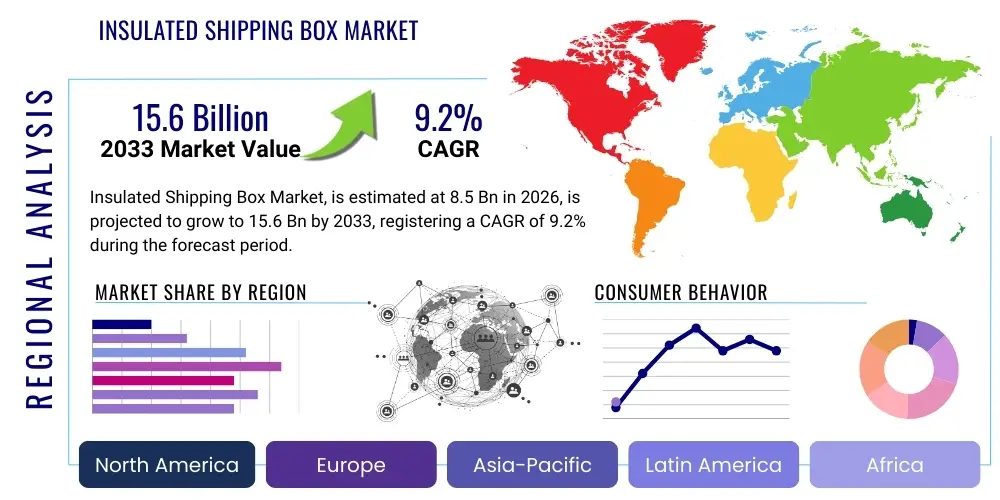

Insulated Shipping Box Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440253 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Insulated Shipping Box Market Size

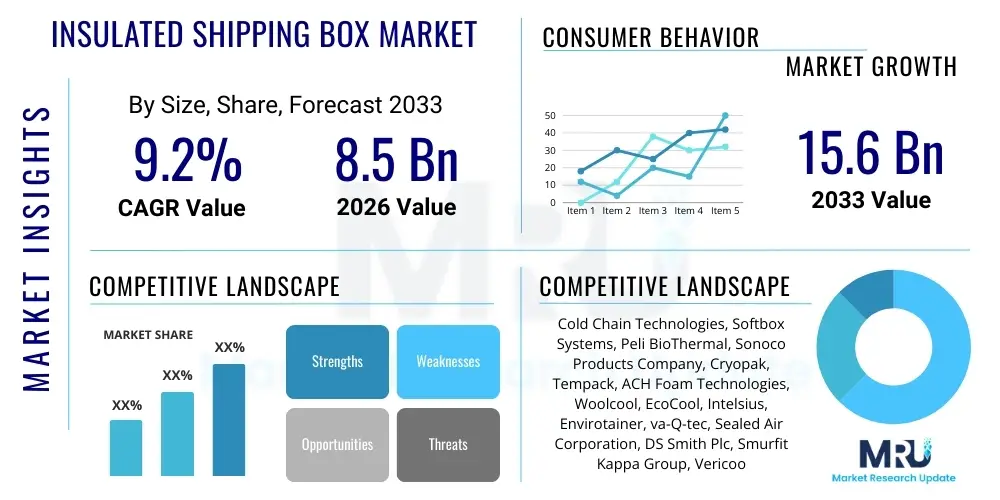

The Insulated Shipping Box Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.2% between 2026 and 2033. The market is estimated at USD 8.5 billion in 2026 and is projected to reach USD 15.6 billion by the end of the forecast period in 2033. This substantial growth is primarily driven by the escalating global demand for safe and temperature-controlled logistics solutions across various industries, including pharmaceuticals, food and beverage, and e-commerce. The increasing complexity of supply chains, coupled with stricter regulatory requirements for the transportation of sensitive goods, further underpins this market expansion. Innovations in material science, focusing on enhanced thermal performance and sustainability, are also playing a crucial role in shaping market dynamics and accelerating adoption rates.

Insulated Shipping Box Market introduction

The Insulated Shipping Box Market encompasses a wide range of packaging solutions designed to maintain specific temperature ranges for perishable and temperature-sensitive goods during transit. These boxes are critical for preserving product integrity and efficacy, especially for items susceptible to degradation from thermal fluctuations. Products typically include pharmaceuticals like vaccines and biologics, fresh produce, seafood, dairy, and various chemical compounds requiring precise environmental control. The primary benefits of these specialized containers include extended product shelf life, compliance with stringent regulatory standards such as those in pharmaceutical and food safety, reduced product spoilage, and enhanced customer satisfaction through reliable delivery of high-quality goods. Key driving factors propelling market growth involve the exponential rise of e-commerce, which necessitates robust cold chain logistics, increasing consumer demand for fresh and high-quality food products, and the continuous expansion of the global pharmaceutical and biotechnology sectors, all of which rely heavily on efficient and secure temperature-controlled shipping methods. Furthermore, technological advancements in insulation materials and packaging design contribute significantly to improving performance and broadening application possibilities across diverse industries.

Insulated Shipping Box Market Executive Summary

The Insulated Shipping Box Market is currently experiencing robust growth, primarily fueled by significant business trends such as the global expansion of e-commerce and the escalating demand for temperature-sensitive products in both the pharmaceutical and food sectors. Businesses are increasingly investing in sophisticated cold chain solutions to ensure product quality and meet stringent regulatory compliance, driving innovation in sustainable and high-performance insulation materials. Regionally, Asia Pacific is emerging as a critical growth engine, propelled by rapid urbanization, expanding healthcare infrastructure, and a booming consumer base with increasing disposable incomes and preferences for online grocery and meal kit services. North America and Europe continue to be mature markets characterized by advanced logistics networks and a strong focus on regulatory adherence and sustainable packaging. From a segmentation perspective, the pharmaceutical and food & beverage industries remain the dominant end-users, with a discernible shift towards eco-friendly and reusable insulation solutions. Material-wise, vacuum insulated panels (VIPs) and advanced phase change materials (PCMs) are gaining traction due to their superior thermal performance, while traditional expanded polystyrene (EPS) foam continues to hold a significant share due to its cost-effectiveness. The market is also witnessing a trend towards customization and integration of smart packaging technologies for real-time temperature monitoring, enhancing overall supply chain transparency and reliability.

AI Impact Analysis on Insulated Shipping Box Market

User inquiries regarding AI's impact on the Insulated Shipping Box Market predominantly revolve around optimizing cold chain logistics, predicting demand fluctuations, and enhancing operational efficiency. Key themes include the potential for AI-driven route optimization to minimize transit times and temperature excursions, intelligent inventory management systems to reduce waste and spoilage, and the integration of machine learning for predictive maintenance of cold chain equipment. Users are also keen to understand how AI can improve real-time monitoring of package conditions, providing actionable insights for immediate intervention and proactive risk mitigation. Concerns often include the initial investment costs, data privacy issues associated with extensive monitoring, and the need for skilled personnel to manage and interpret complex AI algorithms. Overall, the expectation is that AI will transform the precision and responsiveness of temperature-controlled logistics, making the entire insulated shipping process more efficient, reliable, and sustainable through advanced analytics and automation, ultimately leading to significant cost savings and improved product integrity.

- AI-powered demand forecasting optimizes inventory levels and reduces waste for perishable goods.

- Predictive analytics enables real-time temperature deviation alerts and proactive intervention during transit.

- Automated route optimization algorithms enhance delivery efficiency and minimize energy consumption.

- Machine learning models analyze historical data to improve insulation material selection and packaging design.

- AI-driven quality control systems can detect potential compromises in cold chain integrity.

DRO & Impact Forces Of Insulated Shipping Box Market

The Insulated Shipping Box Market is shaped by a confluence of powerful drivers, inherent restraints, promising opportunities, and overarching impact forces that collectively dictate its trajectory. A primary driver is the accelerating expansion of the global e-commerce sector, particularly for temperature-sensitive goods such as groceries, pharmaceuticals, and meal kits, which necessitates robust and reliable cold chain solutions. Simultaneously, the increasing globalization of supply chains for biopharmaceuticals and specialty chemicals, alongside stricter regulatory frameworks for product safety and quality assurance, significantly boosts the demand for highly effective insulated packaging. Furthermore, growing consumer awareness regarding product quality and freshness, coupled with a preference for doorstep delivery of perishable items, further propels market expansion.

Despite these growth factors, the market faces several notable restraints. The relatively high cost associated with advanced insulation materials, such as vacuum insulated panels (VIPs) and phase change materials (PCMs), can pose a barrier to adoption, especially for small and medium-sized enterprises (SMEs). Challenges related to the recycling and sustainable disposal of traditional insulation materials, like expanded polystyrene (EPS) foam, present environmental concerns and contribute to regulatory pressures. Moreover, the often bulky nature of insulated shipping boxes can lead to increased transportation costs and reduced storage efficiency, impacting logistical operations and overall cost-effectiveness for some users. The availability of alternative cold chain solutions, such such as refrigerated vehicles and temperature-controlled warehouses, also creates competitive pressure.

Opportunities within this market are abundant and largely centered on innovation and sustainability. There is significant potential in the development and adoption of eco-friendly and biodegradable insulation materials, addressing environmental concerns and catering to a growing demand for green solutions. The integration of smart packaging technologies, including IoT sensors for real-time temperature monitoring and traceability, offers avenues for enhanced supply chain transparency and product security. Customization for niche applications, such as specialized packaging for cell and gene therapies or advanced biologics, presents premium market segments. Furthermore, geographical expansion into emerging economies, where cold chain infrastructure is rapidly developing, offers substantial untapped market potential. The continuous advancements in material science are expected to yield next-generation insulation solutions with improved performance and reduced environmental footprint, fostering market growth.

The primary impact forces influencing this market include rapid technological advancements in thermal insulation and smart packaging, which continually raise performance benchmarks and introduce new capabilities. Regulatory changes, particularly concerning pharmaceutical cold chain integrity and food safety standards, directly mandate the use of compliant insulated solutions and drive market evolution. Shifting consumer preferences towards convenience, freshness, and sustainable products significantly impact demand patterns and packaging choices. Lastly, ongoing pressures for supply chain optimization, driven by the need for efficiency and cost reduction across diverse industries, compel innovations in packaging design and logistics processes to ensure optimal product delivery while managing operational expenses effectively. These intertwined forces collectively steer market development.

Segmentation Analysis

The Insulated Shipping Box Market is comprehensively segmented to provide granular insights into its diverse applications, material compositions, and end-user landscapes, enabling a detailed understanding of market dynamics and growth opportunities. This segmentation allows stakeholders to identify specific market niches, understand demand drivers for particular product types, and strategically position their offerings. The intricate layers of segmentation reflect the varied requirements across industries, from the ultra-sensitive biopharmaceuticals needing precise temperature control to the burgeoning demand for fresh food delivery, all requiring tailored insulation solutions. Analyzing these segments is crucial for market participants to develop targeted product innovations, optimize distribution channels, and formulate effective marketing strategies that resonate with specific customer needs and industry standards, driving both market penetration and value creation.

- By Material:

- Expanded Polystyrene (EPS) Foam

- Polyurethane (PU) Foam

- Vacuum Insulated Panels (VIP)

- Recycled Content Materials (e.g., recycled paper, recycled plastic fibers)

- Phase Change Materials (PCM) integrated solutions

- Natural Fibers (e.g., wool, cotton, hemp)

- Other Advanced Insulating Materials (e.g., aerogels, innovative foams)

- By Application:

- Food & Beverage

- Perishable Foods (e.g., fruits, vegetables)

- Seafood & Meat Products

- Dairy Products

- Frozen Meals & Ice Cream

- Prepared Meals & Meal Kits

- Beverages (e.g., craft beer, specialty drinks)

- Pharmaceuticals & Healthcare

- Vaccines & Biologics

- Blood Products & Organ Transplants

- Diagnostic Samples & Clinical Trials

- Insulin & Other Temperature-Sensitive Drugs

- Cell and Gene Therapies

- Cosmetics & Personal Care Products

- Chemical Industry (e.g., reagents, specialty chemicals)

- E-commerce Logistics (Cross-industry temperature control)

- Agricultural Products (e.g., floriculture, seeds)

- Industrial Components & Electronics

- Other Specialty Applications

- Food & Beverage

- By End-User:

- Pharmaceutical Companies & Biotech Firms

- Food Processors & Manufacturers

- Meal Kit Delivery Services

- Hospitals, Clinics & Research Laboratories

- Chemical Manufacturers

- Retailers (Online & Brick-and-Mortar)

- Logistics & Shipping Companies (3PLs)

- Direct-to-Consumer (DTC) Brands

- Veterinary Medicine & Animal Health

- Individual Consumers

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Insulated Shipping Box Market

The value chain for the Insulated Shipping Box Market commences with upstream analysis, focusing on the sourcing and processing of raw materials essential for insulation and structural components. This stage involves suppliers of expanded polystyrene (EPS) beads, polyurethane chemicals, various plastics, cardboard, and advanced materials such as fiberglass, silica, and metallic foils for vacuum insulated panels (VIPs), along with phase change materials (PCMs) suppliers. Manufacturers of these base materials are crucial, as their innovation in sustainable and high-performance properties directly impacts the final product's efficacy and cost. The quality, availability, and cost-effectiveness of these primary inputs significantly influence the manufacturing process and the overall competitiveness of insulated shipping box producers. Relationships with these upstream suppliers are critical for maintaining consistent product quality and driving material innovation. Ensuring a resilient and ethical supply chain for these raw materials is a significant consideration for market players, particularly in light of increasing scrutiny on environmental impact and resource sustainability.

Moving downstream, the value chain encompasses the manufacturing, assembly, and distribution of the finished insulated shipping boxes. Manufacturers of insulated boxes convert raw materials into final products, often incorporating specialized designs, sizes, and additional features like temperature monitoring strips or data loggers. This stage also includes packaging design and engineering firms that develop customized solutions to meet specific industry requirements, such as those for pharmaceutical cold chains or precise temperature profiles for gourmet food delivery. Quality control and testing are paramount at this stage to ensure thermal performance and structural integrity. Post-manufacturing, the products enter the distribution channels, which are bifurcated into direct and indirect routes. Direct distribution involves manufacturers selling directly to large end-users, such as major pharmaceutical companies, large food processors, or prominent e-commerce logistics providers, often through long-term contracts and customized supply agreements. This direct model allows for closer collaboration, bespoke solutions, and potentially higher margins.

Indirect distribution channels are characterized by the involvement of intermediaries, including third-party logistics (3PL) providers, specialized cold chain logistics companies, packaging distributors, and online retailers. These intermediaries play a vital role in reaching a broader customer base, especially smaller businesses, individual consumers, and diverse regional markets. 3PLs, in particular, often integrate insulated shipping boxes into their comprehensive cold chain service offerings, providing an end-to-end solution for their clients. Packaging distributors offer a wide range of insulated solutions from various manufacturers, providing convenience and choice to customers. The efficiency of these distribution channels, coupled with effective warehousing and inventory management, directly impacts market penetration and customer accessibility. Both direct and indirect channels must maintain strict adherence to cold chain protocols to ensure product integrity until the final delivery point. Strategic partnerships between manufacturers and these various distribution entities are essential for optimizing market reach, enhancing service levels, and navigating the complexities of diverse customer demands across the global landscape.

Insulated Shipping Box Market Potential Customers

The Insulated Shipping Box Market serves a diverse and expanding base of potential customers whose operations critically depend on maintaining specific temperature conditions for their products during transit. The primary end-users or buyers of these products span across several key industries, each with unique requirements and cold chain complexities. In the pharmaceutical and biotechnology sector, customers include pharmaceutical manufacturers, biotech firms developing advanced therapies, research laboratories, and hospitals. These entities rely on insulated boxes for the safe transportation of vaccines, biologics, blood products, clinical trial samples, and highly sensitive medications that are susceptible to temperature excursions and require stringent regulatory compliance. The integrity of these products is paramount, directly impacting patient safety and treatment efficacy, making reliable insulated packaging an indispensable component of their supply chains.

Another significant segment comprises the food and beverage industry, where potential customers include large-scale food processors, seafood distributors, dairy producers, fresh produce suppliers, and the rapidly growing ecosystem of meal kit delivery services and online grocery retailers. These customers utilize insulated shipping boxes to ensure that perishable items like fresh meat, poultry, seafood, fruits, vegetables, dairy products, and frozen meals reach consumers in optimal condition, preserving freshness, taste, and safety. The expansion of e-commerce has significantly broadened this customer base, as consumers increasingly demand convenient access to fresh and high-quality food delivered directly to their homes. Effective insulation prevents spoilage, extends shelf life, and enhances customer satisfaction, which is crucial for brand reputation and repeat business in the highly competitive food delivery market.

Beyond these dominant sectors, other crucial customers include the cosmetics and personal care industry, which transports temperature-sensitive beauty products; the chemical industry, requiring safe transit for reagents and specialty chemicals; and various industrial applications where certain components or electronics need protection from extreme temperatures. Furthermore, third-party logistics (3PL) providers and dedicated cold chain logistics companies are significant buyers, as they integrate insulated boxes into their comprehensive service offerings for a multitude of clients. Direct-to-consumer (DTC) brands, irrespective of their product category, also represent a growing segment, as they seek reliable and cost-effective ways to deliver temperature-sensitive goods directly to individual consumers, ensuring product quality from factory to doorstep. The varied demands across these customer groups drive ongoing innovation in insulated packaging solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 Billion |

| Market Forecast in 2033 | USD 15.6 Billion |

| Growth Rate | 9.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Cold Chain Technologies, Softbox Systems, Peli BioThermal, Sonoco Products Company, Cryopak, Tempack, ACH Foam Technologies, Woolcool, EcoCool, Intelsius, Envirotainer, va-Q-tec, Sealed Air Corporation, DS Smith Plc, Smurfit Kappa Group, Vericool, IPC (Insulated Products Corporation), Tipa Corp, TemperPack, Thermal Shipping Solutions |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Insulated Shipping Box Market Key Technology Landscape

The Insulated Shipping Box Market is continuously evolving through significant advancements in material science and smart packaging technologies, which are fundamentally transforming how temperature-sensitive goods are transported. At the core of this evolution are innovations in insulation materials, moving beyond traditional expanded polystyrene (EPS) foam to include high-performance alternatives such as vacuum insulated panels (VIPs). VIPs offer superior thermal resistance due to their evacuated core, providing significantly thinner wall profiles while maintaining critical temperature control, which is crucial for maximizing payload space and reducing shipping costs. Phase change materials (PCMs) represent another vital technological development, capable of absorbing and releasing latent heat to maintain specific temperature ranges for extended periods, offering a more stable and predictable thermal environment than traditional ice packs. Furthermore, the development of sustainable insulation materials, including those derived from recycled content, natural fibers like wool and cotton, and biodegradable polymers, is gaining considerable traction, driven by environmental concerns and regulatory pressures to reduce plastic waste and carbon footprint across logistics operations. These material innovations are critical for balancing thermal performance with ecological responsibility.

Beyond the insulating materials themselves, the integration of advanced technologies within the packaging structure is a key trend in the insulated shipping box market. This includes the incorporation of smart packaging solutions that leverage the Internet of Things (IoT) and other digital tools. These technologies enable real-time monitoring of critical parameters such as internal temperature, humidity, and even shock or vibration during transit. Sensors embedded within the packaging transmit data to cloud-based platforms, allowing shippers and recipients to track conditions instantaneously. This capability is particularly invaluable for high-value pharmaceuticals and biologics, where any temperature excursion can render products ineffective or unsafe. Data loggers and RFID tags further enhance traceability and provide an immutable record of the product's environmental conditions throughout its journey, facilitating regulatory compliance and quality assurance. The analytical insights gained from this data can also be used to optimize future cold chain routes, improve packaging designs, and predict potential issues before they occur.

Moreover, manufacturing processes for insulated shipping boxes are also witnessing technological upgrades to enhance efficiency, customization, and cost-effectiveness. Automated production lines, advanced molding techniques, and precision cutting tools allow for the creation of intricate and highly customized packaging solutions tailored to specific product dimensions and thermal requirements. Digital design and simulation tools enable manufacturers to rapidly prototype and test new designs, optimizing thermal performance and structural integrity without extensive physical trials. The adoption of robotics in assembly and packing processes further streamlines operations, reduces labor costs, and improves consistency. Furthermore, the development of modular and reusable insulated packaging systems is a significant innovation. These systems often utilize durable outer shells combined with replaceable insulation inserts or PCMs, promoting circular economy principles by reducing single-use waste and offering a more sustainable and economically viable option for frequent shipments. These technological advancements collectively drive the market towards more efficient, reliable, and environmentally conscious cold chain solutions.

Regional Highlights

- North America: This region represents a mature and significant market, driven by a highly developed pharmaceutical industry, robust e-commerce growth, and stringent regulatory standards for food and drug safety. The United States and Canada are leading adopters of advanced insulated packaging, with a strong focus on sustainable solutions and smart packaging technologies. Demand is particularly high for biopharmaceuticals, clinical trials, and fresh food delivery services.

- Europe: Europe is another key market, characterized by strong regulatory frameworks from entities like the European Medicines Agency (EMA) and a growing emphasis on environmental sustainability. Countries such as Germany, the UK, France, and Switzerland are major hubs for pharmaceutical manufacturing and research, driving consistent demand. The region also exhibits high adoption of advanced materials and a growing preference for reusable packaging solutions to reduce waste.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by rapid economic development, increasing disposable incomes, expanding healthcare infrastructure, and the booming e-commerce sector, especially in countries like China, India, Japan, and Australia. The rising demand for temperature-sensitive drugs, vaccines, and imported fresh produce, coupled with improving cold chain logistics, makes this region a critical growth engine for insulated shipping boxes.

- Latin America: This region is experiencing steady growth, propelled by the expansion of the pharmaceutical and food processing industries, along with improving logistics networks. Countries such as Brazil, Mexico, and Argentina are seeing increased investment in cold chain infrastructure to support both domestic consumption and export of perishable goods. The market here is characterized by a balance between cost-effective and high-performance solutions.

- Middle East and Africa (MEA): The MEA region is an emerging market with significant growth potential, driven by rising healthcare spending, population growth, and efforts to diversify economies beyond oil. Investments in cold chain logistics infrastructure, particularly in countries like UAE, Saudi Arabia, and South Africa, are creating new opportunities for insulated shipping boxes to support the import of pharmaceuticals and fresh food, often in challenging climatic conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Insulated Shipping Box Market.- Cold Chain Technologies

- Softbox Systems

- Peli BioThermal

- Sonoco Products Company

- Cryopak

- Tempack

- ACH Foam Technologies

- Woolcool

- EcoCool

- Intelsius

- Envirotainer

- va-Q-tec

- Sealed Air Corporation

- DS Smith Plc

- Smurfit Kappa Group

- Vericool

- IPC (Insulated Products Corporation)

- Tipa Corp

- TemperPack

- Thermal Shipping Solutions

Frequently Asked Questions

Analyze common user questions about the Insulated Shipping Box market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are insulated shipping boxes primarily used for?

Insulated shipping boxes are primarily used for safely transporting temperature-sensitive goods such as pharmaceuticals (vaccines, biologics), fresh food (meat, dairy, produce), meal kits, and certain chemicals, ensuring they maintain specific temperature ranges to preserve integrity and efficacy during transit.

What are the main types of insulation materials used?

Common insulation materials include Expanded Polystyrene (EPS) foam, Polyurethane (PU) foam, Vacuum Insulated Panels (VIPs) for high performance, Phase Change Materials (PCMs) for stable temperature control, and sustainable options like recycled content or natural fibers (e.g., wool).

How do insulated shipping boxes contribute to cold chain logistics?

They are essential for maintaining the cold chain by protecting products from external temperature fluctuations, extending shelf life, preventing spoilage, and ensuring compliance with stringent regulatory requirements for temperature-sensitive goods from origin to destination.

What are the key drivers for market growth?

Key drivers include the rapid expansion of e-commerce, increasing demand for temperature-sensitive pharmaceuticals and fresh foods, stringent global regulations on product safety, and growing consumer awareness regarding product quality and freshness.

Are there sustainable options available in the market?

Yes, the market is seeing a significant shift towards sustainable solutions, including boxes made from recycled materials, natural fiber insulation (like wool or cotton), biodegradable alternatives, and reusable insulated packaging systems to reduce environmental impact.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager