring or reactive troubleshooting. This integration of AI elevates the value proposition of infrared analyzers, making them essential components of Industry 4.0 infrastructure in energy and heavy industrial sectors, paving the way for fully automated coal handling and utilization.

- AI enables predictive maintenance schedules by analyzing sensor data patterns.

- Machine Learning algorithms significantly improve the accuracy and robustness of chemometric calibration models, adapting to varying coal types.

- Real-time data fusion connects spectral analysis with operational process parameters for holistic optimization.

- AI supports autonomous decision-making in fuel blending and quality sorting processes.

- Enhanced anomaly detection prevents processing of highly detrimental, substandard coal batches.

- Automated spectral drift compensation reduces the frequency and cost of manual instrument recalibration.

DRO & Impact Forces Of Infrared Rapid Coal Quality Analyzer Market

The dynamics of the Infrared Rapid Coal Quality Analyzer Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities. A primary Driver is the imperative for energy producers globally to enhance fuel efficiency and reduce operational costs, which is directly facilitated by rapid, accurate input quality control. The need to comply with increasingly stringent environmental regulations, particularly regarding sulfur and NOx emissions, mandates precise monitoring of coal composition, accelerating the adoption of these rapid analysis tools. The growing international trade of thermal and metallurgical coal further acts as a driver, as rapid quality certification at ports and transaction points is essential for trade efficiency and dispute resolution, where slow laboratory methods are commercially unacceptable.

Conversely, significant Restraints challenge market expansion, notably the high initial capital investment required for high-end, inline infrared spectroscopic systems, which can be prohibitive for smaller mining operations or utility companies in developing economies. Furthermore, the inherent complexity of maintaining accurate calibration models—especially when coal sources fluctuate significantly—requires specialized technical expertise, creating a barrier to widespread adoption. The global long-term trend towards renewable energy sources (solar, wind, hydro) poses a structural threat, as sustained investment in new coal-fired power infrastructure decreases, potentially capping the overall addressable market size in the long run.

Opportunities for growth are abundant, particularly in leveraging the technology for advanced material management. The integration of infrared analyzers with IoT platforms and cloud computing offers opportunities for remote monitoring and centralized quality management across geographically dispersed sites. Moreover, the development of increasingly rugged, portable analyzers is opening up new markets in field exploration and smaller-scale industrial applications. The technology can also be expanded beyond traditional coal analysis to monitor other solid fuels and biomass co-firing materials, diversifying the application base and mitigating risks associated with the decline in conventional coal usage. The powerful impact forces thus push the market toward technological refinement and integration into comprehensive industrial automation schemes.

Segmentation Analysis

The Infrared Rapid Coal Quality Analyzer Market is systematically segmented based on technological type, product deployment (Portability), and the primary end-user application, allowing vendors to tailor solutions precisely to specific industrial needs. The segmentation by technology primarily distinguishes between Near-Infrared (NIR) and Mid-Infrared (MIR) spectroscopy, where NIR dominates high-volume, on-belt applications due to its lower operational cost and robustness, while MIR (often using FTIR) provides higher resolution data, typically favored in sophisticated laboratory settings. This technical differentiation dictates the level of precision, speed, and environmental resistance required for the deployment location.

Segmentation by product deployment separates the market into Benchtop/Laboratory models, which prioritize precision and flexibility for diverse samples, and Portable/Handheld/Inline (On-belt) systems, which prioritize speed, ruggedness, and integration capacity. Inline systems are crucial for power plants and large blending facilities requiring continuous, non-stop quality feedback to optimize processes instantly. Conversely, portable analyzers cater to field testing, geological mapping, and smaller operations that cannot justify permanent, large-scale installations but still require rapid quality assurance.

The application segmentation is critical, highlighting the diverse requirements of the primary end-users. Power generation utilities constitute the largest segment due to their immense volume requirements and the high cost associated with burning substandard fuel. The metallurgical industry (steel and coke production) requires very precise measurement of specific parameters like volatile matter and fixed carbon. The mining and mineral processing sector utilizes these analyzers for crucial processes like mine mapping, selective excavation, and inventory quality control, ensuring that only market-ready product is shipped, emphasizing quality and contractual compliance across the value chain.

- By Technology:

- Near-Infrared (NIR) Spectroscopy

- Mid-Infrared (MIR) Spectroscopy (FTIR)

- By Deployment:

- Benchtop/Laboratory Analyzers

- Portable/Handheld Analyzers

- Inline/On-belt Analyzers (Continuous Monitoring)

- By Application:

- Power Generation (Thermal Power Plants)

- Metallurgical Industry (Coke Ovens, Steel Mills)

- Mining and Mineral Processing

- Coal Trading and Logistics

- Research and Academic Laboratories

- By Measurement Parameter:

- Ash Content

- Moisture Content

- Calorific Value (BTU/MJ)

- Volatile Matter and Fixed Carbon

- Sulfur and other Trace Elements

Value Chain Analysis For Infrared Rapid Coal Quality Analyzer Market

The value chain for the Infrared Rapid Coal Quality Analyzer Market begins with the sourcing of highly specialized upstream components, including high-precision optical sensors, stable light sources (e.g., tungsten-halogen lamps, laser diodes), and advanced signal processing electronics. Manufacturing is characterized by high complexity, requiring expertise in spectroscopy, precision engineering, and robust industrial design to create instruments capable of withstanding the harsh, dusty, and temperature-variable environments of coal handling facilities. Suppliers must maintain rigorous quality control over sensor calibration, as the accuracy of the final measurement is entirely dependent on the stability and reliability of the optical components. This reliance on high-tech, low-volume component providers leads to significant barriers to entry for new manufacturers.

Downstream analysis focuses heavily on software development, specifically the creation and maintenance of sophisticated chemometric models. Unlike conventional equipment, the true value of an infrared analyzer lies in its software—the ability to accurately correlate spectral data with complex physical properties. This necessitates continuous research and development to refine algorithms that compensate for variations in coal particle size, temperature, and heterogeneity. Distribution channels are highly specialized; direct sales models are common for large, complex inline systems, requiring extensive consultation, installation, and post-sales service by factory-trained engineers. Indirect channels utilize specialized regional distributors who possess deep industry knowledge of the local coal and energy sectors, focusing on benchtop and portable unit sales.

The market features a strong emphasis on post-installation support and service, which generates substantial recurring revenue. This includes long-term service contracts for system recalibration, software updates, training, and preventative maintenance. The distinction between direct and indirect distribution often hinges on the product's complexity. Large, mission-critical inline systems typically demand direct manufacturer oversight to ensure integration with existing plant control systems (DCS/SCADA), whereas portable units may be efficiently handled by third-party value-added resellers who provide initial setup and regional technical support to localized mining and trading clients. The highest value addition occurs in the intellectual property related to calibration algorithms and the quality of long-term service provision.

Infrared Rapid Coal Quality Analyzer Market Potential Customers

Potential customers for Infrared Rapid Coal Quality Analyzers are predominantly industrial entities engaged in high-volume handling, processing, and consumption of coal. The largest segment of buyers consists of large-scale thermal power generation utilities. These entities rely on consistent and verified fuel quality to maintain optimal boiler efficiency, minimize slagging and fouling, and adhere to strict emission limits imposed by environmental protection agencies. Their purchasing decisions are driven by the need for continuous, real-time feedback systems to manage fuel blending operations and ensure maximum BTU extraction per ton of coal consumed.

A second major customer group includes metallurgical companies, primarily steel manufacturers utilizing coking coal. The quality parameters required for coking processes are extremely demanding, particularly regarding volatile matter and ash fusion temperature, making accurate and rapid analysis crucial for feedstock preparation and process stability. Furthermore, independent commercial testing laboratories and governmental inspection bodies constitute significant buyers, as they require reliable, rapid methods to verify contract compliance and settle transactional disputes in the global coal trading market. These organizations favor high-precision benchtop or laboratory-grade FTIR analyzers capable of handling diverse samples with high regulatory fidelity.

Finally, the mining and exploration sectors are also key end-users. Mining companies use these analyzers not only for final product quality control but also for geological mapping and segregation of coal seams (selective mining). By using portable or mobile analyzers in the field, they can make faster decisions on where to excavate and how to pre-process the raw material, optimizing resource utilization and minimizing the cost of moving waste material. In summary, the customer base ranges from high-volume processing facilities requiring inline monitoring to field operations requiring portable, robust analytical tools for immediate decision-making, all united by the necessity for fast, reliable coal quality metrics.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $115.5 Million |

| Market Forecast in 2033 | $171.1 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific, Foss Analytical, SICK AG, Bruker Corporation, Eralyze SAS, GE Measurement & Control, KETEK GmbH, Agilent Technologies, FLIR Systems, Mettler Toledo, Varian Medical Systems, Metrohm AG, Shanghai Gengxin Electronics, Hebei Smart Industrial Equipment Co., LTD, Shenyang New Concept Technology Co., Ltd., Unity Scientific, Shimadzu Corporation, PerkinElmer, SPECTRO Analytical Instruments, Hitachi High-Tech Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Infrared Rapid Coal Quality Analyzer Market Key Technology Landscape

The technological landscape of the Infrared Rapid Coal Quality Analyzer Market is dominated by spectroscopic methods, primarily Near-Infrared (NIR) and Fourier-Transform Infrared (FTIR) spectroscopy. NIR technology operates in the 780 nm to 2500 nm wavelength range, focusing on the absorption caused by overtones and combination bands of molecular bonds, particularly those involving hydrogen (C-H, O-H, N-H). This makes NIR highly effective for rapidly quantifying key coal parameters such as moisture, volatile matter, and calorific value. NIR analyzers are favored for inline applications due to their robustness, relatively low maintenance, and ability to penetrate granular materials sufficiently for surface analysis, providing immediate, actionable data on fast-moving conveyor belts.

FTIR technology, which falls under Mid-Infrared (MIR) spectroscopy (typically 2500 nm to 25,000 nm), offers a distinct advantage in generating highly detailed spectral fingerprints unique to molecular structures. Unlike NIR, FTIR directly measures fundamental vibrational modes, allowing for precise identification and quantification of complex organic and inorganic components, including various sulfur and nitrogen compounds crucial for emissions control and detailed geological characterization. While more sensitive to environmental factors like dust and vibration, FTIR is the preferred technology for high-precision laboratory analysis and the development of sophisticated primary calibration models that drive the accuracy of the faster, simpler NIR systems.

Beyond the core spectroscopic techniques, the market’s technological evolution is heavily reliant on advanced chemometrics and digitalization. Modern analyzers utilize multivariate statistical analysis (such as Principal Component Regression or Partial Least Squares) combined with large, dynamic calibration libraries to ensure accuracy across diverse sample matrices. Furthermore, connectivity—incorporating Industrial Internet of Things (IIoT) sensors, Ethernet/Wi-Fi communication, and cloud integration—is now standard. This connectivity facilitates remote monitoring, automated data logging, and seamless integration with plant Distributed Control Systems (DCS), transitioning the analyzer from a standalone instrument to an integral component of the plant’s automated operational intelligence network, thereby maximizing data utilization and system availability.

Regional Highlights

Regional dynamics significantly influence the adoption and growth rate of Infrared Rapid Coal Quality Analyzers, reflecting varying levels of industrialization, regulatory pressures, and indigenous coal reserves.

- Asia Pacific (APAC): This region is the undisputed leader in market size, driven by massive coal consumption in China and India for power generation and steel production. The urgent need to meet escalating energy demand while simultaneously tackling severe air pollution issues forces rapid adoption of advanced quality control technologies. Government initiatives promoting high-efficiency, low-emission (HELE) power plants fuel demand for continuous inline analysis systems.

- North America: Characterized by maturity and slower overall consumption growth, the market focuses on replacing aging infrastructure and ensuring strict environmental compliance. Demand here is high for sophisticated, reliable FTIR and NIR systems that minimize operational labor costs and provide superior accuracy for export certification and quality control of high-value metallurgical coal.

- Europe: Similar to North America, the European market is mature, with emphasis shifting toward analysis of imported coal and increasing utilization of biomass co-firing. Analyzers in this region require highly flexible calibration models to handle a diverse range of imported coal types and alternative fuels, with robust integration into advanced plant automation systems being a prerequisite.

- Latin America (LAMEA): This region represents significant growth potential, driven by expansion in mining activities (e.g., in Colombia and Brazil) and infrastructural development. Market entry is facilitated by demand for rugged, portable analyzers for exploration and initial product sorting, moving towards inline systems as large-scale ports and processing terminals are modernized.

- Middle East and Africa (MEA): Growth is primarily concentrated around developing regional power hubs and export-focused mining operations in South Africa. The focus is on implementing foundational quality control protocols, leading to steady demand for both benchtop units for quality assurance laboratories and robust inline systems for export terminal management, ensuring adherence to international contractual standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Infrared Rapid Coal Quality Analyzer Market.- Thermo Fisher Scientific

- Foss Analytical

- SICK AG

- Bruker Corporation

- Eralyze SAS

- GE Measurement & Control

- KETEK GmbH

- Agilent Technologies

- FLIR Systems

- Mettler Toledo

- Unity Scientific

- Shenyang New Concept Technology Co., Ltd.

- Shanghai Gengxin Electronics

- Hebei Smart Industrial Equipment Co., LTD

- Shimadzu Corporation

- PerkinElmer

- SPECTRO Analytical Instruments

- Hitachi High-Tech Corporation

- Varian Medical Systems

- Metrohm AG

Frequently Asked Questions

Analyze common user questions about the Infrared Rapid Coal Quality Analyzer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of infrared rapid coal quality analyzers over conventional laboratory methods?

The primary advantage is speed. Infrared analyzers provide non-destructive, near real-time results for critical parameters like calorific value and ash content within seconds or minutes, significantly reducing the operational delay incurred by traditional, labor-intensive wet chemistry methods which typically require hours.

Which key parameters can Infrared Rapid Coal Quality Analyzers accurately measure?

These analyzers accurately measure critical coal quality parameters including moisture content, ash content, volatile matter, fixed carbon, and, most importantly, the calorific value (BTU/MJ). Advanced systems can also estimate elemental composition like sulfur content and carbon percentage.

How does the deployment type (Inline vs. Portable) affect analyzer functionality and adoption?

Inline analyzers (on-belt systems) are deployed for continuous, high-volume monitoring in power plants, prioritizing throughput and integration with plant control systems. Portable analyzers prioritize flexibility and ease of transport for field testing, mining exploration, and smaller-scale quality verification points.

What is the role of chemometrics and calibration models in ensuring analyzer accuracy?

Chemometrics is crucial; it involves using multivariate statistical methods to transform raw spectral data into meaningful quality predictions. The accuracy of the analyzer relies entirely on robust, well-maintained calibration models that account for the diverse physical and chemical variations found in different coal samples.

Is the Infrared Rapid Coal Quality Analyzer Market susceptible to the global shift towards renewable energy?

While the long-term shift to renewables restrains demand for new large coal infrastructure, the market remains resilient due to the continued need for efficiency optimization and environmental compliance in existing coal operations. Analyzers also find increasing applications in monitoring alternative solid fuels like biomass co-fired with coal, diversifying their market application.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager