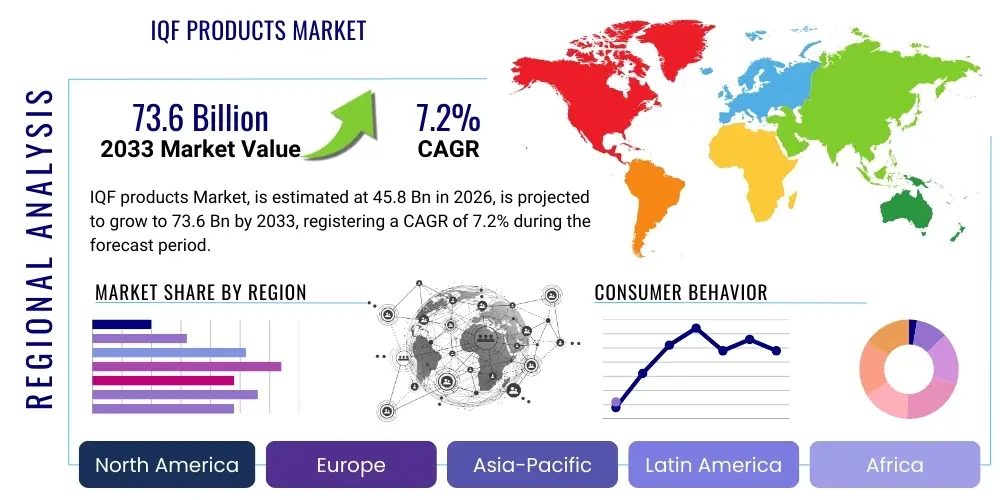

IQF products Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439379 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

IQF products Market Size

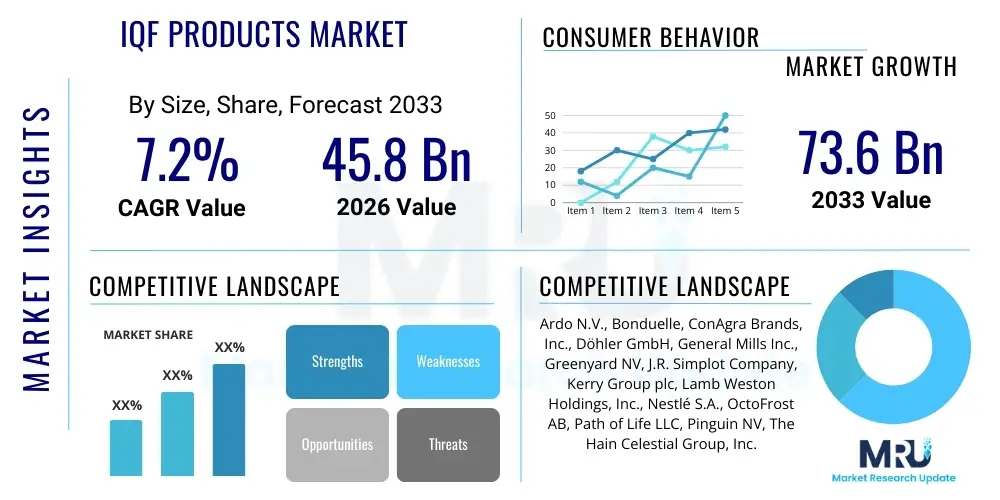

The IQF products Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. The market is estimated at USD 45.8 Billion in 2026 and is projected to reach USD 73.6 Billion by the end of the forecast period in 2033.

IQF products Market introduction

The Individual Quick Freezing (IQF) products market represents a significant and rapidly expanding segment within the global food industry. IQF technology involves rapidly freezing individual pieces of food, such as fruits, vegetables, meat, seafood, and poultry, by circulating cold air or by using liquid nitrogen, ensuring that each piece remains separate and free-flowing. This distinct characteristic prevents clumping, making it easier for consumers and food service operators to portion and use the product without thawing the entire batch. The process maintains the cellular structure, flavor, color, and nutritional value of the food much more effectively than traditional block freezing methods, leading to a superior quality product upon thawing and cooking.

Major applications for IQF products span across various sectors including retail, foodservice, and industrial food processing. In the retail sector, IQF fruits and vegetables are popular for smoothies, side dishes, and ready meals due to their convenience and extended shelf life. Foodservice establishments, such as restaurants, hotels, and catering companies, rely on IQF ingredients for consistent quality, reduced preparation time, and minimal food waste. Industrially, IQF components are critical for manufacturers of frozen meals, bakery products, soups, and confectionery, providing high-quality raw materials that streamline production and offer year-round availability regardless of seasonal harvest.

The primary benefits of IQF products include enhanced food safety through rapid freezing, improved convenience for end-users, and a significant reduction in food spoilage and waste. These products allow for longer storage periods while preserving the sensory and nutritional attributes of fresh produce. Driving factors for market growth encompass increasing consumer demand for convenient and healthy food options, the rising popularity of ready-to-eat and ready-to-cook meals, and the expanding global cold chain infrastructure. Furthermore, a growing awareness of food waste and the desire for sustainable food solutions are compelling consumers and businesses towards IQF options, as they offer better portion control and extended usability, thereby minimizing spoilage throughout the supply chain.

IQF products Market Executive Summary

The IQF products market is experiencing robust growth, propelled by evolving consumer lifestyles and significant advancements in food processing and cold chain logistics. Business trends indicate a strong move towards diversification, with manufacturers expanding their product portfolios to include a wider range of IQF items beyond traditional fruits and vegetables, now encompassing specialty meats, seafood, herbs, and even prepared ingredients like pasta and grains. There is a notable emphasis on clean label products, organic certifications, and sustainable sourcing practices to meet the growing consumer demand for natural and environmentally conscious food choices. Automation and technological integration in IQF processing lines are also key business trends, aimed at enhancing efficiency, reducing operational costs, and improving product quality and consistency across various production scales. Furthermore, strategic collaborations and mergers among key players are shaping the competitive landscape, allowing companies to expand their geographical reach and consolidate market share, leveraging economies of scale and expertise.

Regional trends reveal distinct growth patterns influenced by economic development, dietary habits, and infrastructure capabilities. North America and Europe currently represent mature markets, characterized by high consumer awareness, established cold chain logistics, and a strong preference for convenience foods. Growth in these regions is primarily driven by product innovation, premiumization, and the increasing penetration of IQF products in the foodservice and retail sectors. The Asia Pacific region is poised for the fastest growth, fueled by rapid urbanization, rising disposable incomes, and the modernization of retail infrastructure, particularly in emerging economies like China and India. Latin America and the Middle East & Africa are also showing promising potential, driven by growing populations, increasing foreign investment in food processing, and a burgeoning demand for shelf-stable and hygienic food options. These regions are witnessing significant investment in cold storage and distribution networks to support the expansion of the IQF market, moving away from traditional fresh markets.

Segment trends highlight diverse dynamics across product types and applications. The fruits and vegetables segment continues to dominate, driven by health and wellness trends and the versatility of these ingredients in various culinary applications. However, the meat and seafood segment is experiencing accelerated growth, attributed to the convenience offered to consumers and foodservice providers in handling delicate and perishable protein sources. The prepared meals and convenience food applications are also surging, reflecting the fast-paced lives of modern consumers who prioritize ease of preparation without compromising on quality or nutritional value. Within the retail sector, the proliferation of private label IQF products is a growing trend, as retailers seek to offer affordable and high-quality alternatives to branded products, thereby catering to a broader consumer base. The shift towards plant-based diets is further stimulating the IQF market, with a rising demand for IQF plant-based proteins and alternative meat products, signaling a dynamic and adaptable market landscape that responds to evolving dietary preferences.

AI Impact Analysis on IQF products Market

The integration of Artificial Intelligence (AI) within the IQF products market is a subject of significant interest and evolving expectations among industry stakeholders and consumers alike. Common user questions often revolve around how AI can enhance efficiency in IQF processing, improve quality control, optimize supply chain logistics, and contribute to sustainability efforts. Users are particularly curious about AI's potential to predict demand fluctuations more accurately, personalize product offerings based on consumer data, and ensure a higher degree of food safety through advanced anomaly detection. There's also considerable interest in AI's role in reducing operational costs, minimizing waste, and streamlining complex production processes, alongside concerns regarding data privacy, implementation costs, and the necessary skill sets for adopting such advanced technologies. The overarching theme is the anticipation of AI as a transformative force, enabling smarter, more responsive, and sustainable production and distribution of IQF products while addressing specific challenges related to perishability and market volatility.

- AI-driven predictive analytics optimize inventory management and reduce waste by forecasting demand more accurately.

- Automated quality control systems using computer vision and machine learning identify defects in individual IQF items, ensuring consistent product standards.

- AI-powered systems enhance energy efficiency in freezing processes by optimizing equipment settings and maintenance schedules.

- Robotics and AI in sorting and packaging lines improve speed and precision, minimizing human error and contamination risks.

- Machine learning algorithms analyze sensory data to fine-tune freezing parameters, preserving optimal texture, flavor, and nutritional content.

- AI facilitates traceability across the supply chain, enhancing food safety and compliance with regulatory standards.

- Personalized product development through AI analyzes consumer preferences to create targeted IQF offerings, catering to niche markets and dietary trends.

- AI-assisted maintenance scheduling for IQF machinery reduces downtime and extends equipment lifespan, improving operational efficiency.

- Real-time monitoring and anomaly detection prevent potential issues in freezing tunnels and storage, ensuring product integrity.

- Data-driven insights from AI support strategic decision-making in procurement, production planning, and market entry strategies for IQF products.

DRO & Impact Forces Of IQF products Market

The IQF products market is significantly shaped by a confluence of drivers, restraints, opportunities, and broader impact forces that dictate its trajectory and evolution. Key drivers include the escalating global demand for convenient and healthy food options, fueled by increasingly busy lifestyles and a growing awareness of nutritional well-being. The inherent benefits of IQF technology, such as extended shelf life, preservation of nutritional value, and ease of portion control, directly align with these consumer preferences. Furthermore, the expansion of modern retail infrastructure, particularly in emerging economies, alongside a robust growth in the foodservice sector globally, significantly contributes to the market's expansion. The continuous innovation in food processing and packaging technologies, coupled with improvements in cold chain logistics, also serves as a crucial driving force, making IQF products more accessible and appealing to a broader consumer base. The growing focus on reducing food waste, both at industrial and consumer levels, further propels the adoption of IQF products due to their inherent ability to minimize spoilage and offer better inventory management solutions.

Despite these strong drivers, the IQF products market faces several restraints. A significant barrier is the high initial capital investment required for IQF processing equipment and the establishment of an efficient cold chain infrastructure, which can be prohibitive for smaller players or new entrants. The energy-intensive nature of freezing processes also contributes to higher operational costs, impacting profitability and potentially leading to increased product prices for end-consumers. Additionally, challenges related to maintaining product quality and texture during freezing and storage, especially for delicate items, can sometimes result in consumer perception issues. Complex logistics, including managing precise temperature controls throughout transportation and storage, pose ongoing operational challenges. Moreover, the fierce competition from fresh and other frozen food alternatives, coupled with fluctuating raw material prices, can further constrain market growth and profitability for manufacturers in certain segments of the IQF market.

Opportunities for growth in the IQF products market are abundant and diverse. The burgeoning demand for exotic and seasonal fruits and vegetables year-round presents a significant opportunity for IQF processors to expand their product offerings. The rising popularity of plant-based diets and veganism is creating new avenues for IQF-processed plant-based proteins, meat alternatives, and specialty vegetable blends. Untapped potential in emerging markets, characterized by increasing urbanization, rising disposable incomes, and developing retail landscapes, offers substantial growth prospects for market penetration. Innovations in packaging, such as sustainable and eco-friendly materials, also present an opportunity to cater to environmentally conscious consumers and reduce the market's carbon footprint. Furthermore, technological advancements in freezing techniques, aimed at reducing energy consumption and improving product quality, along with the development of more efficient automation in processing, will unlock new efficiencies and broaden the market's appeal. Strategic partnerships between IQF processors, ingredient suppliers, and food manufacturers can also create synergies, fostering new product development and market expansion into novel application areas. The continuous evolution of consumer dietary preferences and the search for healthier, more convenient, and sustainable food solutions will provide enduring opportunities for innovation and expansion within the IQF products market.

Segmentation Analysis

The IQF products market is comprehensively segmented to provide granular insights into its diverse components, allowing for a detailed understanding of market dynamics, consumer preferences, and strategic opportunities. These segmentations are crucial for businesses to tailor their product development, marketing strategies, and distribution channels effectively, addressing specific needs across various end-user categories and geographical regions. The market's structure reflects the wide array of food items that benefit from IQF technology and the different contexts in which these products are utilized, from raw ingredient supply to finished consumer goods. Analyzing these segments helps stakeholders identify high-growth areas, competitive landscapes, and emerging trends that can influence future market expansion and investment decisions.

- By Product Type:

- Fruits & Vegetables

- Meat & Seafood

- Poultry

- Pasta & Grains

- Dairy (e.g., cheese shreds, yogurt bites)

- Baked Goods (e.g., cookie dough pieces)

- Herbs & Spices

- Others (e.g., convenience food components, pet food ingredients)

- By Application:

- Food Processing Industry (e.g., for ready meals, soups, sauces, baked goods)

- Retail (Supermarkets, Hypermarkets, Convenience Stores, Online Retail)

- Foodservice (Restaurants, Hotels, Cafes, Catering Services, Institutions)

- Household/Direct Consumer

- By Freezing Technology:

- Blast Freezing

- Cryogenic Freezing (using liquid nitrogen or carbon dioxide)

- Fluidized Bed Freezing

- Plate Freezing (less common for IQF but used for certain forms)

- By End-Use Sector:

- Commercial (Industrial Food Manufacturers, Foodservice Providers)

- Residential (Individual Households)

Value Chain Analysis For IQF products Market

The value chain for the IQF products market is a complex ecosystem involving multiple stages, from raw material sourcing to final consumer delivery, each adding value and incurring costs. Upstream analysis begins with the cultivation, harvesting, or sourcing of raw agricultural produce, livestock, and seafood. This stage is critical for ensuring the quality, freshness, and safety of the inputs, which directly impact the final IQF product. Farmers, fishermen, and livestock producers form the initial link, often operating under contracts with food processors to ensure a consistent and high-quality supply. Key considerations at this stage include seasonality, sustainable farming practices, adherence to food safety standards, and logistical efficiency in transporting raw materials to processing facilities. The efficiency and quality control at the upstream level are paramount for mitigating risks and maintaining the integrity of the food product throughout its journey to becoming an IQF item.

The core processing stage involves the sorting, cleaning, cutting, blanching (for certain vegetables), and most importantly, the individual quick freezing process. This stage utilizes specialized IQF freezers, such as fluidized bed freezers or cryogenic freezers, to rapidly freeze individual pieces of food, preserving their cellular structure and preventing clumping. Following freezing, the products are typically packaged in bulk or consumer-sized portions, often requiring advanced packaging materials that can withstand freezing temperatures and protect the product from freezer burn and contamination. Quality control, food safety inspections, and adherence to regulatory standards are rigorously applied throughout this manufacturing phase. Midstream activities also include storage in large cold storage facilities, which necessitates significant investment in temperature-controlled warehouses to maintain the frozen state of the products before distribution.

Downstream analysis focuses on the distribution channels and the final consumption of IQF products. Distribution typically involves a robust cold chain logistics network, transporting products from cold storage to various points of sale or use. This includes wholesalers, distributors, and directly to major retailers, foodservice providers (restaurants, hotels, institutions), and industrial food manufacturers who use IQF ingredients in their own products. Direct and indirect sales channels play a crucial role; direct channels might involve manufacturers selling directly to large institutional buyers or through their own online platforms, while indirect channels leverage third-party distributors and retailers to reach a broader market. The effectiveness of the cold chain, from transportation to in-store freezer management, is vital for maintaining product quality and consumer satisfaction. Marketing and sales efforts at this stage are aimed at educating consumers about the benefits of IQF products and creating brand loyalty, ultimately driving consumer demand and ensuring a smooth flow of products to the end-users. The entire value chain relies on seamless coordination and technological integration to maintain product integrity and efficiency.

IQF products Market Potential Customers

The IQF products market caters to a broad and diverse range of potential customers, spanning across various sectors from individual households to large-scale industrial food processors and the expansive foodservice industry. Each customer segment is driven by unique needs and purchasing criteria, making it essential for manufacturers and suppliers to understand these distinct demands. At the forefront are individual consumers who seek convenience, quality, and extended shelf life in their daily food choices. Busy lifestyles, a growing preference for home cooking with minimal preparation time, and a heightened awareness of health and nutrition drive the demand for IQF fruits, vegetables, and pre-portioned proteins. These consumers value the ability to use only what they need, reducing food waste and ensuring fresh-like quality at any time, making IQF products a staple in modern household freezers. Retail channels, including supermarkets, hypermarkets, convenience stores, and the burgeoning e-commerce platforms, are the primary conduits for reaching this vast residential customer base, offering a wide array of IQF options.

Another significant segment comprises the foodservice industry, encompassing restaurants, hotels, catering companies, cafes, and institutional kitchens like hospitals and schools. For these commercial entities, IQF products offer unparalleled benefits in terms of consistent quality, portion control, labor cost reduction, and year-round availability of ingredients regardless of seasonal variations. Chefs and kitchen managers rely on IQF items to streamline operations, reduce prep time, and minimize spoilage, ensuring a consistent product offering to their patrons while managing costs effectively. The ability to quickly thaw and incorporate specific quantities of ingredients without compromising freshness or flavor is a critical advantage for high-volume commercial kitchens. This sector demands reliable supply chains, bulk packaging, and stringent quality assurance, often engaging in direct procurement or through specialized foodservice distributors to meet their operational needs efficiently.

Industrial food manufacturers represent a robust and growing customer segment, utilizing IQF products as essential raw materials for their own processed food lines. This includes producers of ready-to-eat meals, frozen dinners, soups, sauces, bakery products, confectionery, and even baby food. For these manufacturers, IQF ingredients provide a reliable, pre-processed, and high-quality input that simplifies their production processes, ensures consistency across batches, and extends the shelf life of their finished products. The controlled quality and availability of IQF ingredients enable manufacturers to innovate with new product formulations and maintain year-round production schedules without being hampered by ingredient seasonality. This segment often requires large volumes, specific cuts or preparations, and strict adherence to industrial specifications and certifications. The pet food industry also emerges as a potential customer, increasingly using IQF meats, vegetables, and other ingredients to produce high-quality, convenient, and nutritionally balanced pet meals, responding to the humanization of pets trend and the demand for premium pet food products. The versatility and efficiency of IQF technology make it an attractive solution across a multitude of industries requiring consistent, high-quality, and easy-to-handle food components.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 45.8 Billion |

| Market Forecast in 2033 | USD 73.6 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ardo N.V., Bonduelle, ConAgra Brands, Inc., Döhler GmbH, General Mills Inc., Greenyard NV, J.R. Simplot Company, Kerry Group plc, Lamb Weston Holdings, Inc., Nestlé S.A., OctoFrost AB, Path of Life LLC, Pinguin NV, The Hain Celestial Group, Inc., Uren Food Group Limited, McCain Foods Limited, Kraft Heinz Company, Ajinomoto Co., Inc., AM Frozen Foods, Goya Foods, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

IQF products Market Key Technology Landscape

The IQF products market is underpinned by a dynamic and evolving technological landscape, where innovations are continuously aimed at enhancing freezing efficiency, preserving product quality, and optimizing operational costs. At the core of the IQF process are specialized freezing tunnels, which typically employ methods such as fluidized bed freezing, blast freezing, or cryogenic freezing. Fluidized bed freezers are highly prevalent for small, discrete products like peas, berries, and diced vegetables, using an upward flow of cold air to suspend and freeze individual pieces, ensuring minimal clumping and excellent separation. Blast freezers, while often used for larger items, are adapted for IQF with continuous conveyer systems to rapidly reduce temperature. Cryogenic freezing, utilizing liquid nitrogen or carbon dioxide, offers ultra-rapid freezing, which is particularly beneficial for delicate items like seafood and certain fruits, as it minimizes ice crystal formation and better preserves cellular structure, leading to superior texture and flavor upon thawing. Advancements in these freezing technologies focus on reducing energy consumption, increasing throughput, and improving the precision of temperature control to meet diverse product requirements.

Beyond the primary freezing equipment, the key technology landscape for IQF products encompasses a range of integrated solutions that contribute to overall efficiency and quality. Pre-processing technologies such as advanced sorting systems, optical graders, and precise cutting machinery ensure that only high-quality, uniformly sized raw materials enter the freezing stage. These systems often incorporate computer vision and artificial intelligence to detect defects and foreign materials, enhancing food safety and product consistency. Post-freezing, packaging technologies play a crucial role, with innovations in barrier films, modified atmosphere packaging (MAP), and vacuum sealing designed to prevent freezer burn, maintain product integrity, and extend shelf life during storage and transport. Automated packaging lines, including robotic pick-and-place systems, increase speed and hygiene, reducing labor costs and contamination risks. Furthermore, advancements in industrial refrigeration systems, including energy-efficient compressors, heat recovery systems, and eco-friendly refrigerants, are vital for maintaining the cold chain from production to consumption, ensuring sustainability and compliance with environmental regulations.

The increasing adoption of automation, IoT (Internet of Things), and data analytics further defines the modern IQF technology landscape. IoT sensors are integrated throughout the processing line and cold chain, providing real-time data on temperature, humidity, and equipment performance. This data is then analyzed using sophisticated software platforms to optimize production parameters, predict maintenance needs, and identify potential bottlenecks, thereby improving overall operational efficiency and reducing downtime. Automated control systems manage the entire freezing process, from raw material feed to frozen product output, ensuring consistent quality and minimizing human error. Traceability systems, leveraging technologies like blockchain or advanced RFID, are becoming increasingly important for ensuring transparency and accountability across the supply chain, allowing for rapid recall management and building consumer trust. The convergence of these advanced technologies creates an intelligent, highly efficient, and adaptable production environment, enabling IQF manufacturers to meet stringent quality standards, respond to market demands, and operate more sustainably in a competitive global market.

Regional Highlights

- North America: A mature market characterized by high consumer awareness of frozen convenience foods, strong retail infrastructure, and significant demand from the foodservice sector. Innovations in plant-based IQF products and organic offerings are driving growth, with the United States and Canada leading in consumption and product diversification. The region benefits from established cold chain logistics and a focus on premium, health-conscious options.

- Europe: A leading market driven by a strong emphasis on food safety, sustainability, and quality. Western European countries, particularly Germany, France, and the UK, are key consumers, with increasing demand for IQF berries, vegetables, and pre-cut poultry. Regulatory standards and consumer preferences for locally sourced and "clean label" IQF products significantly influence market trends. Eastern Europe is emerging due to economic development and modernizing retail.

- Asia Pacific (APAC): The fastest-growing region, propelled by rapid urbanization, rising disposable incomes, and the expansion of modern retail chains and foodservice industries in countries like China, India, and Southeast Asian nations. The demand for convenient and hygienic food solutions is soaring, along with an increasing preference for frozen seafood and specialty fruits, driving substantial investment in cold chain infrastructure.

- Latin America: Demonstrates significant growth potential, with Brazil and Mexico as key markets. The region benefits from increasing industrialization of food processing, a growing middle class, and the adoption of modern retail formats. Demand for IQF fruits, vegetables, and meat products is on the rise, driven by urbanization and the need for longer shelf-life food options, though cold chain development remains a focus area.

- Middle East and Africa (MEA): An emerging market experiencing gradual but steady growth, influenced by increasing disposable incomes, changing dietary habits, and a growing expatriate population. Countries like UAE, Saudi Arabia, and South Africa are investing in cold storage and food processing capabilities. Demand is primarily for IQF poultry, meat, and vegetables, driven by food security concerns and convenience, despite varying levels of cold chain maturity across the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the IQF products Market.- Ardo N.V.

- Bonduelle

- ConAgra Brands, Inc.

- Döhler GmbH

- General Mills Inc.

- Greenyard NV

- J.R. Simplot Company

- Kerry Group plc

- Lamb Weston Holdings, Inc.

- Nestlé S.A.

- OctoFrost AB

- Path of Life LLC

- Pinguin NV

- The Hain Celestial Group, Inc.

- Uren Food Group Limited

- McCain Foods Limited

- Kraft Heinz Company

- Ajinomoto Co., Inc.

- AM Frozen Foods

- Goya Foods, Inc.

Frequently Asked Questions

Analyze common user questions about the IQF products market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are IQF products and how do they differ from regular frozen foods?

IQF (Individual Quick Freezing) products are food items frozen rapidly as individual pieces, preventing them from clumping together. This differs from block freezing, where items are frozen in bulk. IQF preserves cellular structure, flavor, color, and nutrients more effectively, offering superior quality, easier portioning, and extended shelf life compared to conventionally frozen foods.

What are the main benefits of using IQF products for consumers and businesses?

For consumers, benefits include convenience, ease of portioning, reduced food waste, preserved nutrition, and year-round availability of seasonal produce. For businesses (foodservice, manufacturers), IQF offers consistent quality, reduced preparation time and labor costs, minimized spoilage, efficient inventory management, and enhanced food safety due to rapid freezing.

Which product types dominate the IQF market, and what are the fastest-growing segments?

The IQF fruits and vegetables segment currently dominates the market due to high consumer demand for healthy and convenient options. However, segments like IQF meat, seafood, poultry, and plant-based protein alternatives are experiencing rapid growth, driven by evolving dietary preferences and the increasing demand for ready-to-cook protein sources.

How does the IQF products market contribute to sustainability and food waste reduction?

IQF products significantly reduce food waste by extending shelf life and enabling precise portion control, both at the consumer and industrial levels. The process also allows for year-round utilization of seasonal produce, minimizing spoilage of fresh crops. Additionally, efficient cold chain logistics associated with IQF products optimize resource use.

What technological advancements are shaping the future of the IQF products market?

Key advancements include more energy-efficient freezing technologies, AI-driven quality control and sorting systems, advanced automation in packaging, IoT sensors for real-time monitoring of the cold chain, and sustainable packaging materials. These innovations aim to improve product quality, reduce operational costs, and enhance environmental sustainability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager