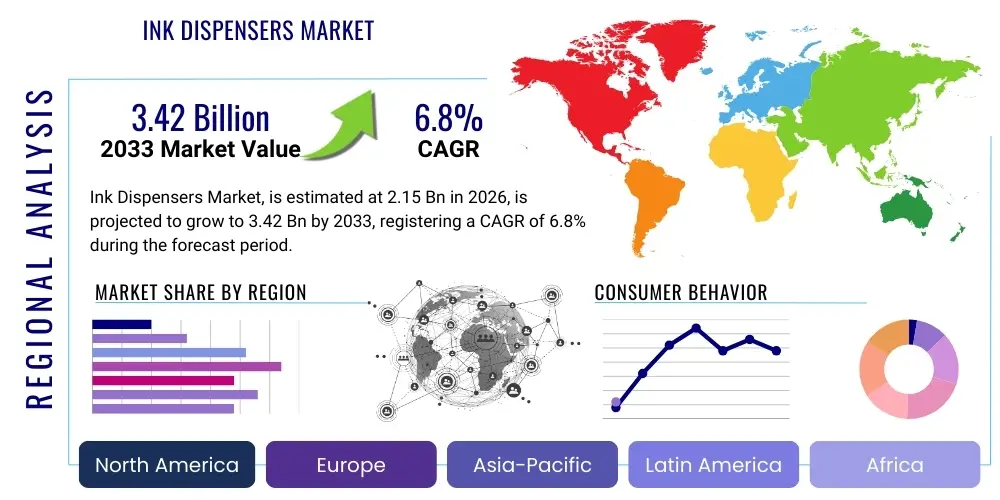

Ink Dispensers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439439 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Ink Dispensers Market Size

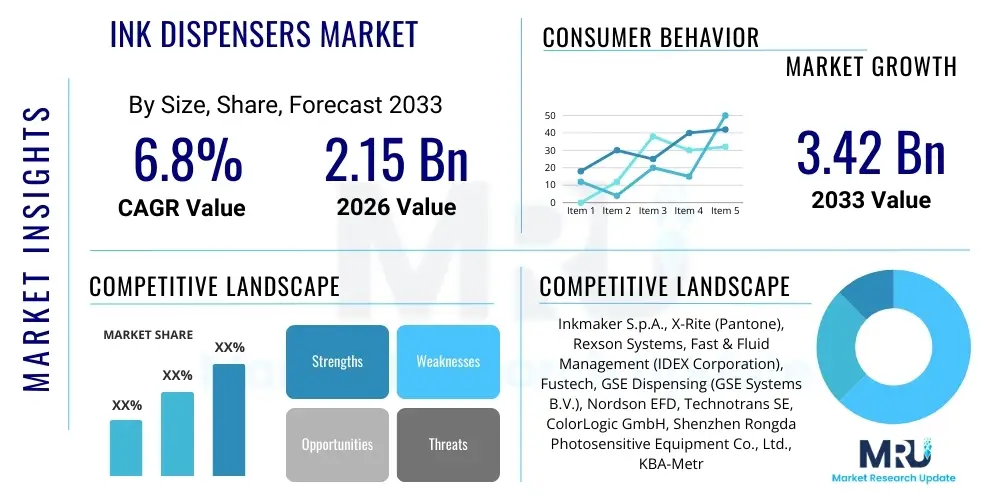

The Ink Dispensers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 2.15 Billion in 2026 and is projected to reach USD 3.42 Billion by the end of the forecast period in 2033.

Ink Dispensers Market introduction

The Ink Dispensers Market is a critical segment within the broader printing and packaging industries, providing automated and precise solutions for the formulation, mixing, and dispensing of printing inks. These systems are designed to ensure color accuracy, consistency, and efficiency in ink preparation, ranging from basic manual units to sophisticated fully automated systems integrated into complex production lines. The core product, an ink dispenser, automates the measurement and mixing of base inks and additives according to predefined recipes, significantly reducing human error and material waste. Major applications span across various printing methods, including flexography, gravure, screen printing, and increasingly, digital printing, serving industries such as packaging, textiles, commercial printing, and specialized industrial applications. The primary benefits derived from these systems include enhanced color matching capabilities, faster production cycles, reduced labor costs, improved inventory management of base inks, and significant waste reduction through precise material usage. Driving factors for market expansion include the burgeoning demand for high-quality, consistent color reproduction in consumer goods packaging, the rising adoption of automation to optimize manufacturing processes, the need for quick turnaround times in print jobs, and growing sustainability concerns that push for efficient resource utilization and minimized waste in the ink preparation process. Furthermore, the ability of modern ink dispensing systems to handle a diverse array of ink chemistries, from solvent-based to water-based and UV-curable, broadens their applicability and drives market penetration across various sectors seeking specialized printing solutions. The continuous evolution in printing technologies and the imperative for operational excellence are consistently fueling the advancement and adoption of ink dispensing systems globally, cementing their role as indispensable tools in modern print production.

Ink Dispensers Market Executive Summary

The Ink Dispensers Market is currently experiencing robust growth, primarily driven by the escalating demand for automation and precision in the global printing industry. Business trends indicate a strong shift towards integrated smart dispensing systems that offer real-time data analytics, remote monitoring, and seamless integration with existing enterprise resource planning (ERP) systems, allowing for optimized workflow and improved supply chain management. Companies are increasingly investing in advanced dispensing technologies to achieve higher color consistency, reduce waste, and enhance operational efficiency, especially in sectors with stringent quality requirements such as food packaging and pharmaceuticals. Regional trends highlight significant market expansion in Asia Pacific, propelled by rapid industrialization, the proliferation of printing and packaging hubs, and increasing disposable incomes fueling consumer demand for packaged goods. North America and Europe continue to be strong markets, characterized by early adoption of advanced technologies, a focus on sustainable manufacturing practices, and a mature infrastructure for high-volume, high-quality printing. Latin America, the Middle East, and Africa are emerging as promising markets, albeit with varying paces of adoption, driven by investments in manufacturing capabilities and a growing consumer base. Segment trends reveal a strong preference for automatic and semi-automatic ink dispensing systems over manual alternatives, driven by the need for higher throughput and accuracy. Furthermore, demand for systems capable of handling UV-curable and water-based inks is on the rise, aligning with environmental regulations and industry shifts towards more sustainable ink formulations. The packaging segment remains the largest application area, benefitting from intricate designs and rapid product cycles, while industrial and textile printing segments are also showing accelerated growth due to increased customization and specialty printing demands. The market's competitive landscape is defined by continuous innovation, strategic partnerships, and a focus on providing comprehensive service and support to diverse end-users.

AI Impact Analysis on Ink Dispensers Market

User questions related to the impact of AI on the Ink Dispensers Market frequently revolve around how artificial intelligence can enhance color accuracy, automate predictive maintenance, optimize ink inventory, and streamline the overall dispensing process. Key themes indicate a strong expectation for AI to move beyond basic automation, offering intelligent solutions for complex color matching scenarios, reducing human intervention, and providing data-driven insights for improved operational efficiency and cost savings. Users are keen to understand how AI algorithms can learn from past dispensing data to minimize errors, predict future ink consumption, and even adapt dispensing recipes in real-time based on environmental conditions or substrate variations, ultimately leading to superior print quality and reduced material waste. Concerns often include the initial investment costs, the complexity of integrating AI systems with legacy equipment, data security implications, and the need for skilled personnel to manage and leverage AI-powered dispensing technologies effectively. Expectations are high for AI to deliver truly autonomous ink kitchen operations, fostering a new era of smart manufacturing in the printing industry.

- AI-driven color matching: Artificial intelligence algorithms can analyze vast datasets of color profiles, substrate properties, and environmental conditions to achieve unparalleled color accuracy and consistency, significantly reducing trial-and-error iterations and setup times.

- Predictive maintenance: AI models can monitor the performance of ink dispensing equipment in real-time, predicting potential failures and scheduling maintenance proactively, thereby minimizing downtime, extending equipment lifespan, and preventing costly production interruptions.

- Optimized ink inventory management: AI can analyze historical consumption data, current production schedules, and future forecasts to optimize base ink and additive inventory levels, reducing excess stock, mitigating obsolescence, and ensuring timely replenishment.

- Automated recipe generation and adaptation: AI systems can learn and adapt ink recipes based on printing results, operator feedback, and even real-time sensor data, autonomously adjusting formulations for optimal performance across different print jobs and materials.

- Enhanced quality control: AI-powered vision systems integrated with dispensers can detect minute inconsistencies in ink formulation or dispensed volumes, ensuring stringent quality control standards are met before the ink reaches the press.

- Energy efficiency and sustainability: AI can optimize the dispensing process to minimize waste, reduce energy consumption, and promote the use of environmentally friendly ink formulations, contributing to the overall sustainability goals of printing operations.

- Integration with smart factories: AI facilitates seamless integration of ink dispensing systems into broader Industry 4.0 frameworks, enabling centralized control, data exchange, and holistic optimization across the entire printing and packaging value chain.

DRO & Impact Forces Of Ink Dispensers Market

The Ink Dispensers Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, collectively shaping its growth trajectory and competitive landscape. A primary driver is the accelerating demand for automation and precision in the global printing and packaging industries. Manufacturers are under constant pressure to deliver high-quality, consistent print products with faster turnaround times, making automated ink dispensing systems indispensable for achieving color accuracy, reducing manual errors, and optimizing operational efficiency. The increasing complexity of print jobs, requiring a wider palette of custom colors and shorter production runs, further necessitates the agility and precision offered by advanced dispensing solutions. Furthermore, the rising focus on sustainability and waste reduction within the printing sector acts as a significant driver, as precise ink dispensing minimizes material waste and contributes to more environmentally responsible manufacturing practices. The growth of emerging markets, particularly in Asia Pacific, Latin America, and Africa, driven by increasing consumer spending and industrial expansion, also presents a substantial opportunity for market players to penetrate new geographies and cater to evolving printing demands. However, the market faces notable restraints, including the high initial capital investment required for sophisticated automatic dispensing systems, which can be a barrier for small and medium-sized enterprises (SMEs) with limited budgets. The complexity of integration with existing printing infrastructures and the need for specialized technical expertise for operation and maintenance also pose challenges. Opportunities lie in the continuous technological advancements, such as the integration of AI and IoT for predictive maintenance and enhanced color management, as well as the development of modular and scalable systems that can cater to a broader range of printing operations. The shift towards sustainable and specialized ink formulations, including water-based and UV-curable inks, also creates new avenues for innovation and market expansion for dispensing equipment designed to handle these specific chemistries. The overall impact forces are pushing the market towards greater intelligence, efficiency, and sustainability, forcing industry players to continuously innovate and adapt to stay competitive and meet the evolving demands of the global printing landscape.

Segmentation Analysis

The Ink Dispensers Market is extensively segmented to reflect the diverse applications, technological variations, and operational requirements across the global printing and packaging industry. This segmentation provides a granular view of market dynamics, enabling stakeholders to understand specific growth drivers, competitive landscapes, and opportunities within niche segments. The market is primarily categorized by the type of dispenser, the type of ink handled, the application sector, the end-use industry, and the level of automation, each influencing purchasing decisions and market penetration. Analyzing these segments helps in identifying trends such as the increasing demand for automatic systems in high-volume production environments, the growing preference for dispensers capable of handling eco-friendly ink types, and the expanding use of these systems beyond traditional commercial printing into specialized industrial applications. Each segment possesses unique characteristics, driving varying levels of adoption and technological advancements, which are crucial for strategic planning and product development within the market.

- By Type:

- Gravity Feed Dispensers

- Pump-Driven Dispensers

- Pressure Feed Dispensers

- Volume-based Dispensers

- Weight-based Dispensers

- By Ink Type:

- Solvent-based Ink Dispensers

- Water-based Ink Dispensers

- UV-curable Ink Dispensers

- Dye-based Ink Dispensers

- Pigment-based Ink Dispensers

- Specialty Ink Dispensers (e.g., metallic, fluorescent)

- By Application:

- Packaging Printing (flexible, rigid)

- Textile Printing

- Commercial Printing (magazines, brochures)

- Industrial Printing (ceramics, automotive)

- Digital Printing (as part of hybrid systems)

- Label Printing

- Decorative Printing

- Publication Printing

- By End-Use Industry:

- Food & Beverage Industry

- Pharmaceutical Industry

- Automotive Industry

- Electronics Industry

- Apparel Industry

- Construction Industry

- Consumer Goods Industry

- Publishing Industry

- By Operation:

- Manual Ink Dispensers

- Semi-Automatic Ink Dispensers

- Automatic Ink Dispensers

- By Component:

- Hardware (pumps, valves, weighing scales, tanks)

- Software (color management, recipe management, reporting)

- Services (installation, maintenance, training)

Value Chain Analysis For Ink Dispensers Market

The value chain for the Ink Dispensers Market begins with the upstream analysis, which primarily involves the raw material suppliers and component manufacturers crucial for building these sophisticated systems. This segment includes suppliers of precision pumps, valves, weighing scales, sensors, control systems, software components, and various metal and plastic fabrication partners. The quality and availability of these specialized components directly impact the final product's performance, reliability, and cost-effectiveness. Key upstream activities focus on research and development for advanced materials, miniaturization, and enhanced sensor technologies to improve dispensing accuracy and longevity. Manufacturers of ink dispensing systems then integrate these components, focusing on design, assembly, and rigorous testing of the units. This stage involves significant investment in engineering expertise and advanced manufacturing processes to ensure the precision and robustness required for industrial applications. Distribution channels play a pivotal role, encompassing both direct and indirect routes. Direct sales are often preferred for larger, highly customized automatic systems, where manufacturers engage directly with major printing houses, packaging companies, and industrial clients, providing tailored solutions, installation, and extensive post-sales support. This direct engagement fosters deeper client relationships and facilitates direct feedback for product improvement. Indirect channels involve a network of distributors, agents, and resellers, particularly for standardized or semi-automatic systems, allowing for broader market reach, especially in regions where manufacturers may not have a direct presence. These intermediaries often provide local sales support, basic installation, and initial technical assistance, acting as crucial links to smaller and medium-sized print shops. The downstream analysis focuses on the end-users—printing companies, packaging converters, textile manufacturers, and industrial printing facilities—who utilize these dispensers for ink preparation. This stage involves equipment installation, calibration, operator training, ongoing maintenance, and the supply of base inks and consumables. Effective after-sales service, technical support, and the availability of spare parts are critical for maintaining customer satisfaction and ensuring the continuous operation of dispensing systems. The efficiency of the entire value chain, from raw material sourcing to end-user support, is paramount in delivering high-quality, reliable, and cost-effective ink dispensing solutions to the global market, with technological innovation at each stage driving competitive advantage.

Ink Dispensers Market Potential Customers

The potential customers for Ink Dispensers Market are diverse, primarily comprising entities within the global printing and packaging ecosystem that require precise, consistent, and efficient ink management. These end-users, or buyers of the product, range from large-scale industrial printing houses to specialized small and medium-sized enterprises (SMEs) engaged in various forms of print production. The largest segment of potential customers includes packaging converters, who produce flexible packaging, rigid packaging, labels, and corrugated boxes for industries like food and beverage, pharmaceuticals, cosmetics, and consumer goods. These converters demand high color accuracy and quick changeovers, making automated ink dispensing systems indispensable for their high-volume, short-run production environments. Textile printing companies represent another significant customer base, especially those involved in digital and screen printing for apparel, home furnishings, and industrial textiles, where color consistency and recipe management are crucial for brand integrity and operational efficiency. Commercial printers, producing magazines, brochures, advertising materials, and promotional items, also constitute a core market, relying on ink dispensers to manage diverse color requirements and optimize ink usage across various print jobs. Furthermore, industrial printing applications, such as printing on ceramics, glass, automotive components, and electronics, are increasingly adopting ink dispensing technologies to handle specialized ink formulations and achieve precise decorative or functional prints. Digital printing service providers, particularly those operating hybrid systems that combine digital and conventional printing, find value in ink dispensers for managing spot colors and specialized ink requirements. The growth of these diverse end-use sectors, driven by evolving consumer demands, stringent quality standards, and the imperative for cost reduction and sustainability, directly fuels the demand for advanced ink dispensing solutions. Ultimately, any business involved in print production that seeks to minimize ink waste, reduce labor costs, improve color accuracy, and enhance overall operational efficiency is a potential customer for ink dispensing systems, reflecting a broad and expanding market reach across the manufacturing landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.15 Billion |

| Market Forecast in 2033 | USD 3.42 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Inkmaker S.p.A., X-Rite (Pantone), Rexson Systems, Fast & Fluid Management (IDEX Corporation), Fustech, GSE Dispensing (GSE Systems B.V.), Nordson EFD, Technotrans SE, ColorLogic GmbH, Shenzhen Rongda Photosensitive Equipment Co., Ltd., KBA-Metronic AG, SPS TechnoScreen GmbH, GRM Systems, InkLogic (Global Graphics Software), Ink Management Systems (IMS), TRESU Group, Bobst Group SA, Mark Andy Inc., Gallus Ferd. Rüesch AG (Heidelberg Group), Koenig & Bauer AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ink Dispensers Market Key Technology Landscape

The Ink Dispensers Market is characterized by a rapidly evolving technology landscape, with continuous innovation driving improvements in precision, automation, connectivity, and sustainability. The fundamental technology revolves around sophisticated dosing and mixing mechanisms, primarily employing gravimetric (weight-based) or volumetric (volume-based) dispensing principles to achieve extreme accuracy. Gravimetric systems, equipped with high-precision load cells, are particularly favored for their ability to deliver precise quantities of ink components, critical for color matching and minimizing waste. Advanced pump technologies, including diaphragm, peristaltic, and gear pumps, are integral to controlling ink flow and managing various ink viscosities and chemistries, from solvent-based to highly viscous UV-curable inks. Beyond the core mechanics, the integration of advanced software is a paramount technological development. Modern ink dispensing systems feature sophisticated color management software that can store, retrieve, and adjust an extensive library of ink recipes, integrate with spectrophotometers for real-time color measurement, and automatically correct formulas to match specific color standards like Pantone or custom brand colors. These software platforms often include inventory management modules that track base ink consumption, automate reordering, and provide detailed reporting on usage and waste. Connectivity features, driven by Industry 4.0 principles, are becoming standard, enabling seamless integration of dispensers with broader manufacturing execution systems (MES) and enterprise resource planning (ERP) platforms. This allows for centralized control, remote monitoring, and predictive maintenance capabilities, leveraging IoT sensors to collect operational data and AI algorithms to predict potential failures, optimize performance, and enhance overall equipment effectiveness (OEE). Furthermore, the development of modular and scalable system designs allows for greater flexibility, enabling users to expand their dispensing capabilities as their production needs evolve. Innovations also include improved cleaning systems to minimize cross-contamination and reduce downtime between color changes, along with robust designs capable of operating in harsh industrial environments. The continuous drive towards more sustainable printing processes is fostering technological advancements in handling eco-friendly ink types, such as water-based and bio-degradable formulations, ensuring that dispensing technology remains at the forefront of environmental responsibility while meeting the growing demands for complex and high-quality print production.

Regional Highlights

- North America: This region showcases a mature market with a high adoption rate of advanced, automated ink dispensing systems. The demand is primarily driven by the stringent quality requirements in packaging, commercial printing, and a strong focus on operational efficiency and waste reduction. Innovation in smart factory integration and IoT-enabled dispensers is prominent, with key players investing heavily in R&D.

- Europe: Europe is a significant market characterized by a strong emphasis on sustainability and environmental regulations, leading to increased demand for dispensers capable of handling water-based and UV-curable inks. Germany, Italy, and the UK are major contributors, driven by a robust packaging industry and specialized printing sectors. The region often leads in the development of sophisticated, highly automated systems.

- Asia Pacific (APAC): APAC is the fastest-growing market due to rapid industrialization, burgeoning manufacturing sectors, and increasing demand for packaged goods in countries like China, India, Japan, and South Korea. The expansion of printing and packaging industries, coupled with rising labor costs, is fueling the adoption of semi-automatic and automatic ink dispensing solutions to enhance productivity and reduce manual errors.

- Latin America: This region presents emerging opportunities, with Brazil and Mexico leading the market due to growing investments in industrial infrastructure and consumer goods manufacturing. The adoption of ink dispensers is driven by the need to modernize printing operations, improve efficiency, and meet the rising demand for high-quality packaging and commercial prints.

- Middle East and Africa (MEA): The MEA market is experiencing gradual growth, with increasing urbanization, industrial development, and foreign investments contributing to the expansion of the printing and packaging sectors. Countries like UAE, Saudi Arabia, and South Africa are key markets, focusing on improving print quality and efficiency, though adoption rates for advanced automation are still developing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ink Dispensers Market.- Inkmaker S.p.A.

- X-Rite (Pantone)

- Rexson Systems

- Fast & Fluid Management (IDEX Corporation)

- Fustech

- GSE Dispensing (GSE Systems B.V.)

- Nordson EFD

- Technotrans SE

- ColorLogic GmbH

- Shenzhen Rongda Photosensitive Equipment Co., Ltd.

- KBA-Metronic AG

- SPS TechnoScreen GmbH

- GRM Systems

- InkLogic (Global Graphics Software)

- Ink Management Systems (IMS)

- TRESU Group

- Bobst Group SA

- Mark Andy Inc.

- Gallus Ferd. Rüesch AG (Heidelberg Group)

- Koenig & Bauer AG

Frequently Asked Questions

What are the primary benefits of using ink dispensing systems in printing operations?

Ink dispensing systems offer significant benefits, including enhanced color accuracy and consistency across print jobs, substantial reduction in ink waste and associated costs, improved operational efficiency through automation, reduced labor requirements, and better inventory management of base inks. They contribute to faster turnaround times and help meet stringent quality standards in various printing applications, ultimately boosting profitability and sustainability for print businesses.

How does the Ink Dispensers Market contribute to sustainability in the printing industry?

The Ink Dispensers Market plays a crucial role in promoting sustainability by minimizing ink waste through precise gravimetric or volumetric dosing, reducing the need for manual mixing which often leads to excess. These systems enable efficient use of base inks, decreasing material consumption and disposal costs. Furthermore, the ability to accurately formulate and reuse leftover inks significantly lowers environmental impact and supports eco-friendly printing practices, aligning with global sustainability goals.

What is the difference between gravimetric and volumetric ink dispensing systems?

Gravimetric ink dispensing systems measure ink components by weight, using highly accurate load cells to ensure precise formulation, which is generally considered superior for critical color matching and waste reduction. Volumetric systems, conversely, measure ink components by volume. While simpler and often less expensive, volumetric systems can be less accurate, especially with varying ink viscosities and densities. Gravimetric systems are preferred for high-precision applications, while volumetric systems may suffice for less demanding tasks.

What are the key technological advancements driving innovation in ink dispensing?

Key technological advancements include the integration of artificial intelligence (AI) for predictive color matching and maintenance, Internet of Things (IoT) connectivity for remote monitoring and data analytics, and advanced software for comprehensive color management and inventory optimization. Innovations in precision pump technologies, modular system designs for scalability, and enhanced cleaning systems also contribute significantly to the market's evolution, offering greater efficiency, accuracy, and versatility to end-users.

Which industries are the primary end-users for ink dispensing systems?

The primary end-users for ink dispensing systems span across several critical industries. The packaging industry, including flexible, rigid, and label packaging, is a major consumer due to its high demand for consistent color and rapid production cycles. Textile printing, commercial printing for publications and marketing materials, and various industrial printing applications (e.g., automotive, ceramics, electronics) also heavily rely on these systems for precise ink formulation and efficient operations. The food & beverage and pharmaceutical sectors, with their stringent regulatory and branding requirements, are also significant users.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Ink Dispensers Market Size Report By Type (Semi-Automatic, Automatic Dispenser), By Application (Paste Inks, Paints & Coatings, Liquid Ink Dispensers, Chemicals & Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Ink Dispensers Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Semi-Automatic, Automatic Dispenser), By Application (Clothing/Garments, Print, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager