Inkjet Printer Head Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439809 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Inkjet Printer Head Market Size

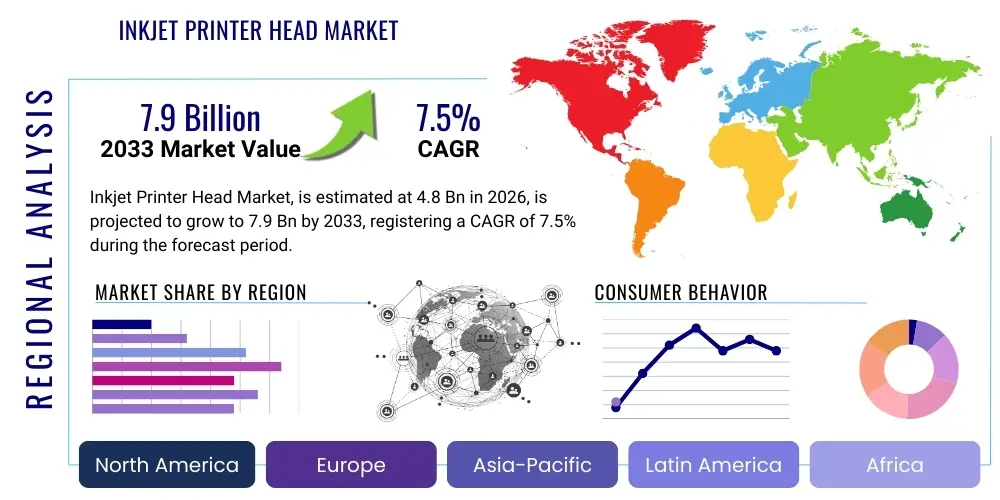

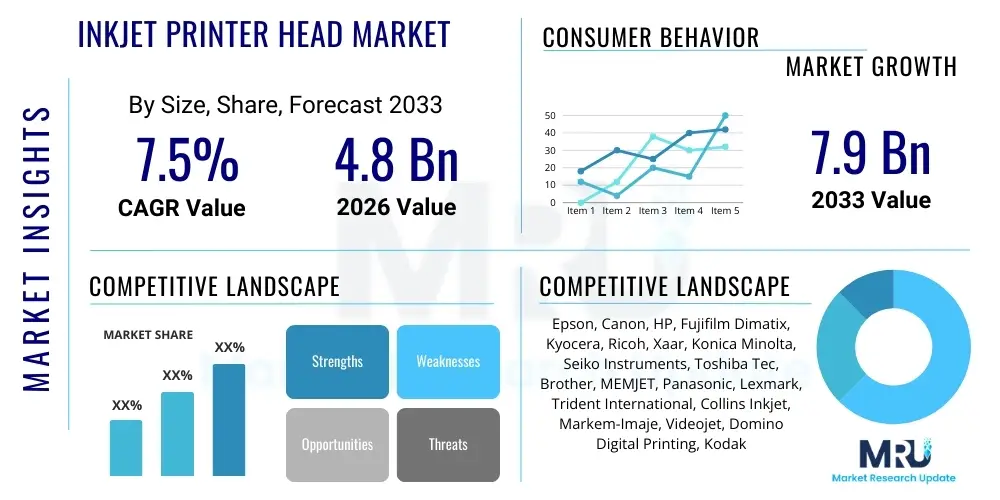

The Inkjet Printer Head Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 4.8 Billion in 2026 and is projected to reach USD 7.9 Billion by the end of the forecast period in 2033.

Inkjet Printer Head Market introduction

The Inkjet Printer Head Market is at the forefront of the digital printing revolution, embodying critical technology that enables precise, high-speed, and versatile deposition of ink. These sophisticated components are fundamental to the operation of inkjet printers across a vast spectrum of applications, ranging from everyday consumer desktop printing to highly specialized industrial manufacturing processes. The market's dynamism is driven by continuous innovation in material science, micro-electromechanical systems (MEMS) technology, and fluid dynamics, leading to ever-improving resolution, speed, and reliability. This evolution has expanded the capabilities of inkjet technology far beyond traditional paper printing, making it indispensable in modern industrial and commercial environments where customization and efficiency are paramount.

Inkjet printer heads are electromechanical devices that propel tiny droplets of ink onto a substrate, forming images or text. There are primarily two types: thermal inkjet heads, which use heat to create a vapor bubble that expels ink, and piezoelectric inkjet heads, which use piezoelectric materials to deform and eject ink. Both technologies offer distinct advantages depending on the application requirements, with piezoelectric heads often favored for industrial uses due to their versatility with a wider range of ink types, including UV-curable, solvent-based, and aqueous inks. The product's inherent ability to handle diverse substrates, from paper and fabric to ceramics and flexible electronics, underscores its broad utility.

Major applications for inkjet printer heads span across consumer electronics, commercial printing, industrial manufacturing, and increasingly, novel areas like 3D printing and biomedical applications. In commercial printing, they facilitate on-demand publishing, personalized marketing materials, and label printing. Industrially, they are critical for textile printing, ceramic tile decoration, direct-to-garment printing, packaging customization, and even the creation of intricate electronic circuits. The core benefits include unparalleled flexibility in design, reduced setup times compared to traditional printing methods, the ability to print variable data, and improved environmental efficiency through lower waste. These advantages, coupled with a growing demand for digital printing solutions and industrial automation, are significant driving factors propelling the market forward.

Inkjet Printer Head Market Executive Summary

The Inkjet Printer Head Market is characterized by robust business trends emphasizing strategic collaborations, intensive research and development investments, and a drive towards greater integration of smart manufacturing principles. Key players are increasingly focusing on developing heads capable of handling a wider array of specialized inks and advanced materials, thereby expanding application possibilities in burgeoning sectors such as printed electronics and additive manufacturing. There is also a notable trend towards miniaturization and increased nozzle density, aiming for higher resolution and faster print speeds. Business models are evolving to include more service-oriented approaches, providing comprehensive solutions that encompass hardware, software, and consumables, which fosters stronger customer relationships and recurring revenue streams for manufacturers.

Regional trends indicate that Asia-Pacific remains the largest and fastest-growing market, primarily due to its expansive manufacturing base, rapid industrialization, and increasing adoption of digital printing technologies across diverse industries like textiles, packaging, and ceramics. Countries such as China, Japan, and South Korea are not only significant consumers but also major innovators and producers of inkjet printer heads. North America and Europe, while representing more mature markets, continue to be strongholds for high-value industrial applications, advanced R&D, and the early adoption of cutting-edge technologies. These regions are driven by the demand for automation, efficiency, and customized production in niche markets, including specialized medical printing and sophisticated graphic arts.

From a segment perspective, the industrial printing application segment is experiencing significant growth, overshadowing traditional consumer desktop printing in terms of market value and technological advancement. Within industrial printing, sub-segments like textile printing, packaging, and direct-to-product customization are witnessing substantial investment and innovation. The demand for industrial inkjet heads is fueled by the need for on-demand production, personalization at scale, and reduced environmental impact compared to conventional methods. Furthermore, the increasing penetration of inkjet technology into emerging fields like 3D printing, flexible electronics manufacturing, and biomedical diagnostics is creating new, high-growth opportunities, driving advancements in both thermal and piezoelectric head technologies to meet highly specific and demanding performance criteria for these specialized applications.

AI Impact Analysis on Inkjet Printer Head Market

The integration of Artificial Intelligence (AI) into the Inkjet Printer Head Market is a subject of growing interest, with common user questions frequently revolving around how AI can enhance print quality, optimize operational efficiency, predict maintenance needs, and unlock entirely new application possibilities. Users are keenly interested in whether AI can lead to more autonomous printing systems, reduce material waste, and improve the overall cost-effectiveness of inkjet technology. There are also expectations regarding AI's role in personalizing print jobs at an unprecedented scale and its potential influence on design automation and intelligent ink formulation. The overarching theme is a desire for smarter, more responsive, and more reliable inkjet printing solutions across all segments.

Based on this analysis, AI's influence is anticipated to be transformative, enabling significant advancements in precision, productivity, and predictive capabilities within the inkjet printing ecosystem. AI algorithms can analyze vast datasets from print operations to identify patterns, optimize parameters, and detect anomalies that human operators might miss, thereby directly contributing to higher print quality and reduced downtime. This intelligent data processing leads to more informed decision-making across the entire printing workflow, from initial design to final output. Furthermore, AI's ability to learn and adapt opens doors for dynamic adjustments in real-time, ensuring consistent performance even under varying environmental conditions or material properties.

The market expects AI to usher in an era of highly optimized and intelligent inkjet systems. This includes advanced calibration for various substrates and ink types, real-time defect detection and correction, and the development of self-diagnosing printer heads that can anticipate failures before they occur. AI-driven solutions are also seen as crucial for managing complex industrial printing setups, automating intricate tasks, and facilitating seamless integration with broader smart factory initiatives. This will not only improve the longevity and performance of printer heads but also revolutionize the entire digital printing landscape by making it more efficient, sustainable, and adaptable to future demands.

- Predictive Maintenance: AI analyzes operational data to forecast potential failures of printer heads, enabling proactive maintenance and significantly reducing unexpected downtime and costly repairs.

- Print Quality Enhancement: AI algorithms optimize print parameters in real-time, detect and correct imperfections, and manage ink droplet placement for superior image resolution and color accuracy across diverse substrates.

- Design and Workflow Automation: AI assists in automating complex design adjustments, optimizing print paths, and streamlining overall production workflows, leading to increased efficiency and faster turnaround times.

- Smart Manufacturing Integration: AI facilitates the integration of inkjet systems into Industry 4.0 environments, enabling seamless communication with other manufacturing equipment for fully automated and optimized production lines.

- Ink and Material Optimization: AI helps in the intelligent formulation and management of inks and other materials, ensuring optimal performance, reducing waste, and adapting to new substrate requirements with greater precision.

- New Application Development: AI accelerates the R&D cycle for novel inkjet applications, particularly in areas like 3D printing, flexible electronics, and bioprinting, by simulating outcomes and optimizing process parameters.

DRO & Impact Forces Of Inkjet Printer Head Market

The Inkjet Printer Head Market is significantly shaped by a confluence of drivers, restraints, and opportunities, all contributing to its evolving impact forces. Key drivers include the escalating global demand for digital printing across commercial, industrial, and consumer sectors, spurred by the need for personalization, on-demand production, and shorter print runs. The industrial sector, in particular, is driving adoption with applications in textiles, packaging, ceramics, and direct-to-product printing, leveraging inkjet's versatility and efficiency. Furthermore, continuous advancements in ink technology and materials science, enabling compatibility with diverse substrates and specialized functionalities, act as a strong impetus for market expansion. These factors collectively push for higher speeds, resolutions, and reliability in printer head technology.

However, the market also faces considerable restraints. The substantial capital investment required for research and development, particularly for advanced piezoelectric and MEMS-based heads, poses a barrier to entry and innovation for smaller players. Complex intellectual property landscapes, characterized by numerous patents, can also stifle competition and slow down the adoption of new technologies. Moreover, the existence of alternative printing technologies, such as toner-based laser printing and traditional analog methods (e.g., screen printing, flexography), presents a competitive challenge, especially in high-volume, less-variable print applications. The sensitivity of inkjet heads to specific ink formulations and maintenance requirements can also be a point of concern for some end-users, requiring careful management to ensure longevity and performance.

Opportunities for growth are abundant and diverse. The burgeoning field of 3D printing, often relying on inkjet-like deposition technologies for material jetting, offers a significant long-term growth avenue. Similarly, the development of flexible electronics, printed sensors, and other functional printing applications represents a high-potential niche where inkjet's precision and ability to deposit conductive or organic materials are invaluable. The growing emphasis on sustainable printing practices, including reduced waste and energy consumption, further aligns with inkjet's inherent benefits and creates avenues for eco-friendly innovations. These opportunities, coupled with the ongoing digital transformation across industries, collectively act as powerful impact forces, compelling market participants to innovate, adapt, and strategically position themselves to capitalize on evolving technological and market demands.

Segmentation Analysis

The Inkjet Printer Head Market is broadly segmented based on several critical factors, primarily distinguishing between the underlying technology used, the diverse range of applications, and the end-use industries served. This segmentation provides a granular view of market dynamics, highlighting varying growth rates and demand patterns across different product types and application verticals. Understanding these segments is crucial for market participants to tailor their product offerings, strategic investments, and marketing efforts effectively, addressing the specific needs of distinct customer groups. The market's complexity necessitates a multi-dimensional approach to segmentation, reflecting the intricate ecosystem of inkjet technology's deployment.

The technological segmentation delineates between thermal and piezoelectric inkjet heads, each possessing unique operational principles and suitability for different ink types and print environments. Thermal heads are typically found in consumer and office printers due to their cost-effectiveness and ease of manufacturing, while piezoelectric heads are predominant in industrial and commercial applications given their robustness, versatility with a broader array of inks (including UV-curable and solvent-based), and higher precision. The application segmentation further refines this view, separating desktop/consumer printing from the more complex and specialized demands of commercial and industrial printing. Each application area drives distinct requirements for speed, resolution, durability, and ink compatibility, influencing the design and material choice for the printer heads.

Finally, the segmentation by end-use industry provides insights into the diverse sectors leveraging inkjet technology, from traditional graphics and publishing to rapidly expanding fields such as textile, packaging, electronics, and even medical applications. The growth in industrial sectors, driven by automation and customization trends, significantly impacts the demand for specific types of inkjet heads engineered for high-volume, continuous operation and specialized material deposition. This comprehensive segmentation analysis is fundamental for forecasting market trends, identifying emerging opportunities, and understanding the competitive landscape within the highly diversified Inkjet Printer Head Market.

- By Type

- Thermal Inkjet Heads

- Piezoelectric Inkjet Heads

- By Application

- Commercial Printing (Signage, Graphics, Publishing, Advertising)

- Industrial Printing (Textiles, Packaging, Ceramics, Electronics, Product Decoration, Labels)

- Desktop/Consumer Printing

- 3D Printing/Additive Manufacturing

- Specialty & Others (Medical, Flexible Electronics)

- By End-Use Industry

- Graphics & Publishing

- Packaging

- Textile & Garment

- Ceramics

- Electronics (Printed Electronics, Circuit Boards)

- Medical & Pharmaceutical

- Automotive

- Others (Decor, Glass, Wood)

Value Chain Analysis For Inkjet Printer Head Market

The value chain for the Inkjet Printer Head Market is a complex and highly integrated ecosystem, encompassing various stages from raw material sourcing to end-user distribution and after-sales support. At the upstream end, the process begins with the intricate supply of highly specialized raw materials and components. This includes advanced ceramic materials for piezoelectric elements, silicon wafers for MEMS fabrication, precious metals for electrical contacts, and high-precision fluidic components. Suppliers in this segment are often specialized manufacturers providing high-quality, high-tolerance inputs that are critical for the performance and longevity of inkjet heads. Research and development activities also form a crucial upstream component, driving innovation in material science and micro-fabrication techniques essential for next-generation print head technology.

Moving further down the value chain, the manufacturing of inkjet printer heads involves highly sophisticated processes, including cleanroom fabrication, micro-assembly, and rigorous quality control. This stage is dominated by a relatively small number of highly specialized companies that possess the proprietary technology and manufacturing expertise. These manufacturers then supply the finished printer heads to Original Equipment Manufacturers (OEMs) who integrate them into complete inkjet printing systems, ranging from desktop printers to large-scale industrial presses. This middle segment of the value chain is characterized by strong partnerships and technical collaborations between print head manufacturers and printer OEMs, as the performance of the final printing system is highly dependent on the synergy between the head and other printer components.

The downstream segment of the value chain involves the distribution and sales of complete inkjet printing systems to end-users. Distribution channels can be direct, particularly for large industrial clients or specialized integrators, where OEMs provide direct sales and technical support. Indirect channels involve a network of distributors, resellers, and value-added integrators who provide local sales, installation, and ongoing maintenance services to commercial and consumer customers. These channels are crucial for market penetration and customer reach, especially in geographically dispersed markets. Post-sales services, including technical support, consumables supply (inks), and replacement parts, form an important part of the downstream value chain, ensuring customer satisfaction and long-term product viability. The efficiency and reliability of these distribution and service networks are vital for sustaining market growth and maintaining customer loyalty in a competitive landscape.

Inkjet Printer Head Market Potential Customers

The potential customers for Inkjet Printer Heads are incredibly diverse, reflecting the broad applicability and versatility of inkjet technology across various sectors. At the most fundamental level, Original Equipment Manufacturers (OEMs) of printers represent a primary customer segment. These include leading manufacturers of consumer desktop printers, large-format commercial printers, and sophisticated industrial printing presses. These OEMs purchase inkjet heads in large volumes for integration into their final products, making their demand heavily influenced by consumer electronics trends, commercial print market dynamics, and industrial automation investments. Their purchasing decisions are driven by factors such as cost-effectiveness, reliability, print quality, and the ability of the heads to integrate seamlessly with their proprietary printer architectures and ink systems.

Beyond OEMs, the market extends to a wide array of end-users who directly benefit from inkjet printing solutions. Commercial print shops and graphic arts studios are significant buyers, utilizing inkjet technology for personalized marketing materials, signage, banners, and on-demand publishing. Their demand is characterized by the need for high-speed, high-resolution output on various substrates, along with the flexibility to handle short to medium print runs. Similarly, industrial manufacturers form a rapidly growing customer base, including textile manufacturers using direct-to-garment and direct-to-fabric printing, packaging companies requiring variable data printing and customization, and ceramic tile producers employing inkjet for high-definition decorative patterns. These industrial customers prioritize durability, throughput, and the ability to work with specialized inks and challenging production environments.

Emerging customer segments also hold significant potential. Companies involved in the burgeoning field of additive manufacturing (3D printing) are increasingly adopting inkjet-like deposition heads for precise material jetting, creating complex geometries with various materials. Electronics manufacturers are exploring inkjet for printing conductive traces, flexible circuits, and OLED displays due to its precision and material versatility. Furthermore, medical and pharmaceutical industries are discovering applications in bioprinting, diagnostics, and customized drug delivery systems. This diverse customer landscape, from mass-market consumer brands to highly specialized industrial and technological innovators, underscores the Inkjet Printer Head Market's robust and expanding demand profile, necessitating tailored solutions and collaborative development to meet their evolving needs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.8 Billion |

| Market Forecast in 2033 | USD 7.9 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Epson, Canon, HP, Fujifilm Dimatix, Kyocera, Ricoh, Xaar, Konica Minolta, Seiko Instruments, Toshiba Tec, Brother, MEMJET, Panasonic, Lexmark, Trident International, Collins Inkjet, Markem-Imaje, Videojet, Domino Digital Printing, Kodak |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Inkjet Printer Head Market Key Technology Landscape

The Inkjet Printer Head Market is underpinned by a sophisticated and rapidly evolving technology landscape, where continuous innovation drives performance enhancements and application expansion. At its core are micro-electromechanical systems (MEMS) technology and thin-film deposition techniques, which enable the precise fabrication of minuscule nozzles and intricate fluidic channels within the print head. These micro-scale components are critical for accurate ink droplet formation, ejection, and placement, directly influencing print resolution and speed. Advancements in MEMS allow for increased nozzle density, leading to higher print quality and faster throughput, while also contributing to the miniaturization and cost-effectiveness of the heads themselves. The integration of advanced materials, particularly for piezoelectric elements and nozzle plates, is also paramount, ensuring durability, chemical resistance to various inks, and consistent performance over extended operational periods.

Beyond the physical structure, the technological landscape also encompasses sophisticated fluid dynamics and control systems. Precise control over ink droplet volume, velocity, and trajectory is achieved through advanced waveform generation and digital signal processing (DSP). This allows for dynamic adjustments to print parameters in real-time, optimizing performance for different ink types, substrates, and printing speeds. Developments in integrated electronics, including application-specific integrated circuits (ASICs) embedded within the printer heads, facilitate high-speed data processing and communication, enabling complex print commands and intelligent error correction. Furthermore, research into novel ink formulations, including UV-curable, solvent-based, aqueous pigment, and even functional inks (conductive, biological), dictates the material compatibility requirements for print head components, pushing the boundaries of material science and surface engineering within the heads.

The continuous drive for higher resolution, increased speed, and greater reliability mandates ongoing research in areas such as nozzle clogging prevention, self-cleaning mechanisms, and advanced thermal management to ensure consistent performance. The integration of artificial intelligence and machine learning is emerging as a key technological frontier, enabling predictive maintenance, real-time print quality optimization, and autonomous control features. These AI-driven capabilities enhance the intelligence and efficiency of inkjet systems, making them more resilient and adaptable to demanding industrial environments. The synergistic development across MEMS, materials science, fluid dynamics, and digital control systems defines the dynamic and high-tech nature of the inkjet printer head market, constantly pushing the boundaries of what is possible with digital printing technology.

Regional Highlights

- North America: This region is a significant market, particularly for high-value industrial and commercial inkjet applications. It leads in technological innovation and specialized printing solutions, driven by demand for automation, personalized marketing, and the adoption of inkjet in emerging sectors like 3D printing and biomedical. The presence of key R&D centers and early technology adopters contributes to its market relevance.

- Europe: A mature yet innovative market, Europe demonstrates strong demand for inkjet printer heads in industrial sectors such as textiles, ceramics, packaging, and graphics. Countries like Germany, Italy, and the UK are at the forefront of adopting advanced digital printing technologies for efficiency and sustainability, fostering a competitive landscape with significant domestic manufacturers and R&D activities.

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market for inkjet printer heads globally. Fueled by rapid industrialization, expanding manufacturing bases (especially in China, Japan, South Korea, and India), and increasing consumer demand for printed products, the region is a powerhouse for both production and consumption. The textile and packaging industries, in particular, are key drivers of growth and technological adoption.

- Latin America: This region is an emerging market with growing adoption of inkjet printer heads, primarily driven by increasing industrialization and rising demand for efficient and customized printing solutions in packaging, textiles, and advertising. Countries like Brazil and Mexico are experiencing growth as they invest in modernizing their manufacturing capabilities and expanding their digital printing infrastructure.

- Middle East and Africa (MEA): The MEA region is experiencing gradual growth, with increasing investments in industrial and commercial infrastructure driving the demand for digital printing technologies. The adoption of inkjet printer heads is largely influenced by urbanization, diversification of economies away from oil, and the need for localized production in sectors such as packaging, signage, and construction.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Inkjet Printer Head Market.- Epson

- Canon

- HP

- Fujifilm Dimatix

- Kyocera

- Ricoh

- Xaar

- Konica Minolta

- Seiko Instruments

- Toshiba Tec

- Brother

- MEMJET

- Panasonic

- Lexmark

- Trident International

- Collins Inkjet

- Markem-Imaje

- Videojet

- Domino Digital Printing

- Kodak

Frequently Asked Questions

Analyze common user questions about the Inkjet Printer Head market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary types of inkjet printer heads and their main differences?

The primary types are thermal inkjet heads, which use heat to create a bubble that ejects ink, and piezoelectric inkjet heads, which use voltage to deform a crystal, pushing out ink. Thermal heads are typically more cost-effective for aqueous inks, common in consumer printers. Piezoelectric heads offer greater versatility with a wider range of ink types (UV, solvent, aqueous) and are preferred for industrial and commercial applications due to their precision and durability.

How is the industrial sector driving the Inkjet Printer Head Market?

The industrial sector is a major driver due to increasing demand for on-demand printing, personalization at scale, and efficiency in manufacturing. Applications in textile, packaging, ceramics, and electronics require high-speed, high-resolution, and robust inkjet heads capable of working with specialized inks and challenging substrates, significantly boosting market growth for advanced industrial solutions.

What role does AI play in the advancement of inkjet technology?

AI is increasingly vital for enhancing inkjet technology through predictive maintenance, optimizing print quality in real-time, automating complex workflows, and enabling smarter integration into manufacturing systems. It helps in analyzing performance data to prevent failures, refine ink droplet placement, and accelerate the development of new applications, leading to more efficient and reliable printing solutions.

What are the key challenges faced by manufacturers in this market?

Key challenges include high research and development costs for advanced micro-electromechanical systems (MEMS) and material science, navigating a complex intellectual property landscape with numerous patents, and intense competition from alternative printing technologies. Ensuring compatibility with diverse, often specialized, ink formulations and managing stringent quality control standards also present significant hurdles.

Which regions are showing significant growth in the Inkjet Printer Head Market?

The Asia Pacific (APAC) region, particularly countries like China, Japan, and South Korea, is experiencing the most significant growth due to its vast manufacturing base, rapid industrialization, and high adoption of digital printing in sectors such as textiles and packaging. North America and Europe also continue to show robust demand, especially for high-value industrial and specialized applications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager