Instant Adhesive Gel Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432784 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Instant Adhesive Gel Market Size

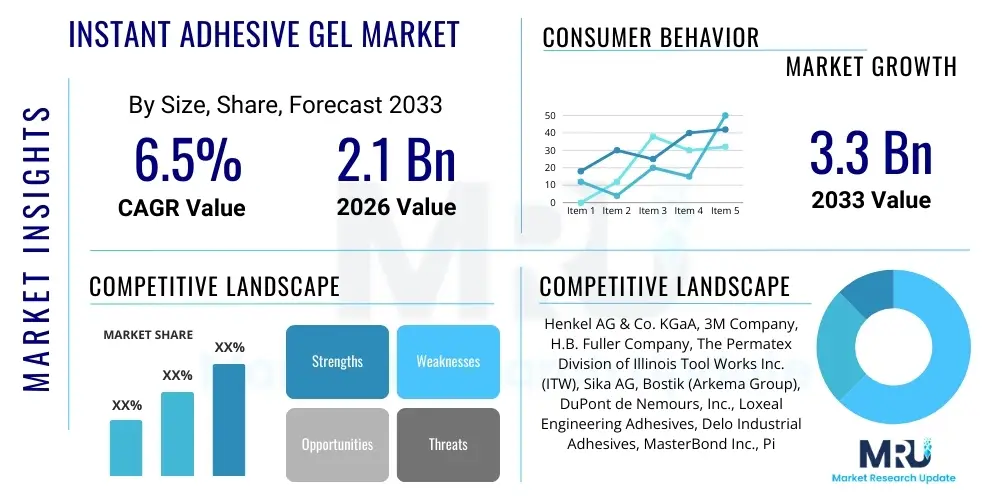

The Instant Adhesive Gel Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 2.1 Billion in 2026 and is projected to reach USD 3.3 Billion by the end of the forecast period in 2033.

Instant Adhesive Gel Market introduction

The Instant Adhesive Gel Market, primarily dominated by cyanoacrylate-based formulations, involves high-viscosity bonding agents designed for rapid setting times across a wide range of substrates, including porous materials, vertical surfaces, and challenging gaps. Unlike traditional liquid superglues, the gel format prevents running and dripping, offering enhanced precision and control, which is critical in delicate assembly operations. These adhesives are known for their exceptional tensile strength, making them indispensable in applications requiring structural integrity and quick turnaround times. The versatility of instant adhesive gels, coupled with their ability to bond dissimilar materials, establishes them as a vital component across sophisticated manufacturing and consumer repair sectors.

Product descriptions emphasize formulations that provide gap-filling capability, impact resistance, and flexibility post-cure, addressing the limitations often associated with low-viscosity instant adhesives. Major applications span high-volume assembly lines in electronics, where quick fixture is necessary for miniaturized components, and in the automotive industry for securing internal trim, sensors, and gaskets. Furthermore, the consumer sector heavily relies on these gels for general household repairs, crafts, and DIY projects, driven by the ease of application and reliability on vertical or overhead surfaces. Specialized instant gels are also prevalent in the medical device sector for assembling disposable instruments, requiring biocompatibility and rigorous quality control.

Driving factors for market expansion include the global trend toward miniaturization in electronics, demanding adhesives that offer precise application and fast curing without compromising integrity. The continuous growth of the electric vehicle (EV) market necessitates lightweight bonding solutions for battery packaging and interior assembly, favoring gel-based instant adhesives over traditional mechanical fasteners. Moreover, the increasing penetration of sophisticated consumer goods, coupled with growing disposable income in emerging economies, accelerates demand for high-performance repair and maintenance solutions. The sustained benefits of instant adhesive gels—speed, versatility, and reduced component clamping time—significantly contribute to lowered manufacturing cycle times and overall cost efficiencies, ensuring their continued market dominance.

Instant Adhesive Gel Market Executive Summary

The Instant Adhesive Gel Market is characterized by robust growth, primarily fueled by accelerated industrial automation and the expanding consumer DIY segment. Business trends indicate a strong focus among key manufacturers on developing specialized, regulatory-compliant formulations, particularly those featuring low odor, non-blooming properties, and enhanced thermal resistance to meet stringent standards in the automotive and aerospace industries. Strategic acquisitions aimed at consolidating specialized technology portfolios, alongside heavy investment in advanced dispensing systems that integrate seamlessly with robotic assembly lines, define the current competitive landscape. The market structure remains moderately concentrated, with leading players prioritizing vertical integration to ensure stable raw material supply chains for cyanoacrylates and auxiliary additives.

Regional trends show Asia Pacific (APAC) maintaining its dominance as the largest and fastest-growing market, largely due to explosive growth in electronics manufacturing (including 5G infrastructure and consumer devices) and significant expansion in automotive production hubs, particularly in China, India, and Southeast Asia. North America and Europe, while mature, exhibit high demand for high-value specialty gels used in medical applications and complex machinery repair, driven by strict quality control and regulatory requirements emphasizing safety and performance. The Middle East and Africa (MEA) and Latin America are poised for accelerated growth, supported by nascent but rapidly developing infrastructure projects and increasing industrialization requiring reliable bonding solutions.

Segmentation trends highlight the Cyanoacrylate chemistry segment retaining its market leadership due to unparalleled speed and substrate versatility. However, hybrid gel systems integrating polyurethane or epoxy chemistries are gaining traction, offering superior resistance to moisture, solvents, and extreme temperatures—properties often lacking in traditional cyanoacrylates. By application, the Electronics segment is projected to exhibit the highest CAGR, spurred by the need for thermal management and vibration dampening in compact electronic assemblies. Furthermore, the shift from liquid instant adhesives to gel formulations is a pervasive trend across all segments, reflecting end-user preference for ease of use, waste reduction, and enhanced application precision in both professional and consumer settings.

AI Impact Analysis on Instant Adhesive Gel Market

User queries regarding AI's impact on instant adhesive gels frequently center on three critical themes: optimization of adhesive dispensing and curing processes, improvement in material science R&D, and the role of predictive maintenance enabled by AI-integrated sensors. Users are particularly concerned about how AI-driven vision systems can ensure flawless, micro-precise application of gels in high-speed manufacturing environments, minimizing material waste and defective bonds. Furthermore, there is significant interest in utilizing machine learning algorithms to rapidly iterate new gel formulations, predicting properties like viscosity stabilization, curing speed, and long-term durability under various stress conditions, thereby shortening the traditional R&D cycle. The core expectation is that AI will transform adhesive application from a reactive process to a highly optimized, quality-controlled, and predictive operation, particularly in highly regulated industries like aerospace and medical devices.

- AI-Driven Dispensing Optimization: Utilizing machine learning models to adjust viscosity parameters, flow rates, and curing parameters in real-time based on environmental conditions and substrate variations, ensuring optimal bond integrity during automated assembly.

- Predictive Material Science: Employing AI algorithms to analyze vast material property databases, accelerating the development of novel cyanoacrylate derivatives with enhanced chemical resistance, flexibility, or thermal stability properties.

- Quality Control via Machine Vision: Integrating AI-powered vision systems on production lines to detect minute inconsistencies in gel bead size, placement, and coverage, immediately identifying and mitigating potential bonding failures before they affect product quality.

- Supply Chain Resilience: Using AI tools for predictive logistics, forecasting demand fluctuations for specialized instant adhesive gels, and optimizing raw material procurement (e.g., cyanoacrylate monomers) to mitigate supply chain disruptions.

- Smart Manufacturing Integration: Facilitating the seamless integration of instant gel application robots within Industry 4.0 frameworks, enabling machines to learn optimal bonding patterns and autonomously adapt dispensing routines for different product variants.

- Enhanced Customization: Allowing manufacturers to use AI to quickly model and produce highly specialized, small-batch gel formulations tailored to unique end-user substrate requirements, maximizing market responsiveness.

DRO & Impact Forces Of Instant Adhesive Gel Market

The Instant Adhesive Gel Market is profoundly influenced by a complex interplay of rapid technological advancements, stringent environmental regulations, and global economic shifts. Key drivers include the pervasive trend of lightweighting in the transportation sector, where substituting heavy mechanical fasteners with high-performance instant bonding agents is critical for fuel efficiency and range extension in EVs. Furthermore, the increasing complexity and density of modern electronic devices necessitate adhesives that offer precision and quick assembly without heat or prolonged clamping. Restraints primarily involve the limited gap-filling capabilities of standard cyanoacrylates compared to slower-curing structural adhesives, as well as the sensitivity of many instant gels to moisture and high temperatures, which restricts their use in extreme outdoor or engine compartment applications. Opportunities emerge through the development of hybrid, high-temperature resistant, and environmentally friendly formulations, alongside massive potential in medical wearables and disposable diagnostics requiring rapid, biocompatible bonding.

Impact forces currently shaping the market dynamics include the high bargaining power of large volume end-users, particularly in automotive and electronics, who demand stringent performance specifications and competitive pricing, placing pressure on manufacturers to innovate efficiently. The threat of substitution, while moderated by the unique speed advantage of instant adhesives, exists from advanced two-part epoxies and UV-curing systems which offer superior durability in specialized applications. However, the moderate to high entry barriers, driven by the need for complex synthesis capabilities for high-purity monomers and adherence to global regulatory standards (like REACH and FDA clearances), stabilize the market structure. Innovation in application equipment, such as precision micro-dispensing technologies, acts as a pivotal force, differentiating product offerings and enhancing overall application accuracy, which is essential for market penetration in sensitive sectors.

The fundamental driving force remains the increasing speed of manufacturing globally; instant adhesive gels reduce process bottlenecks, allowing assembly lines to operate at higher throughputs. However, regulatory constraints, specifically concerning volatile organic compounds (VOCs) and occupational safety related to monomer fumes, pose a continuous restraint requiring significant investment in low-VOC formulations and advanced ventilation systems. The primary opportunity lies in expanding the functional envelope of instant gels—for instance, developing gels that can handle thermal cycling or vibration without brittleness—thereby capturing market share from traditional structural adhesives and solidifying their position as versatile, high-speed bonding solutions across all major industrial segments.

Segmentation Analysis

The Instant Adhesive Gel Market segmentation is primarily defined by the chemical composition, the specific end-user industry, and the product form, which directly dictates performance characteristics and application suitability. Chemical type is crucial, determining curing speed, tensile strength, and resistance profile, with cyanoacrylates being the foundational component. Segmentation by application highlights the diverse industrial reliance on these rapid bonding solutions, spanning high-tech manufacturing to maintenance and repair operations (MRO). The differentiation between liquid and gel forms reflects the evolution of application requirements, moving towards higher viscosity formulations for better gap filling and reduced surface migration, addressing key challenges faced by end-users in vertical and overhead assemblies.

Further analysis of segmentation reveals critical shifts in demand, particularly towards specialized formulations within the industrial category. For example, medical-grade instant adhesive gels must comply with ISO 10993 standards, distinguishing them from standard industrial grades. Similarly, the electronics segment requires non-corrosive, non-blooming formulations that do not damage sensitive components. Geographically, market behavior is differentiated by regulatory maturity and industrial concentration; for instance, European markets prioritize sustainability and low-odor products, while Asian markets prioritize high volume and assembly speed, influencing the dominant type of dispensing equipment and bulk packaging utilized.

- By Chemistry:

- Cyanoacrylate

- Hybrid Gels (e.g., Cyanoacrylate/Epoxy blends)

- Others (e.g., specialized medical formulations)

- By Application:

- Automotive & Transportation (Interior trim, sensor bonding, EV battery sealing)

- Electronics & Electrical (Component mounting, wiring security, housing assembly)

- Medical Devices (Disposable instrument assembly, device packaging)

- Industrial Maintenance & Repair Operations (MRO)

- Consumer Goods & DIY (Household repairs, crafts)

- Footwear & Textile

- Others (Aerospace, Construction)

- By End-Use:

- Industrial

- Commercial

- Consumer

- By Form/Viscosity:

- Gel

- Semi-Gel (High Viscosity Liquid)

Value Chain Analysis For Instant Adhesive Gel Market

The Instant Adhesive Gel value chain begins with the procurement of critical raw materials, predominantly methyl, ethyl, and other alkyl cyanoacrylate monomers, sourced from specialized chemical suppliers. This upstream phase is characterized by stringent quality control, as monomer purity directly dictates the final adhesive performance, curing speed, and stability. Key manufacturers often maintain long-term relationships or proprietary agreements with monomer suppliers to ensure a consistent, high-quality input stream, mitigating the risks associated with volatile chemical pricing and availability. The procurement stage also includes specialized additives such as thickening agents (e.g., fumed silica to achieve gel consistency), stabilizers, colorants, and plasticizers, which transform the basic monomer into the final, functional gel product.

The mid-stream segment involves the manufacturing and formulation process, where chemical companies compound, stabilize, and package the instant adhesive gels. This stage requires significant investment in specialized blending equipment and inert environment processing capabilities to prevent premature polymerization. Differentiation at this stage is achieved through proprietary formulation techniques that enhance features like humidity resistance, shelf life, or specialized dispensing profiles. Downstream activities involve distribution channels, which are bifurcated between direct sales to large industrial OEMs (e.g., automotive manufacturers) and indirect distribution through specialized industrial distributors, MRO suppliers, and large-scale retail chains for the consumer segment. Direct channels emphasize technical support and customized packaging, while indirect channels focus on maximizing geographic reach and inventory availability.

The efficiency of the distribution channel is paramount due to the limited shelf life of cyanoacrylate products, necessitating optimized cold chain or temperature-controlled warehousing and rapid inventory turnover. Direct sales channels are crucial for penetrating high-value markets like aerospace and medical devices, where technical consultation and adherence to specific regulatory standards are non-negotiable. Conversely, the high volume, low margin consumer segment relies heavily on large retail and e-commerce platforms, requiring robust marketing and packaging optimized for user experience. The entire value chain is moving towards greater transparency and traceability, driven by increasing regulatory demands for documentation concerning chemical origin and composition throughout the entire product lifecycle.

Instant Adhesive Gel Market Potential Customers

Potential customers for the Instant Adhesive Gel Market represent a diverse group across industrial, commercial, and consumer sectors, unified by the need for quick, strong, and reliable bonding solutions, particularly for applications involving porous or uneven substrates and vertical surfaces. Major industrial end-users include high-volume assembly operations in the Electronics sector, specifically manufacturers of smartphones, tablets, wearable technology, and semiconductor components, where precision and rapid fixture are essential to high-speed automation. The Automotive industry serves as another critical customer base, relying on instant gels for non-structural interior bonding, securing wire harnesses, dashboard components, and sensors, where vibration dampening and fast curing times are advantageous over mechanical fasteners.

The fastest-growing cohort of institutional buyers are within the Medical and Healthcare sectors, encompassing manufacturers of disposable medical instruments (e.g., syringes, catheters), diagnostic kits, and complex electronic monitoring devices. These customers require sterile, non-toxic, and often high-purity adhesive gels that meet strict biocompatibility standards. Beyond manufacturing, the Maintenance, Repair, and Operations (MRO) segment, including facility managers, professional repair technicians, and general contractors, constitutes a robust customer base that utilizes instant gels for expedient equipment repair, sealing leaks, and securing components during essential maintenance activities, prioritizing gap-filling capacity and versatile material bonding.

Furthermore, the mass-market consumer segment remains foundational, purchasing instant adhesive gels primarily through retail hardware stores, supermarkets, and online marketplaces for household repairs, crafting, and hobbyist projects. This segment values ease of application, superior viscosity control to avoid mess, and the product's ability to tackle various domestic materials like ceramics, plastics, and wood. Companies targeting the consumer market focus heavily on ergonomic packaging, clear instructions, and specialized formulas designed to mitigate the risks associated with rapid bonding to skin. The evolving landscape of customized manufacturing and prototyping, served by 3D printing service bureaus, also represents an emerging, high-value customer group requiring specialized instant gels for post-processing and assembly of printed parts.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.1 Billion |

| Market Forecast in 2033 | USD 3.3 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Henkel AG & Co. KGaA, 3M Company, H.B. Fuller Company, The Permatex Division of Illinois Tool Works Inc. (ITW), Sika AG, Bostik (Arkema Group), DuPont de Nemours, Inc., Loxeal Engineering Adhesives, Delo Industrial Adhesives, MasterBond Inc., Pidilite Industries Ltd., Chemence Ltd., Scigrip Adhesives, Lord Corporation (Parker Hannifin), Tesa SE (Beiersdorf), Franklin International, ThreeBond Co., Ltd., Cyberbond, Dymax Corporation, Huntsman Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Instant Adhesive Gel Market Key Technology Landscape

The technology landscape for Instant Adhesive Gels is continually evolving, driven by the need to overcome the inherent limitations of traditional cyanoacrylates, particularly their poor resistance to moisture, impact, and high thermal loads. A crucial technological focus involves the development of hybrid instant adhesive systems, integrating robust chemistries like modified epoxies, acrylics, or polyurethanes into the cyanoacrylate backbone. These hybrid formulations retain the rapid cure speed characteristic of instant adhesives while significantly enhancing durability, flexibility, and environmental resistance. This hybridization allows instant gels to penetrate structural bonding applications previously reserved for slower, two-part adhesives, widening the overall addressable market, especially in demanding sectors like aerospace and heavy-duty transportation.

Another significant technological advancement centers on precision dispensing and automation systems. As manufacturing processes trend toward micro-assembly and high throughput, the efficacy of the adhesive is highly dependent on the accuracy of its application. State-of-the-art dispensing equipment includes sophisticated volumetric dispensing valves, jetting systems, and robotic integration that can precisely control the amount and placement of the high-viscosity gel down to microliter volumes. Furthermore, technologies focusing on specialized curing mechanisms, such as light-cure instant gels (UV/Visible light cure), are gaining traction. These systems offer immediate on-demand curing, providing users with greater control over the setting process, a necessary feature for achieving optimal alignment before fixture, particularly in optic and medical device assembly.

The third major technological thrust is focused on formulation enhancements addressing user and regulatory concerns. This includes the widespread adoption of low-blooming and low-odor formulations, which significantly improve the work environment by reducing the emission of residual cyanoacrylate monomer fumes (blooming/frosting) that can damage sensitive components or create cosmetic defects. Stabilization technologies are also paramount, aimed at extending the shelf life of the gel in standard storage conditions and preventing polymerization within the application nozzle, ensuring consistency throughout the batch usage. The move towards more sustainable formulations, including solvent-free and bio-based stabilizers and additives, represents a growing technological direction influenced by global green chemistry initiatives and corporate sustainability goals.

Regional Highlights

- Asia Pacific (APAC) stands as the primary engine of growth for the Instant Adhesive Gel Market, characterized by high-volume manufacturing activities, particularly in China, South Korea, Taiwan, and India. This region benefits from the massive scale of the electronics manufacturing industry, including assembly of 5G components, consumer electronics, and expansive automotive production, especially within the rapidly growing electric vehicle sector. The demand here is driven by cost-efficiency, high throughput, and the need for adhesives compatible with robotic assembly lines. Governmental support for industrial expansion and infrastructure development further solidifies APAC's position as the dominant consumer and producer of instant adhesive gels.

- North America represents a mature, high-value market focused on specialty applications and stringent regulatory requirements. Demand is strong in aerospace, advanced medical device manufacturing, and high-tech electronics, where instant gels are utilized for high-reliability bonding. The regional emphasis is less on volume and more on specialized performance characteristics, such as enhanced thermal resistance, shock absorption, and compliance with FDA and UL standards. The strong presence of major adhesive multinational corporations drives continuous technological innovation and premium product adoption across the US and Canada.

- Europe maintains a substantial market share, driven by robust automotive production (particularly luxury and specialty vehicles) and stringent environmental regulations (like REACH). European manufacturers show a high preference for sustainable, low-VOC, and low-odor instant gel formulations. Germany, France, and the UK are key markets, utilizing these adhesives extensively in MRO, precision machinery assembly, and complex consumer durable goods manufacturing, balancing performance needs with environmental accountability.

- Latin America is emerging as a critical growth region, driven by expanding industrial bases in Mexico and Brazil, increased foreign direct investment in manufacturing, and growing construction and infrastructure projects. While the consumer segment growth is strong, industrial demand is accelerating as local manufacturers upgrade their assembly processes, moving away from traditional mechanical fastening methods toward faster, more efficient instant bonding solutions.

- Middle East & Africa (MEA) currently holds the smallest market share but promises substantial future growth, primarily tied to large-scale infrastructure and construction projects, alongside investments in diversification into light manufacturing and assembly. The region's hot and arid climate necessitates specialized instant gels that can withstand extreme temperature variations, focusing demand on heat-resistant and highly stabilized formulations for oil and gas equipment maintenance and facility management.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Instant Adhesive Gel Market.- Henkel AG & Co. KGaA

- 3M Company

- H.B. Fuller Company

- The Permatex Division of Illinois Tool Works Inc. (ITW)

- Sika AG

- Bostik (Arkema Group)

- DuPont de Nemours, Inc.

- Loxeal Engineering Adhesives

- Delo Industrial Adhesives

- MasterBond Inc.

- Pidilite Industries Ltd.

- Chemence Ltd.

- Scigrip Adhesives

- Lord Corporation (Parker Hannifin)

- Tesa SE (Beiersdorf)

- Franklin International

- ThreeBond Co., Ltd.

- Cyberbond

- Dymax Corporation

- Huntsman Corporation

- Aron Alpha (Toagosei Co., Ltd.)

- Parson Adhesives, Inc.

- Infinity Bond

- Devcon (ITW)

Frequently Asked Questions

Analyze common user questions about the Instant Adhesive Gel market and generate a concise list of summarized FAQs reflecting key topics and concerns.What distinguishes instant adhesive gels from traditional liquid instant adhesives?

Instant adhesive gels possess higher viscosity due to thickening agents, preventing running or dripping, making them ideal for vertical surfaces, overhead applications, and filling gaps up to 0.5 mm. They offer superior control and precision compared to low-viscosity liquid formulations.

Which chemical composition dominates the instant adhesive gel market?

Cyanoacrylate remains the dominant chemical base for instant adhesive gels due to its exceptional speed and versatility in bonding a wide variety of substrates. However, hybrid formulations incorporating epoxies or acrylics are increasingly used for enhanced durability and temperature resistance.

What are the primary challenges limiting the use of instant adhesive gels?

The main limitations include reduced performance under extreme moisture or high continuous heat, and their inherent rigidity, which makes them less suitable for highly flexible joints or applications requiring significant impact resistance unless modified with rubber or specialized additives.

How is the growth of the electric vehicle (EV) market impacting demand for instant gels?

The EV market significantly increases demand for instant adhesive gels for lightweighting purposes, substituting mechanical fasteners in interior assembly, securing complex sensor arrays, and specific non-structural battery component bonding where quick fixture and vibration resistance are essential.

What role does advanced dispensing technology play in this market?

Advanced dispensing systems, including robotic jetting and volumetric valves, are crucial for market growth as they ensure micro-precise application of the high-viscosity gel in automated industrial settings, minimizing waste, maximizing throughput, and ensuring consistent bond quality.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager