Inkjet Coding Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436251 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Inkjet Coding Equipment Market Size

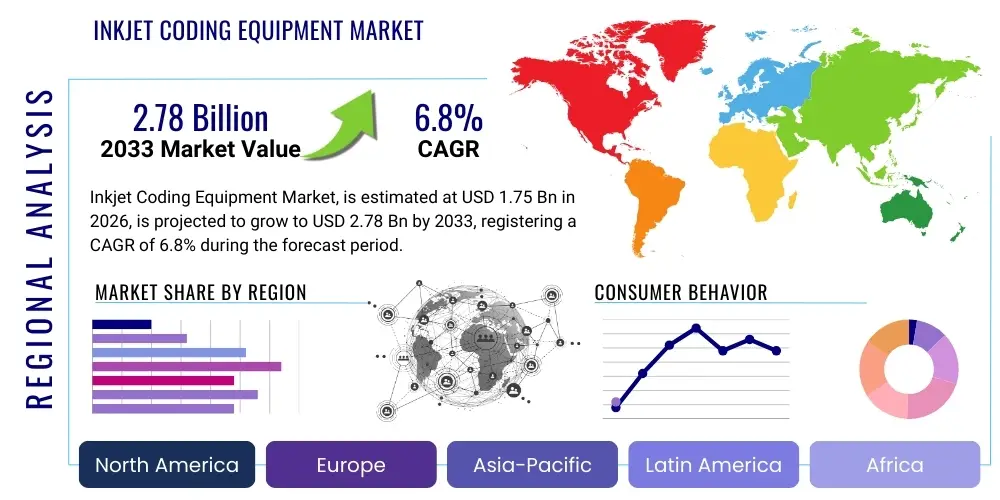

The Inkjet Coding Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.75 Billion in 2026 and is projected to reach USD 2.78 Billion by the end of the forecast period in 2033.

Inkjet Coding Equipment Market introduction

The Inkjet Coding Equipment Market encompasses specialized industrial printers designed for applying variable data, such as expiration dates, batch numbers, barcodes, and serialization codes, directly onto products and packaging materials across various production lines. These systems are foundational components of modern manufacturing and supply chain management, ensuring product traceability, compliance with increasingly stringent global labeling regulations, and enhancing anti-counterfeiting efforts. The core function of these devices is to provide high-speed, non-contact marking capabilities, which is essential for maintaining throughput in fast-paced production environments, particularly in the food and beverage, pharmaceutical, and consumer goods sectors.

The product portfolio within this market is diverse, primarily categorized by technology, including Continuous Inkjet (CIJ), Drop-on-Demand (DOD), Thermal Inkjet (TIJ), and Piezoelectric DOD. CIJ technology dominates high-speed applications due to its reliability and versatility across different substrates, while TIJ is increasingly favored in sectors requiring high resolution and utilizing water-based or solvent-free inks on specific porous materials. Major applications span primary, secondary, and tertiary packaging levels, ranging from coding individual bottles and blister packs to outer cases and pallets, necessitating systems that can handle diverse material types, including plastic, glass, metal, and cardboard.

Driving factors for market expansion include the global mandate for precise track-and-trace systems, spurred by regulations such as the Drug Supply Chain Security Act (DSCSA) and the EU Falsified Medicines Directive (FMD), which demand unique serialization codes. Furthermore, the rapid growth of e-commerce and subsequent increase in packaged goods consumption globally necessitate efficient, durable, and highly readable coding solutions. The key benefit derived from adopting advanced inkjet coding equipment is maximized uptime through reduced maintenance, coupled with superior print quality that meets automated inspection standards, thereby mitigating the risk of costly recalls or regulatory fines.

Inkjet Coding Equipment Market Executive Summary

The Inkjet Coding Equipment Market is characterized by intense technological evolution, shifting towards greater integration with factory automation systems (Industry 4.0) and a strong emphasis on sustainability through the development of environmentally benign inks. Key business trends include the consolidation among major players focusing on comprehensive service contracts and predictive maintenance features powered by IoT connectivity. There is a palpable shift away from traditional solvent-based CIJ systems toward higher resolution, cleaner technologies like TIJ and UV-curable Piezo DOD, especially in regions with strict volatile organic compound (VOC) emission regulations. This transition is being driven by end-users' demand for reduced operational complexity, faster changeover times, and centralized control systems capable of managing multiple coding units simultaneously across large manufacturing sites.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market, propelled by massive industrialization, soaring food processing output, and the implementation of essential serialization laws in key economies like China and India, mirroring standards set by developed regions. North America and Europe, while mature, continue to drive innovation, particularly in pharmaceutical traceability and sustainable packaging solutions, maintaining their dominance in terms of technology adoption rate and average selling price (ASP) for sophisticated, high-performance equipment. Emerging markets in Latin America and MEA are experiencing steady growth, supported by foreign investment in manufacturing infrastructure and the gradual adoption of global product safety standards, creating demand for robust, entry-level to mid-range CIJ systems.

Segment trends indicate that the Food and Beverage industry remains the largest end-user segment due to the sheer volume and rapid expiration cycles of products, demanding exceptional reliability and high contrast printing. Technology-wise, CIJ holds the largest market share due to its proven track record on curved and non-porous surfaces; however, the DOD segment, particularly TIJ, is exhibiting the highest CAGR, fueled by pharmaceutical and cosmetics sectors requiring high-density, precise barcodes and 2D data matrix codes. The emphasis on centralized data management software and integration capabilities, rather than just hardware features, is becoming a defining factor in purchasing decisions, signaling a market maturation towards holistic coding solutions.

AI Impact Analysis on Inkjet Coding Equipment Market

User inquiries regarding AI's influence in the Inkjet Coding Equipment Market predominantly focus on how intelligent systems can enhance quality assurance, minimize operational downtime, and optimize complex coding processes. Key themes revolve around the integration of machine vision (ML-based OCV/OCR) for automatic code verification, the deployment of predictive maintenance algorithms to anticipate component failure and ink consumption patterns, and utilizing AI for dynamic job scheduling across high-mix, low-volume production lines. Users expect AI to transform coding from a necessary operational bottleneck into an integrated, self-optimizing part of the packaging line, ensuring regulatory compliance with near-zero error rates.

The immediate impact of Artificial Intelligence (AI) integration is most evident in enhancing the reliability and consistency of printed codes. AI-powered machine vision systems are increasingly being deployed downstream from the inkjet coder to perform Optical Character Recognition (OCR) and Optical Character Verification (OCV) with unprecedented accuracy. These systems use deep learning models trained on vast datasets of acceptable and defective codes (smudges, misalignments, faint prints) to instantly detect compliance issues. This allows for immediate rejection of non-conforming products, drastically reducing waste and mitigating the risk of costly manual inspection errors or subsequent product recalls, providing a critical layer of defense against traceability failures.

Furthermore, AI significantly contributes to operational efficiency through advanced predictive maintenance and supply chain management. By continuously analyzing sensor data streams from the coding equipment—including ink viscosity, nozzle temperature, print head pressure, and component run-time—AI algorithms can accurately forecast the remaining useful life (RUL) of critical parts like filters and pumps. This shift from time-based maintenance schedules to condition-based monitoring minimizes unscheduled downtime, ensures optimal print quality throughout long production runs, and automates the replenishment of consumables like ink and solvent based on real-time consumption rates and production forecasts, leading to substantial cost savings and improved Mean Time Between Failures (MTBF).

- AI-driven Predictive Maintenance (PdM): Minimizes downtime by forecasting component failure, optimizing scheduled service intervals.

- Enhanced Quality Control (QC): Machine Learning-based OCV/OCR ensures real-time, high-accuracy verification of serialization and batch codes.

- Optimized Ink Management: AI algorithms predict precise ink and solvent consumption based on job complexity and environmental factors, reducing material waste.

- Autonomous System Calibration: Self-adjusting print parameters (e.g., jetting frequency, drop velocity) based on environmental changes (temperature/humidity) for consistent print quality.

- Integration with MES/ERP: Seamless data flow optimization between coding systems and enterprise-level manufacturing execution systems (MES) using intelligent gateways.

DRO & Impact Forces Of Inkjet Coding Equipment Market

The dynamics of the Inkjet Coding Equipment Market are governed by a robust interplay of regulatory mandates, rapid manufacturing modernization, and environmental accountability, shaping the direction of technological investment. Drivers include the global proliferation of stringent governmental serialization and traceability requirements, particularly within the pharmaceutical sector, forcing universal adoption of high-resolution 2D codes. Coupled with this is the continuous push for higher production line speeds and versatility across increasingly complex packaging substrates (e.g., flexible films, sustainable paper-based packaging), compelling manufacturers to invest in faster, more adaptive coding solutions to maintain competitive throughput.

However, the market faces restraints primarily related to the substantial capital expenditure required for sophisticated, fully integrated coding and verification systems, particularly for Small and Medium-sized Enterprises (SMEs). Furthermore, the long-term dependency on proprietary consumables, specifically specialized inks and solvents, creates a significant operational constraint, often leading to high total cost of ownership (TCO). A critical challenge also lies in environmental constraints associated with Volatile Organic Compounds (VOCs) emitted by traditional solvent-based CIJ inks, pushing regulatory bodies and consumers toward demanding sustainable alternatives, which often require system redesigns and new ink formulations.

Opportunities for growth are concentrated in the development and commercialization of next-generation, sustainable coding technologies, specifically UV-curable and water-based inks that align with circular economy principles and emerging green packaging standards. Geographical expansion into rapidly industrializing regions of Southeast Asia and Africa, where infrastructure investment necessitates new factory build-outs compliant with international coding standards, represents a massive untapped customer base. The primary impact forces influencing this market include the high bargaining power of large pharmaceutical and food conglomerates that dictate standards for system integration and performance, and the accelerating pace of digital transformation (Industry 4.0), which makes standalone, non-networked equipment obsolete, thus demanding robust connectivity and remote diagnostics capabilities from equipment suppliers.

Segmentation Analysis

The Inkjet Coding Equipment Market is highly segmented based on core technology, the type of substrate handled, the complexity of the data printed, and the industry utilizing the equipment. Understanding these segmentations is critical for manufacturers to tailor product development and market strategies, addressing the specific requirements for speed, resolution, durability, and compliance across diverse industrial environments. The dominance of CIJ technology reflects its versatility for high-speed primary packaging, while the rapid growth in TIJ highlights the increasing demand for high-resolution, cleaner printing in specialized sectors. Segmentation allows for precise targeting, recognizing that the needs of a beverage bottling plant (high speed, wet environment) differ significantly from those of a pharmaceutical packager (high resolution, 100% verification).

- Technology

- Continuous Inkjet (CIJ)

- Drop-on-Demand (DOD)

- Thermal Inkjet (TIJ)

- Piezoelectric DOD

- End-User Industry

- Food and Beverage

- Pharmaceuticals and Healthcare

- Cosmetics and Personal Care

- Industrial and Automotive

- Chemicals and Petrochemicals

- Others (Construction Materials, Electronics)

- Substrate Type

- Porous (Paper, Cardboard)

- Non-Porous (Plastics, Glass, Metal)

- Printing Resolution

- Low Resolution

- High Resolution (Above 300 dpi)

Value Chain Analysis For Inkjet Coding Equipment Market

The value chain for the Inkjet Coding Equipment Market begins with the upstream suppliers responsible for crucial components, including printhead mechanisms (e.g., specialized micro-electromechanical systems for DOD), ink formulation chemicals (dyes, solvents, polymers), and advanced electronic controls (PCBs, microprocessors). Innovation at this stage, particularly in developing non-toxic, highly adhesive inks and miniaturized, highly durable printheads, directly impacts the final product performance. Key upstream activities involve intensive R&D to meet regulatory requirements regarding ink toxicity and VOC emissions, which requires strong partnerships between equipment manufacturers and chemical suppliers to ensure compatibility and sustainability.

Midstream activities involve the core manufacturing and assembly of the coding systems, encompassing hardware integration, software development (human-machine interface, connectivity protocols), and rigorous quality testing. Equipment manufacturers like Domino, Videojet, and Markem-Imaje focus heavily on modular design to ease maintenance and offer customization, particularly the integration of proprietary software solutions for remote diagnostics and centralized job management. The distribution channel is bifurcated, utilizing both direct sales teams for major global accounts that require highly specialized integration and local distributors or value-added resellers (VARs) for regional SMEs, who provide essential localized service, technical support, and consumable supply management.

Downstream activities center on deployment, integration into existing packaging lines (often requiring coordination with conveyor and filling machine vendors), and post-sale support, including consumable replenishment and maintenance contracts. Direct distribution channels ensure that complex, high-end serialization systems receive expert installation, while indirect channels leverage VARs for quicker regional access and localized support, particularly for consumable sales, which represent a recurring revenue stream critical to the market's financial structure. Effective lifecycle management, focused on maximizing equipment uptime and guaranteeing consistent code quality for end-users like global food processors, defines success in the downstream segment.

Inkjet Coding Equipment Market Potential Customers

Potential customers, or the end-users/buyers of Inkjet Coding Equipment, represent a diverse range of high-volume manufacturing and processing industries worldwide, all unified by the critical requirement for legally compliant, traceable product identification. The primary customer base resides within the Food and Beverage sector, covering everything from canned goods and dairy products to bottled beverages and snacks, where high-speed coding of expiration dates and batch numbers is non-negotiable for public safety and inventory management. This segment demands systems capable of operating reliably in harsh environments characterized by moisture, temperature fluctuations, and continuous operation.

The second most significant customer cohort is the Pharmaceutical and Healthcare industry. These buyers require the most sophisticated high-resolution coding equipment (often TIJ or high-end Piezo DOD) capable of printing intricate 2D data matrix codes compliant with global serialization mandates (DSCSA, FMD). For pharmaceuticals, coding is an absolute necessity for fighting counterfeit drugs and ensuring unit-level traceability from manufacture to dispensing, making error-free printing and automated verification the primary purchasing criteria. Cosmetics and personal care manufacturers also constitute a vital customer segment, prioritizing aesthetic quality, fine print capability on small or irregularly shaped containers, and brand integrity maintenance through unique product markings.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.75 Billion |

| Market Forecast in 2033 | USD 2.78 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Domino Printing Sciences, Videojet Technologies, Markem-Imaje, KGK Jet, Hitachi Industrial Equipment Systems, Linx Printing Technologies, Macsa ID, Rea Jet, Leibinger, Iconotech, Squid Ink Manufacturing, Inkcups Now, Anser Coding, Control Print, ID Technology, Matthews International, Weber Marking Systems, Kortho Coding & Marking, KBA-Metronic, Allen Coding. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Inkjet Coding Equipment Market Key Technology Landscape

The technology landscape of the Inkjet Coding Equipment Market is currently undergoing a rapid evolution characterized by convergence, primarily driven by the need for higher resolution and reduced environmental impact. Continuous Inkjet (CIJ) technology remains the workhorse for high-speed industrial coding, utilizing a stream of electrically charged ink drops to print data at extremely high speeds (up to 300 meters per minute) on virtually any substrate, including curved or irregular surfaces. Recent advancements in CIJ focus on automated self-cleaning printheads and improved solvent management systems to enhance uptime and minimize operator intervention, addressing its historic issues with frequent maintenance and reliance on aggressive solvents.

Drop-on-Demand (DOD) technologies are rapidly gaining ground, particularly Thermal Inkjet (TIJ) and Piezoelectric DOD. TIJ technology, leveraging heat to expel ink drops, offers exceptional resolution (often 600 dpi or higher), making it ideal for pharmaceutical serialization and detailed graphical printing. Its main advantages include zero maintenance and the ability to utilize environmentally friendly water-based inks, although it is typically limited to specific ink types and shorter throw distances. Piezoelectric DOD, using mechanical force rather than heat, handles a wider range of high-viscosity inks, including UV-curable formulations, which provide immediate drying and high resistance to solvents and abrasion, making it suitable for industrial coding on non-porous materials like cable and pipe.

The future technology trajectory points toward "Smart Coding," integrating advanced software solutions based on the Internet of Things (IoT) and AI. This includes systems featuring cloud connectivity for remote diagnostics, firmware updates, and centralized control over entire fleets of printers. Innovations also include the development of food-grade, direct-contact inks (edible inks) for printing directly onto primary food products and the standardization of machine-readable data structures (e.g., GS1 standards) within the coding software itself. This shift emphasizes data integration and operational efficiency over purely mechanical speed, moving the focus from merely applying a code to managing the data associated with that code throughout the product lifecycle.

Regional Highlights

- North America: Characterized by early adoption of advanced serialization technologies, particularly in the pharmaceutical and robust logistics sectors. The market is mature but highly focused on high-resolution TIJ and fully integrated, networked solutions, driven by stringent FDA traceability mandates and significant investment in automation.

- Europe: A major innovation hub for sustainable coding, leading the push for water-based and UV-curable inks to comply with strict EU regulations regarding packaging waste and VOC emissions. The implementation of the Falsified Medicines Directive (FMD) has solidified demand for serialization-ready coding equipment across the region.

- Asia Pacific (APAC): The fastest-growing region globally, fueled by massive expansion in manufacturing capabilities, surging consumer demand for packaged goods, and the establishment of local regulatory standards mimicking Western traceability laws (e.g., in China and India). The market here is vast, covering high-volume, cost-sensitive CIJ applications alongside rapidly emerging high-resolution serialization needs.

- Latin America: Exhibits steady growth driven by foreign direct investment in food and beverage processing and increasing regional trade agreements that necessitate improved product coding and labeling. Demand is currently concentrated in robust, reliable CIJ systems capable of handling diverse production environments.

- Middle East and Africa (MEA): An emerging market showing potential primarily due to infrastructure development, rising urbanization, and imported standards for product integrity, especially in Saudi Arabia and the UAE. Growth is observed in basic coding requirements for consumables, with gradual migration towards more sophisticated solutions expected as industrial standards mature.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Inkjet Coding Equipment Market.- Domino Printing Sciences

- Videojet Technologies

- Markem-Imaje

- KGK Jet

- Hitachi Industrial Equipment Systems

- Linx Printing Technologies

- Macsa ID

- Rea Jet

- Leibinger

- Iconotech

- Squid Ink Manufacturing

- Inkcups Now

- Anser Coding

- Control Print

- ID Technology

- Matthews International

- Weber Marking Systems

- Kortho Coding & Marking

- KBA-Metronic

- Allen Coding

Frequently Asked Questions

Analyze common user questions about the Inkjet Coding Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between CIJ and TIJ coding equipment?

CIJ (Continuous Inkjet) is ideal for high-speed, long-distance printing on non-porous, curved surfaces using solvent-based inks, requiring regular maintenance. TIJ (Thermal Inkjet) offers high-resolution, low-maintenance printing, primarily using water-based inks on specific porous or flat surfaces, making it popular for high-density 2D codes in pharmaceuticals.

How is the Inkjet Coding Market addressing sustainability and environmental concerns?

The market is shifting towards environmentally conscious solutions by prioritizing the development of low-VOC or zero-VOC inks, including water-based, oil-based, and UV-curable formulations. These sustainable inks reduce the health hazards associated with solvents and meet stringent global environmental compliance mandates.

Which end-user industry accounts for the largest share of the Inkjet Coding Equipment Market?

The Food and Beverage (F&B) industry holds the largest market share due to the necessity of printing crucial traceability information (expiry dates, batch codes) at high volumes and high speeds on various substrates under demanding production conditions.

What role does Industry 4.0 play in the adoption of new coding equipment?

Industry 4.0 integration drives the adoption of smart coders featuring IoT connectivity, allowing for real-time remote monitoring, centralized data management via MES/ERP systems, and AI-powered predictive maintenance, thereby maximizing operational efficiency and ensuring compliance.

What are the main restraints impacting the growth of the high-resolution DOD segment?

The main restraints for high-resolution DOD (e.g., TIJ) include higher consumable costs per print compared to CIJ for very high volumes, and limitations regarding the 'throw distance' and substrate compatibility, making them less versatile for coding irregular or highly curved primary products.

What key regulations are driving demand for advanced serialization capabilities?

Key regulations include the US Drug Supply Chain Security Act (DSCSA), the European Falsified Medicines Directive (FMD), and similar regional mandates in Brazil and South Korea. These laws necessitate unit-level serialization, forcing pharmaceutical manufacturers to adopt high-resolution 2D data matrix coding equipment capable of flawless printing and verification.

How do technological advancements enhance the Total Cost of Ownership (TCO) for end-users?

Modern equipment, particularly maintenance-free TIJ systems or advanced CIJ units with automated cleaning cycles and predictive diagnostics, lowers the TCO. Reduced reliance on frequent filter changes, minimized solvent consumption, and fewer unscheduled breakdowns directly translate into lower operating costs and higher production uptime.

What factors influence the choice between UV-curable inks and solvent-based inks?

The choice depends on the substrate and required code durability. Solvent-based inks dry rapidly through evaporation and adhere well to almost all non-porous surfaces but emit VOCs. UV-curable inks dry instantly when exposed to UV light, providing superior abrasion and chemical resistance with zero VOCs, making them highly suitable for harsh industrial applications and specialized packaging.

Which geographical region is expected to show the fastest CAGR for coding equipment?

The Asia Pacific (APAC) region is projected to exhibit the fastest Compound Annual Growth Rate (CAGR). This acceleration is attributed to rapid urbanization, increasing per capita consumption of packaged goods, significant manufacturing expansion, and the ongoing implementation of national traceability standards across major economies like India, China, and Southeast Asia.

Beyond simple date codes, what complex data formats are modern inkjet coders required to print?

Modern coders are required to print complex data formats including high-density 2D Data Matrix codes (essential for pharmaceutical serialization), sophisticated QR codes for consumer engagement and supply chain logistics, human-readable codes, and dynamic variable data pulled directly from MES databases for personalized or highly specified product batches.

What is the strategic importance of service and support in the Inkjet Coding Equipment Market?

Service and support are strategically vital because consistent uptime is paramount in high-speed manufacturing. Comprehensive service contracts, including rapid response maintenance, remote diagnostics, and guaranteed consumable supply, often dictate purchasing decisions over initial hardware cost, contributing significantly to vendor lock-in and recurring revenue.

How does the packaging material trend toward flexibility affect coding equipment design?

The trend toward flexible packaging (pouches, thin films) necessitates coding equipment that can handle non-contact application with extremely fast drying times to prevent smearing. This increases demand for highly responsive CIJ systems and specialized fast-curing inks, ensuring high print quality on materials that are difficult to handle.

What are the key technological breakthroughs improving CIJ equipment efficiency?

Recent CIJ breakthroughs include the implementation of advanced viscosity control systems, automated fluid management, and self-cleaning mechanisms, which drastically extend the time between required operator interventions, enhancing overall efficiency and reducing dependence on highly trained technicians.

Explain the concept of 'throw distance' and its relevance to coding equipment selection.

Throw distance is the maximum distance between the printhead nozzle and the target substrate while maintaining acceptable print quality. CIJ systems generally have a longer throw distance, crucial for printing on irregularly shaped products or recessed areas, whereas TIJ has a short throw distance, requiring closer contact with the packaging surface.

How is competition from laser coding systems influencing inkjet technology development?

Laser coding poses significant competition, especially for permanent marking on stable, high-volume products (e.g., beverages, cables). This pressure forces inkjet manufacturers to continuously improve ink durability (e.g., UV inks) and reliability while stressing the versatility and lower initial capital cost advantage of inkjet over laser for variable data applications.

What are the primary challenges when integrating coding equipment with packaging machinery?

Integration challenges involve synchronizing the coder's speed with the packaging line’s variable throughput, ensuring mechanical stability in vibrating environments, and establishing robust communication protocols (e.g., Ethernet IP, Profinet) between the coder’s operating system and the packaging line’s master PLC or Manufacturing Execution System (MES).

How do regulatory changes regarding food safety impact the ink formulation market?

Strict food safety regulations drive the demand for non-migrating inks, low-migration inks, and direct food contact inks (edible inks). Manufacturers must ensure that ink components do not penetrate the primary packaging material to avoid contamination, shifting the market focus toward specialized, certified ink chemistries.

What is the significance of the shift from low resolution to high resolution coding?

The shift is critical due to serialization and verification requirements. Low resolution is sufficient for simple batch codes, but high resolution (300 dpi+) is mandatory for printing intricate 2D data matrix codes that must be machine-readable by automated inspection systems, significantly reducing the potential for scanning errors in the supply chain.

In the Value Chain, what is the role of Value-Added Resellers (VARs)?

VARs play a crucial role in the indirect distribution channel, especially for regional customers. They provide localized sales, integration services, technical support, training, and ensure the consistent supply of specialized consumables, acting as an essential interface between the major OEM and the smaller end-user market.

How does AI contribute to reducing code compliance errors?

AI, through Machine Learning-based Optical Character Verification (OCV) and Machine Vision systems, is trained to instantly identify and reject products with smudged, illegible, or incorrect codes far faster and more reliably than human inspectors, ensuring near-perfect regulatory compliance before products leave the factory floor.

What emerging substrate types are challenging existing inkjet coding capabilities?

Emerging challenges come from sustainable packaging materials, such as bio-plastics, thin recycled films, and highly porous paper-based packaging, which often require specialized primers or entirely new ink formulations (like flexible UV inks) to ensure high adhesion, contrast, and durability without compromising the substrate integrity.

What are the limitations of Piezoelectric DOD technology compared to CIJ?

While Piezo DOD offers high resolution and versatility with ink types (including UV), its limitations typically include slower printing speeds compared to CIJ for continuous lines and a more complex printhead structure, potentially leading to higher initial equipment costs and sensitivity to handling highly volatile fluids.

How does remote diagnostics technology affect the service model in the market?

Remote diagnostics, enabled by IoT connectivity, allows manufacturers to monitor coder performance globally, identify potential failures proactively, and often resolve issues via remote software adjustments. This minimizes the need for costly field service visits, enhancing uptime, and optimizing maintenance scheduling based on actual equipment usage.

What are the primary applications for low-resolution DOD systems?

Low-resolution DOD systems are typically used for printing large characters on porous secondary packaging, such as shipping cases or corrugated boxes. They commonly apply basic information like gross weights, product descriptions, pallet identification, and large, simple batch codes where ultra-high quality barcodes are not required.

Why is the pharmaceutical sector driving demand for high-end coding equipment?

The pharmaceutical sector demands high-end equipment primarily due to stringent global serialization mandates (unit-level tracking) and the requirement for highly accurate 2D data matrix codes, necessitating high-resolution, verifiable printing with zero defects to combat counterfeiting and ensure patient safety.

How is ink consumption being optimized using modern coding systems?

Modern systems employ advanced software algorithms and AI to precisely calculate and control the volume of ink drops expelled. Through intelligent droplet sizing and velocity control, coupled with real-time monitoring of fluid parameters, systems ensure minimum necessary consumption, optimizing operating costs and reducing material waste.

What role does machine vision play in pharmaceutical coding processes?

In pharmaceuticals, machine vision systems provide 100% inspection capability. They automatically read and verify every serialized code, check for print quality, data accuracy, and positioning, and communicate with the packaging line control system to reject any non-compliant items, ensuring absolute traceability and compliance.

Which geographical segment is most focused on sustainable ink formulations?

Europe is the geographical segment most intensely focused on sustainable ink formulations due to strict regulatory frameworks concerning environmental protection, waste reduction, and limits on Volatile Organic Compound (VOC) emissions, pushing manufacturers towards water-based and UV-curable alternatives.

Why are cosmetics and personal care manufacturers focusing on fine print capability?

Cosmetics and personal care items often involve small containers or sophisticated packaging designs. Manufacturers require fine print capability (high resolution) to apply necessary regulatory information, batch codes, or marketing data in tiny, discreet areas without compromising the aesthetic appeal or brand integrity of the product.

How does the increasing demand for customizable packaging affect coding equipment?

The demand for highly customizable and variable packaging formats necessitates coding equipment with greater flexibility and faster changeover capabilities. Coders must easily interface with variable data sources and adapt print settings automatically for different product sizes, shapes, and material compositions on the fly.

What is the significance of the base year (2025) and forecast period (2026-2033) in this report?

The base year (2025) provides a solid, estimated foundation reflecting the current market conditions and technology adoption rates following recent economic shifts. The forecast period (2026-2033) extrapolates these trends, accounting for anticipated regulatory changes, technological advancements like AI integration, and global manufacturing expansions to project future market valuation and growth trajectory.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager