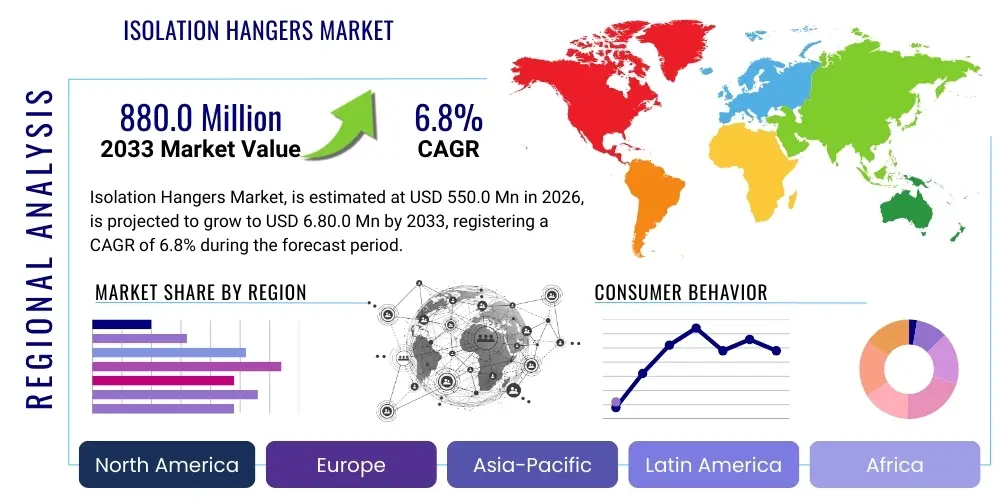

Isolation Hangers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439118 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Isolation Hangers Market Size

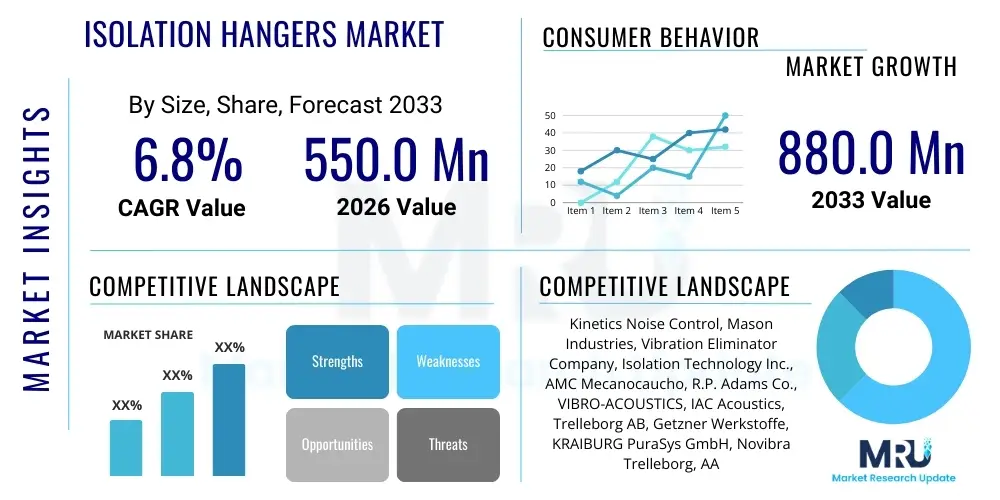

The Isolation Hangers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $550.0 Million in 2026 and is projected to reach $880.0 Million by the end of the forecast period in 2033.

Isolation Hangers Market introduction

Isolation hangers are specialized components designed to minimize the transmission of structure-borne noise and vibration from mechanical equipment, piping, or ductwork into building structures. These products utilize elastic materials such as rubber, neoprene, or steel springs to decouple the vibrating source from the structural support system, significantly enhancing acoustic comfort and reducing equipment wear. They are essential elements in sound control strategies, particularly in sensitive environments like recording studios, hospitals, commercial office spaces, and high-density residential buildings where stringent noise pollution standards must be met. The fundamental function of an isolation hanger is to achieve a low natural frequency compared to the disturbing frequency of the suspended equipment, thereby creating an efficient isolation barrier.

The market for isolation hangers is expanding due to stringent regulatory frameworks concerning noise control in urban planning and commercial construction. Modern building designs increasingly prioritize occupant well-being, driving demand for advanced acoustic solutions. Isolation hangers come in various configurations, including spring hangers for low-frequency vibrations typical of large HVAC units, and rubber or neoprene hangers often used for high-frequency or medium-load applications like suspended ceilings and lightweight piping systems. The selection criteria depend heavily on the equipment weight, the frequency of vibration, the required deflection, and the ambient temperature conditions of the installation site.

Major applications of isolation hangers span across several critical industries. In the Heating, Ventilation, and Air Conditioning (HVAC) sector, they are crucial for isolating air handlers, chillers, and ductwork that generate significant operational noise. Within industrial settings, they manage vibrations from pumps, compressors, and heavy machinery, protecting infrastructure integrity and improving worker safety. Furthermore, their application in building acoustics, particularly in isolating floating floors and suspended architectural elements, positions them as indispensable tools for achieving high-performance acoustic ratings in modern infrastructure projects. Key benefits include improved Sound Transmission Class (STC) ratings, extended equipment life, and compliance with increasingly strict global noise standards, driving consistent market growth.

Isolation Hangers Market Executive Summary

The Isolation Hangers Market exhibits robust growth, primarily propelled by global urbanization and the resultant need for sophisticated noise mitigation solutions in densely populated areas. Business trends indicate a strong shift towards highly engineered, multi-material isolation systems, such as combination spring-neoprene hangers, which offer optimal damping across a broader spectrum of frequencies. Manufacturers are focusing on developing products with enhanced fire resistance, increased load capacities, and easier installation mechanisms, responding directly to demands from large-scale commercial and infrastructure projects. Furthermore, digital integration, including the use of Building Information Modeling (BIM) ready components and specialized selection software, is streamlining the specification process for engineers, boosting market efficiency and adoption rates across various construction verticals.

Regional trends reveal that North America and Europe maintain dominance, driven by mature construction industries, high adoption of green building standards, and strict enforcement of workplace and residential noise ordinances. However, the Asia Pacific (APAC) region is poised for the fastest expansion, fueled by massive infrastructure development, rapid commercialization in countries like China and India, and increasing awareness regarding acoustic comfort in newly constructed facilities. This rapid development necessitates large volumes of isolation products for new data centers, mass transit systems, and high-rise commercial towers. Latin America and the Middle East & Africa (MEA) are also showing promising growth, primarily concentrated in major metropolitan hubs undergoing significant modernization efforts, particularly within the hospitality and healthcare sectors.

Segment trends highlight the mechanical spring hanger segment as the market leader in terms of revenue, attributed to its necessity in isolating heavy, low-frequency vibrating equipment (e.g., large HVAC units). Conversely, the neoprene and rubber hanger segment is expected to show superior volumetric growth due to their widespread use in lighter-load applications such as piping and ceiling suspensions, offering a cost-effective solution for vibration control. The commercial building sector remains the primary end-user segment, consistently investing in high-quality acoustic solutions to ensure tenant satisfaction and optimize facility performance. Strategic alliances between specialized vibration isolation manufacturers and major HVAC equipment providers are also shaping distribution dynamics and product specifications.

AI Impact Analysis on Isolation Hangers Market

Common user questions regarding AI's impact on the Isolation Hangers Market frequently revolve around predictive maintenance, optimal system design, and manufacturing efficiency. Users are keenly interested in whether AI can accurately model complex vibration scenarios in real-time, allowing engineers to select the absolute ideal isolation hanger configuration rather than relying on empirical formulas and broad estimates. Key concerns often include the integration cost of sensor technology into traditional mechanical components and the ability of AI algorithms to handle the variability inherent in construction materials and installation quality. Expectations center on AI streamlining the design-to-installation workflow, potentially identifying potential acoustic flanking paths that traditional methods overlook, thereby increasing the overall efficacy of noise control projects.

While isolation hangers are physical, passive components, AI significantly influences their lifecycle through predictive analytics and optimized system design. AI-powered simulation tools are increasingly used by acoustic engineers to model dynamic loading conditions and frequency responses, allowing for the precise tuning of hanger specifications (deflection, stiffness, damping ratio) prior to installation. This predictive capability reduces over-engineering and minimizes acoustic failures post-construction, saving significant remediation costs. Furthermore, in the manufacturing phase, AI can optimize material usage and quality control for complex spring or polymer formulations, ensuring greater consistency and reliability in mass-produced components, which is critical for maintaining specified isolation performance.

The implementation of Industrial Internet of Things (IIoT) sensors, combined with AI processing, is beginning to transform the maintenance phase of large mechanical installations. Hangers equipped with monitoring capabilities can feed operational vibration data to an AI platform, which then determines if the isolation system is degrading or if the supported equipment requires realignment or maintenance. This capability shifts the industry from reactive maintenance (only fixing problems after noise complaints arise) to proactive acoustic health monitoring, dramatically improving the long-term performance and minimizing acoustic nuisance in high-specification buildings like data centers and performance venues. This digital augmentation adds significant value beyond the physical product itself.

- AI algorithms enable precise, data-driven selection of hanger parameters (stiffness, natural frequency) for complex acoustic environments.

- Predictive maintenance platforms utilizing IIoT integrated hangers forecast system degradation and required component replacement before acoustic failure occurs.

- Generative design tools leverage AI to optimize hanger geometry and material composition for enhanced damping capabilities and reduced material waste.

- AI modeling improves quality control in manufacturing, ensuring strict adherence to specified load and deflection tolerances across production batches.

- Automated BIM integration ensures that AI-selected isolation components are accurately placed and specified within digital construction models.

DRO & Impact Forces Of Isolation Hangers Market

The Isolation Hangers Market is subject to a complex interplay of Drivers, Restraints, and Opportunities, collectively forming the Impact Forces that dictate market direction. The primary driver is the global increase in construction activity coupled with stricter governmental noise pollution regulations, particularly within commercial and mixed-use real estate sectors. This necessitates the mandatory inclusion of high-performance vibration control solutions in mechanical systems. Opportunities arise from technological advancements in material science, leading to the development of highly resilient, environmentally friendly, and durable isolation materials. However, the market faces significant restraints, including the high initial cost associated with specialized isolation components compared to standard fixing methods, and the challenge of educating contractors and installers on the critical importance of proper installation techniques, as misalignment severely compromises performance.

Drivers: Growing global awareness of the negative health impacts associated with noise pollution (such as sleep deprivation and cardiovascular issues) is accelerating the adoption of high-quality acoustic products. Architects and developers are increasingly marketing properties based on superior acoustic performance, using it as a differentiation point in competitive urban markets. Furthermore, the expansion of mission-critical facilities like data centers, where sustained operation of cooling equipment must not induce structural fatigue or noise that could affect nearby operations, provides a robust, high-value segment for advanced isolation systems. The ongoing replacement and retrofitting of aging infrastructure, particularly in mature economies, also drives demand as modern standards require improved acoustic performance compared to original installations.

Restraints: The most prominent restraint is the difficulty in standardizing performance measurement across diverse product types and materials (springs vs. elastomers), which can lead to confusion and incorrect specification. Economic downturns or slowdowns in the construction industry directly suppress demand, as isolation components are often viewed as high-cost specialty items that might be scope-reduced during cost-cutting measures. Moreover, the technical barrier to entry for effective vibration isolation is high; incorrect product selection (e.g., inadequate static deflection for the equipment weight) renders the isolation hanger ineffective, leading to market skepticism regarding the efficacy of vibration control products when installed improperly. This highlights the need for specialized technical support throughout the project lifecycle.

Opportunity: Significant opportunities lie in developing smart isolation systems that incorporate sensors and data logging capabilities for continuous monitoring and remote diagnostics, aligning with the shift towards smart building technologies. Expansion into emerging markets, where rapid infrastructure development is occurring without deeply established acoustic standards yet, presents a chance to integrate high-performance solutions early in the development cycle. Additionally, the transportation sector, particularly high-speed rail and urban mass transit, offers a niche but lucrative opportunity for specialized, heavy-duty isolation components designed for extreme dynamic loading and durability requirements. Manufacturers who invest in sustainable, recyclable materials for their rubber and neoprene components will also capture growing demand from environmentally conscious developers.

Segmentation Analysis

The Isolation Hangers Market is meticulously segmented based on Type, Application, and End-User, reflecting the diverse requirements across various industries demanding vibration and noise control. This detailed segmentation allows manufacturers to target specific functional requirements, such as high-deflection isolation needed for heavy equipment versus high-frequency damping required for sensitive laboratory instruments. The Type segmentation reveals the fundamental material science driving the market, whereas the Application segmentation clarifies the functional role of the hanger (e.g., HVAC vs. structural). Understanding these segments is crucial for strategic market positioning and product development, ensuring that solutions meet specific structural and acoustic performance targets across the global construction ecosystem.

The segmentation by Type, encompassing materials like steel springs, neoprene, rubber, and combined systems, is perhaps the most critical determinant of performance and cost. Spring hangers are favored for their ability to achieve high static deflection, essential for low-frequency vibration isolation, making them dominant in isolating large machinery. Neoprene and rubber components, while offering less static deflection, provide superior high-frequency damping and are often preferred for pipes, ducts, and suspended ceilings due to their excellent resistance to oil, chemicals, and weathering, coupled with lower cost per unit. The growing demand for specialized hybrid hangers (e.g., spring-in-neoprene cup) signifies a market trend toward components that offer the benefits of high deflection combined with inherent damping and fail-safe design.

The Application and End-User segments demonstrate the market’s reliance on capital expenditure in the commercial and industrial sectors. HVAC systems represent the largest application, driven by the sheer volume of air handling units, fans, and chillers installed in every modern building. The commercial building sector, including offices, hotels, and retail complexes, is the leading consumer, consistently driving demand for superior acoustic separation to maximize tenant comfort and rental value. The burgeoning data center market is also a high-growth segment, prioritizing vibration control to prevent resonance and acoustic fatigue in critical mechanical infrastructure that operates 24/7. This granular segmentation provides a roadmap for assessing market saturation and identifying high-potential growth pockets.

- Type:

- Spring Isolation Hangers (Open and Housed)

- Neoprene Isolation Hangers

- Rubber Isolation Hangers (Natural Rubber, EPDM)

- Combination Hangers (Spring and Neoprene/Rubber)

- Application:

- HVAC Equipment (Air Handling Units, Fans, Chillers, Condensers)

- Piping and Ductwork

- Industrial Machinery (Pumps, Compressors, Generators)

- Structural Isolation (Suspended Ceilings, Floating Floors)

- End-User:

- Commercial Buildings (Offices, Retail, Hospitality)

- Residential Complexes (Multi-Family Housing, High-Rises)

- Healthcare Facilities (Hospitals, Laboratories)

- Data Centers and IT Infrastructure

- Industrial and Manufacturing Facilities

Value Chain Analysis For Isolation Hangers Market

The value chain for the Isolation Hangers Market commences with the raw material procurement phase, dominated by high-grade steel necessary for springs and housings, and specialty polymers (neoprene, natural rubber) requiring precise chemical formulation for optimal damping characteristics and durability. Upstream activities involve specialized suppliers ensuring material quality meets stringent engineering standards related to tensile strength, deflection capabilities, and environmental resistance (e.g., UV, ozone). Manufacturers then engage in precision machining, stamping, and complex molding processes, investing heavily in quality control to ensure that load-bearing and isolation specifications are met exactly, as slight deviations can compromise acoustic performance significantly. This early stage requires deep technical expertise in both material science and mechanical engineering to create reliable vibration mounts.

The midstream involves manufacturing, assembly, and testing. Direct distribution channels are often employed when selling highly specialized or custom-engineered isolation systems directly to large contractors, system integrators, or HVAC manufacturers (OEMs). This direct approach facilitates close collaboration on product specifications, crucial for mission-critical installations. Conversely, indirect distribution utilizes a network of specialized mechanical distributors, wholesale suppliers, and acoustical representatives. These intermediaries provide local inventory, technical support, and logistical efficiency, particularly for standard, high-volume products used in routine construction projects. The choice of channel significantly impacts profitability and market reach, with direct channels supporting premium, high-margin, custom products, and indirect channels favoring standardized, accessible items.

Downstream activities focus heavily on installation and post-sales technical support. End-users—typically mechanical contractors, acoustical consultants, and building owners—rely on manufacturer guidance to select and install the hangers correctly. Poor installation is a major cause of failure, emphasizing the importance of detailed documentation, training programs, and site supervision provided by the manufacturer or their authorized distributors. The value chain culminates in the successful operation of the suspended mechanical system, verified through acoustic testing that confirms noise reduction targets have been achieved, ensuring client satisfaction and reinforcing the brand reputation of the isolation product supplier. This end-stage service expertise is a major differentiator in this highly technical market.

Isolation Hangers Market Potential Customers

The primary consumers, or potential customers, in the Isolation Hangers Market are multifaceted, spanning across construction, infrastructure, and industrial operation sectors, though they are most frequently categorized by the end-facility type. The largest segment comprises mechanical, electrical, and plumbing (MEP) contractors who are responsible for installing HVAC equipment and associated piping and ductwork within commercial, institutional, and residential buildings. These contractors purchase isolation hangers based on specifications provided by acoustical consultants or mechanical engineers, focusing primarily on product availability, cost-effectiveness, and ease of installation, provided the required deflection and load capacity are met. Their demand is directly tied to the volume and complexity of new commercial construction and large-scale retrofitting projects.

A highly critical customer segment includes developers and owners of high-value, acoustically sensitive real estate, such as luxury high-rise residential towers, five-star hotels, recording studios, and performance arts centers. For these customers, noise isolation is not merely a compliance issue but a core feature that defines the property's premium status and operational integrity. They mandate the use of the highest quality, often custom-engineered, isolation hangers to ensure absolute acoustic separation between different zones, willing to pay a premium for certified performance and comprehensive warranties. In these contexts, the focus shifts from lowest cost to maximum acoustic performance and long-term reliability.

Furthermore, specialized industrial and infrastructure facilities represent crucial end-users. Data centers, hospitals, and pharmaceutical manufacturing facilities require isolation hangers for mission-critical equipment like emergency generators, MRI machines, specialized ventilation systems, and industrial pumps. In these environments, product failure could lead to catastrophic operational disruption or failure to meet stringent regulatory requirements (e.g., cleanliness standards in labs or uptime in data centers). Therefore, customers in this segment prioritize fail-safe designs, exceptional material durability, and comprehensive technical documentation validating load capacity and seismic rating, often favoring sophisticated spring-neoprene combination hangers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550.0 Million |

| Market Forecast in 2033 | $880.0 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kinetics Noise Control, Mason Industries, Vibration Eliminator Company, Isolation Technology Inc., AMC Mecanocaucho, R.P. Adams Co., VIBRO-ACOUSTICS, IAC Acoustics, Trelleborg AB, Getzner Werkstoffe, KRAIBURG PuraSys GmbH, Novibra Trelleborg, AAF International, Airflow Developments Limited, Sound Seal, Inc., Peabody Engineering, GERB Vibration Control Systems, CDM Acoustic Solutions, Soundown Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Isolation Hangers Market Key Technology Landscape

The technology landscape for isolation hangers is continuously evolving, driven primarily by advances in material science and engineering design methodologies aimed at enhancing performance characteristics such as static deflection, damping efficiency, and environmental resilience. A major technological focus involves refining the metallurgy of the spring elements to ensure greater durability and consistency under long-term cyclic loading, crucial for minimizing fatigue failure. Furthermore, the development of advanced elastomer formulations (neoprene, EPDM, and proprietary rubber compounds) is critical, as these materials must maintain stable isolation properties across wide temperature ranges and resist degradation from ozone, oils, and chemicals commonly found in mechanical rooms. Technological innovation often centers on maximizing the ratio of static deflection achieved per unit of physical size, optimizing space utilization in confined ceiling areas.

A second significant technological trend involves the integration of high-performance damping mechanisms into spring-based isolators. While springs are excellent for static deflection and low-frequency isolation, they can have low inherent damping, potentially leading to resonance problems if external forces excite the system near its natural frequency. Modern isolation hangers address this by incorporating internal damping elements, often utilizing viscoelastic materials or air damping mechanisms within the spring housing. This combination—a high-deflection spring combined with a high-damping material—provides optimal broadband vibration control. Additionally, fail-safe technologies, which ensure that the supported equipment does not drop even in the event of primary isolation component failure, are becoming standard, reflecting heightened safety requirements in construction codes.

The increasing reliance on digital engineering tools represents a crucial technological shift. Manufacturers are leveraging Finite Element Analysis (FEA) and specialized acoustic simulation software to model the dynamic response of isolation systems under realistic operating conditions, reducing the need for extensive physical prototyping. This digital design approach enables rapid iteration and optimization of complex geometries, particularly for injection-molded elastomer components. Furthermore, the push towards integrating isolation hangers with IIoT sensors for remote performance monitoring and predictive maintenance represents the frontier of technological development, transforming the passive component into an active, intelligent part of the building management system, crucial for AEO optimization in smart building searches.

Regional Highlights

The global Isolation Hangers Market exhibits distinct regional dynamics shaped by construction intensity, regulatory maturity, and technological adoption rates.

- North America: Dominates the market, characterized by stringent acoustic performance standards (e.g., LEED certification requirements) and a highly sophisticated commercial construction sector. High demand is concentrated in the renovation of aging infrastructure and the construction of high-tech facilities such as expansive data centers and healthcare complexes. The region maintains a strong preference for high-quality, certified spring hangers and combination isolators.

- Europe: A mature market driven by strict EU noise directives and a strong focus on sustainable and green building practices. Germany, the UK, and France are key consumers, investing heavily in acoustic isolation for residential high-rises and integrated public transportation projects. European manufacturers are often leaders in material science, focusing on low-VOC and recyclable polymer isolation solutions.

- Asia Pacific (APAC): The fastest-growing region, fueled by unprecedented urbanization and massive infrastructural spending, especially in China, India, and Southeast Asia. While price sensitivity remains a factor, the rapid adoption of international building standards in commercial hubs is accelerating the uptake of high-performance isolation systems, moving away from simple rubber pads to engineered spring isolation.

- Latin America (LATAM): Exhibits steady growth, primarily focused on key metropolitan areas such as São Paulo and Mexico City. Demand is concentrated in new commercial and hospitality projects seeking to meet international operational standards. Market penetration is gradually improving as local regulations begin to address acoustic pollution more aggressively.

- Middle East and Africa (MEA): Growth is primarily concentrated in the Gulf Cooperation Council (GCC) countries due to megaprojects in construction (e.g., futuristic cities, large commercial complexes, and entertainment venues). The harsh climate in the MEA necessitates specialized, highly durable isolation materials capable of withstanding extreme temperatures and desert conditions without degradation of performance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Isolation Hangers Market.- Kinetics Noise Control

- Mason Industries

- Vibration Eliminator Company (VEC)

- Isolation Technology Inc. (ITI)

- AMC Mecanocaucho

- R.P. Adams Co.

- VIBRO-ACOUSTICS

- IAC Acoustics

- Trelleborg AB

- Getzner Werkstoffe

- KRAIBURG PuraSys GmbH

- Novibra Trelleborg

- AAF International

- Airflow Developments Limited

- Sound Seal, Inc.

- Peabody Engineering

- GERB Vibration Control Systems

- CDM Acoustic Solutions

- Soundown Corporation

- Fabreeka International

Frequently Asked Questions

Analyze common user questions about the Isolation Hangers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of an isolation hanger in HVAC systems?

The primary function of an isolation hanger is to decouple suspended mechanical equipment, such as air handlers, ducts, and pipes, from the building structure. This prevents the transmission of structure-borne vibration and noise, ensuring compliance with acoustic standards and enhancing occupant comfort by minimizing disruptive mechanical sounds.

How do I choose the correct type of isolation hanger for a given application?

Selection depends on the frequency of the disturbing vibration and the required static deflection. Spring hangers are mandatory for heavy equipment and low-frequency isolation (requiring high deflection, typically 1 to 3 inches). Neoprene or rubber hangers are suitable for lighter loads, high-frequency vibrations, or applications where only moderate deflection is required (less than 0.5 inches), often used for pipe and duct support.

What are the key differences between spring hangers and neoprene hangers?

Spring hangers provide higher static deflection and are necessary for isolating low-frequency vibrations typical of large machinery, offering robust performance but sometimes requiring auxiliary damping. Neoprene hangers provide superior high-frequency damping, chemical resistance, and cost-effectiveness, commonly used for non-critical systems, but they offer significantly less static deflection.

Which end-user segment drives the highest demand for isolation hangers globally?

The commercial buildings segment (including offices, hotels, and retail complexes) currently drives the highest volume and revenue demand. This is due to the large scale of commercial construction projects, strict acoustical requirements enforced by tenants and codes, and the universal need to isolate extensive HVAC and plumbing systems critical to operation.

Are smart or sensor-equipped isolation hangers available in the market?

Yes, technological advancements are leading to the introduction of smart isolation systems. These hangers incorporate embedded sensors (IIoT) to monitor real-time vibration levels and system performance. This data allows for predictive maintenance, remote diagnostics, and verification that the acoustic isolation performance is maintained over the equipment’s lifecycle, aligning with smart building technology trends.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager