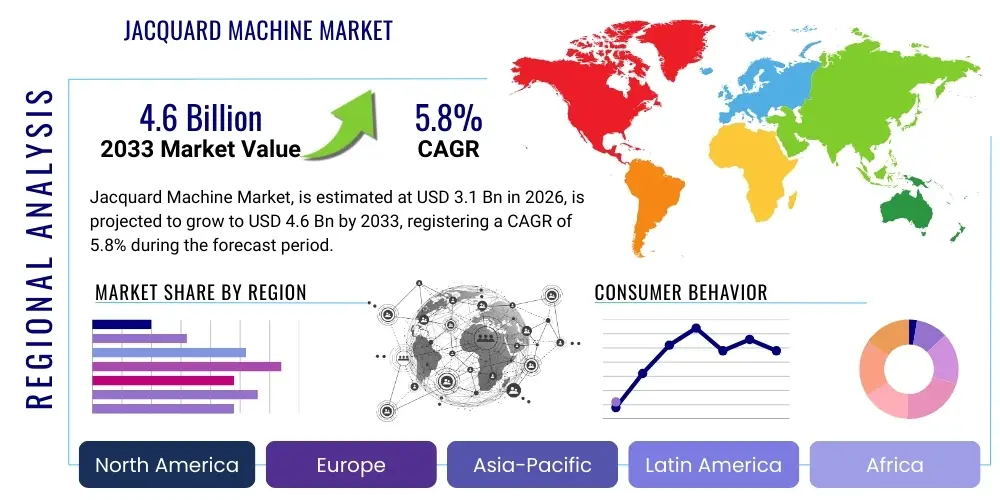

Jacquard Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437460 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Jacquard Machine Market Size

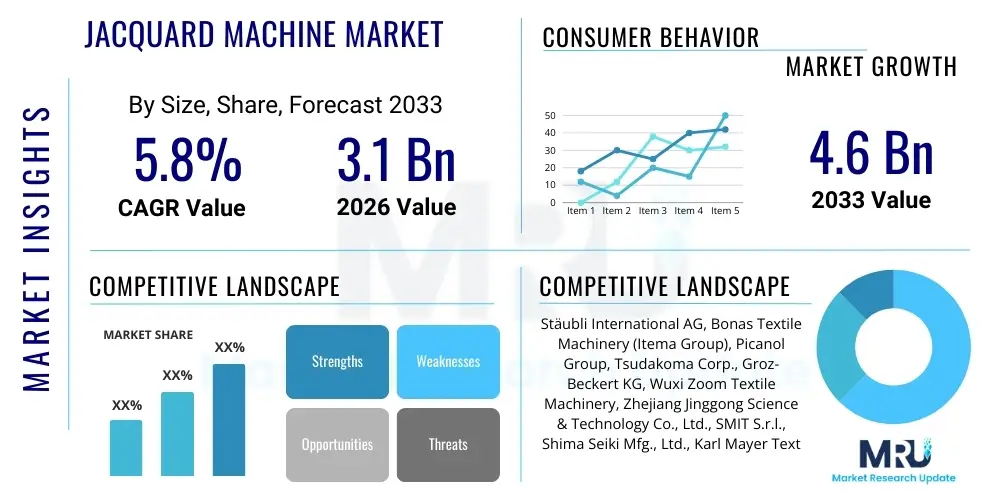

The Jacquard Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 3.1 Billion in 2026 and is projected to reach USD 4.6 Billion by the end of the forecast period in 2033. This substantial growth is primarily fueled by the accelerating demand for high-end, complex textile designs, particularly within the home furnishings and fashion industries globally. Increased investment in automation and digitalization across emerging Asian economies further boosts the replacement cycle of older mechanical systems with modern electronic Jacquard machines, ensuring productivity gains and design versatility.

Market expansion is intrinsically linked to technological advancements focusing on higher speeds, reduced energy consumption, and enhanced pattern management software. Modern electronic Jacquard machines offer unparalleled flexibility, allowing manufacturers to quickly adapt to rapidly changing consumer preferences and seasonal design demands. Furthermore, the rising awareness regarding sustainable and high-quality textiles, such as those used in technical applications like automotive interiors and specialized medical fabrics, positions the Jacquard technology as indispensable for intricate weaving requirements, thereby strengthening its market valuation throughout the forecast horizon.

Jacquard Machine Market introduction

Jacquard machines are highly specialized textile equipment used to control the lifting mechanism of individual warp threads on a loom, enabling the production of intricate, large-scale patterned fabrics such as brocade, damask, and tapestry. The modern Jacquard system, predominantly electronic, has revolutionized the weaving industry by replacing complex mechanical punch cards with sophisticated computer-aided design (CAD) systems, offering unlimited pattern complexity and rapid design changes. Major applications span high-end apparel, luxurious home textiles (curtains, upholstery, bedding), and the burgeoning segment of technical textiles that require precise and dense weaving structures. Key benefits include superior design flexibility, high production speed, significant labor reduction, and improved fabric quality consistency. Driving factors encompass globalization of the textile trade, increasing disposable incomes boosting demand for luxurious home decor, and continuous technological innovation focusing on integration with Industry 4.0 principles, such as predictive maintenance and IoT connectivity.

Jacquard Machine Market Executive Summary

The global Jacquard Machine Market is defined by a robust shift towards electronic mechanisms, driving superior efficiency and design capability across the weaving sector. Business trends indicate a focus on integration capabilities, where manufacturers are increasingly investing in seamless connectivity between CAD software, pattern preparation, and the loom itself, optimizing the entire textile production pipeline. Furthermore, the market is characterized by intense competition among European and Asian manufacturers, with innovation centered on high-speed operation (up to 2000 picks per minute) and reduced operational noise. Regional trends show that Asia Pacific, led by China and India, remains the dominant consumption and production hub, largely due to massive investments in modern textile mills and favorable governmental policies promoting textile export growth. Segment trends highlight the increasing dominance of the Electronic Jacquard category over the Mechanical segment, primarily because of the former's ability to handle highly detailed and complex designs required by the expanding technical textiles sector, such as geotextiles and carbon fiber preforms.

AI Impact Analysis on Jacquard Machine Market

User inquiries regarding Artificial Intelligence (AI) in the Jacquard Machine Market often revolve around predictive maintenance capabilities, pattern generation efficiency, and optimization of loom settings to minimize material waste. Users are keen to understand how AI algorithms can analyze historical performance data, identify anomalies in real-time, and forecast potential mechanical failures before they lead to costly downtime. Furthermore, there is significant interest in AI-driven design tools that can automate pattern modification based on specific fabric parameters or consumer trends, significantly reducing the time spent in the manual design phase. The overarching expectation is that AI integration will lead to unprecedented levels of operational efficiency, quality consistency, and accelerate the design-to-production cycle, ensuring manufacturers maintain competitive edge in a fast-paced global market by optimizing complex variables such as yarn tension, shed timing, and needle selection.

- AI enhances predictive maintenance by analyzing vibration and temperature data from Jacquard heads, forecasting component failure and maximizing uptime.

- Machine Learning (ML) algorithms optimize weaving parameters, such as speed and tension, based on yarn type and complexity, reducing fabric defects.

- AI facilitates automated pattern generation and color matching, significantly accelerating the textile design process based on inputted market trends and constraints.

- Implementation of deep learning models improves quality control by autonomously identifying minute weaving inconsistencies that human inspection might overlook.

- AI-powered inventory management systems predict yarn usage rates and optimize supply chain logistics specific to high-volume Jacquard production orders.

DRO & Impact Forces Of Jacquard Machine Market

The dynamics of the Jacquard Machine Market are dictated by a balanced interplay of drivers (D), restraints (R), and opportunities (O), creating distinct impact forces. Key drivers include the escalating global demand for ornamental and high-quality textiles across residential and commercial sectors, coupled with the necessity for textile manufacturers to upgrade to high-speed electronic equipment to remain competitive. Restraints predominantly involve the substantial initial capital investment required for electronic Jacquard looms and the pervasive skill gap concerning the operation and sophisticated maintenance of these digital systems, particularly in developing regions. Opportunities arise from the rapidly expanding market for technical textiles, which mandate the intricate weaving capabilities offered exclusively by Jacquard technology, and the advent of Industry 4.0, which allows for advanced integration and data utilization, ensuring high precision in specialized applications.

Segmentation Analysis

The Jacquard Machine Market is segmented based on critical technical specifications and applications, providing a clear framework for understanding market dynamics and competitive positioning. Segmentation allows stakeholders to analyze growth pockets within the textile industry, focusing on areas with high technological adoption or significant volume demand. Key segments include the differentiation between mechanical and electronic drive systems, the complexity of patterns measured by hook capacity, the speed of operation, and the end-user application which significantly influences the required machine specification and robustness.

- By Mechanism:

- Electronic Jacquard Machines

- Mechanical Jacquard Machines

- By Hook Capacity:

- Up to 2,000 Hooks

- 2,001 to 10,000 Hooks

- Above 10,000 Hooks (High-Density)

- By Application:

- Apparel and Clothing

- Home Furnishings (Upholstery, Curtains, Bedding)

- Technical Textiles (Automotive, Medical, Geotextiles)

- By End-User:

- Large-Scale Textile Mills

- SMEs and Custom Weavers

Value Chain Analysis For Jacquard Machine Market

The value chain for the Jacquard Machine Market begins with upstream activities, primarily encompassing the procurement of specialized components such as high-precision electronic modules, complex harness cords, magnetic selectors, and advanced CAD/CAM software necessary for design input. Key upstream suppliers include specialized electronics manufacturers and high-grade metal component providers focused on durability and speed. The core manufacturing phase involves sophisticated assembly, testing, and quality control of the entire Jacquard head and its synchronization with various loom types (rapier, air-jet, or water-jet), requiring high levels of engineering expertise, typically concentrated in Europe and specific parts of Asia.

Downstream analysis focuses on the distribution and end-user adoption. Distribution channels are typically a mix of direct sales through dedicated regional offices of major manufacturers and indirect sales via established distributors or specialized textile machinery agents who provide crucial after-sales service and technical support. Direct channels are preferred for large, strategic customers requiring highly customized solutions, while indirect channels serve a broader market, particularly SMEs. The ultimate output feeds into high-value textile manufacturing sectors worldwide, where the performance and reliability of the Jacquard machine directly impact the quality and marketability of the finished fabric.

The post-sale service component, including maintenance, spare parts supply, and operator training, forms a critical part of the downstream value proposition, influencing customer loyalty and repeat purchases. As machines become more digitized, the provision of software updates, remote diagnostics, and data analytics services are becoming integral to the value chain, shifting the focus from transactional sales to long-term service relationships. This dependency necessitates strong collaboration between manufacturers and regional service partners to ensure rapid response times and technical proficiency, especially given the continuous operation required in large textile production facilities.

Jacquard Machine Market Potential Customers

Potential customers for Jacquard machines are diverse, ranging from large, globally integrated textile corporations to specialized, boutique weaving houses focused on niche luxury products. The primary buyer segment consists of high-volume textile mills specializing in the production of interior decoration fabrics, including heavy upholstery, drapery, and high thread-count bedding, where intricate patterns are a defining feature. Another critical customer segment is manufacturers of luxury fashion fabrics, such as silk or rayon brocades and damasks, demanding machines with very high hook capacity and precision to execute complex, multi-color designs that command premium prices in the retail market.

An increasingly important customer base lies within the technical textile sector. Companies producing specialized industrial fabrics, such as multi-layer automotive airbag materials, complex 3D woven structures for composites in aerospace, or medical textiles, are premium buyers of the most advanced electronic Jacquard systems. These applications require extreme accuracy, durability, and often non-conventional fiber types (e.g., carbon fiber, aramid), necessitating state-of-the-art machinery capable of precise control over thousands of individual warps. Geographically, these customers are heavily concentrated in Asia Pacific and parts of Europe, aligning with global manufacturing trends and technological adoption rates.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.1 Billion |

| Market Forecast in 2033 | USD 4.6 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Stäubli International AG, Bonas Textile Machinery (Itema Group), Picanol Group, Tsudakoma Corp., Groz-Beckert KG, Wuxi Zoom Textile Machinery, Zhejiang Jinggong Science & Technology Co., Ltd., SMIT S.r.l., Shima Seiki Mfg., Ltd., Karl Mayer Textilmaschinenfabrik GmbH, Dornier GmbH, Murata Machinery, Ltd., Comez International S.r.l., Jakob Müller AG, Suzhou Tongli Textile Machinery Co., Ltd., Jinsheng Group, Hangzhou Kaier Textile Machinery Co., Ltd., Zhejiang Taitan Co., Ltd., Jiangsu Ningyue Sci & Tech Co., Ltd., ATE Textile Machinery. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Jacquard Machine Market Key Technology Landscape

The contemporary Jacquard Machine Market is defined by the dominance of advanced electronic control systems utilizing magnetic selectors or piezoelectric actuators, which allow for significantly higher speeds and greater reliability compared to historical mechanical systems. Key technological breakthroughs center on the hook driving mechanism, where manufacturers are increasingly using proprietary linear motor technology to reduce maintenance and enhance the precision of the shedding cycle. Integration of sophisticated Computer-Aided Design (CAD) software, such as sophisticated pattern creation suites, is mandatory, enabling designers to translate complex digital patterns directly into machine instructions, thereby drastically reducing sample turnaround time and facilitating complex 3D weaving structures.

Another crucial technological development involves the continuous increase in hook capacity, with leading manufacturers offering systems exceeding 20,000 hooks, allowing for the creation of extremely wide and highly detailed fabrics required in technical textile applications like composites or complex wall coverings. Furthermore, the market is adopting Industry 4.0 standards, incorporating sensors and IoT connectivity for real-time monitoring of machine performance, energy consumption, and thread tension. This digitalization facilitates predictive maintenance scheduling and remote diagnostics, ensuring maximum operational efficiency and minimal production downtime in competitive manufacturing environments.

The focus on sustainability also drives innovation, specifically in developing energy-efficient drive systems and lightweight yet robust materials for the Jacquard head construction. Manufacturers are also developing modular systems that allow textile companies to easily upgrade or expand their existing Jacquard capabilities without replacing the entire loom. This technological flexibility, combined with software enhancements that optimize yarn consumption and minimize waste during pattern changes, underscores the industry's commitment to efficiency and environmental responsibility, solidifying the market's trajectory towards high-tech manufacturing solutions.

Regional Highlights

The regional analysis of the Jacquard Machine Market reveals significant disparity in adoption rates and manufacturing capabilities, largely driven by local textile industry maturity and economic growth profiles.

- Asia Pacific (APAC): APAC is the unequivocally dominant region in both consumption and production of Jacquard machines, led primarily by China, India, and Turkey. This dominance stems from the region's position as the global manufacturing hub for textiles, driven by low labor costs, strong government support for textile exports, and massive domestic demand for apparel and home furnishings. China, in particular, showcases high adoption rates of the latest high-speed electronic Jacquard models as manufacturers aggressively modernize their production lines to meet global quality standards.

- Europe: Europe remains a critical market, characterized less by volume and more by value and technological leadership. Countries like Italy, Germany, and Switzerland host major global Jacquard machine manufacturers (OEMs). The demand here is concentrated on high-end, specialized machinery, particularly for sophisticated technical textiles, luxury fashion, and innovative composites, where precision and quality outweigh cost considerations.

- North America: The North American market is relatively mature, with demand focused primarily on replacement machinery and advanced systems for niche, high-value technical textile applications (e.g., aerospace, defense). Although domestic textile manufacturing has decreased, the surviving companies invest heavily in automation and high-efficiency Jacquard systems to maintain competitive pricing and product differentiation.

- Latin America: This region shows moderate growth potential, driven by textile revitalization in countries like Brazil and Mexico. Demand is price-sensitive, often favoring reliable, mid-range electronic Jacquard machines suitable for producing commodity home textiles and general apparel for regional consumption.

- Middle East and Africa (MEA): Growth in MEA is slow but steady, primarily concentrated in Turkey (already covered under APAC/Europe influence) and certain regions aiming to establish local manufacturing capabilities. Investment in Jacquard technology is closely tied to establishing domestic capacity for high-quality fabrics, reducing reliance on imported goods, particularly in key home furnishing segments.

APAC’s leadership is projected to intensify due to continuous governmental initiatives supporting textile parks and large-scale manufacturing unit establishment, making it the primary target market for new machine sales. The competitive landscape in this region is characterized by aggressive pricing strategies from local manufacturers who are rapidly closing the technology gap with European counterparts, focusing on robust after-sales support and regional customization.

Europe, while smaller in volume, dictates the direction of technological innovation. European manufacturers focus heavily on R&D for piezoelectric actuation, higher hook density, and advanced software integration capabilities. Their market strategy is based on providing solutions for highly specific, high-specification applications, ensuring their profitability relies on technological superiority rather than sheer scale. This dynamic divergence between high-volume APAC and high-tech Europe defines the global market equilibrium.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Jacquard Machine Market.- Stäubli International AG

- Bonas Textile Machinery (Itema Group)

- Picanol Group

- Tsudakoma Corp.

- Groz-Beckert KG

- Wuxi Zoom Textile Machinery

- Zhejiang Jinggong Science & Technology Co., Ltd.

- SMIT S.r.l.

- Shima Seiki Mfg., Ltd.

- Karl Mayer Textilmaschinenfabrik GmbH

- Dornier GmbH

- Murata Machinery, Ltd.

- Comez International S.r.l.

- Jakob Müller AG

- Suzhou Tongli Textile Machinery Co., Ltd.

- Jinsheng Group

- Hangzhou Kaier Textile Machinery Co., Ltd.

- Zhejiang Taitan Co., Ltd.

- Jiangsu Ningyue Sci & Tech Co., Ltd.

- ATE Textile Machinery

Frequently Asked Questions

Analyze common user questions about the Jacquard Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between electronic and mechanical Jacquard machines?

Electronic Jacquard machines utilize microprocessors and magnetic or piezoelectric selectors to control warp threads, offering unlimited pattern size, high operating speeds, and rapid design changes via computer interface. Mechanical Jacquard machines, now largely obsolete, rely on physical punch cards and levers, limiting design complexity and speed while requiring extensive manual pattern preparation.

Which application segment drives the highest demand for advanced Jacquard technology?

The Technical Textiles segment, encompassing automotive interiors, medical textiles, and specialized composites, drives the highest demand for the most technologically advanced electronic Jacquard machines. These applications require extremely high hook capacity, precise control, and the ability to weave high-performance, non-conventional fibers accurately.

How does the integration of Industry 4.0 affect Jacquard machine operations?

Industry 4.0 integration enhances Jacquard operations through IoT connectivity, enabling real-time performance monitoring, remote diagnostics, and predictive maintenance using data analytics. This integration drastically reduces unscheduled downtime, optimizes energy consumption, and improves overall equipment effectiveness (OEE).

What are the key restraint factors limiting market growth?

The primary restraint is the significant upfront capital expenditure required for purchasing modern, high-speed electronic Jacquard machines, particularly impacting Small and Medium Enterprises (SMEs). Additionally, the lack of highly skilled technicians capable of maintaining and operating complex digitized systems in certain developing markets poses a persistent constraint.

Which regional market is expected to demonstrate the fastest growth rate for Jacquard machine adoption?

The Asia Pacific (APAC) region, particularly driven by modernization efforts in India and continued textile expansion in China and Vietnam, is expected to exhibit the fastest growth rate. This rapid adoption is fueled by large-scale investments in new weaving plants and the necessity to replace older mechanical looms with efficient electronic models to meet global textile quality demands.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager