Inline Wet Grinder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438414 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Inline Wet Grinder Market Size

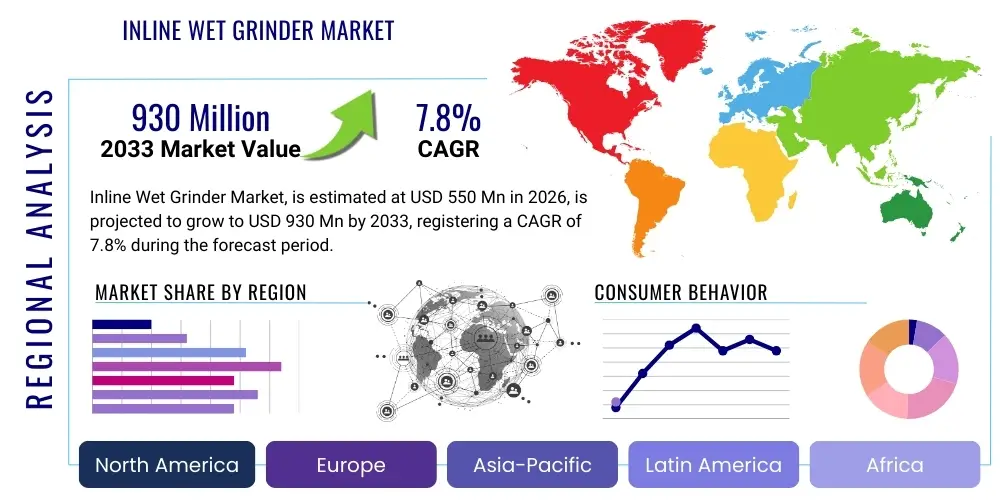

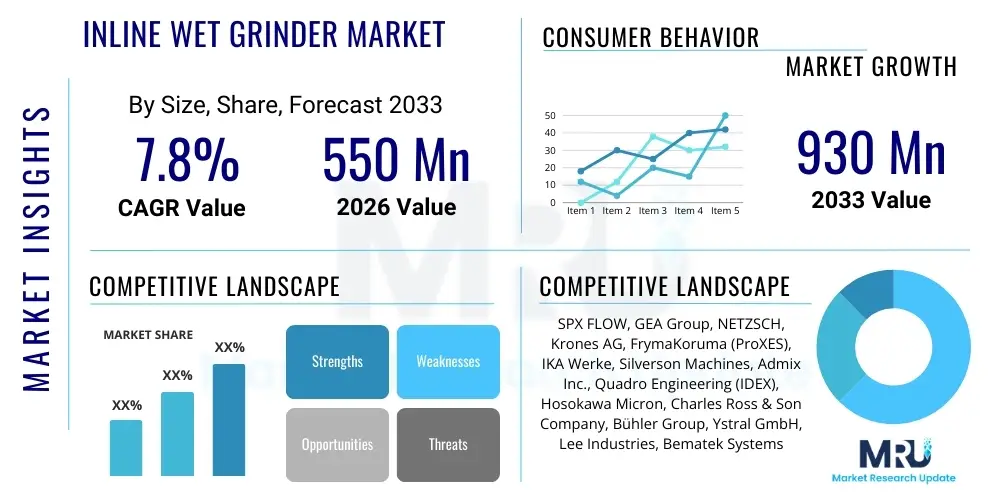

The Inline Wet Grinder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 930 Million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the escalating demand for fine particle size reduction across high-growth industries such as food processing, pharmaceuticals, and specialty chemicals. Inline wet grinders offer superior efficiency, homogeneity, and process integration compared to traditional batch processing methods, making them critical assets in modern manufacturing lines requiring continuous flow and consistent quality output.

The valuation reflects the increasing investment in automated and continuous processing equipment, particularly in emerging economies where food and beverage manufacturing is undergoing rapid modernization. Inline wet grinding technology minimizes cross-contamination risks and maximizes energy efficiency, which aligns perfectly with global industry trends focused on sustainable production and stringent quality control standards. Furthermore, the rising adoption of nanotechnology in various industrial applications is necessitating ultra-fine grinding capabilities, thus fueling demand for advanced inline systems capable of achieving sub-micron particle distributions efficiently and reliably within a pressurized, continuous circuit.

Inline Wet Grinder Market introduction

The Inline Wet Grinder Market encompasses the equipment designed for the continuous reduction of solid particles suspended in a liquid medium, often referred to as slurry or paste, down to a specified fineness. This technology is vital in manufacturing processes where precise control over particle size, dispersion, and homogenization is necessary. Inline grinders differ significantly from batch grinders by operating directly within a pipeline, allowing for seamless integration into existing processing systems, minimizing handling time, and maintaining consistent product quality during high-volume production runs. Key product variants include colloid mills, rotor-stator mixers, and specialized dispersion mills, tailored to handle different viscosities and final particle size requirements.

Major applications of inline wet grinders span across diverse industrial sectors. In the Food & Beverage industry, they are essential for producing smooth sauces, spreads, fruit purees, chocolate refining, and stable emulsions like mayonnaise and salad dressings. The Pharmaceutical sector utilizes them for enhancing drug solubility, preparing stable suspensions, and processing active pharmaceutical ingredients (APIs). Furthermore, the Cosmetics industry relies on these grinders for pigment dispersion in makeup and homogenization of creams and lotions, ensuring textural consistency and aesthetic quality. The inherent benefits of these systems—including reduced processing time, scalability, lower contamination risk, and better energy utilization—are driving their pervasive adoption globally.

The market growth is primarily driven by escalating global consumption of processed foods and beverages, coupled with stricter regulatory mandates regarding product stability and quality, particularly in pharmaceutical and cosmetic formulations. Technological advancements, such as the introduction of automated clean-in-place (CIP) systems and grinders optimized for abrasive or high-viscosity materials, further accelerate market penetration. These factors collectively position the Inline Wet Grinder Market as a crucial enabler of high-throughput, quality-focused manufacturing across multiple core industries.

Inline Wet Grinder Market Executive Summary

The Inline Wet Grinder Market is characterized by robust business trends centered on automation, efficiency, and customized solutions tailored to specific material properties. Manufacturers are increasingly focusing on developing smart grinders equipped with IoT capabilities for real-time monitoring, predictive maintenance, and operational optimization, significantly reducing downtime and improving overall yield. The key business trend involves a shift from standardized equipment to modular, customizable systems that can handle a wider range of materials, pressures, and temperatures, responding directly to the complexity of modern industrial formulations. Furthermore, strategic alliances and acquisitions among technology providers are common, aimed at consolidating expertise in fluid dynamics and material science to enhance grinding performance.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine due to rapid industrialization, burgeoning food processing sectors in China and India, and increasing investments in pharmaceutical manufacturing infrastructure. North America and Europe, while mature markets, exhibit strong demand driven by the stringent regulatory environment necessitating precise process control and the continuous modernization of existing production facilities, particularly favoring energy-efficient and high-shear dispersion technologies. Latin America and the Middle East & Africa (MEA) are emerging regions, propelled by urbanization and expanding consumer bases demanding packaged and processed goods, leading to foundational investments in local manufacturing capabilities.

Segment-wise, the Continuous Flow segment dominates the market due to its scalability and inherent suitability for high-volume production lines. Application analysis indicates that the Food & Beverage industry maintains the largest market share, though the Pharmaceutical segment is projected to register the highest CAGR, driven by the increasing complexity of drug formulations requiring ultra-fine particle reduction for enhanced bioavailability. The market sees a notable trend toward higher capacity units, reflecting the demand for greater throughput and economies of scale across industrial end-users, while commercial applications favor compact, versatile grinders suitable for small to medium-scale operations.

AI Impact Analysis on Inline Wet Grinder Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Inline Wet Grinder Market primarily revolve around how AI can enhance operational efficiency, ensure predictive maintenance, and optimize process control to achieve desired product quality consistently. Key concerns include the feasibility of integrating complex AI algorithms into existing grinding systems, the data security implications of monitoring industrial processes, and the expected ROI from implementing smart, self-optimizing machinery. Users seek to understand how AI can minimize energy consumption during grinding, automate the adjustment of parameters (like rotor speed and gap settings) based on real-time slurry analysis (e.g., viscosity, temperature, particle size distribution), and ultimately reduce reliance on manual operator interventions, thereby standardizing output quality across shifts.

AI is fundamentally transforming the operational paradigm of inline wet grinding from reactive maintenance and standardized parameter setting to a proactive, adaptive control environment. Machine learning models are trained on vast datasets encompassing material input variability, machine vibration patterns, energy consumption metrics, and resultant product quality reports. This capability allows the grinder to predict potential mechanical failures hours or days in advance, scheduling maintenance precisely when necessary, rather than relying on fixed time intervals. Moreover, AI can utilize reinforcement learning to continuously fine-tune operational parameters—such as adjusting pressure differentials or flow rates—to maintain the optimal shear energy required for the target particle size distribution, compensating dynamically for changes in raw material consistency or temperature fluctuations. This leads to reduced scrap rates and significant energy savings, establishing AI as a critical factor in next-generation grinding technology.

- AI-driven Predictive Maintenance: Minimizing unplanned downtime by analyzing vibration and thermal data.

- Real-time Process Optimization: Dynamic adjustment of rotor speed and gap settings based on material properties (viscosity, solids content).

- Enhanced Quality Control: Automated feedback loops ensure consistent particle size distribution (PSD) and homogenization.

- Energy Efficiency Optimization: Machine learning algorithms identify and maintain the minimum energy input required for target fineness.

- Remote Monitoring and Diagnostics: Utilizing IoT sensors and AI platforms for operational oversight across distributed facilities.

- Automated Anomaly Detection: Identifying unusual process behaviors indicative of potential blockages or equipment wear before failure.

DRO & Impact Forces Of Inline Wet Grinder Market

The Inline Wet Grinder Market is shaped by a powerful interplay of technological advancements and industrial necessities. The primary driver is the pervasive demand for high-quality, stable, and homogeneously processed consumer products, particularly in the food, cosmetic, and pharmaceutical industries where consistency directly impacts shelf life, efficacy, and consumer acceptance. Manufacturers are incentivized to invest in inline systems due to their superior throughput and reduced operational footprint compared to traditional batch processing. Restraints primarily involve the high initial capital expenditure required for sophisticated, high-precision inline equipment, which can be prohibitive for small and medium-sized enterprises (SMEs). Furthermore, the complexity of maintaining and integrating these systems with existing legacy infrastructure, requiring specialized technical expertise, poses a significant adoption barrier in certain regions.

Opportunities for market growth are abundant, particularly in developing specialized grinders capable of handling difficult materials, such as highly viscous pastes or temperature-sensitive biological compounds, often required in advanced biopharmaceutical production. The focus on sustainable manufacturing also creates opportunities for providers developing energy-efficient, low-noise systems compliant with emerging environmental regulations. The impact forces acting upon the market are characterized by intense competitive pressure pushing for continuous innovation in rotor-stator design and milling media technology to achieve finer, narrower particle size distributions. Regulatory forces, particularly the FDA and EMA requirements for process validation and consistency in pharmaceutical and food production, strongly favor the adoption of verifiable, automated inline systems over manual, batch-based methods.

The technological impact force is perhaps the most defining, driving the integration of automation, sensors, and smart controls, transforming simple mechanical grinding into precision engineering. This technological evolution increases product differentiation and value proposition for market leaders. Economic impact forces, such as fluctuating raw material costs and global supply chain disruptions, put pressure on manufacturers to maximize process efficiency and yield, making the investment case for high-efficiency inline grinders stronger. Overall, while initial investment hurdles exist, the long-term operational efficiencies, quality assurance capabilities, and sheer throughput capacity offered by inline wet grinding systems ensure that the market trajectory remains overwhelmingly positive.

Segmentation Analysis

The Inline Wet Grinder Market is segmented based on critical operational and structural characteristics, offering a granular view of demand across different industrial needs. Key segmentation includes Type (Colloid Mills, Rotor-Stator Mixers, High-Pressure Homogenizers), Capacity (Low, Medium, High), Application (Food & Beverage, Pharmaceuticals, Cosmetics, Chemicals, Others), and End-User (Commercial, Industrial). This structure allows for precise market sizing and forecasting, reflecting diverse material processing requirements—from general homogenization in commercial kitchens to ultra-fine dispersion required in advanced chemical synthesis. The underlying principle of segmentation reflects the trade-off between shear intensity, energy input, and final particle size output demanded by the specific industry application.

The Colloid Mills segment, known for moderate shear and robust operation, remains fundamental, especially in the production of stable emulsions and suspensions in the food sector. However, the High-Pressure Homogenizers segment is experiencing rapid growth due to its capability to achieve sub-micron particle sizes and cell disruption, critical for high-end pharmaceutical and biotechnology applications. Capacity segmentation highlights the growing need for high-capacity continuous systems in industrialized food production, while low and medium-capacity units serve specialized chemical research and smaller regional processors. Understanding these segments is vital for stakeholders to tailor their product offerings and marketing strategies effectively to address the distinct technical challenges faced by various end-user groups seeking optimized wet grinding solutions.

- Type:

- Colloid Mills

- Rotor-Stator Mixers (High-Shear Mixers)

- Homogenizers (High-Pressure and Valve)

- Bead/Sand Mills (Inline variants)

- Capacity:

- Low Capacity (Up to 500 L/Hr)

- Medium Capacity (500 L/Hr – 2,000 L/Hr)

- High Capacity (Above 2,000 L/Hr)

- Application:

- Food & Beverage (Dairy, Sauces, Purees, Chocolate)

- Pharmaceuticals & Biotechnology

- Cosmetics & Personal Care (Creams, Lotions, Pigments)

- Chemicals & Materials (Paints, Coatings, Adhesives)

- Others (Pulp & Paper, Textiles)

- End-User:

- Industrial Manufacturers (Large-Scale Production)

- Commercial Users (Catering, Small Food Processing Units)

Value Chain Analysis For Inline Wet Grinder Market

The value chain for the Inline Wet Grinder Market begins with Upstream Analysis, focusing on the procurement of raw materials, primarily high-grade stainless steel alloys (304 and 316) for construction, precision components like rotors and stators, and specialized ceramics or hard metals for milling surfaces designed to withstand extreme shear and abrasion. Key upstream activities also involve the sourcing of advanced electronic components for control panels, sensors, and automation systems, necessitating strong relationships with specialized material and component suppliers. Cost control and quality assurance in this stage are paramount, as the durability and hygiene of the final equipment depend heavily on material integrity.

The core of the value chain involves Manufacturing and Assembly, where technological know-how regarding fluid dynamics and mechanical engineering is converted into precise machinery. This stage includes complex machining processes to ensure the tight tolerances necessary for effective shear generation in the grinding chamber. Following manufacturing, Distribution Channels play a crucial role. Direct channels involve sales teams and technical consultants working directly with large industrial end-users (e.g., multinational pharmaceutical companies), often requiring customized engineering solutions and extensive after-sales support. Indirect channels utilize specialized distributors, system integrators, and regional dealers, particularly for smaller, standardized units targeting commercial and regional food processors. These partners provide localized installation, maintenance, and faster response times, bridging the gap between manufacturer and diverse global clientele.

Downstream analysis focuses on Aftermarket Services, which represent a significant revenue stream and a crucial differentiator for manufacturers. This includes scheduled maintenance, supply of proprietary spare parts (rotors, stators, seals), recalibration services, and process optimization consulting. The high dependence of industrial users on uninterrupted continuous processing makes reliable and prompt aftermarket support essential. The final stage involves End-User Operations, where the grinders are integrated into continuous production lines. Successful value delivery hinges on the grinder's ability to consistently meet stringent performance metrics (e.g., energy efficiency, sanitation standards, output quality), driving repeat business and positive market reputation.

Inline Wet Grinder Market Potential Customers

The potential customers for Inline Wet Grinder technology are highly diversified across industrial sectors that require precise particle size reduction, dispersion, or homogenization of liquids and semi-solids. The primary buyer base consists of large-scale Industrial Manufacturers, including major multinational corporations in the Food and Beverage sector (e.g., dairy processors, confectioners, sauce manufacturers) who operate high-throughput continuous lines and prioritize equipment reliability and efficiency. These customers seek grinders that minimize shear heat generation while ensuring high consistency, which is crucial for achieving product stability and minimizing ingredient separation over time.

A rapidly growing segment of potential customers includes Pharmaceutical and Biotechnology firms, particularly those involved in formulation development and bulk API processing. These buyers prioritize equipment certified for stringent hygienic standards (3-A, EHEDG) and capable of validated processes, focusing on achieving superior drug particle reduction for improved bioavailability and uniformity of dosage. The cosmetics industry represents another vital customer base, utilizing inline wet grinders for pigment dispersion in high-end makeup and homogenization of complex emulsion systems in creams and lotions, where textural perfection is a key quality metric. Furthermore, specialty Chemical manufacturers, involved in the production of paints, coatings, and advanced ceramic slurries, constitute key buyers, focusing on obtaining narrow particle size distributions for optimal material performance.

In addition to large industrial players, Commercial End-Users such as regional food processors, specialized catering businesses, and research and development laboratories also represent viable market segments. While their volume requirements are lower, they seek versatile, easy-to-clean, and modular inline systems. Equipment sales to these customers are often facilitated through indirect distribution channels, emphasizing ease of use and affordability. Ultimately, any entity whose final product quality is intrinsically linked to the homogeneity and fineness of its liquid or semi-solid ingredients is a potential buyer, indicating a broad and sustained demand base across the global manufacturing landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 930 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SPX FLOW, GEA Group, NETZSCH, Krones AG, FrymaKoruma (ProXES), IKA Werke, Silverson Machines, Admix Inc., Quadro Engineering (IDEX), Hosokawa Micron, Charles Ross & Son Company, Bühler Group, Ystral GmbH, Lee Industries, Bematek Systems |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Inline Wet Grinder Market Key Technology Landscape

The technological landscape of the Inline Wet Grinder Market is continuously evolving, driven by the need to achieve superior particle size reduction efficiency, enhanced energy performance, and stricter adherence to hygienic design standards. A cornerstone technology is the refinement of rotor-stator geometry and material science. Manufacturers are utilizing advanced computational fluid dynamics (CFD) modeling to optimize the flow path within the grinding chamber, ensuring maximum shear application across all particles with minimal recirculation zones. This optimization leads to narrower particle size distributions (PSD) with fewer passes, significantly improving overall efficiency. Furthermore, the use of highly resistant materials like specialized ceramics and tungsten carbide coatings on high-wear components extends equipment lifespan when processing abrasive materials like mineral slurries or high-solids formulations, reducing maintenance frequency and costs.

Another crucial technological advancement involves the integration of high-precision sensors and control systems, which is foundational to modern Inline Wet Grinding. These systems incorporate sensors for real-time monitoring of pressure, temperature, flow rate, and energy consumption. Combined with Variable Frequency Drives (VFDs), the machine can instantaneously adjust rotor speed to maintain a constant energy-per-volume input, ensuring product consistency regardless of upstream fluctuations in feedstock viscosity or concentration. The shift towards modular design is also prominent, allowing end-users to easily swap out different grinding heads—such as colloid mill heads for homogenization or bead mill attachments for ultra-fine nano-grinding—using the same base unit, thereby maximizing equipment versatility and reducing overall capital expenditure for diversified manufacturers.

The drive towards hygienic and aseptic processing is compelling significant technological investment. Modern inline grinders are increasingly featuring fully Clean-In-Place (CIP) and Sterilize-In-Place (SIP) capabilities, designed with minimal dead spaces and smooth, polished internal surfaces to prevent microbial buildup and cross-contamination. This is particularly vital for pharmaceutical and high-risk food applications. The adoption of magnetic coupling technology in certain high-pressure homogenization systems eliminates the need for dynamic seals, drastically reducing maintenance and the risk of leakage, enhancing the reliability of sterile processing environments. These sophisticated technological integrations underpin the market's trajectory towards fully automated, highly precise, and traceable processing solutions.

Regional Highlights

Regional dynamics significantly influence the growth and structure of the Inline Wet Grinder Market, reflecting varying industrial maturity, regulatory frameworks, and consumer demand patterns. The Asia Pacific (APAC) region currently represents the largest and fastest-growing market, driven by substantial demographic growth, rapidly expanding middle classes, and massive investments in localized manufacturing infrastructure across key economies like China, India, and Southeast Asian nations. The high demand for packaged food, beverages, and accessible pharmaceuticals is fueling the need for high-throughput, continuous processing equipment. Governments in this region are also increasingly enforcing stricter food safety and quality standards, compelling local manufacturers to upgrade from batch to advanced inline grinding systems.

North America and Europe constitute mature markets characterized by high adoption rates of advanced, automated, and specialized grinding systems. In these regions, growth is primarily driven by replacement demand, modernization initiatives, and the increasing focus on specialty applications, such as biopharma formulation development and high-end cosmetic production, requiring ultra-fine processing capabilities (nanogrinding). Regulatory compliance, including cGMP (current Good Manufacturing Practice) standards in pharmaceuticals and rigorous hygiene directives in food processing, mandates the use of cutting-edge, verifiable inline technology, supporting steady demand for high-value equipment and sophisticated aftermarket services. Key players often base their advanced R&D and specialized manufacturing units within these geographies to leverage local expertise and proximity to demanding end-users.

Latin America (LATAM) and the Middle East & Africa (MEA) are emerging regions that are exhibiting accelerating growth rates. LATAM market expansion is supported by urbanization and increasing foreign direct investment in domestic food and beverage production, aimed at reducing reliance on imports. In MEA, particularly in the Gulf Cooperation Council (GCC) countries, significant government efforts to diversify economies away from oil and build robust local industrial capabilities, including food security initiatives and pharmaceutical manufacturing, are creating nascent but strong demand for reliable inline processing machinery. While these regions often prioritize cost-effectiveness, the move towards international quality standards is steadily increasing the adoption of medium-to-high-capacity wet grinding systems across diverse industrial segments.

- Asia Pacific (APAC): Market leader and fastest growth trajectory. Driven by massive food processing and pharmaceutical capacity expansion in China and India. Focus on high capacity and operational efficiency.

- North America: Mature market focused on technological upgrades, specialized pharmaceutical applications, and adherence to stringent FDA regulations. High demand for automation and real-time process control.

- Europe: Strong market driven by modernization, sustainability goals, and strict EHEDG hygiene standards. Significant adoption in premium cosmetics and high-value chemical production.

- Latin America (LATAM): Emerging market growth fueled by increasing packaged food consumption and industrial modernization efforts in Brazil and Mexico. Price sensitivity remains a factor.

- Middle East and Africa (MEA): Growth centered on investments in local food manufacturing for food security and establishment of regional pharmaceutical hubs, particularly in Saudi Arabia and UAE.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Inline Wet Grinder Market.- SPX FLOW Inc.

- GEA Group AG

- NETZSCH Group

- Krones AG

- FrymaKoruma (ProXES Group)

- IKA Werke GmbH & Co. KG

- Silverson Machines Ltd.

- Admix Inc.

- Quadro Engineering Corp. (IDEX Corporation)

- Hosokawa Micron Corporation

- Charles Ross & Son Company

- Bühler Group

- Ystral GmbH

- Lee Industries Inc.

- Bematek Systems Inc.

- Glen Mills Inc.

- Premier Colloid Mill Corp.

- Microfluidics International Corporation

- Pusaka Mitra Makmur (PMM)

- Kinematica AG

Frequently Asked Questions

Analyze common user questions about the Inline Wet Grinder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using an inline wet grinder over a traditional batch grinder?

Inline wet grinders offer significant advantages including continuous processing, which maximizes throughput and scalability; guaranteed consistency due to uniform shear application; reduced risk of cross-contamination; and superior integration into automated industrial pipelines, minimizing manual handling and operational time.

Which industrial segments are the fastest growing consumers of high-shear inline wet grinding technology?

The Pharmaceutical and Biotechnology segments are currently the fastest-growing consumers. This rapid growth is driven by the critical need to achieve sub-micron particle sizes for enhanced drug bioavailability and the necessity of validated, aseptic continuous processing for complex formulations like nano-suspensions and lipid emulsions.

How does AI technology specifically improve the energy efficiency of inline wet grinding processes?

AI improves energy efficiency by utilizing machine learning algorithms to analyze real-time data (viscosity, flow rate, temperature) and dynamically adjust the grinder's operational parameters (rotor speed, gap setting) to maintain the minimum required energy input (specific energy consumption) necessary to achieve the target particle size distribution, thus avoiding wasted power.

What is the typical expected lifespan of critical components, such as rotors and stators, in a high-shear inline grinder?

The lifespan of critical components depends heavily on the abrasiveness of the processed material and operating hours. For non-abrasive applications (like dairy), components can last several years. However, for abrasive materials (pigments, mineral slurries), manufacturers are increasingly utilizing highly wear-resistant materials like tungsten carbide or specialized ceramics to achieve operational lifespans ranging from 6 to 18 months between major replacements.

What are the key hygiene certification standards required for inline wet grinders used in regulated industries like pharmaceuticals and food?

For regulated industries, key certification standards include the European Hygienic Engineering and Design Group (EHEDG) certification, which guarantees cleanability and aseptic design; 3-A Sanitary Standards (particularly in North America); and compliance with Good Manufacturing Practice (GMP) guidelines, ensuring materials traceability and validation capability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager