Jackknife Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432655 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Jackknife Market Size

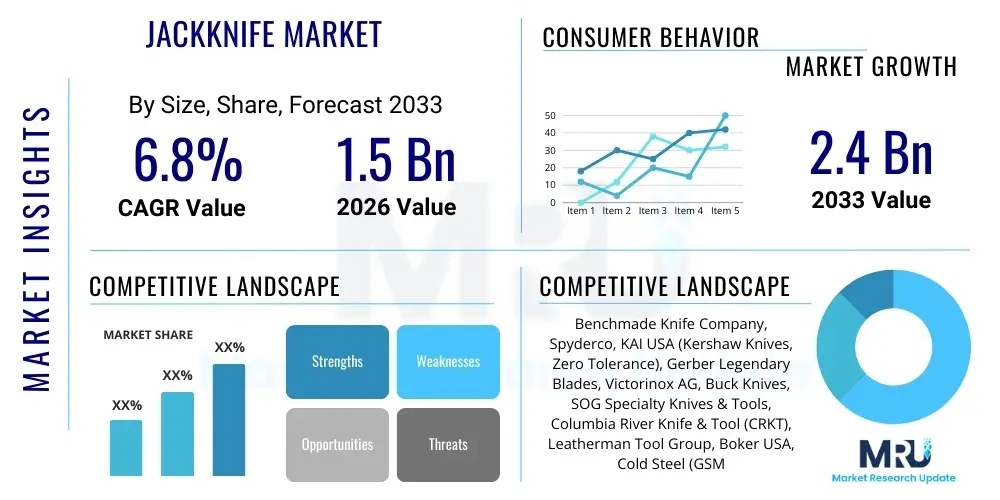

The Jackknife Market, encompassing various folding, utility, and pocket knives utilized across consumer and professional sectors, is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. This robust growth is attributed to increasing demand for multi-functional tools, advancements in material science enhancing durability and performance, and the pervasive adoption of Every Day Carry (EDC) culture globally. The continuous development of specialized locking mechanisms and ergonomic designs also contributes significantly to market expansion and consumer acceptance across diverse application areas.

The market is estimated at USD 1.5 Billion in 2026, reflecting the current valuation of tactical, survival, and general-purpose folding knife sales, including both high-end custom blades and mass-produced utility models. The demand is particularly high in the North American and European regions, driven by established outdoor and defense industries, alongside a strong consumer base for recreational activities like hiking and camping. Strategic investments in automated manufacturing processes allow key players to scale production while maintaining the quality standards expected by professional users, further stabilizing the market foundation.

This market is projected to reach USD 2.4 Billion by the end of the forecast period in 2033. This substantial increase will be fueled by emerging economies in the Asia Pacific region, where industrial expansion necessitates reliable cutting and utility tools. Furthermore, product innovation focusing on lightweight, aerospace-grade materials and integrated smart features—such as tracking or embedded sensor technology—will capture premium segments and stimulate replacements in mature markets. Regulatory clarity in certain regions regarding assisted opening mechanisms could also unlock significant untapped market potential.

Jackknife Market introduction

The Jackknife Market fundamentally deals with the design, manufacturing, and distribution of folding knives, characterized by a blade that pivots into the handle for safe storage and transport. This category of tool, which ranges from simple slip-joint pocket knives to complex, high-performance tactical folders, serves critical functions across myriad applications, including utility tasks, outdoor survival, industrial cutting, and personal defense. The product description emphasizes portability, reliability, and precision engineering, often featuring advanced materials like stainless steel variants (e.g., S30V, D2), titanium, and sophisticated composite handles for improved grip and weight reduction. Major applications span industrial maintenance, construction, military and law enforcement operations, and the vast consumer segment comprising campers, hunters, and EDC enthusiasts. The primary benefits include unmatched portability, immediate availability of a cutting edge, and safety features like liner locks, frame locks, or specialized axis locks that prevent accidental closure during strenuous use, driving its pervasive market presence.

A significant factor driving the Jackknife Market is the continuous evolution of locking technology and blade geometry, which directly impacts user safety and functional longevity. Manufacturers are constantly seeking patented designs that offer robust, one-handed operation while complying with varying international legal standards regarding blade length and mechanism type (manual, assisted, or automatic). Market growth is also intrinsically linked to global outdoor recreation trends and the increasing professionalism of trade services, both requiring durable, dependable cutting instruments. The integration of specialized tool functions—beyond just the primary blade, such as screwdrivers, bottle openers, or glass breakers—transforms the standard jackknife into a comprehensive multi-tool, broadening its appeal and market penetration across diverse consumer demographics.

Jackknife Market Executive Summary

The Jackknife Market Executive Summary indicates a strong trajectory of moderate to high growth, fundamentally shaped by shifting business trends toward specialized tactical gear, robust regional expansion in Asia Pacific driven by industrialization, and segmentation trends favoring high-quality, premium materials. Business trends highlight strategic partnerships between manufacturers and defense contractors, increased investment in automation to achieve tighter tolerances and higher throughput, and a definitive move toward direct-to-consumer (D2C) channels facilitated by e-commerce platforms. Furthermore, sustainability is becoming a key differentiator, with brands exploring recycled materials and modular designs for easier component replacement. Regional trends show North America maintaining dominance due to high discretionary spending on outdoor gear and mature defense procurement, while APAC is rapidly accelerating, particularly in urban utility and construction sectors. Europe demonstrates stable, high-value demand, often favoring established, heritage brands known for craftsmanship.

Segment trends underscore the rising preference for assisted-opening and automatic mechanisms, provided regulatory frameworks permit their use, as these offer superior speed and convenience in emergency or high-stress situations. The material segmentation reveals a dual focus: mass-market demand relies on cost-effective, durable stainless steel (440C, 8Cr13MoV), while the premium segment increasingly demands super steels (M390, CPM S30V) and exotic handle materials (carbon fiber, titanium) that offer superior edge retention and corrosion resistance. The application segment sees tactical and survival uses capturing higher average selling prices (ASPs), though Every Day Carry (EDC) dominates volume due to its wide consumer base. Overall, the market is characterized by intense brand competition focused on innovation in locking safety, ergonomic design, and strategic marketing targeting specific niche communities such as bushcraft or specialized trade professionals, ensuring dynamic market evolution throughout the forecast period.

AI Impact Analysis on Jackknife Market

User queries regarding the impact of Artificial Intelligence (AI) on the Jackknife Market primarily center on manufacturing optimization, supply chain efficiency, and the development of 'smart' tools. Users commonly ask: "Can AI design a better knife?" "How will AI affect traditional craftsmanship?" and "Will future jackknives incorporate sensors or connectivity?" Analysis reveals key themes focusing on AI’s role in optimizing blade metallurgy and geometric design through generative design processes, minimizing material waste during CNC machining, and predictive maintenance for manufacturing equipment. There is a concern that AI automation might displace skilled manual labor, but also an expectation that AI-driven quality control systems will significantly enhance product reliability and consistency, particularly in high-volume production runs. The general anticipation is that AI will not fundamentally change the physical nature of the knife but will revolutionize the processes of how it is designed, manufactured, and distributed, leading to faster innovation cycles and customized products based on consumer usage data.

The application of sophisticated AI algorithms is poised to transform the materials science aspect of the Jackknife Market. By utilizing machine learning models to analyze microstructure and stress test simulations, manufacturers can rapidly iterate on novel steel compositions, predicting factors like wear resistance, hardness, and toughness before physical prototyping even begins. This predictive capability significantly reduces R&D costs and accelerates the introduction of next-generation high-performance blades, addressing a core consumer demand for superior edge retention and corrosion resistance. Furthermore, AI-powered computer vision systems deployed on the production line ensure rigorous quality checks, identifying microscopic defects or inconsistencies in blade grinding and handle alignment far more efficiently and accurately than human inspectors, leading to a demonstrable reduction in manufacturing tolerances and enhancing the overall brand reputation for quality control.

In the supply chain, AI is instrumental in demand forecasting and inventory management, optimizing the flow of exotic raw materials like specialized alloys and handle composites. By analyzing global sales data, seasonal trends, and geopolitical stability, AI models can precisely predict demand fluctuations for specific knife types (e.g., tactical vs. utility), allowing companies to minimize stockouts of popular models and reduce overstocking of slow-moving inventory. This operational efficiency is crucial in a market characterized by high customization and volatile material costs. While the physical end product remains a traditional mechanical tool, AI integration into manufacturing workflows guarantees higher consistency, optimized material utilization, and a more responsive supply chain, ultimately benefiting consumers with superior products delivered more efficiently.

- AI-driven Generative Design optimizes blade geometry and handle ergonomics based on functional requirements and stress simulations.

- Machine Learning algorithms enhance quality control through computer vision systems, detecting microscopic manufacturing defects in critical components.

- Predictive maintenance schedules for CNC machinery minimize downtime and maximize operational efficiency in high-precision manufacturing.

- AI analyzes consumer data and usage patterns to inform the development of highly customized and application-specific folding knives.

- Optimization of supply chain and inventory management using predictive modeling ensures timely procurement of specialized steels and reduction of material waste.

DRO & Impact Forces Of Jackknife Market

The Jackknife Market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities (DRO), forming powerful impact forces that shape its future trajectory. Key drivers include the pervasive growth of Every Day Carry (EDC) culture globally, emphasizing preparedness and utility; rapid technological advancements in metallurgy and composite materials, leading to lighter, stronger, and more corrosion-resistant products; and the expanding application base across professional trades, emergency services, and industrial sectors where reliable cutting tools are non-negotiable safety equipment. These factors collectively push manufacturers to innovate continuously, focusing on safety mechanisms, ease of use, and multi-functional integration, thereby sustaining demand growth across both consumer and commercial segments and representing a strong positive impact force on market valuation.

Conversely, the market faces notable restraints, predominantly stemming from the highly fragmented and often contradictory legal and regulatory landscape surrounding knife ownership and carry mechanisms (especially automatic and assisted openers) across different jurisdictions, which limits cross-border sales and necessitates complex product modifications. The market also suffers from persistent challenges related to counterfeiting and the influx of low-quality, inexpensive replicas, which dilute brand value, erode consumer trust in safety standards, and negatively impact the pricing power of legitimate, high-quality manufacturers. These restrictive forces necessitate extensive legal compliance efforts and continuous consumer education regarding product authentication, thereby slowing market expansion in heavily regulated or economically sensitive regions.

Significant opportunities exist, particularly in the realm of premiumization and specialization, where manufacturers can leverage innovative patented designs and superior materials to capture higher profit margins. The rising global interest in sustainable and ethically sourced manufacturing processes offers a clear pathway for differentiation, appealing to environmentally conscious consumers. Furthermore, market expansion into previously underserved segments, such as specialized culinary or high-precision medical utility applications requiring sterilized, non-corrosive folding tools, presents new revenue streams. The overarching impact forces dictate that success is contingent upon navigating regulatory complexity while capitalizing on technological innovation and maintaining stringent quality control to overcome competitive pressures from low-cost alternatives, favoring companies that invest heavily in R&D and intellectual property protection.

Segmentation Analysis

The Jackknife Market is comprehensively segmented based on several key operational and material characteristics, allowing for detailed market assessment tailored to specific end-user requirements and procurement preferences. Primary segmentation categories include mechanism type (Manual, Assisted Opening, Automatic), blade material (Stainless Steel, Carbon Steel, Super Steels, Ceramics/Exotics), and primary application (Every Day Carry (EDC), Tactical/Defense, Industrial/Construction, Outdoor/Survival). This structure provides a granular view of market dynamics, revealing that while manual locking knives dominate in terms of volume due to their universal legality and reliability, assisted and automatic knives command higher average selling prices in regions where they are permissible, due to the added convenience and speed they offer. The segmentation analysis is critical for manufacturers to tailor their product lines, distribution strategies, and pricing points effectively, targeting diverse niche markets ranging from budget-conscious utility users to high-spending collectors and tactical professionals.

The material segmentation reflects a crucial trend toward performance optimization, where specialized alloys like powdered metallurgy steels (e.g., CPM S30V, M390) are increasingly replacing traditional stainless steel in the mid-to-high-end segments, driven by consumer demand for exceptional edge retention and corrosion resistance. Conversely, the Industrial/Construction application segment prioritizes sheer toughness and ease of sharpening, often utilizing robust carbon steel or D2 tool steel. Application-based segmentation confirms that the Tactical/Defense segment maintains the highest product specifications and prices, requiring superior reliability under extreme conditions, whereas the EDC segment focuses on balancing functionality, aesthetics, and carry-ability (size and weight). Understanding these distinct segment preferences is essential for forecasting growth and allocating resources, as the profitability margins vary dramatically across these sub-markets, highlighting the market's specialized yet diverse nature.

- By Mechanism Type:

- Manual Folding Knives (Slip Joint, Lockback, Liner Lock, Frame Lock)

- Assisted Opening Knives (Spring Assisted)

- Automatic (Switchblade) Knives

- By Blade Material:

- Stainless Steel (440C, 8Cr13MoV)

- Carbon Steel (1095, D2 Tool Steel)

- Premium/Super Steels (S30V, M390, CPM-20CV)

- Exotic Materials (Titanium, Ceramic, Damascus)

- By Application:

- Every Day Carry (EDC)

- Tactical and Defense

- Outdoor and Survival (Hunting, Camping)

- Industrial and Construction Utility

- By End-User:

- Individual Consumers

- Military and Law Enforcement

- Industrial Enterprises

- Outdoor Professionals

Value Chain Analysis For Jackknife Market

The Value Chain of the Jackknife Market begins with upstream activities focused on the procurement and processing of raw materials. This initial stage is dominated by specialized steel mills and metallurgical firms that supply high-grade alloys, powdered metals, and handle materials such as G10, carbon fiber, aluminum, and titanium. The quality and purity of these raw inputs are paramount, directly influencing the final product's performance and price point. Key upstream challenges involve managing the volatility of raw material prices and securing specialized, high-performance alloys, which often require long lead times. Following material sourcing, manufacturing and assembly constitute the core value-adding processes, utilizing precision CNC machining, laser cutting, heat treatment specialization (cryogenic processing), blade grinding, and final assembly, where skilled labor ensures the precise tolerance of locking mechanisms. Efficient heat treatment is a critical competitive differentiator, as it determines the final hardness and edge retention of the blade, significantly impacting consumer value perception.

Midstream activities involve branding, packaging, quality assurance, and inventory management. Brands focus on cultivating a reputation for reliability and innovation, often protected by patents on specific locking mechanisms or design features. Downstream activities encompass the vast network of distribution channels that move the finished product to the end-user. Distribution is highly diversified, including direct channels through brand websites and proprietary stores, and indirect channels such as specialized knife retailers, major sporting goods stores, tactical gear outlets, and large e-commerce platforms like Amazon and specialized outdoor retailers. The selection of distribution channels heavily influences market reach and pricing strategy. High-end, premium brands often rely on certified dealers and specialized boutiques to maintain brand exclusivity and provide expert customer service, while mass-market utility knives utilize broad, high-volume retail networks.

Direct distribution, particularly via e-commerce, is gaining prominence as it allows manufacturers greater control over branding, pricing, and direct engagement with the consumer base, generating valuable feedback on design preferences. Indirect distribution channels, however, remain essential for physical visibility and immediate availability, particularly in industrial and retail environments. The overall efficiency of the value chain is determined by the manufacturer's ability to minimize material costs while maximizing the precision of the assembly process, ensuring patented locking systems are perfectly executed, and maintaining a robust, multi-faceted distribution system to effectively serve the geographically dispersed and functionally diverse global demand for jackknives. Successful players optimize logistics to reduce lead times from material processing to consumer delivery, especially crucial for rapidly iterating product designs.

Jackknife Market Potential Customers

The Jackknife Market serves an exceptionally broad and varied customer base, ranging from dedicated hobbyists and collectors to critical professional users in high-stakes environments. The primary end-users can be broadly categorized into individual consumers focused on Every Day Carry (EDC) and outdoor recreation, and institutional buyers represented by government agencies, military organizations, and large industrial firms. Individual consumers look for a balance of practicality, aesthetics, and reliability, often driven by personal preference for specific designers or locking mechanisms. These buyers utilize the product for general utility tasks, minor repairs, food preparation during camping, and personal readiness. This demographic often engages heavily with online communities and relies on peer reviews, making brand reputation and innovative features paramount drivers for purchase decisions and brand loyalty.

Institutional and professional buyers constitute the high-volume, high-specification segment of the market. Military and law enforcement agencies require knives that meet rigorous durability and safety standards, often specifying anti-glare coatings, specific blade materials suitable for extreme weather, and guaranteed reliable automatic opening mechanisms. For these large contracts, factors such as procurement logistics, guaranteed long-term supply, and adherence to defense standards (e.g., NSN assignment) are more important than aesthetic features. Similarly, professionals in construction, utilities, and telecommunications require heavy-duty utility knives designed for sustained, repetitive cutting tasks, prioritizing ease of replacement for utility blades, ergonomic grip for safety, and robust frame construction to withstand demanding worksite conditions, often procured in large quantities through specialized industrial supply distributors.

A crucial emerging customer segment includes professionals in niche fields requiring specialized tools, such as culinary students seeking portable, high-precision folding tools for on-the-go food preparation, or specialized rescue teams needing glass breakers and strap cutters integrated into their folding rescue knives. This specialization dictates that manufacturers must continuously engage with end-user communities to identify latent needs and develop highly application-specific products. The diversity of the customer base demands that market players offer a tiered product strategy, covering entry-level utility knives for mass consumption, mid-range quality models for outdoor enthusiasts, and ultra-premium, high-performance tactical knives for professional and collector segments, ensuring market penetration across all socio-economic and professional strata.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Benchmade Knife Company, Spyderco, KAI USA (Kershaw Knives, Zero Tolerance), Gerber Legendary Blades, Victorinox AG, Buck Knives, SOG Specialty Knives & Tools, Columbia River Knife & Tool (CRKT), Leatherman Tool Group, Boker USA, Cold Steel (GSM Outdoors), Protech Knives, Microtech Knives, Chris Reeve Knives, Hinderer Knives, LionSteel, FOX Knives, ZT Knives, ESEE Knives. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Jackknife Market Key Technology Landscape

The Jackknife Market is characterized by continuous technological innovation, primarily centered around three core areas: advanced metallurgy for superior blade performance, patented locking mechanisms for enhanced user safety, and sophisticated Computer Numerical Control (CNC) machining for high-precision manufacturing. In metallurgy, the use of powdered steels (e.g., Crucible Particle Metallurgy – CPM) is a defining technological trend. This process produces extremely fine-grained steel with highly uniform carbide distribution, resulting in blades that offer exceptional toughness, superior edge retention, and resistance to chipping, justifying premium pricing. Manufacturers utilize advanced heat treatment protocols, including deep cryogenic processes, to further optimize the crystalline structure of the steel, maximizing its performance characteristics far beyond what traditional rolling processes can achieve.

Safety and reliability hinge on proprietary locking mechanism technologies. Key innovations include the development and refinement of frame locks and liner locks, which provide robust blade security, and more complex mechanisms like Benchmade’s AXIS lock or Spyderco’s Compression lock, which allow for quick, secure, and ambidextrous operation while reducing the risk of accidental blade closure during heavy use. The integration of ceramic ball bearings or specialized washers (such as Teflon or bronze phosphor) into the pivot assembly is also a crucial technological advancement, ensuring buttery-smooth and rapid deployment of the blade, which is essential for assisted-opening and tactical models. This focus on smooth, high-tolerance movement improves the user experience and is a major differentiating factor in the high-end consumer segment.

Manufacturing technology, particularly high-precision, multi-axis CNC milling, is foundational to maintaining the stringent quality requirements of modern folding knives. These machines ensure ultra-tight tolerances on all mating surfaces, particularly the interface between the blade tang and the locking bar, which is vital for long-term safety and performance. Furthermore, advanced surface coatings, such as PVD (Physical Vapor Deposition) and DLC (Diamond-Like Carbon), are used to enhance corrosion resistance, reduce friction, and provide non-reflective surfaces critical for tactical applications. The combination of these technologies—material science, mechanical design innovation, and manufacturing precision—is what defines the competitive technology landscape, driving down defects and significantly extending the lifespan and utility of the finished product, making them reliable tools rather than just simple cutting instruments.

Regional Highlights

The global Jackknife Market demonstrates distinct regional characteristics driven by cultural factors, industrial needs, and regulatory environments concerning knife ownership and carry. North America, specifically the United States, represents the largest and most mature market, characterized by high consumer spending on outdoor recreational activities, a deeply embedded Every Day Carry (EDC) culture, and robust defense and law enforcement procurement. The demand here is driven by a strong preference for high-quality, high-performance American-made brands, particularly those featuring innovative locking systems and premium "super steels." Regulatory variations across U.S. states regarding automatic and assisted knives create localized market complexity, but overall, the region leads in innovation adoption and holds the highest average selling prices (ASPs) globally, acting as a crucial trendsetter.

Europe constitutes the second largest market, where demand is often split between traditional, heritage brands known for craftsmanship (such as Victorinox and Opinel) and modern tactical folding knives. Market fragmentation is a major challenge due to diverse and often strict national regulations regarding blade length, locking mechanisms, and one-handed operation. Countries like Germany and Switzerland maintain strong manufacturing bases focused on precision and multi-functional tools. The trend in Europe leans towards highly engineered, aesthetically pleasing designs that comply meticulously with local laws, prioritizing utility and legality over purely aggressive tactical features. Western Europe exhibits high demand in industrial maintenance and outdoor pursuits, while Eastern Europe shows growing interest in affordable utility models.

The Asia Pacific (APAC) region is projected to be the fastest-growing market, fueled by rapid industrialization, burgeoning middle-class disposable income, and increasing participation in outdoor activities across countries like China, India, and Australia. While APAC is a significant manufacturing hub for mass-market utility knives, domestic consumption is rising quickly, particularly for premium and branded imports from the US and Europe. The demand is heavily concentrated in industrial sectors (construction, manufacturing) requiring dependable, robust utility cutters. Furthermore, Latin America and the Middle East & Africa (MEA) are emerging markets, primarily driven by professional sectors (mining, oil & gas) and military/security needs, exhibiting growing potential but facing challenges related to economic instability and underdeveloped distribution channels.

- North America: Market leader, strong EDC adoption, high demand for premium tactical and high-performance steels; driven by military, law enforcement, and outdoor recreational segments.

- Europe: Mature market, characterized by regulatory constraints and strong demand for traditional heritage brands and precision-engineered utility knives; strong industrial and agricultural usage.

- Asia Pacific (APAC): Highest growth potential, driven by manufacturing expansion, infrastructure projects, and increasing consumer affluence; major focus on both mass-market utility and imported premium tactical gear.

- Latin America: Emerging market, demand concentrated in mining, construction, and security sectors; price sensitivity is high, favoring durable, mid-range products.

- Middle East and Africa (MEA): Growth driven by defense procurement and energy sector applications; focus on rugged, survival-oriented knives capable of enduring harsh environmental conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Jackknife Market, analyzing their product portfolios, technological patents, geographical footprint, and strategic initiatives.- Benchmade Knife Company

- Spyderco Inc.

- KAI USA Ltd. (Kershaw Knives & Zero Tolerance)

- Gerber Legendary Blades (Fiskars Group)

- Victorinox AG

- Buck Knives Inc.

- SOG Specialty Knives & Tools

- Columbia River Knife & Tool (CRKT)

- Leatherman Tool Group

- Boker USA Inc.

- Cold Steel (GSM Outdoors)

- Protech Knives

- Microtech Knives

- Hinderer Knives

- Chris Reeve Knives

- LionSteel

- FOX Knives

- Eickhorn-Solingen Limited

- Shun Cutlery

- WE Knife Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Jackknife market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the most significant factor driving the Jackknife Market growth?

The most significant growth driver is the increasing adoption of Every Day Carry (EDC) culture globally, alongside continuous advancements in material science that enhance blade durability, edge retention, and product safety features, making modern folding knives essential utility tools.

How do regulatory changes impact the sales of jackknives?

Regulatory changes, particularly those governing automatic and assisted-opening mechanisms and specific blade lengths, create significant market fragmentation. Strict regulations in certain regions restrict product import and sales, forcing manufacturers to develop region-specific, compliant manual folding designs.

What blade material provides the best balance of corrosion resistance and edge retention?

Premium powdered metallurgy stainless steels, such as CPM S30V or M390, offer the optimal balance. These materials provide high corrosion resistance due to their stainless content while maintaining superior edge retention and toughness compared to conventional stainless or carbon steels.

Which application segment holds the highest average selling price (ASP) in the market?

The Tactical and Defense application segment consistently holds the highest Average Selling Price (ASP). Products in this segment require stringent testing, proprietary locking mechanisms, and specialized materials suitable for extreme operational reliability, justifying premium pricing and specialized procurement.

Is the Jackknife Market seeing a shift towards automation in manufacturing?

Yes, the market is rapidly integrating high-precision multi-axis CNC machining and AI-driven quality control systems. This shift ensures tighter manufacturing tolerances, greater product consistency, reduced material waste, and faster R&D cycles for complex locking mechanisms and blade geometries.

The comprehensive analysis of the Jackknife Market highlights the criticality of innovation in material science, particularly the continuous exploration of new alloys and composite handles that minimize weight while maximizing mechanical properties. The consumer base is increasingly sophisticated, demanding tools that are not only functional but also aesthetically pleasing, leading to a strong push for custom and semi-custom production runs utilizing highly specialized manufacturing techniques. The high-performance segment relies heavily on patented technology related to pivot systems and locking mechanisms, treating these components as core intellectual property that provides a distinct competitive advantage in the professional and enthusiast markets. Marketing efforts are also highly segmented, often utilizing digital platforms and specialized influencer endorsements to reach niche communities such as bushcraft experts, military surplus collectors, and trade professionals. Regulatory risks associated with the proliferation of folding knives remain a constant challenge, requiring manufacturers to maintain fluid legal compliance strategies across various international jurisdictions. This regulatory pressure contributes to the demand for manual folding knives with highly secure locking mechanisms that avoid the legal complications associated with assisted or automatic mechanisms in specific geographies. Furthermore, the industrial application of specialized utility knives, often featuring replaceable blades for enhanced safety and reduced sharpening time, represents a stable revenue stream, contrasting with the often volatile demand cycles of the enthusiast collector segment. Long-term market sustainability is tied to the ability of key players to successfully transition towards more environmentally friendly manufacturing processes and ethically sourced materials, addressing the growing global emphasis on corporate social responsibility (CSR) and sustainable production practices. The convergence of utility, aesthetics, and mechanical reliability defines the modern Jackknife Market landscape, ensuring its continued evolution and sustained growth trajectory through the projected forecast period.

A deeper dive into the segmentation reveals crucial nuances in consumer behavior. For instance, the Every Day Carry (EDC) market is highly sensitive to overall size and weight, pushing manufacturers to develop ultra-lightweight designs utilizing titanium liners and carbon fiber scales. Conversely, the Survival and Outdoor segment places a premium on robustness, focusing on thicker blade stock, fixed-blade alternatives, or extremely heavy-duty folders designed to withstand batoning and prying actions. This disparity necessitates distinct engineering approaches and material choices for different product lines, optimizing performance for the intended use. In the domain of safety, technological advancements include double-locking mechanisms that require intentional two-step operation to close the blade, mitigating liability risks associated with accidental deployment or failure, a critical feature for professional-grade tools. The increasing sophistication of the supply chain allows for greater personalization options, with many premium brands offering custom handle materials, blade finishes, and even personalized laser etching, catering directly to the collector market which values uniqueness and exclusivity above utility alone. The emergence of 'smart' jackknives, while still nascent, explores integrating minimal electronics, such as non-obtrusive RFID tags for inventory tracking or tool accountability on industrial sites, paving the way for eventual AI-enhanced tool management systems. This dual focus—on perfecting the mechanical reliability of traditional tools and subtly integrating modern technological capabilities—ensures the long-term dynamism of the Jackknife Market, adapting to both traditional user demands and future digital workplace requirements.

Competitive analysis indicates that the market is moderately consolidated, with a few major brands holding significant market share through extensive patent portfolios and global distribution networks. However, the presence of numerous specialized custom knife makers and small-batch manufacturers ensures high competition in the premium segment, often driving innovation in design and materials that eventually trickle down to mass-market production. Strategies employed by market leaders include aggressive investment in intellectual property protection to combat the rampant issue of counterfeiting, which particularly plagues high-demand models. Geographic expansion, especially into high-growth potential regions like Southeast Asia and Latin America, is a key strategic imperative, often facilitated through establishing strong local distributor partnerships to navigate complex import tariffs and regulatory hurdles. Pricing strategies vary widely; while mass-market players compete aggressively on cost and volume, premium brands maintain high pricing through perceived value, warranty programs, and commitment to superior craftsmanship. The impact of e-commerce has been transformative, drastically reducing the barrier to entry for smaller custom makers and allowing specialized brands to bypass traditional retail channels, fostering direct relationships with their dedicated customer base. This digital shift requires robust SEO and AEO strategies to capture search traffic related to specific knife types, steels, and designers, ensuring visibility in a crowded online marketplace and maintaining brand equity in the digital domain. Furthermore, ongoing research into sustainable and recyclable materials, particularly for handle scales and packaging, is becoming a prerequisite for European market entry, signaling a broader industry commitment to environmental responsibility that will shape future product development cycles and supply chain management practices globally.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager