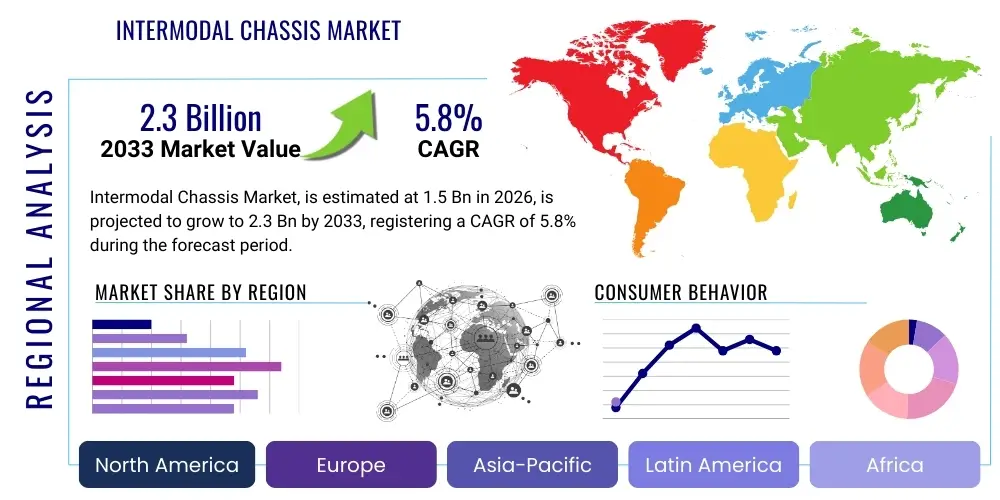

Intermodal Chassis Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440279 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Intermodal Chassis Market Size

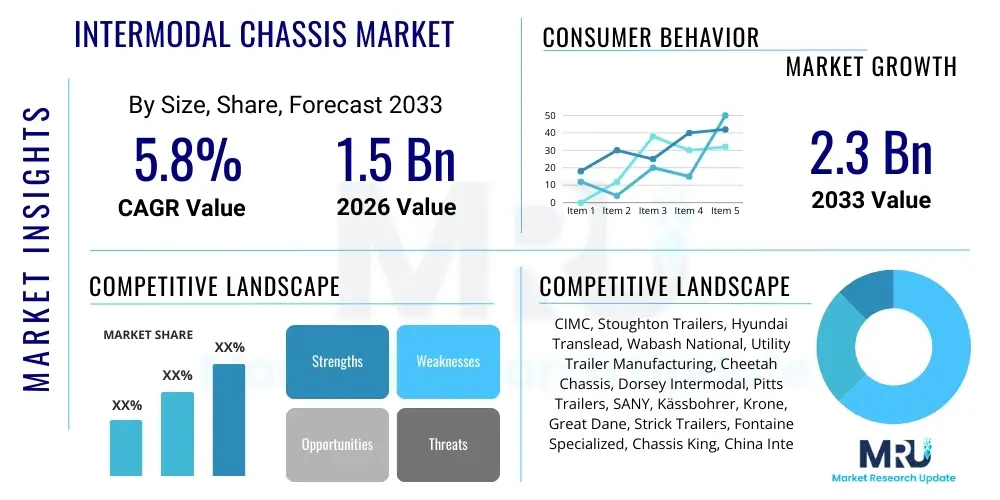

The Intermodal Chassis Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.3 Billion by the end of the forecast period in 2033. This robust expansion is primarily fueled by the escalating demand for efficient and integrated logistics solutions globally, driven by the burgeoning e-commerce sector, increased international trade activities, and a persistent focus on supply chain optimization. The intermodal transport system, which seamlessly integrates various modes of transport such as rail, truck, and ship, relies heavily on these specialized trailers to facilitate the movement of containers, thus underlining their critical role in the global freight ecosystem.

Intermodal Chassis Market introduction

The Intermodal Chassis Market forms a fundamental pillar of modern global logistics, enabling the seamless and efficient transfer of freight containers between different transportation modes. Intermodal chassis are specialized skeletal trailers designed to carry shipping containers over roads, connecting rail yards, ports, and distribution centers to their final destinations. The product's primary function is to provide the necessary framework for trucking companies to transport containers from one point to another, ensuring the integrity and security of goods throughout the journey. Major applications span across various industries including shipping and logistics, retail, manufacturing, and food and beverage, where the need for reliable and timely delivery of goods is paramount. Benefits derived from the use of intermodal chassis include enhanced operational flexibility, reduced transportation costs through optimized modal shifts, improved supply chain efficiency, and a reduced carbon footprint when combined with rail transport. Driving factors for market growth encompass the significant expansion of international trade, the booming e-commerce sector necessitating faster and more frequent deliveries, increasing urbanization leading to greater demand for last-mile logistics, and substantial investments in intermodal infrastructure development across key economic regions. Furthermore, the inherent advantages of intermodal transport in terms of cost-effectiveness for long hauls and environmental benefits continue to solidify the market's growth trajectory. The emphasis on globalized supply chains and just-in-time inventory management also places a high premium on the reliability and availability of intermodal chassis.

Intermodal Chassis Market Executive Summary

The Intermodal Chassis Market is experiencing dynamic shifts, characterized by evolving business trends, distinct regional growth patterns, and diverse segment-specific developments. Business trends highlight a pronounced move towards fleet modernization, with market players investing in technologically advanced and lightweight chassis designs that offer improved fuel efficiency, enhanced durability, and greater operational versatility. There is also a growing adoption of rental and leasing models for chassis, providing logistics companies with greater financial flexibility and reducing the burden of capital expenditure. Sustainability initiatives are driving demand for chassis made from advanced composite materials and those compatible with alternative fuel vehicles, aligning with global environmental objectives. Regional trends indicate robust growth in North America, fueled by significant investments in intermodal rail infrastructure and a strong trucking industry. Asia Pacific, particularly China and India, is emerging as a critical growth hub due to burgeoning manufacturing sectors, expanding trade volumes, and increasing urbanization, which collectively stimulate demand for intermodal transport solutions. Europe demonstrates steady growth, driven by cross-border trade within the EU and a focus on integrating rail and road networks for greener logistics. Segment trends reveal a strong preference for standard and extendable chassis due to their versatility across a wide range of container sizes. The adoption of smart chassis equipped with IoT sensors for real-time tracking and predictive maintenance is also gaining traction, enhancing operational transparency and efficiency. Furthermore, the manufacturing sector's reliance on intermodal transport for raw materials and finished goods continues to bolster demand, while the e-commerce boom specifically drives requirements for rapid and reliable container movement, influencing chassis design towards lighter and more adaptable units. Overall, the market is poised for sustained expansion, underpinned by technological innovation and strategic regional developments.

AI Impact Analysis on Intermodal Chassis Market

User inquiries concerning the impact of Artificial Intelligence (AI) on the Intermodal Chassis Market frequently revolve around themes of operational efficiency, cost reduction, predictive maintenance capabilities, and the potential for autonomous logistics. Common questions explore how AI can optimize chassis utilization, minimize downtime, enhance security during transit, and integrate seamlessly with existing supply chain management systems. Users are keen to understand AI's role in improving fleet management, anticipating maintenance needs, and streamlining dispatch processes, ultimately aiming for a more intelligent and responsive intermodal ecosystem. The overarching expectation is that AI will transform traditional chassis operations into a data-driven, highly optimized, and increasingly automated environment, addressing prevalent challenges such as chassis shortages, misallocation, and operational bottlenecks.

- Predictive Maintenance: AI algorithms analyze sensor data from chassis to predict potential mechanical failures before they occur, enabling proactive maintenance, reducing unscheduled downtime, and extending asset lifespan. This minimizes operational disruptions and optimizes maintenance schedules, shifting from reactive to preventive approaches.

- Optimized Fleet Management: AI-powered systems can analyze vast datasets, including traffic patterns, weather conditions, container demand, and chassis availability, to optimize allocation, routing, and dispatching of chassis, thereby maximizing utilization and reducing empty runs. This leads to significant fuel savings and improved logistical efficiency.

- Enhanced Security and Tracking: AI integrated with GPS and IoT sensors provides real-time location tracking and anomaly detection, identifying unusual stops, unauthorized movements, or potential theft risks, thus bolstering cargo security and improving supply chain visibility. Intelligent algorithms can learn normal operational patterns and flag deviations.

- Autonomous Intermodal Operations: While still nascent, AI is foundational for developing autonomous chassis and self-driving trucks in controlled environments like port terminals and rail yards. This paves the way for reduced labor costs, increased operational speed, and enhanced safety in container handling.

- Demand Forecasting and Resource Planning: AI models can accurately forecast future demand for specific types of chassis based on historical data, economic indicators, and seasonal trends, allowing logistics providers to better plan their inventory and resource allocation, preventing shortages or oversupply.

DRO & Impact Forces Of Intermodal Chassis Market

The Intermodal Chassis Market is profoundly shaped by a confluence of Drivers, Restraints, Opportunities, and broader Impact Forces that dictate its growth trajectory and operational landscape. Key drivers include the relentless expansion of global trade and the pervasive growth of e-commerce, which collectively necessitate a robust and agile intermodal transport infrastructure capable of handling increasing volumes of freight with speed and efficiency. Rapid urbanization and the resultant congestion in metropolitan areas further amplify the need for intermodal solutions that can reduce road mileage and optimize freight movement. Additionally, substantial investments in port modernization, rail network expansion, and multi-modal logistics hubs globally are creating a fertile ground for chassis market growth. However, several significant restraints impede more accelerated market expansion. These include the high initial capital investment required for purchasing and maintaining intermodal chassis fleets, which can be prohibitive for smaller logistics firms. Regulatory complexities and varying standards across different regions and countries can also create operational hurdles and increase compliance costs. The market is also susceptible to supply chain disruptions, geopolitical tensions, and economic downturns, which can lead to fluctuations in freight volumes and dampen investment. Competition from direct over-the-road trucking, especially for shorter hauls, also poses a constraint. Amidst these challenges, considerable opportunities emerge, particularly in the realm of smart chassis equipped with IoT, telematics, and advanced sensor technologies for real-time tracking, predictive maintenance, and optimized utilization. The development of sustainable and eco-friendly chassis solutions, incorporating lightweight materials and energy-efficient designs, presents another significant avenue for growth, aligning with global environmental mandates. Emerging markets in Southeast Asia, Latin America, and Africa offer untapped potential for intermodal infrastructure development and chassis adoption as their economies mature and trade activities intensify. The ongoing evolution of autonomous technologies for yard operations and first-mile/last-mile delivery also offers long-term transformative opportunities for the chassis market. The broader impact forces, encompassing technological advancements in materials science and digital connectivity, environmental regulations pushing for greener logistics, shifting geopolitical landscapes affecting trade routes, and overall global economic health, continually reshape the competitive dynamics and strategic priorities within the intermodal chassis industry, compelling stakeholders to innovate and adapt to remain resilient and competitive.

Segmentation Analysis

The Intermodal Chassis Market is comprehensively segmented to provide granular insights into its diverse components, facilitating a deeper understanding of market dynamics, demand patterns, and growth opportunities. This segmentation allows for targeted strategic planning and product development, addressing the specific needs of various end-users and operational requirements within the global logistics and transportation ecosystem. Key segmentation criteria include the type of chassis, the materials used in their construction, the configuration of their axles, the end-use industries they serve, and their application scope, each revealing distinct market characteristics and growth drivers. Understanding these segments is crucial for stakeholders aiming to optimize their market penetration strategies and capitalize on specific niches within this critical logistics sector.

- By Type:

- Standard Chassis: Widely used for 20-foot and 40-foot containers, offering basic functionality and robust construction for general cargo.

- Gooseneck Chassis: Designed with a raised front section to accommodate taller containers or provide specific weight distribution, commonly used for high-cube containers.

- Extendable Chassis: Feature a retractable frame to adjust length, allowing them to carry containers of varying sizes (e.g., 20, 40, 45, 48, 53 feet), providing enhanced flexibility.

- Specialized Chassis: Custom-designed for unique cargo requirements, such as tank containers, refrigerated containers, or heavy-haul applications, catering to niche market demands.

- By Material:

- Steel: Traditional and most common material, known for its strength, durability, and cost-effectiveness, though heavier.

- Aluminum: Lighter than steel, contributing to better fuel efficiency and reduced wear on tractor components, but generally more expensive.

- Composite Materials: Emerging segment utilizing advanced composites for lightweight, high-strength chassis, offering superior performance and corrosion resistance, albeit at a higher cost.

- By Axle Type:

- Single Axle: Typically for lighter loads or shorter containers, offering greater maneuverability.

- Tandem Axle: Most common configuration, providing increased weight capacity and stability for standard containers.

- Tri-Axle: Used for exceptionally heavy loads or to meet specific weight distribution regulations in certain regions, enhancing load-bearing capability.

- By End-Use Industry:

- Shipping & Logistics: Core users including shipping lines, freight forwarders, and third-party logistics (3PL) providers for container movement.

- Retail: Supporting the transport of goods from distribution centers to retail outlets, particularly for imported products.

- Manufacturing: Facilitating the movement of raw materials to factories and finished goods to ports or distribution hubs.

- Food & Beverage: Essential for transporting temperature-controlled and dry goods, often utilizing specialized chassis for refrigerated containers.

- Others: Includes automotive, chemicals, pharmaceuticals, and other sectors requiring containerized transport.

- By Application:

- Domestic Intermodal: Movement of containers primarily within national borders, leveraging rail and road networks.

- International Intermodal: Facilitating the global movement of containers between continents via sea, rail, and road, crucial for global supply chains.

Value Chain Analysis For Intermodal Chassis Market

The value chain for the Intermodal Chassis Market is a complex network spanning from raw material sourcing to the ultimate delivery and lifecycle management of the chassis, involving various upstream and downstream activities, and a diverse set of distribution channels. Upstream analysis begins with the procurement of critical raw materials such as steel (for main frames, cross members, and structural components), aluminum (for lightweight alternatives and specialized parts), and increasingly, composite materials (for advanced, lighter designs). Key suppliers in this segment include major steel mills, aluminum manufacturers, and specialized composite material producers. Component manufacturers, providing axles, wheels, tires, brakes, suspension systems, lighting, and electrical components, form another crucial upstream layer. These suppliers often specialize in particular parts, ensuring high-quality and performance-specific components are available to chassis manufacturers. Downstream analysis focuses on the journey of the chassis after manufacturing. Once produced, chassis are typically acquired by a variety of entities, including large intermodal equipment providers (IEPs), shipping lines, trucking companies, rail operators, and third-party logistics (3PL) providers. These entities either purchase chassis outright for their fleets, lease them through specialized leasing companies, or manage pooled chassis assets. The end-users, such as freight shippers and retailers, indirectly benefit from the availability and efficiency of these chassis as their goods move through the intermodal network. The distribution channel for intermodal chassis is multi-faceted, encompassing both direct and indirect sales. Direct sales often occur between major chassis manufacturers and large intermodal equipment providers or shipping lines who place bulk orders. This allows for direct negotiations, customization, and streamlined logistics. Indirect channels involve a network of dealers, distributors, and leasing companies that provide chassis to smaller trucking companies, regional logistics firms, and other operators who may not require large fleet purchases or prefer rental options. These intermediaries play a vital role in market penetration, offering financing solutions, maintenance support, and wider geographical reach. Furthermore, the after-sales service and maintenance network, encompassing certified repair shops and spare parts suppliers, forms an integral part of the value chain, ensuring the longevity and operational reliability of the chassis throughout their lifecycle. This integrated approach, from material sourcing to end-user support, underscores the collaborative nature of the intermodal chassis value chain, where efficiency and coordination at each stage are paramount for overall market success.

Intermodal Chassis Market Potential Customers

Potential customers in the Intermodal Chassis Market represent a diverse group of end-users and buyers whose operational requirements are directly tied to the movement of containerized freight. The primary segment comprises large Intermodal Equipment Providers (IEPs), who own and manage extensive fleets of chassis that are then leased or rented to various trucking companies and beneficial cargo owners. These IEPs act as central hubs for chassis availability, serving a broad customer base. Shipping Lines are also major direct purchasers or long-term lessors, as they require chassis for the landside operations of their container fleet, ensuring seamless port-to-door delivery. Furthermore, a substantial customer base consists of Trucking Companies and Motor Carriers, particularly those specializing in intermodal drayage, who need chassis to transport containers between rail yards, ports, and final destinations. Many smaller and medium-sized trucking firms often opt for rental or leasing arrangements from IEPs due to capital expenditure considerations. Railroad Companies, especially those offering intermodal services, may also own chassis to facilitate their own rail-to-road transfers at intermodal terminals. Beyond these direct logistics providers, Third-Party Logistics (3PL) Providers and Freight Forwarders are significant indirect customers, often managing chassis procurement and utilization on behalf of their clients to optimize complex supply chains. Finally, large-scale Manufacturers and Retailers, particularly those with global supply chains and high volumes of containerized imports or exports, represent another critical segment. While they might not always own chassis directly, their demand for efficient and reliable intermodal transport drives the needs of their logistics partners, making them ultimate beneficiaries and influencers of chassis market trends. The diverse needs of these customer segments, ranging from flexible leasing options to specialized chassis types, underscore the importance of tailored solutions within the intermodal chassis industry.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.3 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | CIMC, Stoughton Trailers, Hyundai Translead, Wabash National, Utility Trailer Manufacturing, Cheetah Chassis, Dorsey Intermodal, Pitts Trailers, SANY, Kässbohrer, Krone, Great Dane, Strick Trailers, Fontaine Specialized, Chassis King, China International Marine Containers, GSC Logistics, MEES Trailers, Polar King, Kalmar (Cargotec Corporation) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Intermodal Chassis Market Key Technology Landscape

The Intermodal Chassis Market is increasingly integrating advanced technologies to enhance operational efficiency, safety, and asset utilization, moving beyond traditional mechanical designs to embrace digital and smart solutions. A pivotal technological shift involves the widespread adoption of Internet of Things (IoT) sensors and telematics. These integrated systems provide real-time data on chassis location, speed, mileage, tire pressure, brake status, and even cargo temperature, offering unparalleled visibility into asset performance and condition. This data is crucial for optimizing fleet management, enabling proactive maintenance, and improving security against theft or unauthorized use. Global Positioning System (GPS) tracking, a fundamental component of telematics, allows logistics operators to pinpoint the exact location of each chassis, facilitating efficient dispatch, routing, and inventory management within large intermodal yards and across vast networks. Furthermore, the development and application of advanced materials such as high-strength, lightweight steel alloys and aluminum, along with emerging composite materials, are revolutionizing chassis design. These materials contribute to reducing the overall weight of the chassis, which in turn leads to improved fuel efficiency for the towing vehicle, increased payload capacity, and reduced wear and tear on components, thereby extending the chassis's operational life and lowering operational costs. The integration of remote monitoring and diagnostics capabilities allows for off-site assessment of chassis health, minimizing the need for physical inspections and enabling predictive maintenance scheduling. This prevents costly breakdowns and ensures higher asset availability. Looking ahead, the market is gradually exploring automation and autonomous technologies, particularly for repetitive tasks within port and rail terminals. While fully autonomous intermodal chassis for public roads are still some way off, automated guided vehicles (AGVs) or specialized autonomous units for yard movements are gaining traction, promising increased operational speed and safety in controlled environments. Finally, sophisticated data analytics and AI-powered platforms are being leveraged to process the vast amounts of data collected from IoT devices. These platforms can identify trends, forecast demand, optimize routing algorithms, and even predict potential equipment failures, turning raw data into actionable insights for strategic decision-making in chassis management. This holistic technological integration is transforming the intermodal chassis from a static piece of equipment into a dynamic, data-generating asset critical for the future of smart logistics.

Regional Highlights

- North America: This region is a dominant force in the Intermodal Chassis Market, primarily driven by a robust freight rail network, high adoption rates of intermodal transport, and substantial investments in logistics infrastructure. The U.S. and Canada benefit from a mature logistics industry, a strong emphasis on supply chain efficiency, and significant cross-border trade. Key factors include the growth of e-commerce, the need for long-haul freight solutions, and ongoing modernization of port and rail facilities, creating consistent demand for diverse chassis types, particularly extendable and standard models.

- Europe: The European market demonstrates steady growth, propelled by strong intra-European trade, a focus on sustainable transport solutions, and well-developed intermodal corridors. Countries like Germany, France, and the Netherlands are at the forefront, leveraging extensive rail and inland waterway networks to reduce road congestion and emissions. Regulatory support for intermodal transport and continuous investment in trans-European transport networks further stimulate chassis demand, with a growing emphasis on lighter and more environmentally friendly designs.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by burgeoning economies, rapid industrialization, expanding manufacturing bases, and increasing global trade volumes. China, India, Japan, and Southeast Asian nations are key contributors, experiencing massive infrastructure development and a boom in e-commerce. The need for efficient logistics to support massive production and consumption drives significant demand for intermodal chassis, especially as port capacities expand and new trade routes like the Belt and Road Initiative mature.

- Latin America: This region presents significant growth potential, albeit from a smaller base. Countries such as Brazil, Mexico, and Argentina are witnessing increased investment in port infrastructure and rail networks to support natural resource exports and growing consumer markets. Economic development and integration into global supply chains are gradually driving the adoption of intermodal solutions, creating demand for chassis, particularly standard and heavy-duty types to handle diverse cargo.

- Middle East and Africa (MEA): The MEA region is an emerging market for intermodal chassis, driven by strategic geographical location, growing trade hubs (e.g., UAE, Saudi Arabia), and infrastructure development projects. Investments in new ports, economic zones, and multimodal transport networks are fostering a nascent but growing intermodal industry. The demand is primarily focused on supporting imports and exports, with increasing emphasis on developing regional logistics capabilities and improving connectivity.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Intermodal Chassis Market.- CIMC

- Stoughton Trailers

- Hyundai Translead

- Wabash National

- Utility Trailer Manufacturing

- Cheetah Chassis

- Dorsey Intermodal

- Pitts Trailers

- SANY

- Kässbohrer

- Krone

- Great Dane

- Strick Trailers

- Fontaine Specialized

- Chassis King

- China International Marine Containers

- GSC Logistics

- MEES Trailers

- Polar King

- Kalmar (Cargotec Corporation)

Frequently Asked Questions

What is an intermodal chassis and why is it important for global logistics?

An intermodal chassis is a specialized skeletal trailer designed to transport shipping containers over roads, connecting different modes of transport like rail, ship, and truck. It is crucial for global logistics because it facilitates the seamless and efficient movement of goods from ports and rail yards to their final destinations, enabling the integration of various transportation networks. This efficiency reduces transit times, lowers transportation costs, and supports complex global supply chains that rely on multimodal freight movement.

How is technology impacting the evolution of intermodal chassis?

Technology is profoundly impacting intermodal chassis through the integration of IoT sensors, GPS tracking, and telematics. These innovations provide real-time data on location, condition, and performance, enabling predictive maintenance, optimized fleet management, and enhanced security. Advanced materials are also leading to lighter, more durable, and fuel-efficient designs. Looking ahead, AI and automation are beginning to transform yard operations, paving the way for more intelligent and autonomous logistics. These technological advancements collectively drive greater efficiency, reliability, and cost-effectiveness in intermodal operations.

What are the key drivers for the growth of the Intermodal Chassis Market?

The primary drivers for the growth of the Intermodal Chassis Market include the significant expansion of global trade, particularly driven by increased international import and export activities. The burgeoning e-commerce sector plays a crucial role, demanding faster and more reliable freight movement to meet consumer expectations. Additionally, substantial investments in intermodal infrastructure, such as modernized ports and expanded rail networks, create a robust environment for chassis demand. The ongoing focus on optimizing supply chains for efficiency and sustainability also compels logistics providers to adopt integrated intermodal solutions, further fueling market expansion.

What challenges does the Intermodal Chassis Market face?

The Intermodal Chassis Market faces several challenges, including high initial capital investment costs for acquiring and maintaining fleets, which can be a barrier for smaller operators. Regulatory complexities and varying standards across different regions can complicate operations and increase compliance burdens. The market is also susceptible to global supply chain disruptions, such as port congestion or geopolitical events, which can impact freight volumes and chassis demand. Additionally, intense competition from direct over-the-road trucking, especially for shorter distances, poses a continuous challenge to market share and pricing strategies.

Which regions are leading in the adoption and demand for intermodal chassis?

North America currently leads in the adoption and demand for intermodal chassis, driven by its extensive rail network, mature logistics industry, and high volume of intermodal freight. Asia Pacific, particularly countries like China and India, is emerging as the fastest-growing region, fueled by rapid industrialization, booming e-commerce, and significant investments in trade infrastructure. Europe demonstrates steady growth, supported by robust cross-border trade and a strong focus on sustainable, integrated transport solutions. These regions collectively represent the forefront of intermodal chassis utilization and market expansion globally.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager