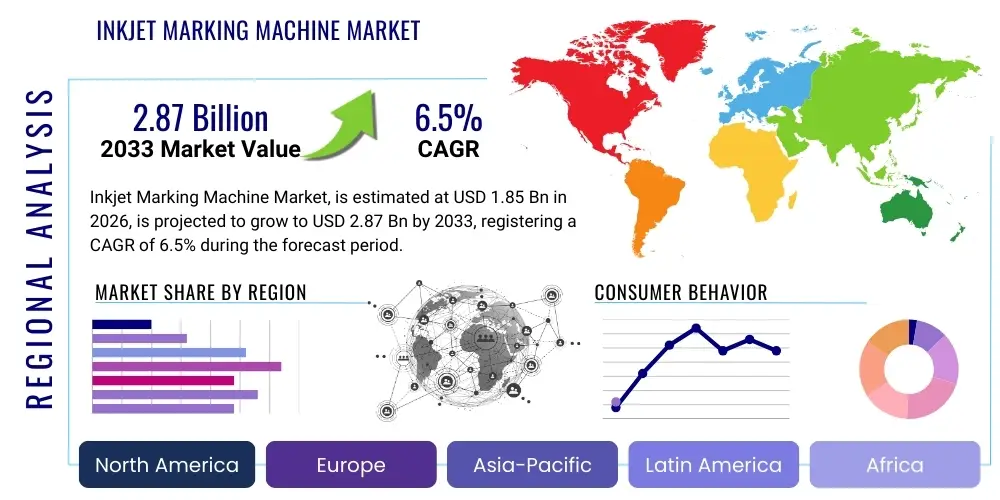

Inkjet Marking Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437781 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Inkjet Marking Machine Market Size

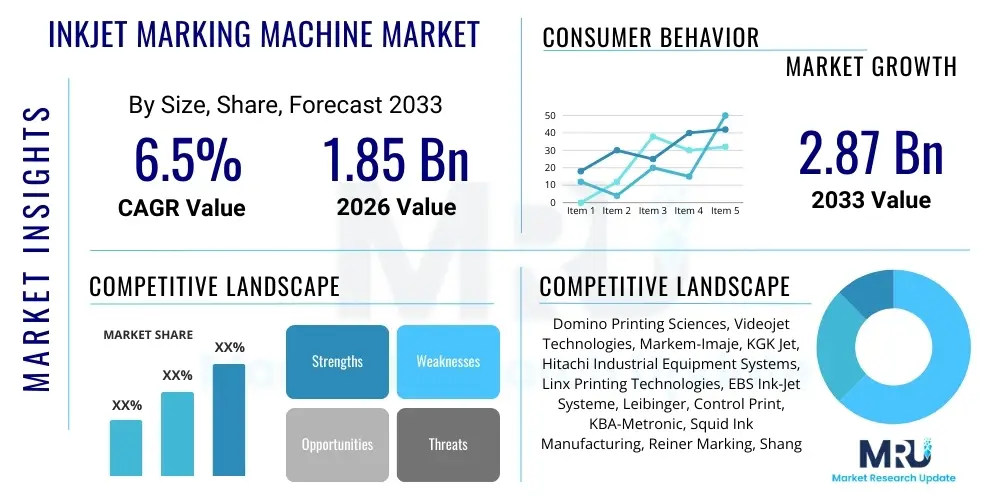

The Inkjet Marking Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 2.87 Billion by the end of the forecast period in 2033.

Inkjet Marking Machine Market introduction

The Inkjet Marking Machine Market encompasses sophisticated industrial devices designed for high-speed, non-contact printing of variable information directly onto products and packaging materials. These machines utilize inkjet technology, primarily Continuous Inkjet (CIJ), Drop-on-Demand (DOD), and Thermal Inkjet (TIJ), to apply essential data such as batch codes, expiration dates, serial numbers, barcodes, and logos. The necessity for traceability and anti-counterfeiting measures across regulated industries drives the core demand for these systems, making them critical components in modern production lines. These systems offer flexibility in substrate material handling, including plastics, metals, glass, and cardboard, ensuring broad applicability across various manufacturing sectors.

Inkjet marking machines provide significant operational benefits, including reduced downtime, high reliability, and the ability to operate effectively in challenging industrial environments. They deliver superior print quality at high line speeds, ensuring regulatory compliance, especially within the food and beverage and pharmaceutical sectors where legibility and permanence of codes are non-negotiable legal requirements. The key driving factors for market expansion include the global surge in packaged consumer goods, stringent governmental regulations mandating product serialization and identification, and the continuous industrial shift towards automated manufacturing processes, known as Industry 4.0.

Major applications of inkjet marking technology span primary, secondary, and tertiary packaging operations. In pharmaceuticals, they ensure compliance with drug tracking systems, while in the food and beverage industry, they manage shelf life and freshness codes. The automotive sector utilizes these machines for marking components for quality control and part identification throughout the supply chain. These benefits, combined with advancements in ink technology—such as specialized inks for dark or challenging surfaces—cement the inkjet marking machine's role as an indispensable tool for inventory management, brand protection, and consumer safety.

Inkjet Marking Machine Market Executive Summary

The Inkjet Marking Machine Market is experiencing robust business growth, fundamentally driven by the accelerated adoption of smart factory initiatives and the imperative for enhanced supply chain transparency. Business trends indicate a strong move toward integrated coding and marking solutions that connect seamlessly with Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES), enabling real-time data collection and operational efficiency improvements. Furthermore, there is a pronounced shift towards environmentally friendly and low-VOC (Volatile Organic Compound) inks, prompted by sustainability goals set by major consumer goods manufacturers and stricter environmental regulations globally. This necessitates continuous R&D investment by key market players in sustainable consumables and more energy-efficient printer designs, often integrating remote diagnostic capabilities for predictive maintenance.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, fueled by massive industrialization, expanding domestic consumption, and the rapid expansion of the manufacturing bases in China and India, particularly in electronics and food processing. North America and Europe, while mature markets, emphasize technological upgrades, seeking high-resolution printing capabilities (such as those offered by TIJ and high-resolution DOD) for complex 2D codes and serialization standards. Latin America and MEA are experiencing steady growth, catalyzed by infrastructural development and the imposition of basic coding regulations on imported and domestically produced goods, creating significant demand for robust, cost-effective CIJ systems.

Segment trends reveal that the Continuous Inkjet (CIJ) segment continues to dominate the market due to its high speed and versatility across almost all substrates, making it the workhorse of industrial coding. However, the Thermal Inkjet (TIJ) segment is projected to exhibit the fastest growth, primarily because of its clean operation, high resolution, and minimal maintenance requirements, making it highly desirable for pharmaceutical and secondary packaging applications. The Food and Beverage industry remains the largest end-user segment, consistently driven by regulatory mandates and high production volumes, ensuring steady demand across all technology types, ranging from marking beverage cans to flexible packaging films.

AI Impact Analysis on Inkjet Marking Machine Market

Common user questions regarding AI's influence center on whether AI can enhance the precision of marking, optimize maintenance schedules, and improve the quality control process. Users frequently inquire about integrating AI vision systems with marking equipment for immediate code validation, reducing operator error, and minimizing waste. Key themes include the implementation of predictive maintenance algorithms trained on machine usage data to forecast component failure before it impacts production, thereby maximizing uptime. There is also a strong expectation that AI will facilitate highly adaptive coding, allowing the marking machine to adjust print parameters automatically based on subtle changes in line speed, environmental conditions, or substrate characteristics, ensuring consistent print quality without manual intervention. Users are seeking AI solutions that transform coding from a simple execution task into a proactive, data-driven element of the production process.

- Predictive Maintenance Optimization: AI algorithms analyze historical operational data (e.g., ink viscosity, pressure levels, print head performance) to accurately predict potential equipment failures, significantly reducing unplanned downtime.

- Automated Quality Inspection: Integration of AI-powered machine vision systems immediately reads, verifies, and grades printed codes (barcodes, data matrix codes, text legibility), automatically rejecting non-compliant products at high speeds.

- Dynamic Print Parameter Adjustment: AI enables the machine to autonomously adjust ink drop speed, solvent addition rates, or nozzle temperature in real-time to compensate for ambient temperature fluctuations or line speed variations, maintaining optimal print quality.

- Inventory and Consumable Management: AI systems track ink and solvent consumption patterns and automate reordering processes, optimizing supply chain logistics for consumables and minimizing stockouts.

- Enhanced Data Analytics and Traceability: AI processes the vast amount of data generated by marking machines (timestamps, batch IDs, location data) to provide deeper insights into production efficiency and regulatory compliance reporting.

DRO & Impact Forces Of Inkjet Marking Machine Market

The Inkjet Marking Machine Market is heavily influenced by a combination of powerful drivers and stringent restraints, balanced by emerging opportunities. The primary driver is the global trend toward stricter regulatory compliance and product traceability, particularly in regulated industries like pharmaceuticals, requiring unit-level serialization. Furthermore, the rapid growth of e-commerce and subsequent expansion of packaging operations necessitates high-speed, reliable coding solutions to handle massive SKU proliferation. Restraints primarily involve the high initial capital investment required for advanced coding technologies, which can be prohibitive for small and medium-sized enterprises (SMEs), alongside the operational challenge related to frequent maintenance and cleaning required by CIJ systems, and the ongoing cost management of specialized inks and solvents.

Key opportunities center around the development of specialized, sustainable inks, such as UV-cured and food-grade inks, addressing both environmental concerns and specialized marking requirements (e.g., direct food contact). The proliferation of high-resolution TIJ technology into industrial environments previously dominated by CIJ offers an opportunity for cleaner, less maintenance-intensive operations, particularly in high-volume secondary packaging. Additionally, the increasing demand for advanced data integration capabilities, driven by Industry 4.0, presents substantial opportunities for manufacturers to offer software-integrated, network-ready marking solutions that provide real-time operational feedback and remote diagnostics, thus creating new value-added service streams.

The impact forces within this market are significant. Regulatory mandates, such as the EU Falsified Medicines Directive (FMD) and similar regulations globally, exert constant pressure for technological adaptation, forcing companies to upgrade older systems. Technological advancements, particularly in print head design and ink chemistry, act as a disruptive force, improving efficiency and reducing reliance on traditional solvent-based systems. Economically, the cost of consumables remains a major factor influencing purchasing decisions, prompting companies to favor systems with high ink mileage and low solvent usage. These forces collectively shape a competitive landscape focused on delivering high uptime, versatility, and compliance assurance.

Segmentation Analysis

The Inkjet Marking Machine Market is highly segmented based on the core technology deployed, the physical characteristics of the machine, the type of data printed, and the specific industry application. This segmentation reflects the diverse needs of the manufacturing sector, ranging from high-speed, 24/7 operations requiring CIJ stability to intermittent, high-resolution marking demands met by TIJ systems. Understanding these segments is crucial as manufacturers tailor their product portfolios—from stationary high-capacity printers to mobile, handheld marking devices—to maximize penetration across various operational scales and technical requirements. The market structure emphasizes solutions that balance speed, print quality, cost of ownership, and ease of integration into existing production lines.

- By Technology

- Continuous Inkjet (CIJ)

- Drop-on-Demand (DOD)

- Thermal Inkjet (TIJ)

- Piezoelectric Inkjet

- By Print Type

- Monochrome

- Color

- By Product Type

- Stationary/Fixed

- Portable/Handheld

- By End-Use Industry

- Food and Beverage

- Pharmaceuticals and Healthcare

- Automotive and Aerospace

- Cosmetics and Personal Care

- Electronics and Semiconductors

- Building and Construction

- Industrial and Chemical

- Others (Wire and Cable, Textiles)

- By Application

- Primary Packaging Coding

- Secondary Packaging Coding

- Tertiary (Pallet) Marking

- Direct Product Marking

- By Printing Resolution

- Low Resolution

- High Resolution

Value Chain Analysis For Inkjet Marking Machine Market

The value chain for the Inkjet Marking Machine Market begins with upstream activities focused on the procurement of core components and raw materials. This involves sourcing specialized microelectronics, fluid management systems (pumps, valves), print heads (often supplied by specialized ODMs or internally manufactured), and the essential chemical raw materials necessary for formulating inks and solvents. The successful functioning of the market relies heavily on the quality and reliability of precision engineering required for robust print head technology, which determines machine longevity and performance. Upstream efficiency in raw material sourcing directly impacts the profitability and reliability of the final product, creating interdependence between chemical suppliers and equipment manufacturers.

Midstream activities involve the design, manufacturing, assembly, and quality assurance of the complete inkjet marking system. Manufacturers often engage in vertical integration, developing proprietary software and ink formulations to lock in recurring revenue streams and maintain competitive differentiation. Distribution channels are typically a mix of direct sales forces handling key multinational accounts and a robust network of authorized distributors and value-added resellers (VARs). These distributors are critical for providing localized technical support, installation services, and rapid supply of consumables, especially in geographically dispersed markets. Indirect channels often utilize specialized packaging automation integrators who bundle marking machines with conveyors and packaging lines.

Downstream activities focus heavily on installation, maintenance, and the continuous supply of consumables (inks, solvents, filters), which represent the major revenue stream post-initial sale. Direct sales channels are often preferred for highly complex or specialized machines requiring dedicated engineering support, ensuring close customer relationship management. The indirect channel plays a vital role in servicing SMEs and providing aftermarket support, particularly in emerging markets where local presence and quick service response are essential competitive advantages. The effectiveness of the service network ultimately determines customer satisfaction and retention, making technical training and parts availability critical downstream components.

Inkjet Marking Machine Market Potential Customers

Potential customers for Inkjet Marking Machines are diverse, spanning nearly every sector involved in mass manufacturing and packaged goods production where traceability, compliance, and product information are mandatory. The primary segment comprises high-volume manufacturers, particularly within the Food and Beverage industry, including producers of bottled water, soft drinks, processed foods, and confectionery, who require rapid coding of expiry dates, batch codes, and logos on primary packaging. These buyers prioritize machine speed, uptime, and resistance to humid or wash-down environments. Their purchasing decisions are heavily influenced by the Total Cost of Ownership (TCO) and compliance with food safety regulations.

A secondary, highly regulated segment is Pharmaceuticals and Healthcare. These buyers require high-resolution printing for complex 2D data matrix codes necessary for serialization (unit-level tracking) to comply with global drug safety mandates. Their demand is shifting rapidly toward clean, high-precision TIJ and advanced CIJ systems. Other critical industrial customers include the Automotive sector (marking components, wires, and engine parts for long-term traceability) and the Electronics industry (coding PCBs and sensitive components requiring non-contact, high-precision marking). These industrial end-users prioritize permanence of the mark and integration into automated assembly lines.

Furthermore, packaging and contract manufacturers represent significant potential customers, often requiring flexible marking solutions capable of handling varied product runs and substrate materials for multiple clients. The Cosmetics and Personal Care industry also constitutes a steady customer base, needing aesthetic and durable coding on glass, plastics, and metal packaging. The selection criteria for potential buyers universally revolve around regulatory compliance, integration capabilities with existing automation infrastructure, reliability in harsh conditions, and the efficiency of the consumable supply chain.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.87 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Domino Printing Sciences, Videojet Technologies, Markem-Imaje, KGK Jet, Hitachi Industrial Equipment Systems, Linx Printing Technologies, EBS Ink-Jet Systeme, Leibinger, Control Print, KBA-Metronic, Squid Ink Manufacturing, Reiner Marking, Shanghai Rottweil, Zanasi, ITW Diagraph, Matthews Marking Systems, BestCode, Macsa ID, Needham Inks, Wale Apparatus |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Inkjet Marking Machine Market Key Technology Landscape

The technology landscape of the Inkjet Marking Machine market is dominated by four core printing methods, each suited for distinct industrial requirements. Continuous Inkjet (CIJ) remains the foundational technology, known for its ability to operate at extremely high speeds and print small characters onto virtually any substrate, regardless of material or shape, making it ideal for primary packaging in challenging environments. CIJ systems continuously circulate ink, with drops precisely charged and deflected to form the required code, while unused drops are recirculated. Recent advancements in CIJ technology focus on reducing solvent consumption, improving print head self-cleaning mechanisms, and enhancing data connectivity for remote monitoring and diagnostics, increasing uptime reliability.

Drop-on-Demand (DOD) technologies encompass both Valvejet and Piezoelectric systems. Valvejet is typically used for large-character marking on secondary (corrugated boxes) or tertiary packaging (pallets), valued for robustness and low maintenance. Piezoelectric DOD, particularly high-resolution versions, are gaining traction for complex coding requirements on flat surfaces, offering superior image quality compared to traditional CIJ. Crucially, Thermal Inkjet (TIJ) technology has witnessed exponential growth. TIJ uses heat to instantly vaporize ink, creating a bubble that ejects a droplet, offering exceptionally high resolution, clean operation, and zero scheduled maintenance due to the use of disposable print cartridges. This simplicity and quality make TIJ the preferred choice for pharmaceuticals, cosmetics, and secondary packaging where detailed 2D codes are mandatory.

The market is increasingly seeing convergence, where manufacturers offer platforms capable of supporting multiple technologies to provide integrated solutions. Connectivity is paramount; modern marking machines are equipped with interfaces (Ethernet, OPC UA) for seamless integration with factory automation networks and centralized coding management software. The development of specialized, highly pigmented and UV-curable inks represents a significant technological advancement, allowing for durable marking on difficult substrates (e.g., black rubber, glossy plastics) and instantaneous drying, which is crucial for fast production lines. The overarching technological trend is moving toward higher resolution, reduced environmental impact through solvent minimization, and smart capabilities driven by embedded sensors and IoT integration.

Regional Highlights

The global Inkjet Marking Machine Market exhibits distinct regional dynamics driven by varying levels of industrial maturity, regulatory enforcement, and consumer market growth rates. The regional analysis below outlines the primary market characteristics and drivers across major geographical segments.

- Asia Pacific (APAC)

- APAC dominates the global market, driven by rapidly expanding manufacturing sectors in China, India, and Southeast Asian nations.

- High demand is sustained by massive production volumes in Food and Beverage, Electronics, and Automotive industries.

- Market growth is fueled by increasing foreign direct investment in local manufacturing and improving regulatory standards for traceability, prompting investments in advanced coding equipment.

- North America

- North America is characterized by high technological maturity and a strong demand for high-resolution coding solutions, particularly TIJ, for pharmaceutical serialization and e-commerce packaging.

- Market stability is ensured by stringent FDA regulations and the continuous push towards Industry 4.0 integration, focusing on real-time data capture and predictive maintenance.

- Labor costs necessitate highly automated and reliable systems, minimizing manual intervention.

- Europe

- Europe is a mature market driven by strict regulatory frameworks such as the EU Falsified Medicines Directive (FMD) and rigorous environmental standards.

- There is high adoption of clean, environmentally compliant technologies, including UV-curable inks and solvent-minimal CIJ systems.

- Key demand segments include premium consumer goods, automotive components, and food processing industries, emphasizing precise, durable, and aesthetic marking.

- Latin America (LATAM)

- LATAM is an emerging market showing steady growth due to increased industrialization, particularly in Brazil and Mexico.

- Demand is largely focused on robust, entry-level to mid-range CIJ systems for basic expiry and batch coding in the expanding domestic food and beverage market.

- Market penetration is supported by localized distribution and service networks addressing challenges related to infrastructure and customs complexity.

- Middle East and Africa (MEA)

- Growth in MEA is moderate but accelerating, supported by government initiatives to diversify economies away from oil and establish localized manufacturing capabilities.

- The market is seeing rising awareness regarding food safety and imported goods traceability, driving initial investments in coding equipment across various sectors.

- The requirement for systems capable of handling high temperatures and dust, common in regional climates, influences technology choice towards durable industrial solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Inkjet Marking Machine Market.- Domino Printing Sciences

- Videojet Technologies (A Danaher Company)

- Markem-Imaje (A Dover Company)

- KGK Jet

- Hitachi Industrial Equipment Systems Co., Ltd.

- Linx Printing Technologies (A Danaher Company)

- EBS Ink-Jet Systeme GmbH

- Leibinger GmbH & Co. KG

- Control Print Ltd.

- KBA-Metronic GmbH

- Squid Ink Manufacturing, Inc.

- Reiner Marking

- Shanghai Rottweil Industry Co., Ltd.

- Zanasi s.r.l.

- ITW Diagraph

- Matthews Marking Systems

- BestCode

- Macsa ID

- Needham Inks Limited

- Wale Apparatus Company Inc.

Frequently Asked Questions

Analyze common user questions about the Inkjet Marking Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between CIJ and TIJ marking technologies?

Continuous Inkjet (CIJ) is designed for high-speed operation, flexibility in substrate material and shape, and low print resolution, requiring specialized solvents and regular maintenance. Thermal Inkjet (TIJ) offers high print resolution, requires zero maintenance, uses disposable cartridges, and is typically used for slower lines or flat, porous substrates in clean environments like pharmaceutical secondary packaging.

Which industry segment drives the highest demand for inkjet marking machines?

The Food and Beverage industry segment consistently drives the highest volume of demand for inkjet marking machines. This is due to the mandatory requirement for printing batch numbers, expiration dates, and traceability codes on high volumes of primary and secondary packaging to ensure regulatory compliance and consumer safety.

What is the importance of ink formulation in the inkjet marking market?

Ink formulation is critical as it dictates adhesion, drying speed, permanence, and regulatory compliance (e.g., migration safety for food contact). Specialized inks, such as UV-curable, pigmented, or food-grade options, enable durable coding on challenging substrates like dark glass or oily metals, directly impacting production line efficiency and compliance.

How does Industry 4.0 influence the purchasing decisions for coding equipment?

Industry 4.0 demands integrated, networked coding solutions capable of real-time communication with MES/ERP systems. Purchasing decisions are now highly influenced by the machine’s ability to provide remote diagnostics, predictive maintenance data, and centralized code management to optimize overall equipment effectiveness (OEE) and minimize operational errors.

Is the use of portable or handheld inkjet marking machines growing?

Yes, the segment for portable or handheld inkjet marking machines is showing significant growth, driven by flexibility requirements for low-volume production, marking large or stationary objects (like pallets or large components), and applications in warehousing or logistics where traditional fixed systems are impractical.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager