Jelly Filled Cables Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434425 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Jelly Filled Cables Market Size

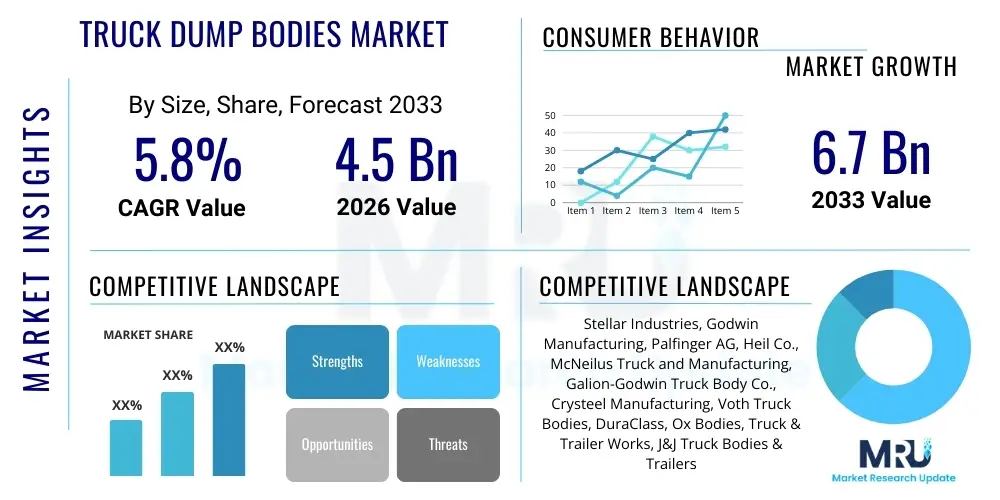

The Jelly Filled Cables Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.22 Billion by the end of the forecast period in 2033.

Jelly Filled Cables Market introduction

Jelly filled cables, predominantly utilized in telecommunication and data transmission networks, are designed to withstand harsh environmental conditions, specifically moisture ingress. These cables incorporate a petroleum-based filling compound, often a gel or grease, within the interstices of the conductor bundle or optical fibers. This hydrophobic jelly acts as a water-blocking agent, preventing water migration along the cable length, which is crucial for maintaining signal integrity and cable longevity, particularly in buried or duct applications. The robust protective measures inherent in their design make them indispensable components in extending reliable connectivity, forming the backbone of traditional fixed-line infrastructure and certain industrial control systems where moisture resistance is paramount.

The core utility of jelly filled cables spans across various critical sectors, driven primarily by the global necessity for robust and uninterrupted communication services. Major applications include subscriber loop access networks, local area networks (LANs) requiring underground installation, and specific military or industrial environments where standard dry cables would fail due to condensation or immersion risks. The demand is intrinsically linked to infrastructure development initiatives, especially in emerging economies focused on expanding their copper-based or early-stage fiber-to-the-home (FTTH) deployments. Furthermore, their relatively low cost compared to highly specialized armored cables, combined with excellent reliability in moist environments, solidifies their position in legacy network upgrades and maintenance activities.

Key market driving factors include the continuous expansion of global telecommunications infrastructure, particularly in regions still relying heavily on copper infrastructure for the last mile connection, and the increasing investment in underground utility networks designed for longevity. The principal benefit of these cables lies in their unparalleled resistance to moisture, which drastically reduces maintenance costs and service interruptions over the cable's lifespan. While fiber optic deployment is rapidly replacing copper, jelly filled cables continue to see sustained demand in hybrid networks, rural connectivity projects, and specific industrial control applications where electromagnetic interference shielding provided by copper is essential. The balance between cost-effectiveness and high environmental protection remains the central attractive proposition for system integrators and telecom operators globally.

Jelly Filled Cables Market Executive Summary

The Jelly Filled Cables Market demonstrates resilient growth, primarily fueled by ongoing global efforts to modernize legacy telecommunication infrastructure and the continued necessity for highly durable, moisture-resistant cabling solutions in critical utility sectors. Current business trends indicate a bifurcated demand structure: mature markets primarily focus on maintenance, replacement, and hybrid network optimization, while developing regions prioritize large-scale deployment to bridge connectivity gaps, driving significant volume growth, particularly for standard copper paired cables. Geographically, Asia Pacific remains the dominant growth engine, propelled by aggressive fixed-line expansion and urbanization projects that necessitate extensive underground cabling. Technological stagnation regarding the jelly compound itself contrasts with advancements in jacketing materials and manufacturing efficiency, aimed at reducing weight and installation complexity.

Regional dynamics heavily influence consumption patterns and product specifications. North America and Europe, characterized by established fiber networks, see sustained, albeit moderated, demand for specialized jelly filled cables in industrial settings, challenging environments, and remote rural areas where trenching and burial are common. Conversely, Latin America and Africa represent high-potential markets where the foundational build-out of voice and basic data services relies heavily on cost-effective, durable copper cabling, underpinning the consistent demand for jelly filled products. These regions are also witnessing the transition from aerial to buried cables in urban centers to improve aesthetic and network security, further boosting the adoption rates of filled cable types.

Segment trends reveal that while copper conductor cables still hold the largest market share due to historical deployment volumes and their necessity in DSL and traditional telephony, the fastest growth is observed in the fiber optic segment where jelly filling is used for protection in loose-tube designs intended for direct burial. By application, the telecommunications sector remains overwhelmingly dominant, yet utility and infrastructure segments (e.g., traffic control, signaling, and specialized sensor networks) are demonstrating accelerated adoption. The strategic focus of manufacturers is shifting towards creating environmentally friendly jelly alternatives (non-petroleum-based) and enhancing the cable jacket's resistance to UV and rodents, ensuring product relevance in a world increasingly dominated by FTTH initiatives.

AI Impact Analysis on Jelly Filled Cables Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Jelly Filled Cables Market predominantly revolve around network optimization, predictive maintenance, and the secondary effects of AI-driven infrastructure demand. Key concerns focus on whether AI-managed fiber networks will completely phase out copper, or if AI tools can enhance the lifespan and performance of existing copper-based, jelly filled assets. Users also seek clarity on how AI-powered geospatial analysis and deployment planning might reduce installation costs and time for new underground jelly filled infrastructure. The consensus emerging from this analysis is that AI does not directly replace the product but rather optimizes the infrastructure surrounding it, particularly by enabling sophisticated condition monitoring, fault prediction (e.g., detecting minor moisture breaches before catastrophic failure), and streamlining supply chain logistics for replacement and repair parts, thus indirectly influencing inventory and operational expenditure management for network operators maintaining large fleets of these cables.

- AI-driven predictive maintenance forecasts cable failures by analyzing environmental sensor data, extending the service life of installed jelly filled cables.

- Geospatial AI optimizes cable route planning for underground installations, minimizing material waste and installation complexity.

- AI enhances supply chain management for jelly filled cable components and replacement stock, improving inventory efficiency for global network operators.

- Advanced AI analytics assist in managing hybrid networks (copper and fiber), optimizing traffic flow and extending the economic viability of existing jelly filled copper infrastructure.

- Machine learning algorithms are being employed in quality control during the manufacturing process, ensuring consistent jelly filling distribution and material integrity.

DRO & Impact Forces Of Jelly Filled Cables Market

The market is predominantly driven by the critical need for resilient communication infrastructure in harsh environments, especially underground and aerial deployments susceptible to water damage and high humidity. The consistent demand stems from infrastructure maintenance and upgrades in vast existing copper networks, where replacing a segment of legacy infrastructure with an equivalent, moisture-resistant jelly filled cable is often more cost-effective than undertaking a full fiber conversion. Furthermore, emerging economies are heavily investing in fixed-line connectivity expansion, utilizing jelly filled cables for robust, immediate deployment solutions. These drivers are intrinsically linked to government-backed initiatives aiming to achieve universal access to telecommunications services, ensuring a stable foundational demand for durable cabling solutions.

Restraints in the market largely center on the accelerating technological substitution by fiber optic cables, which offer vastly superior bandwidth and reduced susceptibility to electromagnetic interference, minimizing the need for the high environmental protection provided by jelly compounds in new primary deployments. Additionally, environmental concerns regarding the petroleum-based filling compound, which can complicate recycling and disposal, pose a regulatory challenge in developed markets, pushing operators toward 'dry' water-blocking cable designs that use tapes or powders instead of gel. Volatility in raw material prices, specifically copper and the polymers used for jacketing, also imposes cost pressures on manufacturers, potentially hindering market expansion by increasing the final product cost.

Significant opportunities exist in developing highly customized jelly filled cables for specialized industrial networks, such as those in mining, petrochemicals, and railway signaling, where extreme operational conditions necessitate high durability and moisture resistance beyond standard specifications. The transition to non-petroleum, eco-friendly filling compounds represents a major opportunity for market differentiation and compliance with stricter environmental regulations (RoHS, REACH). Impact forces, such as rapid urbanization and increased spending on smart city infrastructure, mandate the shift of utility lines underground, which directly increases the requirement for environmentally protected cables like the jelly filled variety. Simultaneously, stringent regulatory mandates related to network uptime and reliability compel operators to utilize the most durable cabling solutions available, reinforcing the foundational demand despite technological substitution trends.

Segmentation Analysis

The Jelly Filled Cables Market is segmented based on the critical parameters of conductor material, cable type, and the ultimate application sector, providing a granular view of demand distribution and growth dynamics. The core segmentation revolves around the shift from traditional copper conductors to advanced fiber optics, reflecting the evolving technological landscape of telecommunication infrastructure. Analyzing these segments helps stakeholders understand where immediate volume growth (copper-based legacy maintenance) contrasts with future high-value expansion (specialized fiber optic applications requiring robust environmental protection).

- By Conductor Material:

- Copper Conductor (Twisted Pair)

- Fiber Optic (Loose Tube Design)

- By Cable Type:

- Single Jacket Cables

- Double Jacket Cables (Armored/Non-Armored)

- Drop Cables

- By Application:

- Telecommunication (Access Networks, Subscriber Loops)

- Industrial Control Systems

- Utility Infrastructure (Power Grid Monitoring, Signaling)

- Railway & Traffic Management

- Oil & Gas and Mining

Value Chain Analysis For Jelly Filled Cables Market

The value chain for jelly filled cables begins with the procurement of critical raw materials, primarily high-grade copper rods or optical fiber preforms, polyethylene/PVC compounds for jacketing, and the specialized hydrophobic filling jelly (petroleum distillates, silicone-based gels). Upstream activities are dominated by large commodity suppliers, where cost fluctuations in copper or crude oil significantly influence the final cable price. Manufacturers must maintain strong supplier relationships and utilize hedging strategies to mitigate volatility. The quality control at the material input stage, especially ensuring the purity and viscosity of the jelly filling, is paramount to the cable’s long-term performance and water-blocking effectiveness.

Midstream activities involve the complex manufacturing processes, including drawing the conductor, insulating individual pairs, twisting, stranding, and critically, injecting the jelly compound under controlled pressure to ensure complete interstitial filling without voids. This process requires specialized extrusion and filling machinery. Companies often invest heavily in highly automated production lines to achieve economies of scale and maintain strict tolerances. Downstream, the value chain focuses on distribution and installation. Cables move from manufacturers through large industrial distributors, specialized telecom equipment suppliers, or directly to major network operators (Direct). Indirect channels involve distributors serving smaller ISPs, private enterprises, and regional utility contractors, who require immediate access to smaller volumes and specialized lengths. Effective logistics and warehousing are crucial due to the bulk and weight of the final product.

The final stage involves the system integrators, civil engineering contractors, and telecom operators who install and maintain the cables. Direct sales are often preferred by large Tier 1 operators for bulk orders, allowing manufacturers to offer customized specifications and direct technical support. Indirect distribution, though sometimes adding margin layers, provides necessary market penetration, geographical reach, and localized inventory management, particularly important in vast regions like APAC or MEA. The profitability across the chain is often concentrated at the manufacturing stage for proprietary or specialized armored cables, while the distribution stage focuses on service quality, rapid delivery, and providing complementary installation accessories and tools.

Jelly Filled Cables Market Potential Customers

The primary customers for jelly filled cables are entities responsible for establishing, maintaining, and expanding fixed communication infrastructure, particularly those operating in environments prone to moisture ingress. Telecommunication carriers and network operators, ranging from large Tier 1 incumbents maintaining extensive legacy copper networks (e.g., DSL lines and traditional voice services) to newer regional ISPs expanding fixed wireless access (FWA) backhaul or short-distance fiber links, constitute the largest buyer group. These customers prioritize cable durability, longevity, and compliance with strict water penetration standards, as network downtime directly translates to significant revenue losses and regulatory penalties.

Another crucial customer segment includes government utilities and public infrastructure agencies. This encompasses electric power utilities utilizing cables for SCADA systems and monitoring sensors, municipal traffic control departments requiring reliable underground signaling cables, and railway authorities needing robust communication and signaling lines that can withstand vibration and high humidity in tunnels and ballast beds. For these buyers, the non-negotiable requirements are high reliability in critical safety applications and resistance to environmental factors that would compromise standard cables, making the moisture-proof jelly filling essential for sustained operation.

Furthermore, specialized industrial sectors such as mining, petrochemical refining, and heavy manufacturing represent significant niche buyers. In these hazardous or extreme environments—where cables are often exposed to aggressive chemicals, high moisture levels, or potential flooding—jelly filled cables are deployed for critical control systems and internal communication backbones. Finally, civil engineering firms and large-scale infrastructure project developers act as indirect buyers, purchasing the cables on behalf of end-clients for major projects like new residential developments, industrial parks, or large-scale utility trenching operations where the installation environment necessitates robust environmental protection.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.22 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Prysmian Group, Nexans, Sumitomo Electric, LS Cable & System, Corning Inc., General Cable (now part of Prysmian), Sterlite Technologies, Belden Inc., Furukawa Electric, CommScope, ZTT Group, Polycab India, KEI Industries, Southwire Company, HFCL, Amphenol Corporation, AFL (Fujikura), TE Connectivity, B3 Cable Solutions, Excelitas Technologies. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Jelly Filled Cables Market Key Technology Landscape

The technology landscape for jelly filled cables is primarily focused on enhancing the environmental resistance characteristics, improving installation efficiency, and mitigating the ecological footprint associated with the filling compound. A key area of innovation involves the development of advanced hydrophobic gels. While traditional jellies are petroleum-based, there is a distinct shift toward synthetic or semi-synthetic gels that maintain excellent water-blocking properties while being easier to remove, non-toxic, and often exhibiting better temperature stability across a wider operating range. Furthermore, manufacturers are employing sophisticated compound formulations to reduce the stickiness of the jelly, which streamlines the splicing and termination process, reducing installer labor time and costs—a critical factor for large-scale field deployments.

Material science advancements extend significantly into the cable jacket and armor technologies. For direct burial applications, multi-layered jacketing utilizing high-density polyethylene (HDPE) reinforced with UV stabilizers and, increasingly, rodent-resistant additives (such as fiberglass yarns or specialized chemical compounds embedded in the outer sheath) is becoming standard. For copper jelly filled cables, the technology is stable, focusing on precision manufacturing of twisted pairs to maximize transmission performance (reducing crosstalk and enabling higher DSL speeds) before the jelly infusion stage. The integration of moisture barrier tapes (often aluminum laminate) underneath the jacket, in conjunction with the jelly filling, provides a dual layer of defense against longitudinal water ingress, crucial for maintaining long-term service integrity in challenging subterranean conditions.

Within the fiber optic segment of the jelly filled market (primarily loose tube designs), the technological focus is on optimizing tube strength and minimizing signal attenuation caused by macrobending or microbending stress induced by the filling material or external pressure. Modern loose tubes are often filled with thixotropic jelly that minimizes movement of the fibers while maintaining flexibility during installation. Precision manufacturing allows for high fiber counts within a compact, jelly-filled core, enabling efficient bandwidth deployment without sacrificing the rugged protection offered by the filling compound. Overall, the technology is characterized by incremental improvements aimed at durability, installation ergonomics, and environmental compliance rather than radical paradigm shifts.

Regional Highlights

- Asia Pacific (APAC): APAC is the largest and fastest-growing regional market, driven by massive government investments in fixed broadband infrastructure, particularly in countries like India, China, and Southeast Asian nations. The high population density, coupled with ongoing urbanization and the necessity of deploying cables in often humid or water-logged environments, ensures consistent high-volume demand for jelly filled copper and fiber cables. This region utilizes jelly filled cables extensively for last-mile connectivity and regional backbone deployment where cost-effectiveness and robustness are primary concerns.

- North America: The market in North America is mature, characterized by high replacement demand and specialized applications. While new large-scale trunk deployments utilize dry fiber designs, jelly filled cables remain critical for utility and energy sectors, remote rural connectivity projects (where direct burial is preferred), and legacy network maintenance. The focus here is on high-performance armored jelly filled fiber cables used in severe weather zones and areas requiring robust physical protection against mechanical damage and moisture intrusion.

- Europe: European demand is driven by the strict regulations requiring high network reliability and the continuous upgrading of existing municipal utility networks. There is a strong regional trend toward environmentally sustainable materials, pushing manufacturers to innovate non-petroleum based or 'low-oozing' jelly compounds. Eastern Europe, currently undergoing significant infrastructure modernization, shows higher growth rates for standard copper jelly filled cables compared to the highly saturated and fiber-dominant Western European markets.

- Latin America: This region presents a strong growth potential characterized by increasing telecommunications penetration and infrastructure build-out in urban and remote areas. The challenging geographical conditions, including heavy rainfall and subterranean water tables, necessitate the use of jelly filled cables for robust network longevity. Market activity is marked by competitive pricing and a high demand for standard copper cables used in expanding basic telephony and early-stage DSL services.

- Middle East and Africa (MEA): The MEA market is dynamic, propelled by major investments in smart city projects and oil and gas infrastructure expansion. In the Middle East, high temperatures and dust require specialized jacket materials, yet the requirement for water blocking remains critical in coastal or below-ground utility trenches. In Africa, rapid mobile backhaul deployment and foundational fixed-line expansion create significant opportunities for cost-effective, durable jelly filled copper cables, necessary for enduring harsh desert and often humid coastal environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Jelly Filled Cables Market.- Prysmian Group

- Nexans

- Sumitomo Electric Industries, Ltd.

- LS Cable & System Ltd.

- Corning Inc.

- General Cable (now part of Prysmian)

- Sterlite Technologies Ltd.

- Belden Inc.

- Furukawa Electric Co., Ltd.

- CommScope Holding Company, Inc.

- ZTT Group

- Polycab India Limited

- KEI Industries Limited

- Southwire Company, LLC

- HFCL Limited

- Amphenol Corporation

- AFL (Fujikura Ltd.)

- TE Connectivity Ltd.

- B3 Cable Solutions

- Excelitas Technologies Corp.

Frequently Asked Questions

Analyze common user questions about the Jelly Filled Cables market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of the jelly filling in communication cables?

The primary function of the jelly filling, typically a non-toxic hydrophobic compound, is to serve as a water-blocking agent. It fills the air gaps within the cable core, preventing the longitudinal migration of moisture. This ensures the protection of copper conductors or optical fibers from water ingress, which is critical for maintaining signal integrity and cable lifespan, especially in underground or direct burial applications.

Are jelly filled cables being replaced entirely by dry fiber optic designs?

While new, high-bandwidth trunk deployments often favor dry fiber optic designs, jelly filled cables maintain strong market relevance. They are indispensable for maintaining vast legacy copper networks (DSL, telephony), highly reliable industrial control systems, and specialized direct burial fiber optic applications where superior environmental protection against moisture and physical damage is non-negotiable and cost-effective.

What are the environmental concerns associated with traditional jelly filled cables?

Traditional jelly filling utilizes petroleum-based compounds, which raise environmental concerns regarding biodegradability and disposal, complicating cable recycling processes. This has driven market innovation towards developing and adopting eco-friendly, synthetic, or non-petroleum-based filling gels that offer comparable water-blocking properties while minimizing environmental impact and improving ease of installation.

Which regions demonstrate the highest growth potential for the Jelly Filled Cables Market?

The Asia Pacific (APAC) region exhibits the highest growth potential, fueled by extensive government-backed infrastructure projects and rapid expansion of fixed-line telecommunication access in emerging economies. The high demand for robust, cost-effective, and moisture-resistant cabling solutions for both copper and fiber deployments underpins this regional dominance.

What types of applications specifically require the use of jelly filled cables?

Jelly filled cables are mandatory for applications involving high moisture risk, including direct burial installations, cables run through underground conduits and ducts susceptible to condensation, and aerial cables that must withstand prolonged exposure to humidity and rainfall. Key sectors include telecommunication subscriber loops, railway signaling, and industrial control systems in mining and utility infrastructure.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager