IR Cutoff Filter Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440227 | Date : Jan, 2026 | Pages : 242 | Region : Global | Publisher : MRU

IR Cutoff Filter Market Size

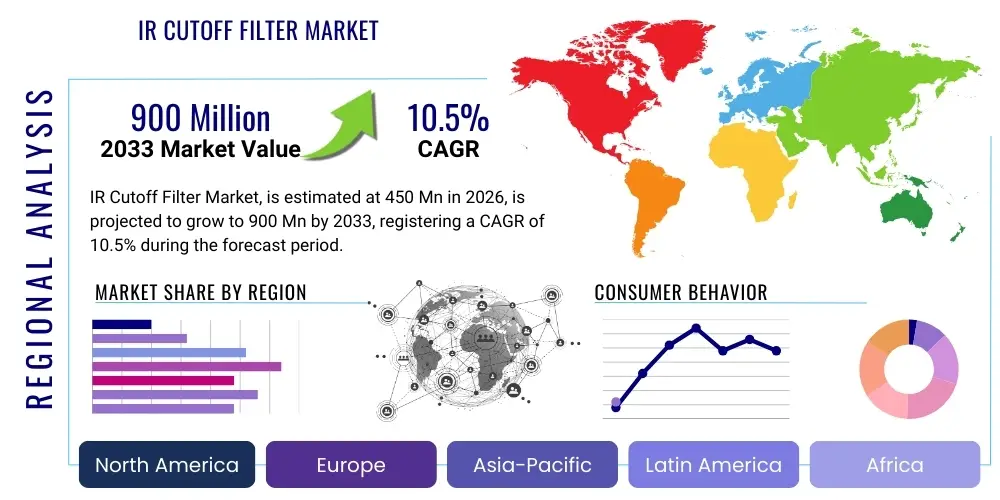

The IR Cutoff Filter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 900 Million by the end of the forecast period in 2033. This robust growth is primarily driven by the escalating demand for high-performance imaging solutions across various industries, including consumer electronics, automotive, security and surveillance, and medical applications. The continuous innovation in camera technologies, coupled with the miniaturization of optical components, further propels market expansion, making IR cutoff filters an indispensable element in modern optical systems. The market’s trajectory reflects a broader trend towards enhanced visual fidelity and the integration of advanced sensors in everyday devices and sophisticated industrial equipment, where precise light management is paramount.

IR Cutoff Filter Market introduction

The IR Cutoff Filter Market encompasses the global trade and technological advancements of optical filters designed to block or attenuate infrared (IR) light while allowing visible light to pass through. These specialized filters are crucial components in a vast array of imaging and sensing devices, ensuring accurate color reproduction and preventing image degradation caused by unwanted infrared radiation. Essentially, an IR cutoff filter acts as a gatekeeper for light, meticulously selecting which wavelengths are permitted to reach a sensor, thereby optimizing performance and extending the operational lifespan of sensitive optical components. Their primary function is to eliminate the 'infrared contamination' that can distort colors or introduce noise, particularly in digital cameras and machine vision systems, where true-to-life color accuracy is a critical requirement for both aesthetic appeal and functional performance. The growing ubiquity of camera-equipped devices and the increasing sophistication of their image processing capabilities directly fuel the demand for these precision-engineered filters.

Product descriptions of IR cutoff filters typically highlight their spectral transmission characteristics, material composition, and optical coatings. These filters are commonly fabricated from glass or plastic substrates, often treated with multi-layer dielectric coatings that precisely define their cutoff wavelength and transmission profiles. Major applications span from consumer electronics, such as smartphones, tablets, and digital cameras, to industrial and specialized fields like automotive imaging systems for advanced driver-assistance systems (ADAS), security and surveillance cameras, medical imaging equipment, and even specialized machine vision systems used in manufacturing and quality control. The benefits derived from using IR cutoff filters are multifaceted, including significantly improved image quality, enhanced color fidelity, reduced sensor noise, and protection of image sensors from excessive IR exposure, which can lead to overheating or premature degradation.

Key driving factors for the IR Cutoff Filter Market include the relentless growth of the global consumer electronics market, particularly the proliferation of smart devices with integrated cameras that demand superior image quality in varying lighting conditions. Furthermore, the burgeoning automotive industry, with its increasing reliance on camera-based safety features and autonomous driving technologies, presents a substantial growth impetus. The expansion of smart city initiatives and the rising demand for advanced security and surveillance systems, which operate effectively day and night, also contribute significantly to market acceleration. Technological advancements in optical coatings and substrate materials, allowing for thinner, more efficient, and cost-effective filters, further fuel market expansion by enabling broader integration into diverse applications. The convergence of these factors creates a robust and expanding ecosystem for IR cutoff filter manufacturers.

IR Cutoff Filter Market Executive Summary

The IR Cutoff Filter Market is experiencing a period of significant expansion, characterized by dynamic business trends, evolving regional market dynamics, and diversified segment growth. In terms of business trends, the market is witnessing increased consolidation among key players aiming to leverage economies of scale and expand product portfolios, alongside a rise in strategic partnerships and collaborations focusing on research and development for next-generation optical solutions. There's a noticeable shift towards customization and application-specific filter designs, driven by the specialized requirements of emerging technologies such as augmented reality (AR), virtual reality (VR), and advanced medical diagnostics. Furthermore, manufacturers are increasingly investing in automation and advanced manufacturing techniques to improve production efficiency, reduce costs, and enhance the precision of filter fabrication, ensuring filters meet stringent performance specifications for high-resolution imaging devices. The emphasis on high-volume production for consumer electronics and specialized, low-volume production for high-value industrial applications defines the dual operational strategies within the market.

Regional trends indicate that the Asia Pacific (APAC) region continues to dominate the IR Cutoff Filter Market, primarily due to the presence of a vast manufacturing base for consumer electronics, automotive components, and surveillance systems in countries like China, South Korea, Japan, and Taiwan. This region also exhibits high adoption rates of smart devices and significant investments in smart city infrastructure, further stimulating demand. North America and Europe represent mature markets, characterized by strong demand from advanced automotive technologies, medical imaging, and defense applications, coupled with a focus on premium and high-performance filters. These regions are also at the forefront of R&D, pushing innovations in optical materials and coating technologies. Latin America, the Middle East, and Africa are emerging markets, showing promising growth propelled by increasing urbanization, rising disposable incomes, and growing investments in public security infrastructure, driving the demand for camera-equipped devices and associated optical components.

Segmentation trends reveal robust growth across various product types and end-use industries. Filters categorized by material, such as glass-based and plastic-based, show distinct market preferences depending on application cost, durability, and optical performance requirements. Application-wise, consumer electronics remain the largest segment, but automotive and security and surveillance segments are exhibiting the fastest growth rates due to increasing integration of cameras in vehicles and sophisticated monitoring systems. The industrial and medical sectors also contribute significantly, driven by demand for precise machine vision and diagnostic imaging. Technological advancements are leading to thinner, lighter, and more efficient filters, influencing purchasing decisions and fostering innovation across all segments. The trend towards multi-spectral imaging and compact camera modules also necessitates highly integrated and miniature IR cutoff filter solutions, creating new opportunities for specialized filter manufacturers and driving segment-specific innovations in optical engineering.

AI Impact Analysis on IR Cutoff Filter Market

The burgeoning field of Artificial Intelligence (AI) profoundly influences the IR Cutoff Filter Market, primarily by driving the need for more sophisticated and precise optical components in AI-powered vision systems. Users frequently inquire about how AI enhances the performance of devices employing these filters, the specific requirements AI imposes on filter design, and the implications for future market growth. The core theme revolves around AI's ability to extract deeper insights from visual data, which in turn demands higher fidelity, clearer images, and more accurate color reproduction from the underlying hardware. This user expectation translates into a market need for filters that can maintain optical integrity under diverse lighting conditions, offer superior signal-to-noise ratios, and are compatible with advanced image processing algorithms. Consumers and industrial users alike seek to understand if current filter technologies are adequate for next-generation AI applications or if new innovations are imperative to meet the rigorous demands of machine learning and computer vision, especially in areas like autonomous navigation, advanced surveillance analytics, and diagnostic imaging. The conversation often extends to the potential for AI itself to optimize filter design and manufacturing processes, suggesting a synergistic relationship where AI not only drives demand but also innovates production.

- AI systems in autonomous vehicles demand high-resolution, color-accurate imaging, increasing the need for robust IR cutoff filters that perform reliably across varied environmental conditions and maintain spectral integrity for object recognition algorithms.

- The proliferation of AI-enabled smart security cameras requires superior IR cutoff filters to ensure clear, true-color images during daylight and seamless transition to IR imaging at night, crucial for accurate facial recognition and anomaly detection.

- AI-powered medical imaging devices leverage sophisticated image processing, necessitating precision IR cutoff filters to deliver pristine, artifact-free data for diagnostic accuracy and detailed analysis in fields like ophthalmology and microscopy.

- Industrial AI vision systems, used for quality control and automation, depend on highly consistent and spectrally stable IR cutoff filters to ensure reliable data input for defect detection and precise robotic guidance.

- The development of AI in consumer electronics, particularly in advanced smartphone cameras, pushes for thinner, smaller, and more efficient IR cutoff filters capable of supporting computational photography features and enhanced low-light performance.

- AI algorithms for multi-spectral and hyperspectral imaging applications drive demand for custom IR cutoff filters that precisely define specific wavelength bands, enabling AI to analyze material composition and other complex visual data.

- The need for edge AI processing in devices mandates low-power, high-efficiency optical components, including IR cutoff filters, that can contribute to the overall energy optimization of camera modules.

DRO & Impact Forces Of IR Cutoff Filter Market

The IR Cutoff Filter Market is shaped by a complex interplay of drivers, restraints, and opportunities, collectively acting as impact forces that dictate its growth trajectory and evolutionary path. Key drivers for the market include the explosive growth of the consumer electronics sector, particularly the ubiquitous integration of high-resolution cameras in smartphones, tablets, and wearable devices, where accurate color reproduction is paramount for user experience. The expanding automotive industry, driven by the adoption of Advanced Driver-Assistance Systems (ADAS) and the progression towards autonomous vehicles, heavily relies on precise imaging sensors requiring IR cutoff filters for environmental perception and safety. Furthermore, the increasing global demand for advanced security and surveillance systems, capable of operating effectively in varying light conditions, provides a significant boost to the market. Technological advancements in imaging sensors, which are becoming more sensitive to infrared light, necessitate more effective IR cutoff filters to maintain optimal visible light performance. The continuous miniaturization of optical modules also pushes for compact and high-performance filter designs, thereby innovating the market from within.

Despite the strong tailwinds, the market faces several restraints that could impede its growth. One significant restraint is the increasing cost pressure on manufacturers, especially those catering to high-volume consumer electronics, where price competitiveness is fierce. The complex manufacturing processes involved in producing high-quality, precision-coated filters can be expensive, limiting profit margins and discouraging smaller players. Another challenge is the rise of alternative imaging technologies or software-based solutions that attempt to mitigate the effects of IR contamination digitally, potentially reducing the perceived necessity for hardware filters in certain low-end applications. Moreover, the volatility in raw material prices, particularly for specialized optical glasses and coating materials, can impact production costs and lead times. The technical challenge of achieving perfect spectral separation without introducing other optical aberrations or color shifts also remains a constant concern for engineers, requiring significant R&D investment to overcome.

Opportunities within the IR Cutoff Filter Market are abundant and diverse, promising sustained growth and innovation. The emergence of new applications in augmented reality (AR) and virtual reality (VR) devices, which require sophisticated optical paths and precise light management, opens up significant avenues for specialized IR cutoff filters. The burgeoning market for drones and robotics, equipped with advanced vision systems for navigation, inspection, and delivery, presents another high-growth opportunity. Furthermore, the continuous advancements in medical imaging technologies, particularly in diagnostic equipment that relies on highly accurate visual data, will fuel demand for ultra-precision filters. The development of smart city infrastructure, with its reliance on vast networks of sensors and cameras for traffic management, public safety, and environmental monitoring, also presents a substantial, untapped market. Lastly, the ongoing research into novel materials and coating techniques, such as meta-surfaces and plasmonic filters, offers the potential for revolutionary filter designs that are thinner, lighter, and more efficient, expanding the boundaries of current optical capabilities and unlocking new applications.

Segmentation Analysis

The IR Cutoff Filter Market is comprehensively segmented to provide a detailed understanding of its diverse components, aiding in strategic market analysis and investment decisions. This segmentation allows for a granular view of market dynamics across different product types, materials, applications, and end-use industries. Each segment reflects unique demand characteristics, technological requirements, and competitive landscapes, contributing to the overall market structure. The inherent versatility of IR cutoff filters, combined with their critical role in optical systems, necessitates this detailed breakdown to accurately assess market size, growth potential, and emerging trends within each specific sub-market. Understanding these segments is crucial for manufacturers to tailor their product offerings, for suppliers to identify key demand areas, and for investors to pinpoint lucrative opportunities, thereby enabling a more targeted and effective approach to market engagement and development.

- By Product Type:

- Absorption Type IR Cutoff Filters

- Reflection Type IR Cutoff Filters

- Hybrid Type IR Cutoff Filters

- By Material:

- Glass-based IR Cutoff Filters

- Borosilicate Glass

- B270 Glass

- Other Optical Glasses

- Plastic-based IR Cutoff Filters

- Polycarbonate

- Acrylic

- Other Polymers

- Glass-based IR Cutoff Filters

- By Application:

- Consumer Electronics

- Smartphones

- Digital Cameras (DSLRs, Mirrorless, Compact)

- Tablets and Laptops

- Wearable Devices (Smartwatches, AR/VR Headsets)

- Drones (Consumer)

- Automotive

- ADAS (Advanced Driver-Assistance Systems)

- Autonomous Vehicles

- In-Cabin Monitoring Systems

- Dash Cams

- Security and Surveillance

- CCTV Cameras

- IP Cameras

- Thermal Imaging Cameras (with visible spectrum)

- Access Control Systems

- Industrial

- Machine Vision Systems

- Robotics

- Industrial Cameras

- Quality Control and Inspection

- Medical and Healthcare

- Endoscopes

- Microscopes

- Diagnostic Imaging Equipment

- Surgical Navigation Systems

- Defense and Aerospace

- Military Reconnaissance

- Guidance Systems

- UAVs (Military)

- Night Vision Devices (integrated with visible)

- Other Applications (e.g., Scientific Research, Broadcasting)

- Consumer Electronics

- By Spectral Range:

- Short-wave IR Cutoff Filters (e.g., <700nm)

- Mid-wave IR Cutoff Filters (e.g., <800nm)

- Long-wave IR Cutoff Filters (e.g., <900nm)

- Custom/Broadband IR Cutoff Filters

- By Coating Technology:

- Dielectric Coatings

- Metallic Coatings

- Hybrid Coatings

- By Form Factor:

- Wafer-level Filters

- Individual Piece Filters (Cut and Polished)

- Custom Shapes and Sizes

- By Sales Channel:

- Direct Sales (to OEMs)

- Indirect Sales (through Distributors, Online)

Value Chain Analysis For IR Cutoff Filter Market

The value chain for the IR Cutoff Filter Market is a sophisticated network that encompasses multiple stages, from the procurement of raw materials to the delivery of finished products to end-users. Understanding this chain is critical for identifying areas of efficiency, potential bottlenecks, and opportunities for value addition. The upstream segment of the value chain involves the sourcing and processing of essential raw materials and components. This primarily includes the manufacturing of optical glass substrates, such as borosilicate, soda-lime, or specialized filter glasses, which require high purity and precise optical properties. Additionally, the production of various coating materials, including metallic oxides, rare earth elements, and other dielectric compounds, is crucial. These materials are often sourced from specialized chemical and material suppliers, who play a foundational role in determining the quality and performance of the final filter product. Expertise in material science and precision engineering is paramount at this stage, setting the stage for the optical performance of the filters.

Moving further along the value chain, the manufacturing and assembly phase involves several complex steps. This includes precision grinding, polishing, and shaping of the optical substrates to meet specific dimensions and tolerances. The most critical step is the application of multi-layer dielectric or metallic coatings, typically performed using advanced vacuum deposition techniques such as ion-assisted deposition (IAD) or sputtering. This coating process precisely controls the spectral transmission and reflection characteristics of the filter, defining its IR cutoff point and visible light transmittance. Quality control and testing are integrated throughout this stage to ensure filters meet stringent optical, environmental, and mechanical specifications. The downstream segment of the value chain focuses on distribution and integration. This involves selling the finished IR cutoff filters to Original Equipment Manufacturers (OEMs) who integrate them into their camera modules, sensors, and other imaging systems. These OEMs represent a vast range of industries, including consumer electronics, automotive, security, industrial, and medical.

The distribution channels for IR cutoff filters are typically a mix of direct and indirect approaches. Direct sales are common for large-volume orders and for established, long-term relationships with major OEMs, where direct communication and technical support are crucial. Manufacturers often have dedicated sales teams that work closely with OEM design engineers to ensure the filters meet specific application requirements. Indirect channels involve distributors, value-added resellers, and online platforms, which serve smaller OEMs, research institutions, and custom solution providers. These indirect channels provide broader market reach and cater to diverse customer needs, offering a range of standard and semi-custom filter options. The efficiency of the distribution network is vital for timely delivery and market penetration, ensuring that the specialized optical components reach the assembly lines of product manufacturers globally. The entire value chain is characterized by a high degree of specialization and technical expertise, with each stage contributing significantly to the final product's performance and market competitiveness.

IR Cutoff Filter Market Potential Customers

The IR Cutoff Filter Market caters to a diverse array of potential customers across numerous industries, each with specific requirements for optical filtering solutions in their imaging and sensing devices. These end-users, or buyers of the product, are primarily manufacturers and integrators of systems that incorporate digital cameras or image sensors sensitive to infrared light. At the forefront are consumer electronics giants, including smartphone manufacturers, digital camera producers (DSLR, mirrorless, compact), and developers of smart home devices that integrate visual capabilities. These companies require high-volume, cost-effective, yet high-performance filters to ensure superior image quality, accurate color representation, and overall user satisfaction in their mass-market products. The relentless pace of innovation in consumer gadgets continually drives demand for thinner, lighter, and more advanced filters that can meet evolving design and functionality criteria.

Another major segment of potential customers includes automotive OEMs and their Tier 1 suppliers. With the rapid evolution of Advanced Driver-Assistance Systems (ADAS), parking assist, and autonomous driving technologies, vehicles are increasingly equipped with multiple cameras for environmental perception, pedestrian detection, lane keeping, and traffic sign recognition. These automotive applications demand extremely robust, reliable, and high-performance IR cutoff filters that can withstand harsh environmental conditions, including extreme temperatures, vibrations, and humidity, while providing consistently clear and accurate visual data crucial for safety and navigation. The medical and healthcare sector also represents a significant customer base, with manufacturers of endoscopes, microscopes, diagnostic imaging equipment, and surgical navigation systems relying on precision IR cutoff filters to obtain high-fidelity images for accurate diagnosis and minimally invasive procedures. The stringent regulatory requirements and the need for absolute accuracy in medical applications drive demand for filters with exceptional optical performance and reliability.

Furthermore, the security and surveillance industry, encompassing manufacturers of CCTV, IP cameras, and advanced surveillance systems, is a substantial consumer of IR cutoff filters. These customers require filters that ensure clear, true-color images during daylight and seamless transition to night vision modes, where IR illumination is used, enabling continuous monitoring and effective threat detection. Industrial sectors, including manufacturers of machine vision systems for quality control, automation, and robotics, also represent key buyers. These applications demand filters that provide consistent and repeatable optical performance to ensure the accuracy and reliability of automated inspection and guidance tasks. Lastly, the defense and aerospace industries utilize IR cutoff filters in reconnaissance systems, guidance platforms, and various military optical devices where precise spectral control is critical for mission success. This broad spectrum of end-users underscores the pervasive and indispensable role of IR cutoff filters in modern technological ecosystems, making them a foundational component for advanced imaging and sensing across diverse applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 900 Million |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | VIAVI Solutions Inc., SCHOTT AG, Edmund Optics, Hoya Corporation, AGC Inc., Optosigma Corporation, Union Optical Co. Ltd., Chroma Technology Corp., Nitto Denko Corporation, Shenzhen Sun&Lynn Circuits Co., Ltd., Ofil Systems Ltd., Zhejiang Lante Optics Co., Ltd., Wavelength Opto-Electronic (S) Pte Ltd, Shanghai Optics Inc., JML Optical Industries Inc., Tower Optical Corporation, Foctek Photonics Inc., Changchun Daheng Optics Co., Ltd., LightPath Technologies, II-VI Incorporated (now Coherent Corp.) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

IR Cutoff Filter Market Key Technology Landscape

The key technology landscape of the IR Cutoff Filter Market is defined by continuous innovation in materials science, precision manufacturing processes, and advanced optical coatings, all aimed at enhancing filter performance, reducing size, and improving cost-efficiency. At the core, the substrate materials are critical, with optical-grade glass (e.g., borosilicate, B270, and specialized doped glasses) being preferred for high-performance applications due to its superior optical clarity, thermal stability, and mechanical strength. Plastic substrates, such as polycarbonate and acrylic, are gaining traction for cost-sensitive, high-volume consumer electronics due to their lightweight nature and moldability, though they may have limitations in optical dispersion and temperature resistance. The selection of substrate material directly impacts the filter's durability, spectral response, and overall suitability for specific environments. Advances in glass thinning and chemical strengthening technologies are enabling the production of ultra-thin and robust filters, essential for compact camera modules in smartphones and other portable devices.

The most defining technological aspect lies in the optical coating processes, which are responsible for precisely controlling the spectral transmission characteristics. Multi-layer dielectric coatings, applied using advanced vacuum deposition techniques like ion-assisted deposition (IAD), electron beam evaporation, or sputtering, are standard. These processes allow for the deposition of multiple thin layers of metallic oxides (e.g., TiO2, SiO2, Ta2O5) with varying refractive indices, creating an interference effect that reflects infrared light while transmitting visible light. Recent advancements focus on developing more complex coating stacks to achieve sharper cutoff slopes, higher visible light transmission, and broader IR blocking, minimizing residual IR leakage that can degrade image quality. Plasma-enhanced chemical vapor deposition (PECVD) and atomic layer deposition (ALD) are also emerging as promising techniques for ultra-precise and highly uniform coatings, especially for wafer-level optics, enabling mass production of miniature filters for high-volume applications like smartphone cameras. These coating innovations are critical for meeting the ever-increasing demands for optical performance in a shrinking form factor.

Beyond materials and coatings, the technological landscape also encompasses advancements in filter design, integration, and testing. Custom filter designs with specific spectral profiles are increasingly common for specialized applications in medical diagnostics, industrial machine vision, and scientific instrumentation. Wafer-level optics (WLO) technology, where filters are manufactured directly on large wafers and then diced into individual components, is a significant trend for achieving cost-effectiveness and miniaturization in high-volume production. This approach integrates filter fabrication into the semiconductor manufacturing workflow, allowing for unprecedented scalability. Furthermore, sophisticated optical metrology and testing equipment, including spectrophotometers and interferometers, are essential to ensure the filters meet stringent quality standards and performance specifications. The integration of artificial intelligence and machine learning in optimizing coating designs and manufacturing parameters is an emerging area, promising to further enhance filter efficiency and reduce development cycles. The convergence of these technological innovations is driving the market towards more versatile, higher-performance, and cost-efficient IR cutoff filter solutions, enabling new applications and improving existing ones.

Regional Highlights

- Asia Pacific (APAC): The APAC region stands as the undisputed powerhouse in the IR Cutoff Filter Market, primarily driven by its massive manufacturing ecosystem for consumer electronics, automotive components, and surveillance systems. Countries like China, South Korea, Japan, and Taiwan are at the forefront of producing smartphones, digital cameras, and other smart devices, all of which are major consumers of IR cutoff filters. The region also witnesses significant investments in smart city initiatives and public infrastructure, boosting the demand for advanced security and surveillance cameras. The presence of a vast skilled labor force, established supply chains, and government support for technological advancements further solidifies APAC's dominance, making it a critical hub for both production and consumption. The rapid urbanization and rising disposable incomes also fuel the adoption of camera-equipped devices, thereby accelerating market growth.

- North America: North America represents a mature yet highly innovative market for IR cutoff filters, characterized by strong demand from advanced technological sectors such as autonomous vehicles, medical imaging, and defense and aerospace. The region is a hotbed for research and development in AI-powered vision systems and advanced optics, leading to the adoption of high-performance and customized filters. The presence of leading automotive manufacturers and technology giants drives significant investment in cutting-edge camera systems for ADAS and in-cabin monitoring. Additionally, a robust healthcare infrastructure fuels demand for precision filters in diagnostic and surgical equipment. The market here is driven by quality, performance, and customization rather than sheer volume, focusing on high-value applications and technological leadership.

- Europe: Europe holds a significant share in the IR Cutoff Filter Market, primarily propelled by its strong automotive industry, particularly in countries like Germany, France, and Italy, which are pioneers in advanced driver-assistance systems. The region also boasts a well-established industrial automation sector and a sophisticated medical technology market, requiring high-precision optical components. Europe's focus on stringent quality standards and environmental regulations also influences filter development, pushing for sustainable manufacturing practices and durable products. While less dominant in high-volume consumer electronics production compared to APAC, Europe excels in specialized, high-performance applications and contributes significantly to technological advancements in optical coatings and materials.

- Latin America: The Latin American market for IR cutoff filters is an emerging region experiencing steady growth. This growth is primarily attributable to increasing urbanization, a growing middle class, and expanding investments in public safety and smart city projects, which necessitate more sophisticated security and surveillance infrastructure. The rising penetration of smartphones and digital cameras, coupled with the gradual adoption of automotive ADAS features in some countries, also contributes to market expansion. While the region relies heavily on imports for advanced optical components, local manufacturing and assembly are gradually increasing, indicating a growing potential for market development.

- Middle East and Africa (MEA): The MEA region is an evolving market for IR cutoff filters, characterized by increasing government expenditure on infrastructure development, security enhancements, and smart city initiatives, particularly in the Gulf Cooperation Council (GCC) countries. The rising awareness and adoption of surveillance technologies for public and commercial safety are key drivers. Furthermore, the growing penetration of consumer electronics and the nascent development of automotive and industrial sectors contribute to the gradual expansion of the market. Challenges include reliance on imports and varying levels of technological adoption, but significant potential exists due to ongoing economic diversification and strategic investments in critical infrastructure across the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the IR Cutoff Filter Market.- VIAVI Solutions Inc.

- SCHOTT AG

- Edmund Optics

- Hoya Corporation

- AGC Inc.

- Optosigma Corporation

- Union Optical Co. Ltd.

- Chroma Technology Corp.

- Nitto Denko Corporation

- Shenzhen Sun&Lynn Circuits Co., Ltd.

- Ofil Systems Ltd.

- Zhejiang Lante Optics Co., Ltd.

- Wavelength Opto-Electronic (S) Pte Ltd

- Shanghai Optics Inc.

- JML Optical Industries Inc.

- Tower Optical Corporation

- Foctek Photonics Inc.

- Changchun Daheng Optics Co., Ltd.

- LightPath Technologies

- II-VI Incorporated (now Coherent Corp.)

Frequently Asked Questions

Analyze common user questions about the IR Cutoff Filter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is an IR Cutoff Filter and why is it essential?

An IR Cutoff Filter is an optical component designed to block infrared (IR) light while allowing visible light to pass through. It is essential in cameras and imaging systems to prevent IR contamination, which can distort colors, reduce image clarity, and negatively impact sensor performance, ensuring accurate color reproduction and optimal image quality in the visible spectrum.

How does AI impact the demand for IR Cutoff Filters?

AI significantly impacts demand by driving the need for higher quality and more precise image data for AI-powered vision systems in autonomous vehicles, security cameras, and industrial automation. AI's ability to extract nuanced information from images requires pristine, color-accurate input, thus increasing the need for advanced IR cutoff filters that ensure optimal spectral fidelity.

What are the primary applications of IR Cutoff Filters?

The primary applications include consumer electronics (smartphones, digital cameras), automotive (ADAS, autonomous driving), security and surveillance (CCTV, IP cameras), industrial (machine vision, robotics), and medical/healthcare (endoscopes, diagnostic imaging). These filters are critical wherever accurate visible light imaging is required in the presence of IR light.

What technological advancements are shaping the IR Cutoff Filter market?

Key technological advancements include the development of multi-layer dielectric coatings for sharper spectral cutoffs, the use of advanced substrate materials for enhanced durability and performance, wafer-level optics (WLO) for miniaturization and cost-efficiency, and increasingly sophisticated manufacturing processes like ALD for ultra-precise coatings, all contributing to superior optical performance in compact forms.

Which regions are leading the growth in the IR Cutoff Filter market?

The Asia Pacific (APAC) region leads the market due to its extensive manufacturing base for consumer electronics and significant investments in smart infrastructure. North America and Europe also hold substantial market shares, driven by demand from advanced automotive, medical, and defense sectors, focusing on high-performance and custom filter solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager