Inkjet Marking Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434642 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Inkjet Marking Equipment Market Size

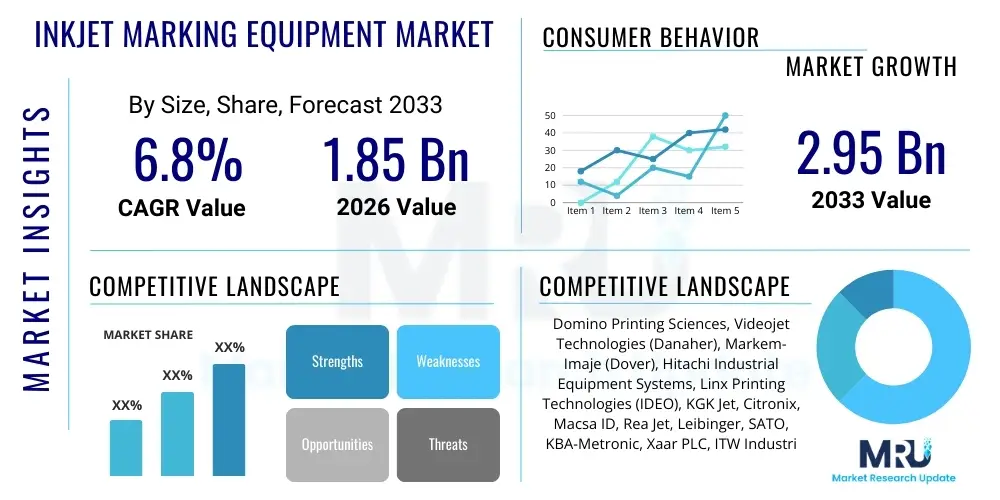

The Inkjet Marking Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 2.95 Billion by the end of the forecast period in 2033.

The steady expansion is primarily attributed to stringent global regulatory requirements mandating product traceability, particularly within the food and beverage, pharmaceutical, and cosmetic industries. Inkjet marking systems offer high-resolution, non-contact printing capability necessary for variable data such as expiration dates, batch codes, and serialization numbers on diverse substrates, ranging from flexible packaging films to rigid bottles and cartons. The increasing automation across manufacturing sectors globally demands faster, more reliable, and integrated coding solutions, driving the adoption of Continuous Inkjet (CIJ) and Drop-on-Demand (DOD) technologies.

Furthermore, technological advancements focusing on optimizing uptime, reducing solvent consumption, and improving print quality on challenging surfaces are cementing the inkjet technology's dominance over legacy marking methods like stamping or labeling. The transition towards sustainable manufacturing practices is also influencing the market, encouraging vendors to develop eco-friendly inks (e.g., UV-curable and water-based inks) that comply with environmental safety standards while maintaining production efficiency. This robust foundation of regulatory compliance, automation requirements, and technological innovation provides a strong trajectory for market valuation growth through 2033.

Inkjet Marking Equipment Market introduction

The Inkjet Marking Equipment Market encompasses industrial-grade printing systems utilized for applying essential alphanumeric data, barcodes, QR codes, and logos directly onto products and packaging during the manufacturing process. These systems are crucial for compliance, inventory management, anti-counterfeiting measures, and consumer safety. The primary technologies involved include Continuous Inkjet (CIJ), Drop-on-Demand (DOD), and Thermal Inkjet (TIJ), each suited for specific production speeds, substrate types, and marking durability requirements. CIJ printers are known for their high-speed, 24/7 reliability in harsh industrial environments, while TIJ and DOD systems excel in applications requiring high-resolution, static codes.

Major applications span various sectors, including the high-volume fast-moving consumer goods (FMCG) market, where rapid coding of expiration dates is essential, and the heavily regulated pharmaceutical sector, which requires complex 2D data matrix codes for track-and-trace serialization initiatives. The benefits of using modern inkjet marking equipment include non-contact application, minimal downtime, versatility across porous and non-porous materials, and seamless integration into high-speed production lines. This integration capability is a key driving factor, allowing manufacturers to achieve operational efficiencies and adhere to global supply chain standards without compromising throughput.

Driving factors propelling market growth include stringent global food safety regulations (e.g., FDA requirements and EU directives), the escalating need for counterfeit protection due to expanding global supply chains, and the ongoing trend of digitalization in manufacturing (Industry 4.0). Additionally, the rising adoption of specialized inks, such as food-grade, invisible UV, and high-adhesion inks for challenging substrates, further expands the applicability and utility of these marking systems across diverse industrial landscapes.

Inkjet Marking Equipment Market Executive Summary

The Inkjet Marking Equipment market exhibits dynamic growth, fundamentally driven by compliance mandates and the widespread adoption of automation across global manufacturing. Current business trends indicate a strong pivot towards integrated solutions that connect coding equipment directly with Enterprise Resource Planning (ERP) systems and Manufacturing Execution Systems (MES) for enhanced data governance and real-time operational insights. Vendors are heavily investing in developing compact, modular systems with intuitive touch interfaces, reducing the skill requirement for operation and maintenance, thereby lowering the total cost of ownership (TCO). This focus on digitalization and user-friendliness represents a significant strategic shift among market leaders aimed at securing long-term service contracts and market share.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, fueled by rapid industrialization, particularly in emerging economies like China and India, coupled with increasing consumer awareness driving stricter local quality and traceability standards. North America and Europe, characterized by established regulatory frameworks and high labor costs, prioritize advanced, automated solutions such as high-resolution TIJ and laser marking systems to optimize efficiency and minimize manual intervention. The Middle East and Africa (MEA) and Latin America are experiencing steady adoption rates, primarily driven by investments in new food processing and beverage bottling plants requiring foundational CIJ coding capabilities.

Segment trends reveal that the Continuous Inkjet (CIJ) technology segment maintains market dominance due to its speed and resilience, especially in primary packaging coding. However, the Thermal Inkjet (TIJ) segment is rapidly gaining traction in secondary packaging and pharmaceutical serialization due to its superior print quality and clean operation, aligning with cleaner manufacturing environments. The Food & Beverage end-user segment remains the largest consumer, but the Pharmaceutical sector is demonstrating the highest growth rate, driven by complex global serialization mandates (e.g., the Drug Supply Chain Security Act - DSCSA), which necessitate precise, verifiable marking equipment.

AI Impact Analysis on Inkjet Marking Equipment Market

Users frequently inquire about how Artificial Intelligence (AI) and Machine Learning (ML) integration will transform the reliability, predictive maintenance capabilities, and efficiency of inkjet marking processes. Key themes revolve around the potential for AI to preemptively diagnose component failures, optimize fluid consumption (ink and solvent), and ensure code accuracy and compliance through real-time quality assurance. Concerns often focus on the complexity and cost of integrating AI-powered vision systems with legacy coding machinery, and the data privacy implications of transmitting sensitive production metrics. Overall expectation is that AI will move inkjet marking equipment from being merely a data application tool to an intelligent, self-optimizing component of the Industry 4.0 ecosystem.

The current impact of AI is focused primarily on two critical areas: enhancing quality inspection and enabling highly accurate predictive maintenance. AI-driven vision systems are increasingly deployed downstream of the inkjet coder to verify code legibility, placement accuracy, and compliance against mandated standards at high speeds. This reduces human error and waste associated with illegible or misplaced codes. Furthermore, ML algorithms analyze operational telemetry—such as printhead temperature, nozzle function, fluid pressure, and environmental conditions—to predict potential mechanical failures or print quality degradation hours or days before they occur. This transition from reactive repair to proactive maintenance significantly increases equipment uptime, a critical metric in high-volume production environments.

Looking forward, AI is expected to revolutionize consumable management. ML models can optimize the mixing and delivery of solvents and inks based on real-time factors like ambient temperature, humidity, and production line speed, ensuring optimal print performance while minimizing waste and consumption. Moreover, AI will facilitate the automatic calibration and changeover of printing jobs, allowing equipment to self-adjust settings based on substrate material recognition or uploaded work orders. This cognitive functionality minimizes setup time and enhances the flexibility of production lines, making short runs and customized packaging more economically viable, thereby cementing AI's role as a driver of operational excellence in the marking sector.

- AI-powered Predictive Maintenance: Forecasting printhead and component failures based on real-time operational data analysis.

- Real-time Code Quality Verification: Utilizing machine vision and AI algorithms for instantaneous inspection of code legibility and compliance.

- Optimized Consumable Usage: ML-driven adjustments of ink viscosity and solvent ratio based on environmental variables for reduced waste.

- Automated Setup and Calibration: AI algorithms facilitating rapid, error-free changeovers for different packaging substrates or print jobs.

- Enhanced Anti-Counterfeiting: Analyzing serialization data patterns in real-time to detect anomalous or fraudulent marking activities across the supply chain.

DRO & Impact Forces Of Inkjet Marking Equipment Market

The market is significantly influenced by stringent global regulatory landscapes (Driver) demanding serialized traceability, yet faces substantial headwinds from the high initial capital expenditure (Restraint) required for advanced systems. This creates an Opportunity for service providers offering equipment rental or pay-per-use models. The primary Impact Force is the rapid adoption of Industry 4.0 principles, which necessitates seamless integration of coding systems into automated manufacturing ecosystems, pressuring vendors to deliver connectivity and data management features beyond simple printing functions. This interplay of regulatory push, technological pull, and cost barriers defines the competitive dynamics.

Key drivers include the global mandate for pharmaceutical serialization, pushing companies to invest in high-resolution, verifiable coding systems capable of handling unique identifier codes (UICs) and complying with regulations such as the European Falsified Medicines Directive (FMD). Furthermore, consumer demand for transparency and sustainability accelerates the adoption of advanced inkjet systems that can print comprehensive product information or utilize environmentally friendly inks. The continual rise in industrial automation across manufacturing sectors, especially in high-growth economies, demands high-speed, reliable marking systems that minimize operator interaction and maximize line uptime, directly fueling market expansion.

Restraints primarily revolve around the total cost of ownership (TCO), which includes not only the initial equipment cost but also the recurring expense of proprietary inks, solvents, and consumables. Compatibility issues when integrating new marking equipment with heterogeneous legacy production lines pose a technical challenge for many older facilities. Opportunities lie in the shift towards modular, flexible printing systems that can adapt quickly to evolving packaging designs and substrate materials. The development of specialized application inks, such as migrating inks for porous materials or highly durable inks for automotive parts, presents niche market opportunities. The strongest impact force is the necessity for digitalization, forcing traditional hardware vendors to transition into comprehensive solution providers offering software, data analytics, and robust cybersecurity features alongside the physical coding equipment.

Segmentation Analysis

The Inkjet Marking Equipment market is segmented based on technology type, ink type, printing speed, and the diverse end-user industries they serve. Technology segmentation (CIJ, DOD, TIJ) determines suitability for specific industrial requirements, where CIJ dominates high-speed, general industrial coding, and TIJ offers high resolution for detailed graphics and serialization. Segmentation by ink type reflects the growing regulatory and environmental demands, driving innovation towards safer and more durable formulations. End-user segmentation highlights the dominance of the Food & Beverage and Pharmaceutical sectors, which are the main compliance-driven purchasers, while the industrial and automotive sectors require specialized durable coding.

- Technology Type

- Continuous Inkjet (CIJ)

- Drop-on-Demand (DOD)

- Piezoelectric Inkjet (PIJ)

- Thermal Inkjet (TIJ)

- Ink Type

- Solvent-Based Inks

- Water-Based Inks

- UV-Curable Inks

- Specialty Inks (Invisible, Pigmented, Food-Grade)

- Printing Speed

- Low Speed (Up to 100 products/minute)

- Medium Speed (100–300 products/minute)

- High Speed (Above 300 products/minute)

- End-User Industry

- Food and Beverage

- Pharmaceutical and Healthcare

- Cosmetics and Personal Care

- Automotive and Aerospace

- Industrial and Construction Materials

- Electronics and Electricals

Value Chain Analysis For Inkjet Marking Equipment Market

The value chain for the Inkjet Marking Equipment market is highly structured, starting with raw material procurement and complex component manufacturing, extending through system assembly and sophisticated software development, and culminating in sales, distribution, and extensive after-sales service. Upstream activities are dominated by specialized suppliers providing printheads (e.g., Xaar, Seiko, Konica Minolta), advanced electronics, and chemicals required for ink and solvent production. The quality and reliability of these upstream components directly dictate the performance and lifespan of the final marking system. Key manufacturers maintain tight control over ink formulation to ensure compatibility and maintain proprietary consumable revenue streams, securing a competitive advantage.

Midstream involves the core manufacturing and integration processes where Original Equipment Manufacturers (OEMs) design, assemble, and integrate the printing hardware with control software and data management platforms. This stage focuses heavily on quality control, modular design for easy integration, and ensuring compliance with machine safety standards. Downstream activities are crucial and include direct sales channels for major industrial customers and indirect distribution channels involving highly specialized distributors and system integrators. System integrators play a vital role, especially for complex serialization projects, as they configure the inkjet equipment to interface seamlessly with existing manufacturing lines, conveying systems, and ERP systems.

Direct distribution often serves large, multinational corporations that require global service agreements and standardized equipment. Indirect channels, utilizing distributors, are essential for reaching smaller and medium-sized enterprises (SMEs) in local markets, providing localized support and maintenance. The after-sales service component, covering maintenance contracts, consumable supply (ink, solvent), and technical support, constitutes a significant and high-margin segment of the total market value. Customer retention heavily relies on the efficiency of this service network, which ensures minimal production downtime for critical marking operations.

Inkjet Marking Equipment Market Potential Customers

Potential customers for Inkjet Marking Equipment span nearly every industry involved in high-volume manufacturing and packaging, with the common requirement being the need to apply essential variable data for traceability, inventory control, and consumer information. The largest and most demanding segment includes global producers in the Fast-Moving Consumer Goods (FMCG) sector, covering food, beverages, and household goods, which require high-speed CIJ systems for applying date codes and batch numbers directly onto primary and secondary packaging at rapid rates.

The Pharmaceutical and Medical Device industries represent the segment with the highest growth potential and strictest technical demands. These sectors are mandated to implement unit-level serialization for regulatory compliance, requiring highly accurate, high-resolution TIJ or specialized PIJ systems capable of printing complex 2D data matrix codes onto blister packs, vials, and cartons. These buyers prioritize validation capabilities, data integrity features, and integration with robust software management systems to comply with mandates like DSCSA and FMD.

Additionally, significant customers include manufacturers in the industrial components, automotive, and construction sectors, which require robust coding solutions for permanent marking on durable, often challenging substrates such as metal, rubber, and plastics. For these applications, pigmented or highly adhesive solvent-based inks and resilient printheads are necessary to withstand harsh environments, abrasion, and temperature extremes, ensuring the code remains legible throughout the product's lifespan.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.95 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Domino Printing Sciences, Videojet Technologies (Danaher), Markem-Imaje (Dover), Hitachi Industrial Equipment Systems, Linx Printing Technologies (IDEO), KGK Jet, Citronix, Macsa ID, Rea Jet, Leibinger, SATO, KBA-Metronic, Xaar PLC, ITW Industrial, Epilog Laser |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Inkjet Marking Equipment Market Key Technology Landscape

The Inkjet Marking Equipment technology landscape is characterized by the ongoing competition and specialization between Continuous Inkjet (CIJ), Thermal Inkjet (TIJ), and Piezoelectric Drop-on-Demand (PIJ/DOD) systems. CIJ remains the foundational technology, prized for its ability to operate reliably at high speeds and in challenging industrial environments, utilizing electrostatically charged ink droplets deflected through a gutter. Recent advancements in CIJ focus on improving reliability through self-cleaning printheads and reducing solvent consumption by optimizing fluid management systems, thereby extending maintenance intervals and reducing environmental impact. Vendors are also integrating advanced diagnostics and IoT capabilities into CIJ systems for remote monitoring and predictive maintenance.

Thermal Inkjet (TIJ) technology has experienced significant growth, particularly in sectors demanding high resolution, such as pharmaceutical serialization and secondary packaging. TIJ uses heat to rapidly vaporize ink, creating a bubble that expels a droplet, resulting in extremely clean, high-DPI (dots per inch) prints suitable for complex 2D codes. The key advantage of TIJ is its maintenance-free operation due to the use of replaceable, disposable cartridges containing both the printhead and ink reservoir. Technological developments are focused on increasing the throw distance and improving ink compatibility, allowing TIJ to mark on non-porous materials like films and metals, expanding its application scope beyond porous cardboard.

Piezoelectric Inkjet (PIJ), or larger DOD systems, use mechanical deformation (via piezoelectric crystals) to eject droplets, allowing them to handle a wider range of fluid viscosities, including heavily pigmented and UV-curable inks. This makes PIJ essential for marking darker substrates or achieving highly durable, abrasion-resistant marks (e.g., in the electronics and industrial sectors). The technological focus here is on developing wider print swaths and integrating sophisticated curing mechanisms (UV LED) directly into the printing head. Furthermore, the convergence of inkjet marking with machine vision systems and cloud-based data repositories represents the cutting edge, ensuring that the applied code is not just printed, but verified and logged instantly for compliance and supply chain visibility.

Regional Highlights

Regional dynamics significantly influence the adoption and technological preference within the Inkjet Marking Equipment market, driven by varying regulatory stringency, industrial maturity, and capital investment rates. Asia Pacific (APAC) currently dominates the market in terms of volume and exhibits the highest growth rate. This acceleration is attributed to massive industrial expansion, particularly in the manufacturing hubs of China, India, and Southeast Asia, coupled with evolving local food safety and pharmaceutical traceability regulations. Manufacturers in APAC prioritize rugged, high-uptime CIJ systems that can handle large production volumes cost-effectively, although demand for high-resolution TIJ is rapidly increasing due to foreign investment and rising quality standards.

North America and Europe represent mature, high-value markets characterized by a strong emphasis on automation, high-resolution printing, and environmental compliance. These regions are early adopters of advanced technologies, including AI-integrated vision systems, high-speed serialization solutions (TIJ and specialized PIJ), and environmentally sustainable inks (UV-curable and water-based). The market stability is driven by mandatory pharmaceutical track-and-trace requirements and the continuous modernization of existing production facilities aimed at reducing labor costs and optimizing energy efficiency. The intense regulatory framework here ensures persistent demand for compliant and validated marking equipment.

The Latin America (LATAM) and Middle East & Africa (MEA) regions are emerging markets showing promising growth, primarily fueled by investments in food and beverage processing plants and localized manufacturing growth spurred by governmental initiatives. Adoption in these regions tends to favor reliable, easy-to-maintain CIJ technology due to its versatility and lower initial capital outlay compared to highly sophisticated TIJ or laser systems. However, increasing global trade and expanding international distribution channels are gradually necessitating compliance with international traceability standards, pushing larger regional producers towards higher-specification marking equipment.

- North America: Focus on high-resolution TIJ for serialization; significant adoption of AI-integrated inspection systems; strict pharmaceutical compliance (DSCSA).

- Europe: Driven by environmental regulations requiring solvent reduction; mandatory Falsified Medicines Directive (FMD) compliance; preference for integrated, modular systems.

- Asia Pacific (APAC): Largest market volume and highest growth; demand driven by general industrialization and expanding local compliance mandates (food safety); heavy CIJ utilization.

- Latin America (LATAM): Growth concentrated in food, beverage, and primary manufacturing sectors; increasing adoption of CIJ for baseline coding requirements.

- Middle East and Africa (MEA): Emerging industrialization and new manufacturing facility construction driving demand; slow but steady transition towards better traceability protocols.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Inkjet Marking Equipment Market.- Domino Printing Sciences

- Videojet Technologies (Danaher Corporation)

- Markem-Imaje (Dover Corporation)

- Hitachi Industrial Equipment Systems Co., Ltd.

- Linx Printing Technologies (IDEO)

- KGK Jet

- Citronix Inc.

- Macsa ID S.A.

- Rea Jet Coding and Marking Systems

- Leibinger Group

- SATO Holdings Corporation

- KBA-Metronic GmbH

- Xaar PLC (Printhead technology supplier)

- ITW Industrial Marking and Coding

- EBS Ink-Jet Systeme GmbH

- Control Print Limited

- Squid Ink Manufacturing Inc.

- Anser Coding Inc.

- Pulsar Technologies (A SATO company)

- Avery Dennison Corporation (Focus on solutions integration)

Frequently Asked Questions

Analyze common user questions about the Inkjet Marking Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving demand for Inkjet Marking Equipment?

The primary driver is the stringent global and regional regulatory requirement for product traceability and serialization, especially in the pharmaceutical and food and beverage sectors, necessitating high-speed application of variable data like batch codes and expiration dates.

How do CIJ, TIJ, and DOD technologies differ in application?

CIJ (Continuous Inkjet) is favored for high-speed production lines and general industrial applications due to its resilience. TIJ (Thermal Inkjet) offers superior high-resolution printing for detailed codes and serialization on porous and non-porous materials. DOD (Drop-on-Demand) is generally used for larger characters or specialized inks (e.g., highly pigmented) that require precise droplet control.

What role does Industry 4.0 play in the future of marking equipment?

Industry 4.0 drives the need for connectivity, demanding that inkjet equipment integrates seamlessly with MES and ERP systems. This enables real-time data exchange, remote diagnostics, AI-driven predictive maintenance, and automated job changeovers, increasing overall manufacturing efficiency and data integrity.

Which regional market shows the highest growth potential for inkjet marking?

The Asia Pacific (APAC) region is projected to exhibit the highest growth rate, driven by significant industrial expansion, increasing consumer safety awareness, and the ongoing implementation of modern quality control and traceability standards across high-volume manufacturing sectors.

Are UV-curable inks becoming a major market trend?

Yes, UV-curable inks are a major trend, particularly in North America and Europe. They offer immediate drying, excellent durability, high adhesion to diverse substrates (like plastics and glass), and are generally considered more environmentally friendly than traditional solvent-based inks, aligning with sustainable manufacturing goals.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager