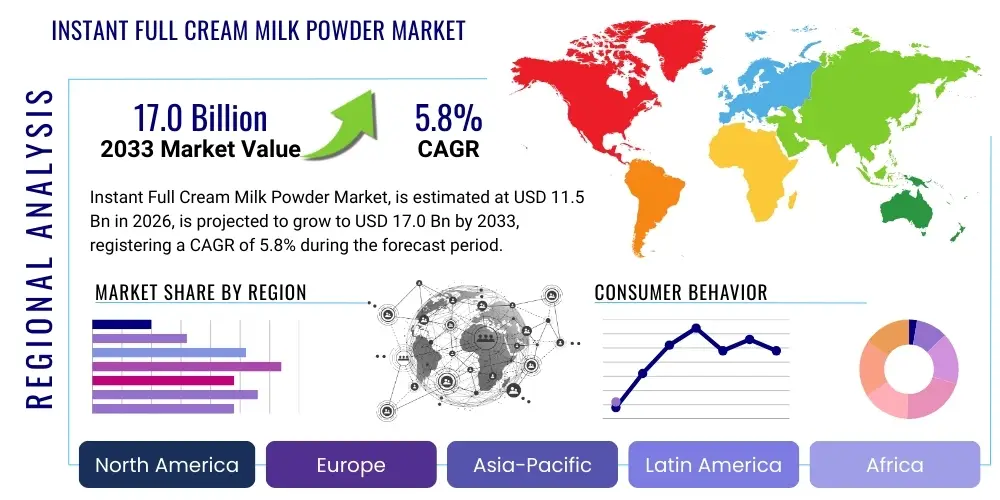

Instant Full Cream Milk Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435752 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Instant Full Cream Milk Powder Market Size

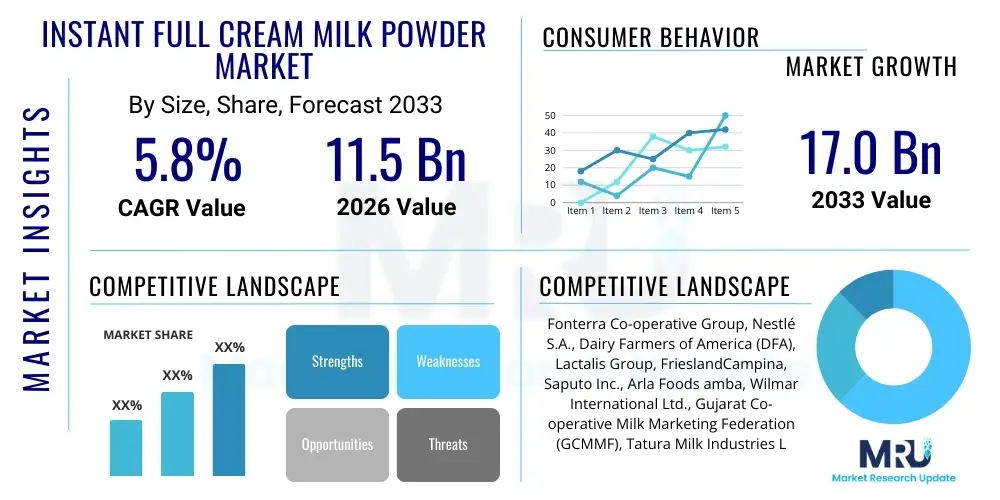

The Instant Full Cream Milk Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 11.5 Billion in 2026 and is projected to reach USD 17.0 Billion by the end of the forecast period in 2033.

Instant Full Cream Milk Powder Market introduction

Instant Full Cream Milk Powder (IFCMP) is a dairy product derived from fresh, pasteurized whole milk, manufactured through a process that removes nearly all moisture, typically via spray drying, to yield a fine, free-flowing powder. The "instant" characteristic refers to its enhanced solubility, allowing it to dissolve rapidly and completely in water, which significantly improves consumer convenience compared to standard whole milk powder. This high functionality makes IFCMP a critical ingredient across various sectors, maintaining the nutritional profile, flavor, and creamy texture associated with fresh milk.

The primary applications of IFCMP span human consumption, including direct reconstitution as a beverage, and extensive use as an essential component in the industrial food processing sector. Major end-use categories include the production of infant formula, confectionery, bakery items, prepared mixes, and specialized food supplements. The product offers significant benefits over liquid milk, most notably extended shelf life, reduced storage space, and elimination of the need for refrigeration, making it invaluable in areas with limited cold chain infrastructure or for humanitarian aid logistics.

Market expansion is principally driven by surging global population growth, rapid urbanization in developing economies, and evolving consumer preference for convenient, shelf-stable, and nutritionally rich food sources. Furthermore, the rising demand for infant formula, particularly in the Asia Pacific region due to increasing disposable incomes and greater awareness of packaged nutritional products, acts as a pivotal growth catalyst. Manufacturers are also continually innovating packaging solutions to ensure product integrity and maintain freshness, thereby broadening market penetration.

Instant Full Cream Milk Powder Market Executive Summary

The Instant Full Cream Milk Powder market is exhibiting robust growth, propelled by strong business trends centered on supply chain resilience, product premiumization, and strategic market diversification into functional food segments. Key manufacturers are focusing on enhancing traceability protocols and investing in sustainable processing technologies to meet stringent consumer and regulatory demands. There is a notable trend towards fortifying IFCMP with essential micronutrients, catering to health-conscious consumers seeking enhanced nutritional value beyond basic dairy consumption. Geographic expansion into high-growth emerging markets, particularly in Southeast Asia and Africa, remains a core strategy for achieving scale and mitigating risks associated with reliance on mature, saturated markets.

Regionally, the Asia Pacific dominates the market consumption landscape, driven by its immense population base, traditional reliance on packaged dairy, and burgeoning demand from the infant nutrition sector. Europe and North America, while having mature liquid milk markets, show strong demand for IFCMP in industrial applications such as high-end confectionery and specialized sports nutrition products, where consistent quality and high fat content are critical. Political stability, favorable trade agreements, and fluctuating global milk production levels significantly influence regional supply dynamics, leading to shifts in pricing and import dependency across different continents.

Segment trends highlight the dominance of the institutional (B2B) application segment, particularly in sectors like bakery, confectionery, and infant food manufacturing, which require large volumes of standardized powder. However, the retail segment is experiencing accelerated growth, driven by consumer preference for convenient pantry staples and the expansion of modern retail channels in developing nations. Manufacturers are actively segmenting the retail offering, introducing specialized versions (e.g., instant dissolving, high-protein variants) to capture diverse consumer needs, ensuring market growth remains broad-based across various user types and applications.

AI Impact Analysis on Instant Full Cream Milk Powder Market

Common user questions regarding AI's impact on the Instant Full Cream Milk Powder (IFCMP) market frequently revolve around how artificial intelligence can stabilize volatile supply chains, improve dairy quality control, and enable precise consumer demand forecasting. Users are keenly interested in AI’s role in optimizing the complex processing stage—specifically spray drying—to minimize energy consumption and maximize product yield. There is significant concern about the adoption cost versus the benefit realization for mid-sized manufacturers, particularly concerning predictive maintenance of highly specialized equipment. Overall, user expectations center on AI driving efficiency, enhancing product safety through advanced sorting and contamination detection, and ultimately leading to more predictable pricing and inventory management across the dairy value chain.

- AI-driven predictive demand forecasting optimizes inventory levels, reducing spoilage and minimizing storage costs for both raw materials (milk) and finished goods.

- Implementation of machine learning algorithms for real-time quality control checks during the drying process ensures consistent moisture content and particle size, enhancing instant solubility.

- AI facilitates advanced supply chain transparency and traceability, monitoring milk origin, processing conditions, and distribution logistics to ensure compliance and prevent fraudulent activities.

- Utilization of AI in automated processing plant optimization leads to energy efficiency improvements, particularly in high-energy consumption areas like pasteurization and spray drying.

- Predictive maintenance analytics, powered by AI, minimize downtime of critical manufacturing equipment, thus ensuring continuous production stability and maximizing operational throughput.

DRO & Impact Forces Of Instant Full Cream Milk Powder Market

The Instant Full Cream Milk Powder market is characterized by a dynamic interplay of propelling drivers, market restraints, and significant strategic opportunities, collectively shaping its trajectory and competitive landscape. The market drivers primarily stem from increasing global population and the necessity for shelf-stable dairy products, particularly in regions where access to fresh, chilled milk is limited or unreliable. However, the industry faces substantial restraints, including the inherent volatility in global raw milk prices, which directly impacts manufacturing costs and retail profitability, alongside increasing scrutiny from environmental regulatory bodies concerning the carbon footprint of dairy production.

Opportunities for expansion are predominantly linked to product innovation, specifically the development of fortified and customized milk powders tailored for specific dietary requirements such as sports nutrition, geriatric care, and clinical dietetics. Leveraging technological advancements to improve processing efficiency and reduce environmental impact also presents a significant avenue for competitive differentiation. Moreover, the robust growth in the institutional food service segment, coupled with the rising consumption of packaged snacks and convenience foods utilizing IFCMP as a core ingredient, offers long-term sustainable growth prospects.

The core impact forces driving strategic decisions include shifting trade policies, climate change effects on global pasture productivity, and intensifying competition from plant-based dairy alternatives. These forces necessitate continuous operational agility, investment in diversified sourcing strategies, and a strong emphasis on maintaining product quality consistency across varying regulatory environments to ensure market share retention and sustainable financial performance. Manufacturers must prioritize supply chain digitalization to manage risk exposure effectively against these influential market forces.

Segmentation Analysis

The Instant Full Cream Milk Powder market is segmented based on critical parameters including Application, Distribution Channel, and End-User, reflecting the diverse consumption patterns globally. Understanding these segments is crucial for manufacturers to tailor their production, marketing, and distribution strategies effectively. The segmentation analysis reveals that the industrial application segment holds the largest market share due to the substantial volumes required by F&B manufacturers, while the retail segment demonstrates the highest growth potential driven by household convenience and necessity purchasing. Geographic variations in dietary habits and regulatory standards further refine the strategic approach within each segment.

- By Application:

- Infant Formula

- Confectionery & Bakery

- Dairy Products (Yogurt, Ice Cream)

- Beverages & Food Supplements

- Household/Direct Consumption

- By Distribution Channel:

- Business-to-Business (B2B)

- Retail (Supermarkets, Hypermarkets, Online Retail)

Value Chain Analysis For Instant Full Cream Milk Powder Market

The value chain for Instant Full Cream Milk Powder begins with the upstream activities of raw milk procurement, which involves dairy farming, collection, and initial chilling. This stage is characterized by high sensitivity to environmental factors, feed costs, and stringent hygiene standards. Efficient logistics and robust supplier relationships are vital here to ensure a consistent volume and quality of fresh milk supplied to the processing facilities. Upstream analysis highlights the necessity for advanced farm management systems and adherence to global animal welfare and sustainability standards, which increasingly influence consumer purchasing decisions and regulatory compliance requirements.

The core processing stage involves highly sophisticated industrial operations, including pasteurization, standardization, homogenization, evaporation, and the critical step of spray drying to achieve the instant properties. Investment in state-of-the-art drying technology and stringent quality control protocols is paramount to guarantee the extended shelf life, nutritional integrity, and dissolution characteristics of the final product. Downstream analysis focuses on packaging, which includes specialized airtight materials and Modified Atmosphere Packaging (MAP) techniques designed to protect the powder from moisture and oxygen ingress, maintaining product stability throughout its lifecycle.

The distribution channel utilizes both direct and indirect routes. Direct sales (B2B) often cater to large institutional buyers like infant formula producers or confectionery factories, involving bulk packaging and specialized logistics. Indirect sales involve retail channels, utilizing distributors and wholesalers to reach supermarkets, convenience stores, and the burgeoning e-commerce platforms. Effective channel management requires strategic partnerships to navigate complex international trade regulations and ensure efficient cold-free storage and transit, ultimately delivering value to both the industrial customer and the end consumer.

Instant Full Cream Milk Powder Market Potential Customers

The potential customer base for Instant Full Cream Milk Powder is highly diverse, spanning large multinational corporations, specialized industrial producers, and individual households globally. The primary end-users in the B2B segment are manufacturers of infant nutrition products, where IFCMP serves as a high-quality, standardized protein and fat source. These customers demand strict adherence to regulatory specifications, consistency in nutrient profile, and guaranteed supply volumes, often requiring long-term contractual agreements and rigorous supplier audits.

Another significant segment comprises the confectionery, bakery, and prepared food industry sectors. These customers utilize IFCMP to enhance texture, flavor, and binding properties in products such as chocolates, biscuits, powdered soup mixes, and ready-to-eat meals. For this group, functionality, emulsification properties, and competitive pricing are critical determinants in procurement decisions. The flexibility and stability offered by IFCMP make it an indispensable ingredient in complex food formulations requiring precise control over moisture content and fat distribution.

The retail customer base includes individual consumers seeking a convenient, long-lasting alternative to fresh milk, particularly in regions where refrigeration is limited or during emergency preparedness scenarios. Furthermore, the burgeoning popularity of functional and fortified foods has expanded the consumer segment to include health-conscious individuals, fitness enthusiasts, and the elderly who rely on milk powder for convenient protein and calcium supplementation. Marketing efforts target convenience, extended shelf life, and the ease of reconstitution to drive retail adoption.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 11.5 Billion |

| Market Forecast in 2033 | USD 17.0 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fonterra Co-operative Group, Nestlé S.A., Dairy Farmers of America (DFA), Lactalis Group, FrieslandCampina, Saputo Inc., Arla Foods amba, Wilmar International Ltd., Gujarat Co-operative Milk Marketing Federation (GCMMF), Tatura Milk Industries Ltd. (Bega Cheese), Promac Group, Olam International, Synlait Milk Ltd., Miraka Limited, Mengniu Dairy, Yili Group, Meiji Holdings Co., Ltd., DMK Group, Glanbia plc, China Modern Dairy Holdings Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Instant Full Cream Milk Powder Market Key Technology Landscape

The manufacturing of Instant Full Cream Milk Powder relies heavily on precision processing technologies, primarily focusing on achieving rapid and complete solubility while preserving the milk's nutritional and organoleptic properties. The core technology remains spray drying, which involves atomizing concentrated milk into a fine mist in a hot air chamber. However, modern advancements incorporate multi-stage drying techniques, often including fluid bed drying after the initial spray drying, which reduces energy consumption and optimizes particle structure for enhanced instant properties. Manufacturers are consistently refining nozzle designs and temperature profiles to create uniform, porous particles that dissolve instantly without clumping.

Beyond the drying process, significant technological efforts are concentrated on improving traceability and food safety throughout the production chain. Implementation of sensor technology and IoT devices allows for real-time monitoring of critical control points, from raw milk receiving to final packaging. Advanced spectral analysis and non-destructive testing methods are increasingly utilized to detect contaminants, adulteration, and ensure the consistent composition of fat, protein, and moisture levels in the finished powder. This technological integration is crucial for maintaining compliance with stringent global import standards, particularly in sensitive sectors like infant nutrition.

Furthermore, packaging innovation constitutes a vital part of the technology landscape. Manufacturers are moving towards barrier packaging films, vacuum sealing, and the use of Modified Atmosphere Packaging (MAP) with inert gases (like nitrogen) to minimize oxidation and protect the essential fatty acids present in full cream milk powder. These packaging advancements are essential for extending the product's shelf stability from months to years, which is a major value proposition for international trade and distribution in challenging environmental conditions, ensuring that the powder reaches the consumer with optimum quality and freshness.

Regional Highlights

The global Instant Full Cream Milk Powder market exhibits pronounced regional disparities in both production capacity and consumption demand, driven by demographic shifts, economic development, and cultural preferences.

- Asia Pacific (APAC): Dominates the consumption landscape due to large populations, particularly in China and India, increasing disposable income, and high utilization in infant formula manufacturing. The region is characterized by high import dependency in certain nations, balanced by substantial domestic production capabilities in others, necessitating complex supply chain strategies.

- Europe: A major global producer and exporter, leveraging advanced dairy farming technologies and stringent quality standards (e.g., EU regulations). While household consumption of powder is moderate, the region is a significant hub for B2B applications, especially in high-value confectionery and specialized food ingredient production.

- North America: Marked by strong domestic production and high utilization rates in the industrial sector, particularly in processed foods and sports nutrition supplements. Market growth is stable, focusing on premiumization, organic variants, and functional fortification to meet evolving health trends.

- Latin America: Demonstrates significant growth potential, driven by rising purchasing power, improving urbanization rates, and the need for shelf-stable dairy solutions in diverse climatic zones. Brazil and Mexico are key markets showing increased demand for both retail and industrial applications.

- Middle East and Africa (MEA): Highly dependent on imports due to limited domestic milk production capacity in arid regions. IFCMP is a critical food staple and ingredient, particularly in nations with high population growth and challenging logistics, making this region a crucial target for major global exporters.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Instant Full Cream Milk Powder Market.- Fonterra Co-operative Group

- Nestlé S.A.

- Dairy Farmers of America (DFA)

- Lactalis Group

- FrieslandCampina

- Saputo Inc.

- Arla Foods amba

- Wilmar International Ltd.

- Gujarat Co-operative Milk Marketing Federation (GCMMF)

- Tatura Milk Industries Ltd. (Bega Cheese)

- Promac Group

- Olam International

- Synlait Milk Ltd.

- Miraka Limited

- Mengniu Dairy

- Yili Group

- Meiji Holdings Co., Ltd.

- DMK Group

- Glanbia plc

- China Modern Dairy Holdings Ltd.

Frequently Asked Questions

Analyze common user questions about the Instant Full Cream Milk Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the growth of the Instant Full Cream Milk Powder Market?

Market growth is primarily driven by rapid urbanization, high demand for shelf-stable and convenient nutritional products, increasing utilization in the infant formula sector, and the necessity for extended product shelf life in regions with underdeveloped cold chain infrastructure.

How does Instant Full Cream Milk Powder differ fundamentally from standard Whole Milk Powder?

IFCMP is processed specifically to achieve superior solubility, allowing it to dissolve rapidly and uniformly in water without clumping, unlike standard whole milk powder, which may require agitation or warm water, making the instant version highly preferred for direct consumer use.

Which region holds the largest market share in terms of IFCMP consumption?

The Asia Pacific (APAC) region currently holds the largest consumption share, driven by its massive population base, rising middle-class consumption patterns, and robust manufacturing activity in the bakery and infant nutrition sectors, particularly in East and South Asia.

What major challenges restrict the market expansion of Instant Full Cream Milk Powder?

The market faces restrictions primarily due to the high volatility of global raw milk prices, which impacts profitability, increasing competition from fortified plant-based milk alternatives, and stringent regulatory requirements regarding food safety and dairy traceability across international borders.

What is the significance of spray drying technology in IFCMP production?

Spray drying is the cornerstone technology for IFCMP production as it rapidly removes moisture while forming specialized, porous particles. This process is essential for achieving the required "instant" characteristic of fast solubility, while simultaneously minimizing thermal damage to sensitive nutrients and flavor compounds.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager