Jacketed Reactors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433990 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Jacketed Reactors Market Size

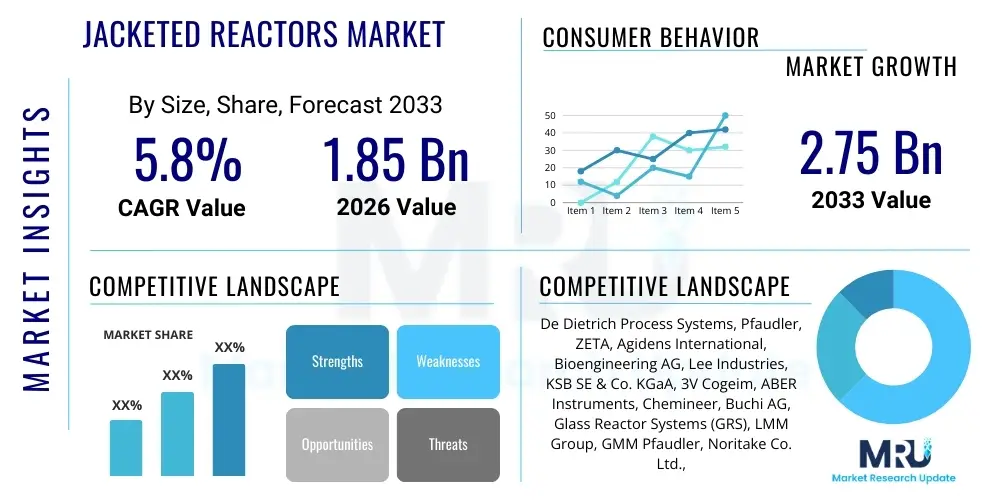

The Jacketed Reactors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1.85 Billion in 2026 and is projected to reach $2.75 Billion by the end of the forecast period in 2033.

Jacketed Reactors Market introduction

Jacketed reactors are fundamental pieces of equipment in the process industries, primarily used for controlling the temperature of chemical reactions within a contained vessel. These reactors feature an outer jacket surrounding the main vessel, through which a heating or cooling medium (such as steam, chilled water, or thermal oil) is circulated. This precise temperature control is critical for maintaining reaction kinetics, ensuring product quality, preventing dangerous thermal runaways, and optimizing yield in sensitive processes. They are indispensable across a wide spectrum of applications, ranging from small-scale laboratory processes to large-scale industrial manufacturing, making them a cornerstone technology in the chemical and pharmaceutical sectors.

The primary applications of jacketed reactors span across chemical synthesis, fermentation, crystallization, polymerization, and dissolution processes. Key driving factors propelling market growth include the escalating demand for specialty chemicals, the rapid expansion of the biopharmaceutical sector, and stringent regulatory requirements for reaction consistency and safety, particularly in advanced materials manufacturing. The benefit profile of these systems centers on enhanced operational flexibility, improved safety protocols through effective exothermic reaction management, and superior batch consistency, which are crucial differentiators in highly regulated environments like drug manufacturing and fine chemical production.

Furthermore, the market is benefiting significantly from technological advancements focused on reactor materials and digitalization. The increasing adoption of exotic alloys and glass-lined materials to handle highly corrosive substances is expanding their applicability. Simultaneously, the integration of advanced process analytical technology (PAT) and automated control systems enhances real-time monitoring and process optimization. These innovations not only improve efficiency and throughput but also solidify the jacketed reactor's role as a vital piece of infrastructure essential for modern, high-precision chemical processing across global industrial landscapes.

Jacketed Reactors Market Executive Summary

The Jacketed Reactors Market exhibits robust business trends driven primarily by continuous investments in pharmaceutical manufacturing and specialty chemical production, particularly in emerging economies. A major business trend involves the shift towards modular and customizable reactor systems that offer greater flexibility for multi-product facilities, minimizing downtime and optimizing batch changeovers. Companies are focusing heavily on developing high-pressure and high-temperature reactors suitable for complex catalytic reactions, positioning product innovation as a key competitive differentiator. Furthermore, sustainability initiatives are influencing design choices, pushing manufacturers towards energy-efficient thermal management systems and materials with extended service life, which translates into higher initial capital expenditure but lower long-term operational costs for end-users.

Regionally, the Asia Pacific (APAC) market is experiencing the most significant growth, fueled by massive capacity expansions in China and India, which are becoming global hubs for bulk drug and generic pharmaceutical production. North America and Europe, while mature, maintain dominance in terms of technological adoption and demand for premium, highly automated, and regulatory-compliant stainless steel and glass-lined reactors used in cutting-edge biotechnology and fine chemical synthesis. Regional trends also show a rising emphasis on local manufacturing to secure supply chains, catalyzed by geopolitical shifts and pandemic-related disruptions, driving demand for locally sourced reactor components and services in established industrial zones.

Segmentation trends highlight the increasing demand for high-capacity stainless steel reactors in the bulk chemical sector, while the pharmaceutical and biotech industries predominantly favor glass-lined reactors due to their inert properties and easy cleaning, crucial for preventing cross-contamination. Capacity-wise, the demand is polarized: large-volume reactors (above 10,000 liters) are vital for petrochemicals, whereas smaller, versatile reactors (100–1,000 liters) are critical for R&D and pilot plant operations in biotechnology. The rising prevalence of continuous flow chemistry is creating a niche demand for specialized micro-reactors and continuous stirred-tank reactors (CSTRs) with advanced jacketing designs tailored for high throughput and consistent process variables.

AI Impact Analysis on Jacketed Reactors Market

Common user questions regarding AI's impact on the Jacketed Reactors Market frequently revolve around how artificial intelligence can enhance predictive maintenance schedules, optimize complex thermal profiles, and improve overall reaction safety and yield. Users are specifically concerned with the feasibility of integrating machine learning algorithms with existing legacy control systems and the capability of AI to handle the multivariate data generated by jacketed reactor operations, which include temperature, pressure, stirring speed, and flow rates of heating/cooling mediums. The consensus expectation is that AI will transform jacketed reactor operation from a reactive, manual process to a highly predictive and autonomous system. Key themes emerging from user inquiries center on reducing energy consumption through smart temperature control, minimizing batch failure rates via anomaly detection, and accelerating scale-up processes by accurately modeling thermodynamic behavior.

AI's primary influence is manifested through the development of sophisticated digital twins for jacketed reactors. These virtual representations, powered by machine learning, simulate the behavior of the physical reactor under various stress conditions and operational parameters, allowing operators to test process changes without risking physical infrastructure or product quality. This capability dramatically shortens R&D cycles and facilitates seamless scale-up from pilot to commercial production by optimizing parameters like heat transfer coefficient and residence time in real-time. Moreover, the vast data collected from integrated sensors, including vibration analysis and acoustic monitoring, is processed by AI algorithms to forecast equipment degradation, identifying potential failures in agitators, seals, or jacket integrity well before they manifest, thereby shifting maintenance from time-based to condition-based and significantly increasing asset uptime.

Furthermore, AI plays a crucial role in operational efficiency and regulatory compliance. In exothermic reactions, AI-driven process control systems can predict potential thermal runaway based on subtle changes in reaction kinetics, automatically adjusting cooling parameters with precision far exceeding traditional PID controllers, thus enhancing overall plant safety. For regulatory environments like pharmaceuticals, AI systems can log, verify, and analyze every operational parameter, ensuring complete batch history records are consistent and readily auditable. This robust data management and predictive control capability solidifies AI as a transformative tool that enhances reactor safety, improves yield consistency, and drives substantial energy savings by precisely calculating the minimum energy required to maintain optimal reaction temperatures.

- AI-enabled Predictive Maintenance: Utilizing sensor data and machine learning to forecast mechanical component failures (e.g., agitator seals, bearings) and optimize maintenance schedules.

- Real-time Process Optimization: Employing algorithms to dynamically adjust heating/cooling medium flow and temperature based on real-time reaction kinetics, maximizing yield and minimizing energy consumption.

- Digital Twin Simulation: Creating accurate virtual models for testing new reaction recipes, optimizing scale-up parameters, and training operators in a risk-free environment.

- Enhanced Safety Protocols: AI systems predict and mitigate thermal runaways in exothermic reactions by performing automated, rapid parameter adjustments based on anomaly detection.

- Quality Control and Anomaly Detection: Machine vision and data analytics identify inconsistencies in mixing, crystallization, or purity profiles early in the batch process.

- Automated Documentation: AI assists in generating comprehensive, tamper-proof audit trails for regulatory compliance, streamlining validation processes in GMP environments.

DRO & Impact Forces Of Jacketed Reactors Market

The Jacketed Reactors Market is influenced by a dynamic interplay of Drivers, Restraints, and Opportunities, which collectively determine the momentum and direction of future growth. A key driver is the robust expansion of the global specialty chemical and pharmaceutical industries, which necessitates highly controlled and scalable reaction environments. Technological advancements in automation and material science, particularly the use of highly corrosion-resistant alloys and robust glass linings, further drive demand by expanding the operational envelope of these reactors. Conversely, significant restraints include the high initial capital investment required for high-specification reactors, especially those tailored for aseptic or high-pressure applications, and the complex regulatory approval processes, particularly in highly controlled markets like Western Europe and North America, which can slow down market penetration for new technologies.

Opportunities for market players are primarily found in developing modular reactor systems that cater to continuous manufacturing processes, a trend increasingly adopted in the pharmaceutical sector for efficiency and quality consistency. Furthermore, integrating smart sensing and IoT capabilities offers substantial opportunity for manufacturers to transition towards providing value-added services centered around data analysis and remote operational support, enhancing reactor efficiency and predictive maintenance services. The growing demand for advanced bioprocessing equipment, including highly specialized bioreactors that often incorporate jacketing for tight temperature control, represents another critical avenue for expansion, particularly within the burgeoning cell and gene therapy sector where precise environmental control is paramount for cell viability and proliferation.

The impact forces currently shaping the market are centered around globalization of manufacturing and geopolitical supply chain shifts. The push for localized pharmaceutical production in various regions mandates immediate investment in new reactor capacity, creating sharp demand spikes. Additionally, environmental regulations regarding solvent usage and waste management impact reactor design, driving demand for more efficient mixing technologies and closed-loop temperature control systems that minimize energy loss. These forces compel market participants to invest heavily in R&D focusing on energy efficiency and modularity, ensuring that new reactor designs are compliant with evolving sustainability standards while maintaining high performance parameters essential for modern chemical synthesis and bioprocessing applications.

Segmentation Analysis

The Jacketed Reactors Market is segmented based on critical characteristics including Type, Material of Construction, Capacity, and End-Use Industry. This multi-faceted segmentation provides a comprehensive view of specific demand pockets and technological preferences across different industrial sectors. Understanding these segments is vital for manufacturers to tailor their product offerings, whether focusing on the robustness required for bulk chemical processing or the sterility and inertness demanded by biopharmaceutical applications. The market structure reflects a clear delineation between the large-volume, high-pressure demands of petrochemicals and the small-to-medium-volume, high-purity demands of the fine chemical sector, driving specialized product development in each category.

Segmentation by Material of Construction—a key differentiator—shows a heavy reliance on Stainless Steel (primarily 304 and 316L) for standard chemical processing due to its mechanical strength and cost-effectiveness. However, the Glass-Lined Reactors segment is poised for rapid growth, particularly in applications involving highly corrosive acids or ultra-pure processes where metal contamination must be strictly avoided. Furthermore, high-performance alloys such as Hastelloy and Inconel are utilized in niche segments requiring extreme resistance to aggressive chemical attack and very high operating temperatures or pressures, catering to specialized segments like polymer synthesis and advanced battery material production, reflecting the market’s technological diversity.

The End-Use Industry segmentation highlights the pharmaceutical and chemical sectors as the dominant consumers. The pharmaceutical industry, driven by stringent cGMP regulations, demands highly polished, sanitary designs and robust validation documentation, often favoring glass-lined or high-grade stainless steel reactors. Conversely, the bulk chemical sector prioritizes scalability, robust design, and efficiency, primarily utilizing large stainless steel vessels. The emerging biotechnology and food & beverage segments, while smaller, are showing accelerated adoption rates due to the increasing need for precise fermentation and processing temperature control, suggesting future diversification in demand sources and necessitating specific customizations related to surface finish and cleanability standards.

- Type:

- Glass Jacketed Reactors

- Stainless Steel Jacketed Reactors

- Alloy Jacketed Reactors (e.g., Hastelloy, Titanium)

- Glass-Lined Steel Reactors

- Capacity:

- Small-Scale (Up to 100 Liters)

- Medium-Scale (100 Liters to 1,000 Liters)

- Large-Scale (1,000 Liters to 10,000 Liters)

- Industrial/Bulk Scale (Above 10,000 Liters)

- End-Use Industry:

- Pharmaceutical and Biotechnology

- Chemical and Petrochemical

- Food and Beverage

- Polymer and Material Science

- Research Laboratories

- Jacket Type:

- Conventional Jackets

- Half-Coil Jackets

- Dimple Jackets

Value Chain Analysis For Jacketed Reactors Market

The value chain for the Jacketed Reactors Market begins with upstream activities focusing on the sourcing and processing of raw materials, primarily high-grade stainless steel (316L), carbon steel, specialty alloys (like Hastelloy or Inconel), and high-purity borosilicate glass and glass lining materials. The quality and availability of these materials are critical, as they directly impact the corrosion resistance, pressure ratings, and longevity of the final reactor vessel. Key upstream suppliers include major metal fabricators, specialized glass lining providers, and component manufacturers focusing on high-integrity components such as agitator seals, valves, and complex sensor technologies. Fluctuations in global commodity prices for steel and nickel significantly influence manufacturing costs, exerting pressure on midstream profitability and necessitating robust supply chain risk management strategies among reactor manufacturers.

Midstream activities involve the specialized manufacturing and assembly process, which requires highly skilled welding, precise material cladding (for glass-lined reactors), surface finishing (essential for pharmaceutical-grade equipment), and rigorous quality control testing (hydrostatic and pneumatic tests). This manufacturing phase is where core intellectual property related to heat transfer efficiency, agitation design, and modularity is applied. Manufacturers often differentiate themselves through superior engineering design, offering customized solutions based on specific process requirements, such as high viscosity mixing or advanced heat exchange rates, driving a preference for experienced, vertically integrated firms capable of handling both vessel fabrication and sophisticated internal component integration.

The downstream component of the value chain focuses on distribution, installation, and after-sales service. Distribution channels include direct sales forces, especially for large, custom industrial projects, and specialized industrial equipment distributors or system integrators who can bundle the reactor with peripheral equipment (e.g., thermal control units, condensers, vacuum pumps). Direct distribution is favored for complex or highly customized orders where technical consultation is mandatory. After-sales services, including installation verification, validation (IQ/OQ/PQ for pharma), routine maintenance, and seal replacement, constitute a significant and profitable segment of the downstream value chain, ensuring long-term customer relationships and supporting the critical nature of the equipment in continuous manufacturing environments. The complexity of installation and validation means localized service teams are crucial for market success.

Jacketed Reactors Market Potential Customers

Potential customers for jacketed reactors primarily encompass industries where precise thermal control is mandatory for chemical synthesis, material transformation, or biological processing. The largest segment of end-users is the pharmaceutical and biotechnology industry, including both large multinational drug manufacturers and smaller contract development and manufacturing organizations (CDMOs). These buyers require aseptic, high-purity reactors, typically glass-lined or high-grade stainless steel (316L), certified to meet stringent Current Good Manufacturing Practice (cGMP) standards. Their purchasing decisions are heavily influenced by documentation support, validation services, and compliance with global regulatory bodies like the FDA and EMA, prioritizing reliability and contamination control above all else.

The second major group includes companies within the bulk chemical, fine chemical, and petrochemical sectors. These end-users demand high-volume, robust reactors capable of handling extreme pressures and temperatures over long operational cycles. Customers in the bulk chemical industry, such as producers of polymers, monomers, and basic organic compounds, prioritize scalability, cost-effectiveness, and mechanical durability, often utilizing large-scale stainless steel or specialized alloy reactors with dimple or half-pipe jackets for efficient utility flow. Their buying criteria often focus on total cost of ownership (TCO) and energy efficiency for large-scale continuous or semi-batch production processes.

Furthermore, a growing segment of potential customers is found in emerging high-growth industries, specifically specialty polymer manufacturers, advanced material developers (e.g., battery cathode materials), and the burgeoning food and beverage industry for specialized fermentation and extraction processes. These buyers look for versatile, medium-scale reactors that can handle complex multi-step reactions or proprietary processing techniques. Research institutions, universities, and dedicated R&D centers also represent consistent customers for small-scale and laboratory-grade glass reactors, essential for foundational research and process optimization before commercial scale-up, ensuring a continuous pipeline of future industrial adoption.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.85 Billion |

| Market Forecast in 2033 | $2.75 Billion |

| Growth Rate | CAGR 5.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | De Dietrich Process Systems, Pfaudler, ZETA, Agidens International, Bioengineering AG, Lee Industries, KSB SE & Co. KGaA, 3V Cogeim, ABER Instruments, Chemineer, Buchi AG, Glass Reactor Systems (GRS), LMM Group, GMM Pfaudler, Noritake Co. Ltd., Amar Equipment Pvt. Ltd., Tycon Alloy Industries, Swiss-Flow, JAYHAWK GTR, Shanghai Yutong Boiler. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Jacketed Reactors Market Key Technology Landscape

The technology landscape of the Jacketed Reactors Market is rapidly evolving, driven by the necessity for enhanced process efficiency, superior safety, and tighter regulatory compliance. A crucial technological focus lies in advanced thermal management systems. Manufacturers are increasingly moving away from simple conventional jackets toward specialized designs like half-pipe coil and dimple jackets. Half-pipe jackets are preferred for large reactors due to their structural rigidity and ability to handle high fluid flow rates and varying temperatures, ensuring rapid and uniform heat exchange. Dimple jackets, characterized by a thin metal shell welded to the main vessel, offer cost-efficiency and superior heat transfer characteristics due to increased turbulence of the utility fluid, making them popular for high-pressure industrial applications.

Material science and surface engineering represent another significant technological domain. The development of advanced glass-lining technology, offering greater thermal shock resistance and superior corrosion protection against a wider pH range, is paramount for the pharmaceutical and fine chemical industries. Furthermore, the increasing use of exotic materials such as high-nickel alloys (e.g., Hastelloy) is enabling reactions that require exceptionally corrosive environments or extremely high temperatures and pressures that stainless steel cannot withstand. Surface finishing techniques, including high-purity electro-polishing, are essential for sanitary applications to prevent microbial growth and facilitate easier, validated cleaning procedures, thereby significantly reducing the risk of batch contamination and enhancing overall operational security.

Digitalization and automation are transforming the operational technology (OT) layer of jacketed reactors. Modern reactors are equipped with sophisticated sensor arrays and integrated Process Analytical Technology (PAT) tools that provide real-time data on parameters like pH, dissolved oxygen, and particle size distribution within the reaction mixture. This data feeds into advanced Distributed Control Systems (DCS) or PLC platforms, often incorporating supervisory control capabilities and predictive modeling software. The adoption of modular, skid-mounted reactor designs, which come pre-validated and ready for rapid deployment, is also gaining traction, particularly in the biotech sector where flexibility and speed-to-market are critical. These technological advancements collectively enhance precision, reduce human error, and integrate the reactor seamlessly into complex, fully automated manufacturing ecosystems.

Regional Highlights

- Asia Pacific (APAC): APAC currently dominates the market in terms of production volume and is the fastest-growing region, driven by the rapid expansion of the chemical and pharmaceutical manufacturing base in China, India, and South Korea. Government initiatives promoting domestic manufacturing, coupled with lower operating costs compared to Western nations, have led to significant capacity additions for bulk chemicals and Active Pharmaceutical Ingredients (APIs). The demand here is largely focused on large-scale stainless steel reactors for bulk production, though there is accelerating demand for high-specification glass-lined reactors as local regulatory standards tighten, pushing for higher quality pharmaceutical production infrastructure.

- North America: North America is characterized by high technological maturity and is a leader in adopting advanced, automated reactor systems. The demand is heavily concentrated in the specialty chemical, biotechnology, and personalized medicine sectors. This region places a premium on high-purity, cGMP-compliant stainless steel reactors and systems designed for continuous flow chemistry. Investment is driven by R&D intensity, with a strong focus on utilizing reactors in highly regulated environments like biologics manufacturing, necessitating advanced temperature control precision, robust validation packages, and integrated automation systems.

- Europe: Europe maintains a strong market share, supported by major players in the specialty chemicals and advanced materials sector, particularly in Germany, Switzerland, and the UK. The market here is defined by stringent environmental and safety regulations, driving demand for energy-efficient reactors and advanced containment solutions. European manufacturers often invest in high-end glass-lined steel and exotic alloy reactors to handle complex, hazardous chemistries. The region shows consistent demand for modular and flexible systems to adapt to smaller-batch, high-value chemical synthesis requirements, focusing heavily on operational safety and reducing environmental impact.

- Latin America (LATAM): The LATAM market is growing steadily, primarily centered in Brazil and Mexico, fueled by increasing domestic demand for pharmaceuticals and agrochemicals. While the market size is smaller than APAC or North America, it presents significant opportunities as local economies invest in upgrading manufacturing capabilities and reducing reliance on imported finished products, leading to gradual investment in medium-scale, reliable stainless steel reactors for foundational chemical processes.

- Middle East and Africa (MEA): The MEA region's demand is concentrated around the petrochemical sector, particularly in Saudi Arabia and the UAE, requiring large industrial-scale stainless steel and alloy reactors for oil and gas processing derivatives. There is emerging growth in pharmaceutical manufacturing, especially in countries aiming for pharmaceutical self-sufficiency, which drives niche demand for smaller, compliant reactors. Market growth is closely tied to national industrial diversification strategies and large-scale infrastructure projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Jacketed Reactors Market.- De Dietrich Process Systems

- Pfaudler

- ZETA GmbH

- Bioengineering AG

- Lee Industries

- GMM Pfaudler

- Buchi AG

- Chem Resist Group Ltd.

- JAYHAWK GTR

- Amar Equipment Pvt. Ltd.

- Thaletec GmbH

- 3V Cogeim

- Noritake Co. Ltd.

- AGI Glassplant

- Chemline Group

- Tycon Alloy Industries

- Jiangsu Hanlin Electric Power Equipment Co., Ltd.

- Shanghai Yutong Boiler

- Kühni AG

- Swiss-Flow

Frequently Asked Questions

Analyze common user questions about the Jacketed Reactors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary differences between stainless steel and glass-lined jacketed reactors?

Stainless steel reactors offer superior mechanical strength, better heat transfer coefficients, and are used primarily for bulk chemical and standard synthesis where corrosion is manageable. Glass-lined reactors are essential for highly corrosive media (acids, alkalis) or high-purity processes like pharmaceuticals, providing excellent chemical inertness and easy cleaning, crucial for preventing product contamination.

How does the jacket type (dimple, half-coil, conventional) affect reactor performance?

Jacket type determines the efficiency and uniformity of heat transfer. Conventional jackets are simple but offer lower efficiency. Dimple jackets enhance turbulence and heat transfer but are typically limited to smaller vessels. Half-coil jackets are favored for large vessels due to their structural integrity and ability to handle high-velocity heating/cooling mediums, ensuring precise temperature maintenance.

What major regulatory standards impact the design and sale of jacketed reactors, particularly in the pharmaceutical industry?

The pharmaceutical industry mandates compliance with cGMP (current Good Manufacturing Practices) guidelines, requiring high surface finish standards, detailed validation documentation (IQ/OQ/PQ), and pressure vessel certifications (e.g., ASME, PED). These regulations drive demand for highly specialized, sanitary designs that facilitate sterilization and contamination control.

Is the market trending towards continuous flow reactors, and how does this affect traditional batch jacketed reactor demand?

While continuous flow reactors are gaining traction for specific high-efficiency processes, particularly in pharmaceuticals, traditional batch jacketed reactors remain dominant, especially for large-scale, complex, or multi-step synthesis. The trend necessitates innovation in batch reactor design, focusing on modularity and better integration with semi-continuous processing steps.

What role does digitalization play in optimizing the operation of modern jacketed reactors?

Digitalization involves integrating IoT sensors, Process Analytical Technology (PAT), and advanced control systems (DCS/PLC) to enable real-time monitoring and predictive maintenance. This significantly enhances operational safety, optimizes energy consumption by fine-tuning thermal profiles, and improves batch consistency and yield through precise, automated control.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager