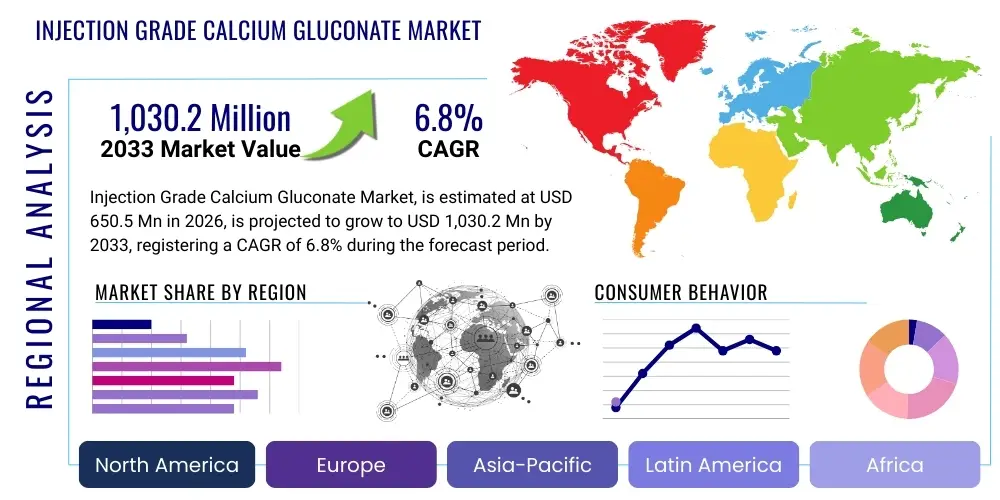

Injection Grade Calcium Gluconate Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436741 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Injection Grade Calcium Gluconate Market Size

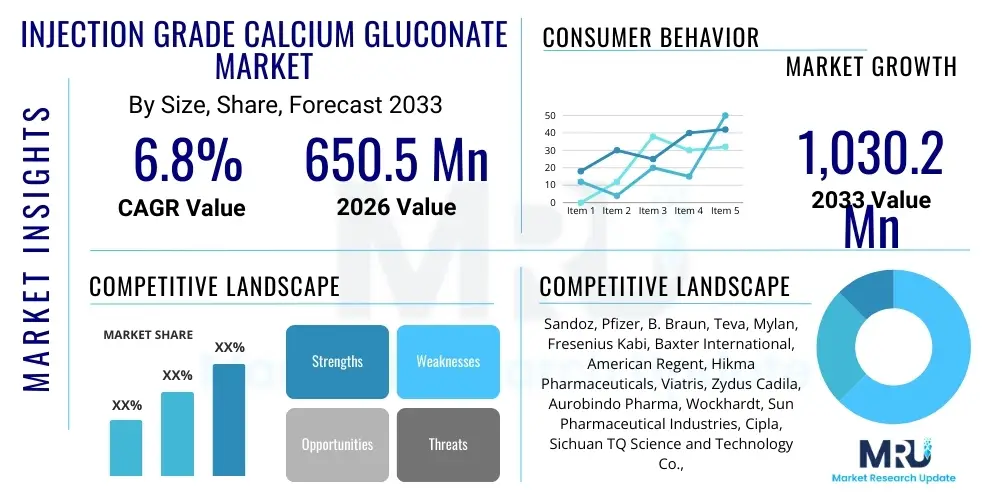

The Injection Grade Calcium Gluconate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 650.5 million in 2026 and is projected to reach USD 1,030.2 million by the end of the forecast period in 2033.

Injection Grade Calcium Gluconate Market introduction

The Injection Grade Calcium Gluconate Market encompasses the global manufacturing, distribution, and utilization of sterile calcium gluconate solutions administered intravenously. Calcium gluconate injection is an essential medication used primarily to treat acute hypocalcemia (low serum calcium levels), particularly in urgent clinical situations where rapid calcium restoration is required. This injectable formulation is crucial for managing severe conditions such as tetany, neonatal hypocalcemia, and certain adverse effects related to blood transfusions, positioning it as a cornerstone drug in hospital emergency departments and critical care units worldwide. The market growth is intricately linked to the rising global prevalence of chronic diseases that affect calcium homeostasis, including kidney disease and nutritional deficiencies, alongside an increasing number of complex surgical procedures requiring electrolyte management.

The product, chemically described as the calcium salt of gluconic acid, is preferred over calcium chloride in many clinical settings due to its lower risk of local tissue necrosis if extravasation occurs. Its major applications extend beyond simple deficiency correction, serving as a critical agent in treating hyperkalemia by stabilizing the cardiac membrane, managing magnesium sulfate overdose by reversing neuromuscular blockade, and acting as an antidote in specific poisoning cases. The inherent stability and established efficacy profile of the injection grade product ensure its continued demand across established healthcare systems and rapidly developing economies striving to enhance critical care infrastructure. Furthermore, regulatory bodies strictly govern the production and purity standards of injectable solutions, ensuring high-quality pharmaceutical-grade calcium gluconate is accessible to medical practitioners.

Driving factors for this specialized pharmaceutical market include the global expansion of geriatric populations, who are more susceptible to electrolyte imbalances and bone disorders; technological advancements in drug delivery systems ensuring improved bioavailability and safety; and greater penetration of insurance coverage across emerging markets, improving access to critical care medications. The fundamental therapeutic benefits, coupled with its inclusion on the World Health Organization's (WHO) List of Essential Medicines, solidify its market stability. However, the market faces constraints related to stringent pricing controls imposed by government procurement agencies and the potential for drug shortages stemming from complex manufacturing processes and reliance on specific raw material sourcing, demanding robust supply chain management from key market players.

Injection Grade Calcium Gluconate Market Executive Summary

The Injection Grade Calcium Gluconate Market is characterized by stable demand driven by mandatory use in critical care and emergency medicine, experiencing moderate growth fueled primarily by demographic changes and expanding critical care infrastructure globally. Business trends indicate a focus on manufacturing process optimization to mitigate supply chain vulnerabilities and ensure product purity, which is paramount for injectable pharmaceuticals. Leading manufacturers are investing in robust quality control systems to comply with stringent global regulatory requirements, such as those set by the FDA and EMA. Mergers and acquisitions remain low to moderate, focusing mainly on securing reliable API (Active Pharmaceutical Ingredient) sources and expanding geographic distribution networks into high-growth regions like Asia Pacific and Latin America, where healthcare spending is rapidly increasing and the need for essential medicines is acute. Patent expiry dynamics play a limited role as calcium gluconate is largely a generic, essential drug, placing competitive emphasis on cost efficiency and manufacturing scale.

Regional trends reveal that North America and Europe hold significant market share due to mature healthcare systems, high levels of critical care utilization, and established protocols for electrolyte management. However, the Asia Pacific region is poised for the highest growth rate, propelled by massive investments in public and private hospitals, increasing surgical volumes, and rising awareness regarding electrolyte disturbances, particularly in heavily populated countries like China and India. Middle East and Africa (MEA) present nascent but growing opportunities, particularly in Gulf Cooperation Council (GCC) countries benefiting from high healthcare expenditures and modernization efforts. Latin America demonstrates steady growth, influenced by improving access to emergency medical services and governmental initiatives aimed at stocking essential hospital supplies, though economic instability in certain nations poses a consistent challenge to consistent procurement and distribution.

Segment trends confirm that the application segment treating Hypocalcemia dominates the market share, given its wide range of underlying causes, from nutritional deficiencies to parathyroid disorders. Within end-users, Hospitals, particularly those with large Emergency Departments and Intensive Care Units (ICUs), remain the largest consumers due to the acute nature of conditions requiring immediate IV administration. Formulation-wise, the 10% solution is the standard and most frequently used concentration globally, although specialized pediatric and neonatal units may utilize lower concentrations. Future growth is anticipated within the Ambulatory Surgical Centers (ASCs) segment, reflecting the growing trend toward outpatient procedures, which still require immediate access to critical care drugs for unexpected complications, demanding smaller, distributed inventory management solutions across these decentralized facilities.

AI Impact Analysis on Injection Grade Calcium Gluconate Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Injection Grade Calcium Gluconate Market frequently center on supply chain reliability, predictive medicine applications, and enhanced clinical decision support systems. Users are keen to understand how AI can mitigate the historical risk of drug shortages common to essential injectable generics, asking specific questions about demand forecasting accuracy and raw material procurement optimization. Furthermore, significant interest exists in AI's role in clinical settings—specifically, whether AI algorithms can predict which critically ill patients are most likely to develop severe hypocalcemia requiring intervention, thereby enabling proactive rather than reactive administration. Concerns often revolve around the high initial investment cost required for implementing AI-driven manufacturing oversight and the regulatory hurdles associated with using AI for critical drug demand prediction in life-saving scenarios. Key themes emerging are efficiency improvements in manufacturing, enhanced supply chain resilience, and precision in clinical use.

In the manufacturing domain, AI is being deployed to optimize fermentation and purification processes involved in producing gluconic acid, ensuring higher yield consistency and purity compliance, which are vital for injection grade quality. Machine learning models analyze real-time data from bioreactors and filtration systems to identify anomalies and potential contamination risks faster than conventional quality assurance methods, substantially reducing batch rejection rates. This increased precision in process control directly addresses regulatory compliance challenges and enhances the consistency of the finished product. By utilizing predictive maintenance, AI also minimizes downtime in high-volume production lines, contributing significantly to maintaining stable supply levels and preventing the localized shortages that often plague the market for essential, low-cost generics.

From a clinical perspective, AI tools are integrated into Electronic Health Records (EHRs) and Critical Care Information Systems (CCIS) to provide advanced decision support for physicians. Algorithms analyze complex patient data—including renal function, existing drug regimens (e.g., proton pump inhibitors, diuretics), and pre-existing conditions—to identify patients at high risk of rapid electrolyte destabilization. This capability allows for more timely monitoring and immediate preparation of Calcium Gluconate Injection, transforming emergency response protocols. Moreover, AI aids in pharmacokinetic modeling, helping clinicians determine optimal dosing strategies for patients with varying metabolic rates and comorbidities, thereby maximizing therapeutic effect while minimizing risks associated with hypercalcemia, particularly crucial in sensitive patient populations such as neonates and those with severe cardiac impairment.

- AI optimizes global supply chain logistics, drastically improving demand forecasting accuracy for essential generics.

- Machine learning enhances manufacturing purity and consistency through real-time contamination detection in API production.

- Predictive analytics in Critical Care Information Systems (CCIS) identify high-risk patients needing proactive calcium intervention.

- AI supports clinical decision-making by recommending precise, individualized dosing based on patient-specific physiological data.

- Automation, powered by AI vision systems, ensures higher quality control in the sterile filling and packaging of injectables.

- Advanced algorithms analyze post-market surveillance data to rapidly detect and address potential drug adverse events or purity issues.

DRO & Impact Forces Of Injection Grade Calcium Gluconate Market

The market for Injection Grade Calcium Gluconate is subject to a complex interplay of Drivers, Restraints, and Opportunities (DRO) which collectively dictate its trajectory and market forces. A primary driver is the indispensable nature of the product in treating life-threatening conditions such as severe symptomatic hypocalcemia, hyperkalemia, and magnesium toxicity, ensuring consistent, inelastic demand regardless of economic fluctuations. Furthermore, the global rise in chronic kidney disease (CKD) and sepsis—conditions routinely causing severe electrolyte imbalances—acts as a continuous demand generator within hospital settings. However, the market faces significant restraints, principally defined by intense price competition inherent to the generic injectable segment, which exerts downward pressure on profit margins. Additionally, the recurring susceptibility to global supply chain disruptions and stringent regulatory oversight concerning sterile manufacturing practices present substantial operational hurdles that manufacturers must constantly overcome to maintain market presence and product availability.

Opportunities for market expansion are centered on penetrating underserved emerging markets, particularly in regions where critical care infrastructure is rapidly developing but access to essential medicines remains inconsistent. Manufacturers have the chance to secure long-term procurement contracts with government bodies and international aid organizations focusing on building robust public health systems. Additionally, process innovation presents a key opportunity; developing more stable, ready-to-use formulations (e.g., pre-filled syringes) that simplify administration, reduce preparation errors, and enhance efficiency in emergency settings can command a slight premium and differentiate products in a highly commoditized market. Focusing research and development efforts on novel stabilization techniques to extend shelf life in varying climate conditions also opens avenues for expansion into geographically challenging regions, enhancing global distribution resilience and reaching remote healthcare facilities.

The impact forces within this market are predominantly high, owing to the critical clinical utility of calcium gluconate. Regulatory Impact is extremely high; any deviation in purity or sterility compliance leads to mandatory product recalls, instantly impacting market reputation and supply. Economic Impact is moderate to high; while the product cost itself is low, its use is non-discretionary in critical care, maintaining fundamental sales stability, but intense generic competition prevents significant price appreciation. Technological Impact focuses less on creating novel molecules and more on optimizing manufacturing reliability (as seen with AI) and improving safety profiles through better packaging and delivery formats, ensuring consistent, high-quality supply is the competitive edge. The ultimate impact force is the Clinical Need; as long as critical care medicine exists and diseases causing acute electrolyte shifts prevail, the demand for Injection Grade Calcium Gluconate remains permanently secured, making it a foundationally resilient segment of the pharmaceutical market.

Segmentation Analysis

The Injection Grade Calcium Gluconate Market is meticulously segmented based on Application, Formulation, and End-User, allowing for detailed analysis of consumption patterns and demand drivers across different clinical environments. This segmentation is crucial for manufacturers to tailor their production volumes and distribution strategies, ensuring products reach the points of greatest need, such as high-volume critical care units or specialized pediatric wards. Understanding the market dynamics across these segments highlights the concentration of demand in emergency and specialized medical fields. The dominance of Hypocalcemia treatment reflects the wide etiology of conditions leading to calcium depletion, spanning from specific endocrine disorders to general malnutrition and acute illnesses requiring massive fluid resuscitation.

Segmentation by Formulation primarily separates the market into the standard 10% solution and other concentrations (5% or less), reflecting the regulatory and clinical preference for a highly concentrated standard dose suitable for rapid infusion in adults, while lower concentrations cater to neonatal and precise pediatric dosing requirements. The End-User segmentation provides insight into procurement volumes, with Hospitals—encompassing trauma centers, general ICUs, and operating theaters—representing the bulk of demand due to their operational capacity to manage critical, acute cases. Non-hospital settings, while smaller in volume, represent a growing area as out-of-hospital emergency medical services (EMS) and Ambulatory Surgical Centers (ASCs) increasingly stock essential critical care medications to manage unforeseen complications during procedures or transport.

Detailed analysis of these segments confirms that market growth will be driven not just by increasing volume consumption in high-traffic end-users (Hospitals), but also by the need for customized product presentations (Formulation) that enhance safety and efficiency in acute care environments. The ongoing necessity for this essential medicine ensures stability across all segments, but strategic focus on optimizing supply chains to meet sudden regional spikes in demand related to trauma or infectious disease outbreaks, which often destabilize electrolyte levels, offers a significant competitive advantage. Manufacturers are also increasingly observing the market for specialized indications outside of core uses, such as emerging off-label applications, which, if validated, could incrementally shift application segment share.

- By Application:

- Hypocalcemia (Primary Segment)

- Hyperkalemia

- Magnesium Sulfate Overdose (Antidote)

- Cardiac Arrest

- Calcium Channel Blocker Toxicity

- By Formulation:

- 10% Solution (Standard Concentration)

- 5% Solution and Other Low Concentrations

- By End-User:

- Hospitals (ICUs, Emergency Departments, Operating Rooms)

- Clinics

- Ambulatory Surgical Centers (ASCs)

- Emergency Medical Services (EMS)

Value Chain Analysis For Injection Grade Calcium Gluconate Market

The Value Chain for Injection Grade Calcium Gluconate is relatively straightforward but highly sensitive, beginning with the upstream production of raw materials. The key raw material is gluconic acid, typically produced through fermentation of glucose (often derived from corn starch or other carbohydrate sources). Upstream analysis involves assessing the reliability and consistency of glucose suppliers and the biotechnology firms specializing in the fermentation process. Consistency in raw material quality is non-negotiable, as impurities at this stage directly impact the final purity required for sterile injectable production. Manufacturers must establish stringent quality agreements and maintain diversified sourcing strategies to mitigate dependence on a single geographical or economic region, particularly since fluctuations in agricultural commodity prices can indirectly influence overall production costs, although typically, the value added downstream in sterile formulation overshadows raw material price volatility.

The midstream stage involves the highly regulated manufacturing and sterile formulation of the injectable product. This is the stage where most of the regulatory scrutiny, capital expenditure, and specialized technical expertise reside. It encompasses the chemical synthesis of calcium gluconate from gluconic acid, followed by purification, sterile filtration, and aseptic filling into vials or ampoules. Due to the high risk of contamination in injectable manufacturing, facilities must adhere to Current Good Manufacturing Practices (cGMP) standards established by global health authorities. The efficiency of this stage, including yield rates and minimizing batch recalls, directly determines the competitiveness and profitability of the finished product. Market leaders distinguish themselves through proprietary stabilization techniques that ensure a longer shelf life and maintain solution clarity, a critical quality parameter for injectable products.

Downstream analysis focuses on distribution channels, which are vital for this essential, life-saving drug that requires swift deployment. Distribution is predominantly indirect, flowing from pharmaceutical manufacturers to centralized hospital group purchasing organizations (GPOs), major national drug wholesalers, and specialized medical distributors. Direct sales are minimal, usually restricted to large-volume government contracts or direct sales to massive hospital networks. The cold chain requirements are generally less stringent than for biologics, but secure and rapid logistics are crucial due to the product's immediate need in emergency settings. Potential customers, including Hospitals and EMS providers, prioritize established suppliers with proven track records of reliable supply and product consistency, underscoring the importance of robust logistics networks capable of supporting just-in-time inventory systems across a complex global market.

Injection Grade Calcium Gluconate Market Potential Customers

The primary customer base for Injection Grade Calcium Gluconate consists of institutions and organizations involved in acute patient care, where prompt intervention for critical electrolyte imbalances is mandatory. Hospitals, specifically their Emergency Departments (EDs), Intensive Care Units (ICUs), Cardiac Care Units (CCUs), and Operating Rooms (ORs), represent the overwhelming majority of end-users. These facilities require continuous, high-volume inventory due to the frequent presentation of patients suffering from conditions such as severe sepsis, massive trauma requiring multiple blood transfusions (which can chelate calcium), acute renal failure, and drug overdoses (particularly magnesium sulfate in obstetrics). Procurement decisions are driven by internal Pharmacy and Therapeutics (P&T) committees, prioritizing product reliability, safety presentation (e.g., lack of preservatives, ease of administration), and competitive pricing secured through GPO contracts.

Beyond traditional hospital settings, the market is increasingly served by specialized, high-acuity facilities such as Ambulatory Surgical Centers (ASCs) and specialized critical care clinics. Although ASCs perform elective, low-risk procedures, they are mandated to maintain crash carts stocked with essential emergency medications, including calcium gluconate, to address unexpected anesthetic complications or cardiac events. This customer segment places a premium on ready-to-use formats (pre-filled syringes) that streamline emergency protocols and reduce the risk of dosing errors in high-stress situations. Similarly, standalone dialysis centers also constitute a recurring customer group, as chronic kidney patients frequently suffer from deranged calcium and phosphate metabolism, requiring prophylactic or acute calcium supplementation.

Furthermore, Emergency Medical Services (EMS) organizations and military field hospitals represent crucial end-users. EMS teams require injectable calcium gluconate in their ambulances and rescue helicopters for immediate pre-hospital treatment of severe hyperkalemia or cardiac arrest management protocols, where time is a critical factor. These organizations typically procure through government tenders or specialized distributors handling tactical medical supplies. The decision to purchase in these segments is highly influenced by regulatory guidelines and standardized protocols, emphasizing the necessity of robust, temperature-stable products suitable for storage and use in varied field environments. Ultimately, the entire potential customer ecosystem is united by the need for an assured, high-quality, and readily available supply of this essential injectable medication.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650.5 million |

| Market Forecast in 2033 | USD 1,030.2 million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sandoz, Pfizer, B. Braun, Teva, Mylan, Fresenius Kabi, Baxter International, American Regent, Hikma Pharmaceuticals, Viatris, Zydus Cadila, Aurobindo Pharma, Wockhardt, Sun Pharmaceutical Industries, Cipla, Sichuan TQ Science and Technology Co., Ltd., Akorn Operating Company LLC, Hospira (a Pfizer Company), Luitpold Pharmaceuticals. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Injection Grade Calcium Gluconate Market Key Technology Landscape

The technology landscape for Injection Grade Calcium Gluconate centers less on novel drug discovery and more heavily on advanced manufacturing processes that ensure product safety, stability, and ease of administration. A crucial technological focus is Aseptic Processing and Terminal Sterilization techniques. Since calcium gluconate is administered intravenously into critically ill patients, achieving and maintaining the highest standards of sterility is non-negotiable. Manufacturers utilize sophisticated controlled environment technologies, including advanced HVAC systems, HEPA filtration, and isolator technology, to minimize the risk of particulate contamination and microbial ingress during the filling process. Continuous process verification and validation using Process Analytical Technology (PAT) tools are becoming standard, providing real-time quality assurance data that significantly reduces batch-to-batch variability and enhances regulatory compliance across global jurisdictions.

Another significant technological area is the development of advanced drug delivery and packaging systems. Historically, calcium gluconate was supplied in glass vials, which carry risks of breakage and incompatibility with certain hospital plastics or admixture components. Modern technological advances include the transition to non-PVC bags, pre-filled syringes, and standardized plastic ampoules. Pre-filled syringes are particularly important as they eliminate the need for aspiration and dilution, minimizing the potential for medication errors and reducing preparation time in time-sensitive critical care scenarios. These advanced containers often incorporate technologies to enhance chemical stability, such as oxygen scavengers or specialized glass coatings, ensuring the long-term integrity of the solution, which is prone to precipitation or crystallization under suboptimal storage conditions.

Furthermore, technology related to API synthesis and optimization plays a foundational role. While the chemical formula is established, optimizing the fermentation process for gluconic acid production to achieve high yields and extremely low levels of relevant impurities (such as endotoxins and heavy metals) is a constant area of focus. Companies leverage modern bioprocessing technologies, including genetically engineered microbes and advanced bioreactor designs, to improve efficiency. The integration of serialization and track-and-trace technologies (e.g., 2D matrix codes) at the packaging level is also a critical technological requirement, particularly in developed markets, designed to combat pharmaceutical counterfeiting and ensure the integrity of the supply chain from the manufacturing floor to the patient bedside, addressing significant concerns about drug safety and authenticity.

Regional Highlights

Regional dynamics play a crucial role in shaping the Injection Grade Calcium Gluconate Market, reflecting disparities in healthcare expenditure, regulatory frameworks, and demographic patterns. North America, particularly the United States, commands a substantial market share, characterized by high spending on critical care, advanced hospital infrastructure, and standardized emergency medical protocols that mandate the immediate availability of essential injectable drugs. Demand remains stable, driven by high chronic disease prevalence (e.g., diabetes, renal failure) and sophisticated trauma care. The region is marked by intense generic competition and centralized procurement via large GPOs, pressuring manufacturers to maintain impeccable supply chain reliability and cost-efficiency to secure lucrative national contracts. Strict regulatory oversight ensures minimal quality variation, making market entry challenging for new generic players.

Europe represents another mature and sizable market, where utilization is robust, influenced by the well-established public healthcare systems across the continent. Western European nations, including Germany, France, and the UK, maintain high consumption rates due to comprehensive coverage of critical care treatments. Procurement in Europe is often governed by national tenders or centralized regional hospital purchasing groups, where pricing and supply consistency are paramount. Eastern Europe is experiencing moderate growth, correlated with ongoing investments in hospital modernization and the harmonization of healthcare standards with the EU, creating increasing demand for high-quality essential injectables. Regulatory adherence to the European Medicines Agency (EMA) standards dictates the quality parameters for market participants across the region.

The Asia Pacific (APAC) region is projected to be the fastest-growing market segment throughout the forecast period. This growth is primarily fueled by rapid economic development, significant government investment in healthcare infrastructure expansion (especially in India and China), and a burgeoning population that is both aging and increasingly accessing modernized medical services. While pricing remains highly sensitive, the sheer volume of patients and the expansion of critical care units drive exponential demand growth. Manufacturers often adopt dual strategies: premium quality positioning for developed APAC nations (like Japan and South Korea) and high-volume, cost-competitive manufacturing for emerging economies. Latin America and the Middle East & Africa (MEA) offer niche opportunities, particularly as major urban centers in Brazil, Mexico, Saudi Arabia, and South Africa continue to upgrade their emergency and intensive care facilities, increasing the need for reliably supplied, essential acute medications.

- North America (US and Canada): Market dominance driven by established critical care infrastructure and high chronic disease burden; focus on supply resilience and GPO contract negotiation.

- Europe (Germany, UK, France): Stable, mature market with demand guaranteed by public healthcare protocols; procurement highly sensitive to pricing and regulatory compliance (EMA).

- Asia Pacific (China, India, Japan): Highest growth trajectory fueled by massive hospital expansion, rising geriatric population, and improving insurance penetration; market characterized by high volume and increasing quality standards.

- Latin America (Brazil, Mexico): Steady growth linked to improving emergency medical services and governmental stocking programs; demand subject to regional economic stability.

- Middle East and Africa (GCC Countries, South Africa): Emerging market opportunities driven by healthcare tourism and modernization efforts; demand concentration in urban and affluent areas.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Injection Grade Calcium Gluconate Market.- Sandoz (Novartis AG)

- Pfizer Inc. (including Hospira products)

- B. Braun Melsungen AG

- Teva Pharmaceutical Industries Ltd.

- Mylan N.V. (Viatris)

- Fresenius Kabi AG

- Baxter International Inc.

- American Regent, Inc.

- Hikma Pharmaceuticals PLC

- Zydus Cadila Healthcare Ltd.

- Aurobindo Pharma Limited

- Wockhardt Ltd.

- Sun Pharmaceutical Industries Ltd.

- Cipla Ltd.

- Akorn Operating Company LLC

- Sichuan TQ Science and Technology Co., Ltd.

- Luitpold Pharmaceuticals, Inc.

- Dr. Reddy's Laboratories Ltd.

- Grifols, S.A.

- CSPC Pharmaceutical Group Limited

Frequently Asked Questions

Analyze common user questions about the Injection Grade Calcium Gluconate market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary clinical indications for Injection Grade Calcium Gluconate?

The injection is primarily used for the emergency treatment of acute, symptomatic hypocalcemia, particularly conditions causing tetany. It is also critical for managing hyperkalemia (high potassium levels) by stabilizing the heart muscle membrane and acts as an immediate antidote for magnesium sulfate overdose.

How does the generic nature of Calcium Gluconate Injection affect market pricing and competition?

As calcium gluconate is an essential, generic medicine, the market experiences intense price competition. Profitability relies heavily on manufacturing scale, supply chain efficiency, and securing large-volume contracts through Group Purchasing Organizations (GPOs), driving down unit costs while prioritizing supply reliability.

Which geographical region is expected to demonstrate the highest growth rate in this market?

The Asia Pacific (APAC) region, led by China and India, is forecasted to exhibit the highest Compound Annual Growth Rate (CAGR). This acceleration is due to rapid development of critical care infrastructure, increasing healthcare access, and a large patient population requiring acute medical intervention.

What regulatory challenges face manufacturers in the Injection Grade Calcium Gluconate Market?

Manufacturers face extremely stringent regulatory challenges, particularly concerning maintaining cGMP standards for aseptic processing. Regulators (such as the FDA and EMA) demand exceptionally high purity levels, strict control over endotoxins, and robust evidence of stability throughout the product's shelf life, often leading to costly compliance measures.

How are technological advancements impacting the delivery of Calcium Gluconate Injection?

Technology is focusing on enhanced delivery systems, moving from traditional vials to safer, more efficient options like pre-filled syringes and non-PVC bags. These innovations reduce preparation time, minimize medication errors in critical settings, and improve overall product stability and safety for hospital staff and patients.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager