Ink Wetting Agents Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440256 | Date : Jan, 2026 | Pages : 248 | Region : Global | Publisher : MRU

Ink Wetting Agents Market Size

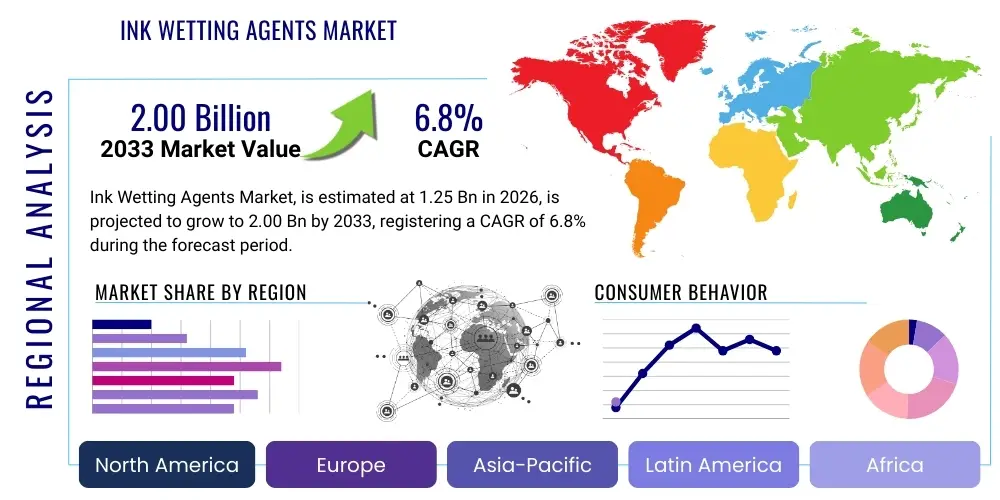

The Ink Wetting Agents Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 2.00 Billion by the end of the forecast period in 2033.

Ink Wetting Agents Market introduction

Ink wetting agents are critical chemical additives that modify the surface tension of ink formulations, enabling them to spread uniformly and adhere effectively to various substrates. These specialized chemicals, primarily surfactants and polymers, play a pivotal role in achieving high-quality print results by reducing surface defects such as pinholes, craters, and poor leveling. Their functionality extends beyond simple wetting, significantly influencing pigment dispersion, color strength, drying characteristics, and overall print stability, thereby enhancing the aesthetic and functional properties of printed materials across numerous applications.

The primary applications of ink wetting agents span across a diverse range of printing technologies and industries. They are indispensable in traditional offset printing, flexographic printing, gravure printing, and increasingly vital in advanced digital printing methods, including inkjet and 3D printing. Major end-use sectors include packaging (food, beverage, consumer goods), commercial printing (magazines, brochures, marketing materials), textile printing, and specialized industrial applications such as automotive finishes, electronic displays, and medical devices. The benefits derived from incorporating these agents are profound, encompassing improved print consistency, enhanced substrate compatibility, faster production speeds, and superior image resolution, all contributing to elevated product appeal and functional performance.

Several driving factors are propelling the growth of the ink wetting agents market. The escalating demand for high-quality, vibrant, and durable printed products, particularly within the booming packaging industry and the rapidly expanding digital printing sector, is a primary catalyst. Furthermore, continuous advancements in ink formulation technologies, including the development of water-based and UV-curable inks driven by environmental regulations and sustainability goals, necessitate sophisticated wetting agents that can perform effectively in these complex systems. The increasing adoption of personalized and on-demand printing solutions also fuels innovation and demand for specialized wetting agents tailored to specific ink chemistries and printing processes, ensuring optimal performance across a spectrum of new applications and materials.

Ink Wetting Agents Market Executive Summary

The Ink Wetting Agents Market is undergoing significant transformation, driven by evolving business trends that emphasize sustainability, technological integration, and customization. There is a discernible shift towards eco-friendly and bio-based wetting agents, reflecting stringent environmental regulations and growing consumer preference for sustainable products. Furthermore, ink manufacturers are increasingly seeking specialized wetting agents that can enhance the performance of advanced ink systems, such as high-speed digital inks and conductive inks for electronics. Consolidation among key players and strategic partnerships aimed at research and development are also prominent trends, fostering innovation in product offerings and application-specific solutions across various printing and coating sectors.

Regional trends reveal a dynamic landscape with Asia-Pacific emerging as the dominant market, propelled by its robust manufacturing base, burgeoning packaging industry, and rapid industrialization, particularly in countries like China and India. This region benefits from significant investment in printing and packaging infrastructure, driving both production and consumption of wetting agents. North America and Europe, while mature markets, continue to lead in innovation and the adoption of high-performance and sustainable wetting agents, driven by stringent regulatory frameworks and a strong focus on premium print quality. Latin America and the Middle East & Africa regions are also exhibiting steady growth, fueled by economic development, increasing disposable incomes, and expanding industrial activities, creating new opportunities for market expansion and localized product development.

Segment-wise, the market is witnessing significant shifts, with water-based inks and UV-curable inks experiencing accelerated growth due to their environmental advantages and performance characteristics. This growth, in turn, amplifies the demand for wetting agents specifically designed for these ink types, which often present unique formulation challenges. The packaging application segment remains a cornerstone of the market, driven by consumer goods demand and the need for visually appealing and durable packaging. Digital printing, including inkjet and 3D printing, represents a high-growth segment, demanding wetting agents that ensure precise droplet formation, rapid curing, and excellent adhesion on diverse substrates. This evolution across segments underscores the need for continuous innovation and diversification in wetting agent chemistries to meet the evolving demands of the global printing and coating industries.

AI Impact Analysis on Ink Wetting Agents Market

User questions regarding the impact of AI on the Ink Wetting Agents Market frequently revolve around how artificial intelligence can optimize ink formulation, predict performance, enhance quality control, and streamline manufacturing processes. Common inquiries explore the potential for AI algorithms to precisely select and dosage wetting agents for desired print characteristics, reduce development cycles for new ink systems, and even manage complex supply chains for raw materials. There's also significant interest in AI's role in addressing sustainability challenges by predicting the environmental footprint of different formulations and identifying greener alternatives. Users seek to understand if AI can make the ink development process more efficient, cost-effective, and responsive to rapidly changing market demands, ultimately improving the overall consistency and quality of printed products while minimizing waste and resources.

- AI-driven formulation optimization for precise wetting agent selection and dosage.

- Predictive analytics for ink performance and stability across various substrates and environmental conditions.

- Automated quality control systems using AI for real-time defect detection and correction in printing processes.

- Enhanced R&D acceleration through AI-guided material discovery and combinatorial chemistry.

- Supply chain optimization and demand forecasting for wetting agent raw materials, reducing costs and lead times.

- Development of smart manufacturing processes for ink production, improving efficiency and reducing waste.

- Personalized ink formulations tailored to specific client needs and printing equipment configurations.

- Identification and development of sustainable, bio-based wetting agents using AI-driven molecular design.

- Real-time monitoring of printing parameters to dynamically adjust wetting agent concentration for optimal results.

DRO & Impact Forces Of Ink Wetting Agents Market

The Ink Wetting Agents Market is propelled by several robust drivers, notably the surging global demand for high-quality printing in diverse sectors such as packaging, publishing, and textiles, where aesthetic appeal and functional performance are paramount. The rapid expansion of digital printing technologies, including inkjet and 3D printing, specifically necessitates advanced wetting agents to ensure precise droplet control, superior resolution, and substrate compatibility. Furthermore, increasing consumer preference for visually appealing products and the growth of e-commerce, which relies heavily on sophisticated packaging, significantly boost the consumption of printing inks and, consequently, their essential additives. The ongoing shift towards environmentally friendly water-based and UV-curable inks also acts as a powerful driver, as these formulations often require specialized wetting agents to achieve optimal performance and stability while adhering to stringent environmental regulations.

However, the market faces several restraints that could impede its growth trajectory. The volatility of raw material prices, primarily petrochemical derivatives and specialty chemicals used in the synthesis of wetting agents, poses a significant challenge, leading to unpredictable production costs and impacting profit margins. Stringent environmental regulations, while driving innovation in some areas, can also present hurdles by limiting the use of certain effective but less eco-friendly chemistries, pushing manufacturers towards more expensive or less performant alternatives. Moreover, the inherent complexity in formulating inks, where a delicate balance of various additives is required, means that integrating new wetting agents often requires extensive R&D, adding to costs and development timelines. The maturity of traditional printing markets in developed regions also represents a restraint, as growth opportunities are more concentrated in emerging economies.

Opportunities for growth are abundant within the Ink Wetting Agents Market, particularly in the development of bio-based and sustainable wetting agents that align with global green initiatives and consumer demand for eco-conscious products. Emerging economies, especially in Asia-Pacific and Latin America, present significant untapped potential due to their expanding manufacturing sectors, growing middle-class populations, and increasing industrialization. Specialized applications, such as printed electronics, security printing, and advanced functional coatings, offer niche but high-value growth avenues, demanding bespoke wetting agent solutions. Innovation in smart packaging, which integrates functionalities like indicators or sensors, also creates new requirements for ink systems that necessitate advanced wetting agents. Furthermore, advancements in nanotechnology and surface chemistry open doors for developing next-generation wetting agents with enhanced performance characteristics, broader compatibility, and improved sustainability profiles, offering manufacturers competitive differentiation and market expansion.

Segmentation Analysis

The Ink Wetting Agents Market is comprehensively segmented by various parameters to provide a detailed understanding of its dynamics, market size, and growth opportunities across different categories. These segmentations are crucial for identifying specific market trends, competitive landscapes, and consumer preferences, enabling businesses to tailor their strategies effectively. The market is primarily bifurcated by the chemical type of the wetting agent, the specific application of the ink it modifies, the base ink type, and the end-use industry that utilizes the printed materials. This multi-faceted segmentation allows for a granular analysis of how different product characteristics and application requirements influence market demand and innovation.

- By Type

- Surfactants

- Anionic Surfactants

- Cationic Surfactants

- Non-ionic Surfactants

- Amphoteric Surfactants

- Polymeric Wetting Agents

- Other Specialty Wetting Agents

- Surfactants

- By Application

- Packaging Inks

- Publication Inks

- Textile Inks

- Digital Inks (Inkjet, 3D Printing)

- Other Specialty Inks (Security, Conductive, etc.)

- By Ink Type

- Water-based Inks

- Solvent-based Inks

- UV-curable Inks

- Oil-based Inks

- By End-Use Industry

- Printing & Packaging

- Textiles & Apparel

- Automotive

- Electronics

- Construction

- Healthcare

- Others (e.g., Furniture, Promotional Products)

Value Chain Analysis For Ink Wetting Agents Market

The value chain for the Ink Wetting Agents Market begins with the upstream suppliers of raw materials, which are predominantly petrochemical companies providing basic chemicals like ethylene oxide, propylene oxide, fatty alcohols, and other specialty monomers or polymers. Natural oil derivatives are also significant for bio-based wetting agents. These raw material providers form the foundational layer, influencing cost structures and supply stability. The next stage involves the chemical manufacturers who specialize in synthesizing and formulating these raw materials into various types of wetting agents, such as surfactants (anionic, cationic, non-ionic, amphoteric) and polymeric dispersions, tailoring them to specific performance requirements for ink applications. This segment involves significant R&D investment to develop novel chemistries and improve existing ones.

Following the manufacturing of wetting agents, these products move into the hands of ink formulators and manufacturers. These companies integrate the wetting agents into their diverse range of inks for different printing processes and substrates, optimizing their formulations to achieve desired print quality, adhesion, drying speed, and color vibrancy. The distribution channel plays a crucial role in bridging the gap between wetting agent manufacturers and ink producers, as well as between ink producers and printing houses. This channel can be direct, particularly for large-volume sales to major ink manufacturers, involving dedicated sales teams and technical support. Alternatively, it can be indirect, utilizing a network of distributors, agents, and specialty chemical suppliers who cater to smaller ink manufacturers or specific regional markets, providing localized inventory and technical assistance.

The downstream segment of the value chain consists of the diverse end-users who apply these inks, primarily printing companies. This includes commercial printers, packaging converters, textile printers, digital printing service providers, and specialized industrial printers. These end-users, in turn, serve a wide array of industries such as consumer goods, food and beverage, pharmaceuticals, automotive, electronics, and fashion. The direct interaction between ink manufacturers and large printing corporations often leads to customized ink and wetting agent solutions. Indirectly, the final consumers of printed goods, through their demand for high-quality packaging, magazines, textiles, or electronic displays, drive the entire value chain, emphasizing the need for efficient, high-performance, and cost-effective ink wetting agents that contribute to superior product presentation and functionality.

Ink Wetting Agents Market Potential Customers

The primary potential customers and end-users of ink wetting agents are inherently tied to the expansive printing and coatings industries, where surface tension control and superior wetting properties are paramount for product performance. At the forefront are ink manufacturers, ranging from global chemical giants to specialized regional players, who formulate various types of inks including water-based, solvent-based, UV-curable, and oil-based systems. These manufacturers are constantly seeking innovative wetting agents to enhance their ink's flow, leveling, pigment dispersion, and adhesion characteristics across a multitude of substrates, ensuring their products meet stringent quality and performance standards required by their diverse clientele.

Beyond ink manufacturers, a significant segment of potential customers includes large-scale commercial printing houses and packaging converters. These entities utilize vast quantities of inks for applications such as flexible packaging, corrugated boxes, labels, magazines, brochures, and newspapers. Their demand for ink wetting agents is driven by the need for high-speed printing operations, consistent print quality, reduction of defects (like streaking, mottling, or poor ink transfer), and efficient adhesion on challenging surfaces. The shift towards sustainable printing practices also makes them seek eco-friendly wetting agent solutions that can be integrated into their production processes without compromising efficiency or final product aesthetics, especially for food-contact packaging.

Furthermore, specialized industries represent another crucial customer base. This includes textile manufacturers engaged in fabric printing, requiring wetting agents for vibrant and durable designs; automotive companies for coatings and interior finishes; electronics manufacturers utilizing conductive inks for printed circuit boards or displays; and construction material producers where specialized coatings are applied. The digital printing sector, encompassing inkjet and 3D printing, is a rapidly growing customer segment, seeking highly customized wetting agents that enable precise droplet control, rapid curing, and superior resolution for complex geometries and advanced materials. These diverse end-users underscore the broad applicability and critical role of ink wetting agents in modern manufacturing and consumer product industries.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 2.00 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Evonik Industries AG, BYK-Chemie GmbH (Altana AG), The Dow Chemical Company, Solvay S.A., Air Products and Chemicals, Inc., Ashland Global Holdings Inc., Croda International Plc, Elementis Plc, The Lubrizol Corporation (Berkshire Hathaway), Momentive Performance Materials Inc., Stepan Company, Arkema S.A., Eastman Chemical Company, Shin-Etsu Chemical Co., Ltd., Wacker Chemie AG, Sasol Limited, Nouryon (AkzoNobel Specialty Chemicals), Kao Corporation, CLARIANT AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ink Wetting Agents Market Key Technology Landscape

The Ink Wetting Agents Market is continuously evolving, driven by advancements in material science and a persistent demand for enhanced print performance and sustainability. A significant area of innovation lies in the development of novel surfactant chemistries, moving beyond traditional ethoxylates to more sophisticated structures. This includes low-VOC (Volatile Organic Compound) and VOC-free surfactants, as well as specialty fluorosurfactants and siloxane-based wetting agents, which offer ultra-low surface tension reduction and excellent leveling properties, particularly crucial for challenging substrates and high-resolution digital printing applications. The focus is also on creating multi-functional surfactants that can provide not only wetting but also pigment dispersion, defoaming, or rheological modification, simplifying ink formulations and improving overall performance.

Another pivotal technological trend is the rise of polymeric wetting agents. Unlike small molecule surfactants, polymers offer robust, long-lasting performance and superior compatibility with various ink resins and pigments, leading to enhanced dispersion stability, film formation, and adhesion. Research efforts are concentrated on designing block copolymers and graft copolymers with tailored structures that exhibit amphiphilic properties, allowing for efficient wetting across a wide range of surface energies. These polymeric solutions are particularly advantageous in water-based and UV-curable ink systems, where they contribute to improved film integrity, scratch resistance, and environmental durability, addressing the stringent demands of high-performance printing applications like automotive coatings and industrial graphics.

Furthermore, the integration of green chemistry principles and nanotechnology is profoundly shaping the technology landscape. The development of bio-based and biodegradable wetting agents, derived from renewable resources such as natural oils and carbohydrates, is gaining traction, driven by environmental regulations and corporate sustainability goals. These agents aim to provide comparable performance to synthetic counterparts while minimizing ecological impact. Nanotechnology is also being leveraged to create nano-emulsions and finely dispersed wetting agent particles that can offer superior surface coverage and more uniform film formation at lower concentrations. High-throughput screening and computational chemistry tools are accelerating the discovery and optimization of new wetting agent formulations, enabling manufacturers to rapidly develop solutions that meet the ever-increasing demands for efficiency, performance, and environmental responsibility across the diverse and dynamic printing industry.

Regional Highlights

- North America: A mature market characterized by robust R&D, stringent environmental regulations driving demand for sustainable solutions, and high adoption of advanced digital printing technologies. The region leads in specialty ink applications and innovation.

- Europe: Driven by strict environmental policies, favoring water-based and UV-curable inks. Strong focus on high-performance printing for packaging and automotive sectors. Significant investment in research and development of bio-based agents.

- Asia Pacific (APAC): The largest and fastest-growing market, fueled by rapid industrialization, expanding manufacturing bases (especially in China and India), and booming packaging and consumer goods industries. A hub for both production and consumption of wetting agents.

- Latin America: Exhibiting steady growth due to economic development, increasing disposable incomes, and rising demand for packaged goods. Opportunities for market expansion as printing infrastructure develops.

- Middle East and Africa (MEA): An emerging market with growing industrialization and urbanization. Increasing demand from the construction, packaging, and textile industries, creating new avenues for market penetration.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ink Wetting Agents Market.- BASF SE

- Evonik Industries AG

- BYK-Chemie GmbH (Altana AG)

- The Dow Chemical Company

- Solvay S.A.

- Air Products and Chemicals, Inc.

- Ashland Global Holdings Inc.

- Croda International Plc

- Elementis Plc

- The Lubrizol Corporation (Berkshire Hathaway)

- Momentive Performance Materials Inc.

- Stepan Company

- Arkema S.A.

- Eastman Chemical Company

- Shin-Etsu Chemical Co., Ltd.

- Wacker Chemie AG

- Sasol Limited

- Nouryon (AkzoNobel Specialty Chemicals)

- Kao Corporation

- CLARIANT AG

Frequently Asked Questions

Analyze common user questions about the Ink Wetting Agents market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are ink wetting agents and why are they essential in printing?

Ink wetting agents are chemical additives, primarily surfactants or polymers, used to reduce the surface tension of ink. They are essential because they enable the ink to spread evenly on a substrate, prevent defects like pinholes or streaking, and ensure optimal adhesion, significantly contributing to the final print quality and consistency.

What are the main types of ink wetting agents available in the market?

The market primarily features two main types: surfactants (including anionic, cationic, non-ionic, and amphoteric variants) and polymeric wetting agents. Each type is chosen based on the specific ink chemistry, substrate, and desired performance characteristics, with continuous innovation in both categories.

How do ink wetting agents contribute to improved print quality and efficiency?

By lowering surface tension, wetting agents facilitate better substrate wetting, leading to sharper images, vibrant colors, and consistent ink transfer. They also prevent common printing defects, reduce ink waste, and can enhance drying speeds, ultimately boosting both the aesthetic quality and operational efficiency of printing processes.

What are the key drivers for the growth of the Ink Wetting Agents Market?

Key drivers include the escalating demand for high-quality printed materials in packaging and commercial sectors, the rapid expansion of digital printing technologies, and the increasing shift towards environmentally friendly water-based and UV-curable ink formulations. Continuous innovation in ink technologies also fuels demand for advanced wetting agents.

What impact do environmental regulations have on the development of ink wetting agents?

Environmental regulations significantly influence the market by promoting the development and adoption of eco-friendly and bio-based wetting agents. They push manufacturers to reduce VOCs, ensure biodegradability, and minimize the use of hazardous substances, thereby driving innovation towards sustainable and compliant solutions in ink formulations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager