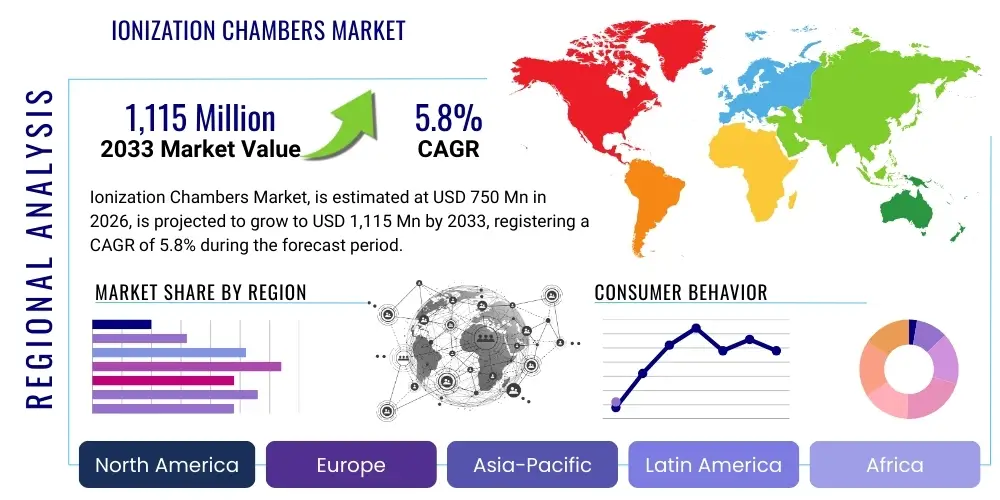

Ionization Chambers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436989 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Ionization Chambers Market Size

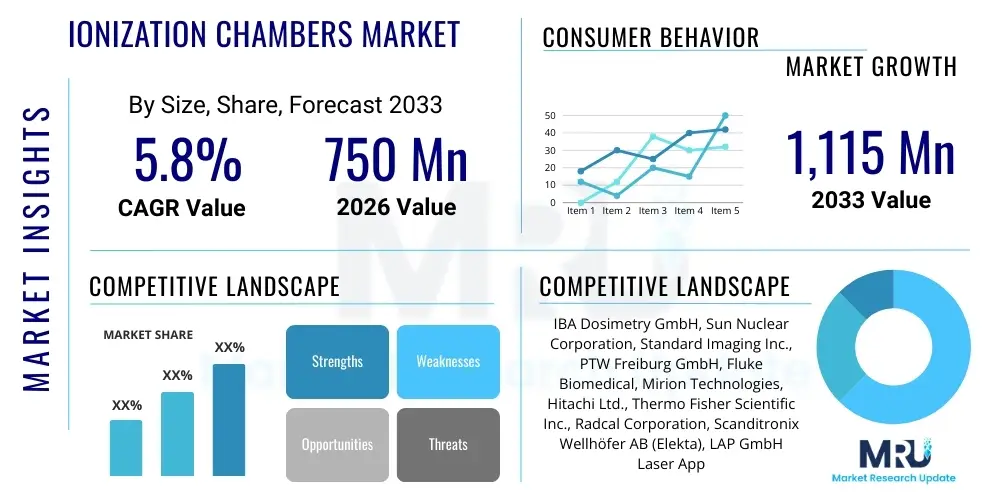

The Ionization Chambers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $750 Million in 2026 and is projected to reach $1,115 Million by the end of the forecast period in 2033.

Ionization Chambers Market introduction

The Ionization Chambers Market encompasses devices essential for accurate measurement of ionizing radiation, playing a critical role in medical physics, nuclear industry safety, environmental monitoring, and research laboratories. Ionization chambers operate on the principle of collecting the charge generated when ionizing radiation passes through a gas-filled cavity, providing a reliable and stable measurement of absorbed dose, dose rate, or exposure. Their robust design, high accuracy, and energy independence make them indispensable tools, particularly in radiation therapy planning and quality assurance protocols where precise dosimetry is paramount. The increasing global focus on nuclear safety regulations and the expansion of advanced medical imaging and therapeutic techniques are primary drivers bolstering the adoption of these devices across various end-user sectors.

The products within this market are generally segmented based on their design and application, including thimble chambers, parallel-plate chambers, and well-type chambers. Major applications involve the calibration of radiation sources, patient dose verification in oncology, environmental monitoring near nuclear facilities, and personal dosimetry for occupational safety. The inherent benefit of ionization chambers lies in their linearity over a wide range of dose rates and their suitability for absolute dosimetry, meaning they can measure radiation doses directly without needing calibration against another reference standard, which is a significant advantage in critical applications.

Driving factors for market growth include the escalating incidence of cancer globally, necessitating increased demand for radiotherapy equipment and associated quality assurance tools. Furthermore, stringent regulatory mandates regarding radiation protection in industrial and research settings require high-precision monitoring devices. Technological advancements, such as the development of compact, portable, and internet-connected ionization chambers for remote monitoring and enhanced data processing, further contribute to market expansion and efficiency improvements in dose verification processes globally.

Ionization Chambers Market Executive Summary

The Ionization Chambers Market demonstrates robust growth driven by the convergence of expanding oncology treatment infrastructure and increasingly stringent global radiation safety standards. Business trends indicate a shift toward sophisticated, compact, and wireless dosimetry solutions that integrate seamlessly with modern medical linear accelerators (LINACs) and diagnostic imaging systems. Key industry players are focusing on strategic partnerships and mergers to consolidate technological expertise and expand geographic reach, especially in emerging economies where healthcare investment is rapidly accelerating. The demand for specialized chambers capable of high-resolution measurements in complex fields, such as those generated by proton therapy or small-field stereotactic radiosurgery (SRS), is a dominant commercial trend shaping product development and investment strategies.

Regional trends reveal that North America and Europe currently dominate the market, largely due to established healthcare infrastructure, high research and development expenditure, and the presence of major market vendors. However, the Asia Pacific region is anticipated to exhibit the highest Compound Annual Growth Rate (CAGR) over the forecast period. This accelerated growth in APAC is primarily attributed to rising governmental initiatives to improve cancer treatment accessibility, increasing installation of radiation therapy units, and growing awareness regarding industrial radiation safety. Countries like China and India are emerging as significant consumption hubs, driven by large patient populations and the rapid adoption of advanced medical technologies.

Segment trends underscore the dominance of the medical application segment, specifically in external beam radiotherapy (EBRT) and brachytherapy quality assurance. Within product segmentation, thimble chambers remain the highest revenue generator owing to their versatility and standard use in reference dosimetry. Technology segmentation shows increasing adoption of liquid ionization chambers (LICs) and advanced micro-ionization chambers designed for highly localized dose measurements. The emphasis across all segments is on achieving higher precision, faster response times, and improved durability to meet the critical requirements of modern high-dose-rate clinical applications and rigorous industrial monitoring environments.

AI Impact Analysis on Ionization Chambers Market

User queries regarding the impact of Artificial Intelligence (AI) on the Ionization Chambers Market center around automation of dosimetry processes, integration of smart calibration systems, and predictive maintenance. Common questions include whether AI can enhance the speed and accuracy of dose verification readings, how machine learning algorithms can minimize human error in quality assurance (QA), and the potential for AI-driven data analysis to optimize chamber usage and lifespan. Users are highly interested in the capability of AI to correlate chamber measurements with complex treatment plans, detect anomalies immediately, and streamline regulatory reporting, transforming the traditionally labor-intensive steps of calibration and quality control into highly efficient, automated workflows. Expectations are high for AI to move beyond simple data processing towards intelligent decision support in clinical and industrial radiation safety settings.

The primary influence of AI is expected to be indirect, focusing on optimizing the ecosystem surrounding ionization chambers rather than redesigning the fundamental physics of the device itself. AI algorithms are being developed to analyze vast datasets generated by daily QA checks, identifying subtle trends and predicting potential chamber drift or failure before it impacts clinical quality. This predictive maintenance capability dramatically improves the reliability of dosimetry equipment, ensuring chambers maintain high precision throughout their operational life. Furthermore, AI facilitates the integration of chamber output data into comprehensive treatment planning systems, allowing for real-time dose reconstruction and immediate feedback on treatment delivery accuracy.

In clinical dosimetry, AI can process complex fluence patterns, such as those found in Volumetric Modulated Arc Therapy (VMAT), and rapidly compare measured dose distributions (acquired using chamber arrays or specialized detectors) against planned doses. This expedited verification process reduces the time required for patient setup and treatment QA, increasing clinical throughput. The automation of the calibration cycle using deep learning models to compensate for environmental variables or detector variations represents a significant operational improvement, ensuring consistency across different devices and treatment centers globally. This integration ultimately enhances the overall quality and safety standards managed by ionization chambers.

- AI optimizes calibration curves and corrects for environmental drift in real-time.

- Predictive maintenance schedules for chambers are generated by analyzing usage patterns and historical measurement data.

- Automated dose verification and comparison against complex treatment plans (e.g., VMAT, SRS).

- Enhanced data logging and anomaly detection in industrial and environmental monitoring applications.

- Facilitation of seamless integration of dosimetry data into electronic health records (EHR) systems.

- Development of smart QA platforms that minimize human intervention and potential systematic errors.

DRO & Impact Forces Of Ionization Chambers Market

The dynamics of the Ionization Chambers Market are defined by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively shape the competitive landscape and growth trajectory. The fundamental market driver is the pervasive and growing necessity for precise radiation measurement across various high-stakes sectors, coupled with strict global regulations requiring mandatory dosimetry checks. Restraints largely center on the high initial cost of advanced chamber systems and related QA infrastructure, alongside the technical challenge of maintaining absolute accuracy in environments with extremely high radiation fields or rapidly changing dose rates. Opportunities are abundant, driven by technological breakthroughs in micro-chamber fabrication, integration with sophisticated digital platforms, and the untapped potential of emerging markets for widespread adoption of modern radiotherapy techniques.

Key drivers include the global expansion of nuclear medicine, the continuous upgrade of radiotherapy centers with advanced linear accelerators (LINACs), and the increasing adoption of highly conformal radiation delivery techniques such as Intensity Modulated Radiation Therapy (IMRT) and Stereotactic Body Radiation Therapy (SBRT), all of which require highly reliable and spatially accurate dosimetry tools like ionization chambers. Furthermore, increasing global concerns regarding nuclear security and environmental fallout necessitate robust and widespread monitoring systems based on ionization chamber technology. These forces create a consistently high demand floor for accurate, primary-standard measurement devices, positioning them as non-negotiable components of radiation safety and quality assurance protocols worldwide.

The market faces technical restraints, notably the inherent sensitivity of gas-filled chambers to temperature and pressure variations, which require complex correction factors and regular calibration, often adding operational complexity and cost. Furthermore, competition from solid-state detectors (e.g., diodes and MOSFETs) in certain applications, especially those requiring immediate feedback or very high spatial resolution, poses a restraint on market share growth for traditional chambers. However, the opportunity for innovation lies in developing miniature, ruggedized chambers tailored for specialized environments (like proton therapy or space radiation monitoring) and integrating IoT capabilities for remote monitoring and predictive maintenance, thereby mitigating some of the traditional operational restraints.

- Drivers: Growing global prevalence of cancer treatments; Stringent radiation safety and regulatory requirements; Technological advancements in radiation delivery systems (IMRT, VMAT); Expansion of nuclear power and research facilities.

- Restraints: High initial investment and maintenance costs; Sensitivity to environmental factors (temperature/pressure); Competition from alternative dosimetry technologies (e.g., solid-state detectors); Need for specialized expertise in calibration and operation.

- Opportunities: Integration of IoT and AI for automated QA and remote monitoring; Expansion into emerging markets (APAC, LATAM); Development of chambers optimized for high-energy modalities (proton/heavy ion therapy); Miniaturization for specific in-vivo dosimetry applications.

- Impact Forces: Regulatory compliance requirements drive non-discretionary purchases; Technological innovation enhances measurement accuracy and efficiency; Healthcare expenditure growth directly correlates with chamber adoption in oncology; Global nuclear safety standards dictate monitoring equipment specifications.

Segmentation Analysis

The Ionization Chambers Market is systematically segmented based on Product Type, Application, and End-User, reflecting the diverse requirements and technological variations across its multiple application domains. This segmentation is crucial for understanding specific market dynamics, identifying high-growth niches, and tailoring product development to meet specialized needs. Product type differentiation is critical, ranging from standard reference-grade chambers used for absolute dosimetry to specialized chambers designed for complex clinical fields or high-flux industrial environments. The performance characteristics, such as chamber volume, material composition, and geometry, vary significantly across these segments, catering to distinct measurement challenges.

The segmentation by Application highlights the market's heavy reliance on the healthcare sector, particularly radiation therapy (radiotherapy, brachytherapy), where chambers are used for patient dose verification, machine output calibration, and quality assurance. Secondary applications include industrial processes (non-destructive testing, sterilization), environmental monitoring (background radiation levels), and high-energy physics research. The rapid growth of advanced radiotherapy techniques, such as proton and carbon ion therapy, is creating a high-value sub-segment demanding specialized, water-equivalent ionization chambers capable of handling high-linear energy transfer (LET) radiation.

End-User segmentation clarifies the consumption pattern, with Hospitals and Diagnostic Centers representing the largest volume consumers due to the routine nature of cancer treatment and QA. Research Institutes and Academic Centers drive demand for highly specialized and customizable chambers for cutting-edge studies, while Nuclear Power Plants and Industrial Facilities require chambers robust enough for continuous, long-term monitoring in harsh environments. Analyzing these segments provides strategic insights into the most lucrative areas for market entry and expansion, particularly where regulatory oversight is stringent, necessitating certified, high-quality dosimetry equipment.

- By Product Type:

- Standard Ionization Chambers (Thimble Chambers)

- Parallel-Plate Ionization Chambers (Plane-parallel chambers)

- Well-Type Ionization Chambers

- Liquid Ionization Chambers (LICs)

- Micro-Ionization Chambers

- By Application:

- Medical Dosimetry (Radiotherapy, Diagnostic Imaging QA, Brachytherapy)

- Nuclear Safety and Power Generation

- Environmental Monitoring and Survey Meters

- Research and Academic Institutions

- Industrial Applications (Non-destructive testing, Sterilization)

- By End-User:

- Hospitals and Cancer Treatment Centers

- Diagnostic Laboratories and Imaging Centers

- Research and Academic Institutions

- Nuclear Facilities and Regulatory Bodies

Value Chain Analysis For Ionization Chambers Market

The value chain for the Ionization Chambers Market begins with upstream activities involving the sourcing of highly specialized materials such as high-purity graphite, conductive plastics, and various noble gases (e.g., Argon, Nitrogen) used for the chamber cavity filling. The complexity of manufacturing stems from the stringent requirements for material homogeneity, precise machining of electrodes (guard rings, collecting electrodes), and meticulous assembly under controlled environments to ensure minimal leakage current and optimal performance. R&D is a continuous upstream activity, focusing on developing thinner windows, smaller volumes, and materials resistant to radiation damage (radiation hardness) to enhance measurement accuracy and lifespan, particularly for use in challenging high-dose-rate clinical settings.

Midstream activities involve the primary manufacturing, assembly, and rigorous testing and calibration processes. Calibration is perhaps the most critical midstream activity, as ionization chambers often serve as reference standards. This requires specialized secondary standard dosimetry laboratories (SSDLs) or primary standard dosimetry laboratories (PSDLs) to ensure traceability to international standards, such as those maintained by the BIPM (International Bureau of Weights and Measures). Effective manufacturing also requires strict quality control systems to manage tolerances, as small variations in chamber geometry can significantly affect dosimetry accuracy. Companies often invest heavily in robotic assembly and advanced metrology equipment to meet the required precision.

Downstream activities involve distribution, sales, installation, and post-sales support. Due to the highly technical nature of the product, distribution often relies on specialized channels, including direct sales teams for major accounts (large hospital networks, nuclear facilities) and certified regional distributors who provide localized support and repair services. Direct and indirect channels both play a role; direct sales facilitate consultative selling for complex integrated systems, while indirect channels (distributors, resellers) manage accessories and lower-cost standard chambers. Post-sales technical support, training for clinical physicists and technicians, and mandatory annual recalibration services represent significant revenue streams in the downstream market segment, ensuring the long-term operational integrity of the installed base.

Ionization Chambers Market Potential Customers

The primary customers for ionization chambers are institutions and organizations requiring precise measurement of ionizing radiation for safety, regulatory compliance, or therapeutic efficacy. The largest segment of end-users consists of hospitals and dedicated cancer treatment centers, particularly those equipped with advanced linear accelerators (LINACs) and actively practicing external beam radiation therapy (EBRT), Intensity Modulated Radiation Therapy (IMRT), and Stereotactic Radiosurgery (SRS). These clinical settings mandate daily and periodic quality assurance checks using high-quality chambers to ensure accurate radiation delivery to patients, making them perennial buyers of reference chambers, array chambers, and related dosimetry phantoms.

Another significant customer base includes specialized research institutes and academic centers, often focusing on medical physics, nuclear engineering, and high-energy particle research. These users frequently require unique or custom-designed ionization chambers, such as those with extremely small volumes (micro-chambers) for localized dose profiling or chambers built with specific materials for experimental measurements. Government and regulatory bodies, including national laboratories and environmental protection agencies, also represent critical buyers, utilizing chambers for environmental monitoring, assessing occupational exposure, and ensuring compliance with national radiation protection laws. The need for traceable, high-accuracy instruments positions ionization chambers as essential capital equipment for these institutional buyers.

Furthermore, the industrial sector, encompassing nuclear power generation facilities, non-destructive testing firms, and manufacturers utilizing radiation sterilization techniques (e.g., medical device sterilization), relies heavily on robust ionization chambers for continuous area monitoring, source calibration, and leakage detection. These customers prioritize chambers that offer high durability, long-term stability, and compatibility with industrial control systems. The underlying characteristic uniting all potential customers is the absolute requirement for dosimetry instruments that adhere to the highest international standards of accuracy and reliability, ensuring safety and quality in radiation-related processes across diverse high-risk environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $750 Million |

| Market Forecast in 2033 | $1,115 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | IBA Dosimetry GmbH, Sun Nuclear Corporation, Standard Imaging Inc., PTW Freiburg GmbH, Fluke Biomedical, Mirion Technologies, Hitachi Ltd., Thermo Fisher Scientific Inc., Radcal Corporation, Scanditronix Wellhöfer AB (Elekta), LAP GmbH Laser Applications, RAE Systems (Honeywell), Biodex Medical Systems, Varian Medical Systems (Siemens Healthineers), Fuji Electric Co., Ltd., Canberra Industries (Mirion Technologies), Gammex Inc., DoseVue, Tracerco, Centronic. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ionization Chambers Market Key Technology Landscape

The technology landscape of the Ionization Chambers Market is characterized by continuous refinement aimed at achieving superior precision, reduced size, and enhanced signal processing capabilities. While the fundamental operational principle of gas collection remains constant, modern innovations focus heavily on electrode materials, gas composition optimization, and micro-electromechanical systems (MEMS) integration. For instance, the use of proprietary conductive coatings and materials with ultra-low recombination properties helps maintain linearity even at high dose rates, which is crucial for modern flattening filter free (FFF) beams used in advanced radiotherapy. The development of sealed chambers that minimize pressure and temperature corrections, or the use of liquid ionization chambers (LICs) that offer near water-equivalence and high spatial resolution, represents significant technological progress aimed at simplifying clinical workflow and improving measurement accuracy in heterogeneous media.

A critical technological trend involves the transition from traditional analog output to highly digitized, integrated systems. Modern ionization chambers are increasingly paired with advanced electrometers and data acquisition systems capable of high-speed data sampling and noise reduction. Furthermore, there is a strong focus on wireless and networked chambers (such as array chambers used in planar dosimetry) that allow for immediate data transfer and integration with hospital information systems (HIS) or regulatory reporting platforms. These advancements support the movement towards remote quality assurance and automated calibration procedures, significantly reducing the reliance on manual data handling and enhancing overall measurement traceability, a key requirement for regulatory bodies.

The manufacturing technology itself has advanced, particularly in the micro-ionization chamber segment. These small-volume detectors, essential for measuring doses in small radiation fields (e.g., stereotactic applications) or complex geometries, are often produced using sophisticated fabrication techniques to maintain structural integrity and minimize uncertainty. Furthermore, specialized technologies for handling high-LET radiation, such as those used in emerging proton and heavy-ion therapy centers, require unique chamber designs (e.g., vented vs. sealed chambers, materials optimized for proton Bragg peak measurements) to ensure accurate absolute dosimetry. This technological diversification ensures that ionization chambers remain the gold standard for absolute dose measurements across the expanding spectrum of radiation applications.

Regional Highlights

- North America: This region dominates the global market, driven by substantial healthcare expenditure, the presence of major oncology research centers, and widespread early adoption of advanced radiotherapy technologies such as proton therapy and VMAT. Stringent regulatory oversight from bodies like the FDA necessitates mandatory use of high-quality dosimetry equipment, fueling consistent demand. The market here is mature but focuses heavily on high-end, interconnected QA solutions.

- Europe: Europe represents a strong market, characterized by advanced medical infrastructure, high awareness of radiation protection, and the presence of leading manufacturers and standardization bodies (e.g., EURAMET). Countries like Germany, the UK, and France invest significantly in nuclear safety and cutting-edge oncology equipment. The market growth is stable, emphasizing the integration of chambers into centralized quality management systems (QMS).

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region. This explosive growth is fueled by increasing government investment in public health infrastructure, a rapidly expanding patient pool requiring cancer treatment, and rising disposable incomes leading to the adoption of advanced medical devices in countries like China, India, and Japan. Market penetration for basic and advanced chambers is increasing as new cancer centers are established and nuclear power capabilities expand across the region.

- Latin America (LATAM): Growth in LATAM is moderate, primarily concentrated in countries like Brazil and Mexico, which are upgrading their public and private healthcare systems. The demand is often project-based, linked to the establishment of new radiotherapy units or compliance upgrades in industrial facilities. Price sensitivity and reliance on imports are key regional characteristics.

- Middle East and Africa (MEA): This region offers nascent opportunities, particularly in Gulf Cooperation Council (GCC) countries where significant oil wealth is being channeled into developing world-class medical cities and specialized cancer centers. South Africa also maintains a substantial market due to its established mining and nuclear research sectors. Market expansion is driven by infrastructure development and technology transfer initiatives.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ionization Chambers Market.- IBA Dosimetry GmbH

- Sun Nuclear Corporation

- Standard Imaging Inc.

- PTW Freiburg GmbH

- Fluke Biomedical

- Mirion Technologies

- Hitachi Ltd.

- Thermo Fisher Scientific Inc.

- Radcal Corporation

- Scanditronix Wellhöfer AB (Elekta)

- LAP GmbH Laser Applications

- RAE Systems (Honeywell)

- Biodex Medical Systems

- Varian Medical Systems (Siemens Healthineers)

- Fuji Electric Co., Ltd.

- Canberra Industries (Mirion Technologies)

- Gammex Inc.

- DoseVue

- Tracerco

- Centronic

Frequently Asked Questions

Analyze common user questions about the Ionization Chambers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of ionization chambers in modern healthcare?

The primary application is absolute dosimetry in radiation therapy, including the calibration of linear accelerators (LINACs) and verification of patient dose delivery during complex treatments like IMRT, VMAT, and brachytherapy, ensuring treatment accuracy and patient safety.

How do ionization chambers compare to solid-state detectors like diodes?

Ionization chambers are preferred for absolute dose measurements and primary calibration due to their stability and near water-equivalent response, offering energy independence. Diodes, being solid-state, are typically used for relative dosimetry and high spatial resolution measurements due to their higher sensitivity and instantaneous response, but they require frequent calibration.

Which geographical region is expected to show the fastest market growth?

The Asia Pacific (APAC) region is projected to exhibit the fastest growth rate, driven by significant increases in healthcare infrastructure development, rising incidence of cancer, and greater investment in modern radiotherapy equipment across populous nations such as China and India.

What is the role of AI in the future development of ionization chamber technology?

AI is crucial for enhancing the ecosystem by enabling automated quality assurance (QA), optimizing chamber calibration processes, performing predictive maintenance, and analyzing complex dosimetry data rapidly to ensure high precision and regulatory compliance with minimal human error.

What are the main types of ionization chambers available in the market?

The main types include Thimble Chambers (standard reference detectors), Parallel-Plate Chambers (used for superficial dose measurements and electron beams), Well-Type Chambers (used for source strength measurement in brachytherapy), and Micro-Ionization Chambers (for small field dosimetry).

Why is temperature and pressure correction necessary for gas-filled ionization chambers?

The signal output of a gas-filled chamber is directly proportional to the mass of gas in its volume. Since the density of the gas changes with ambient temperature and atmospheric pressure, correction factors must be applied to normalize the measured current to standard temperature and pressure (STP) conditions, ensuring accurate dose calculation.

What is the significance of the guard ring in an ionization chamber design?

The guard ring is essential in high-precision ionization chambers. Its purpose is to define the sensitive volume precisely and prevent leakage currents from the cable or stem from being collected by the central electrode. This isolation minimizes signal noise and ensures that only charge generated within the defined active volume is measured, leading to highly accurate results.

How does the Ionization Chambers Market interact with the nuclear power industry?

In the nuclear power industry, ionization chambers are vital for ensuring operational safety. They are used extensively for area monitoring within the facility, detecting potential radiation leaks, measuring environmental radiation surrounding the plant, and monitoring occupational exposure for personnel working in high-radiation zones, supporting stringent regulatory standards.

What factors restrain the widespread adoption of advanced ionization chamber systems?

Restraints include the significant initial capital outlay required for high-precision dosimetry systems, the need for specialized technical expertise for calibration and routine operation, and the logistical challenges associated with maintaining traceability to primary standard laboratories for mandatory annual checks.

What defines a "reference class" ionization chamber?

A reference class chamber is a detector designed and built to the highest precision standards, exhibiting excellent long-term stability, minimal leakage current, and robust construction. These chambers are used as the absolute standard for calibrating high-energy radiation beams in clinical settings and must be traceable to national or international primary standards.

In the context of the value chain, what is the role of the upstream segment?

The upstream segment involves the sourcing and meticulous preparation of ultra-pure raw materials, including high-grade plastics, conductive materials for electrodes, and specific filling gases, coupled with continuous R&D into proprietary materials that enhance radiation hardness and minimize signal recombination effects at high dose rates.

How are Ionization Chambers used in environmental monitoring?

Environmental monitoring uses ruggedized and often large-volume ionization chambers to continuously measure low levels of background radiation or radiation emanating from specific sources like nuclear waste sites. These devices provide stable, reliable data on ambient exposure rates over long periods, fulfilling critical public safety mandates.

What key technological innovation is driving efficiency in clinical dosimetry?

The key innovation is the development of array ionization chambers (e.g., 2D arrays) and parallel-plate arrays that allow simultaneous measurement of dose distributions across a large area. This speeds up complex machine QA procedures, such as IMRT verification, reducing the time a linear accelerator must be offline for calibration.

What differentiates a sealed ionization chamber from a vented chamber?

A vented chamber has a small opening to allow the internal gas pressure to equilibrate with the atmosphere, requiring temperature and pressure correction (TPC). A sealed chamber is hermetically sealed at a fixed pressure, ideally eliminating the need for TPC, though they may still require correction for long-term changes or thermal expansion effects.

What is the expected impact of proton therapy market growth on ionization chambers?

The expansion of proton therapy centers increases demand for specialized water-equivalent ionization chambers designed to accurately measure dose in the Bragg peak region, where standard photon-optimized chambers may struggle. This creates a high-growth niche for manufacturers focusing on high-Linear Energy Transfer (LET) dosimetry solutions.

Why do Hospitals and Cancer Centers constitute the largest end-user segment?

Hospitals and Cancer Centers perform routine, high-stakes radiation treatments. Ionization chambers are regulatory requirements for both initial commissioning and daily quality assurance (QA) of radiation delivery machines, making their purchase and regular maintenance essential for clinical operation and patient safety protocols.

What is the primary function of a Well-Type ionization chamber?

Well-Type chambers are designed to measure the activity or output of radioactive sources, particularly low-activity sources used in brachytherapy or nuclear medicine. The source is placed inside the cavity (the well), maximizing the geometric efficiency and signal collection for accurate source strength determination.

How do global regulatory mandates influence the Ionization Chambers Market?

Regulatory mandates, such as those set by the IAEA, ICRP, and national bodies, require frequent, traceable dosimetry checks for all radiation sources and medical accelerators. These mandates ensure quality standards and safety, making the periodic purchase and recalibration of certified ionization chambers non-discretionary purchases for end-users globally, thereby stabilizing market demand.

What role does standardization play in the market?

Standardization, typically facilitated by primary dosimetry laboratories, ensures that measurements taken with different chambers in different locations are comparable and accurate. Traceability to international standards (e.g., through air kerma or absorbed dose to water standards) is mandatory for clinical and regulatory acceptance, establishing strict performance criteria for manufacturers.

Where do the key competitive advantages lie for market players?

Competitive advantages are centered on manufacturing precision, providing traceable calibration services, developing chambers optimized for emerging modalities (like FFF beams or proton therapy), and successfully integrating chambers with advanced software platforms for automated QA and data management.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager