Joystick Handle Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433753 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Joystick Handle Market Size

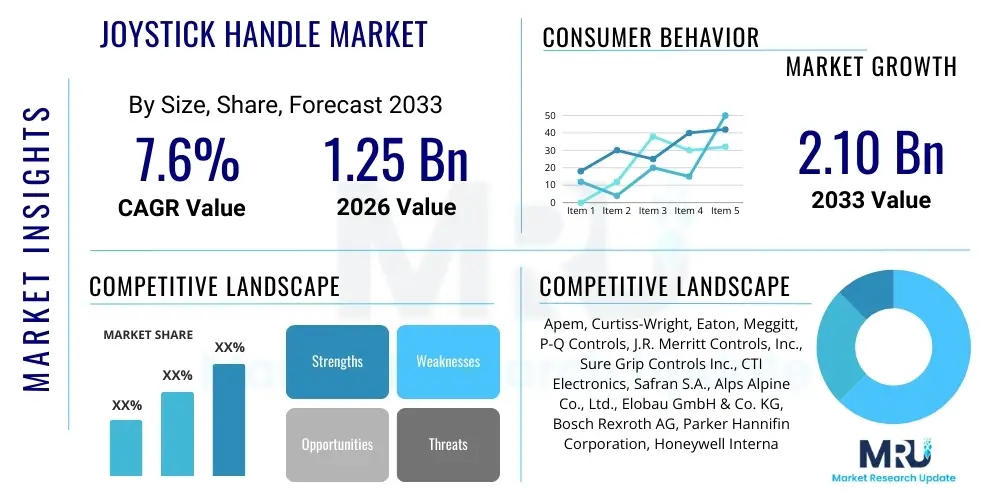

The Joystick Handle Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.6% between 2026 and 2033. The market is estimated at $1.25 Billion in 2026 and is projected to reach $2.10 Billion by the end of the forecast period in 2033.

Joystick Handle Market introduction

The Joystick Handle Market encompasses the design, manufacturing, and distribution of control input devices primarily utilized in heavy machinery, aviation systems, medical equipment, and advanced gaming applications. These handles serve as critical human-machine interfaces (HMIs), converting operator physical input (force, direction, angle) into electronic signals that dictate machine movement or function. The product range is diverse, featuring devices categorized by sensing technology, such as Hall Effect, potentiometers, and contactless sensors, ensuring high durability, precision, and extended operational life, especially in high-demand environments. Key characteristics include multi-axis control capabilities (up to 3-axis), ergonomic designs optimized for continuous use, and robust construction to withstand industrial abuse or rapid movement requirements in aerospace applications.

Major applications driving market expansion include the increasing adoption of sophisticated automation in construction and mining equipment, where precision control enhances operational efficiency and safety. Furthermore, the defense and aerospace sectors rely heavily on high-specification joystick handles for flight simulation, drone control, and weapon system command. The intrinsic benefits of using dedicated joystick handles—superior tactile feedback, instantaneous response time, and reduced operator fatigue compared to standard keyboard/mouse inputs—are paramount drivers. These devices offer a higher degree of proportionality and simultaneous control over multiple variables, which is essential for complex tasks like remote manipulation or surgical robotics. Technological advancements in integrated electronics, modular designs, and enhanced sealing (IP ratings) are consistently improving product reliability, thereby accelerating market penetration across traditionally demanding sectors.

The market's growth is predominantly fueled by the global emphasis on infrastructure development, leading to increased demand for controlled heavy machinery, particularly in emerging economies. The rising complexity of modern machinery necessitates advanced HMIs capable of managing intricate algorithms, further boosting the demand for multi-functional, custom-engineered joystick handles. The transition towards electrification and automation in vehicles, including electric forklifts and autonomous guided vehicles (AGVs), represents a substantial latent opportunity. Regulatory requirements mandating stringent safety standards in industrial controls also drive manufacturers to adopt high-reliability, fault-tolerant joystick technologies, ensuring market buoyancy throughout the forecast period.

Joystick Handle Market Executive Summary

The Joystick Handle Market is exhibiting robust growth, fundamentally driven by pervasive automation trends across industrial and mobile equipment sectors globally. Key business trends indicate a strong industry focus on developing Hall Effect technology joysticks due to their enhanced longevity and freedom from mechanical wear, appealing particularly to Original Equipment Manufacturers (OEMs) in construction and aerospace. Consolidation among smaller specialized manufacturers and larger industrial component suppliers is shaping the competitive landscape, pushing innovation towards modularity and integration capabilities, especially concerning CAN bus and Ethernet protocols for seamless system compatibility. Manufacturers are also prioritizing ergonomic customization and ruggedized designs capable of surviving extreme operational specifications, ensuring relevance in mission-critical applications.

Regionally, the market presents distinct growth dynamics. Asia Pacific (APAC) is projected to be the fastest-growing region, powered by rapid urbanization, significant investments in infrastructure projects, and the expansion of the regional manufacturing base, particularly in China and India. North America and Europe, while mature markets, maintain high revenue shares, focusing heavily on technology substitution, replacing older potentiometer-based systems with advanced contactless solutions, and sustaining strong demand from the high-value aerospace and defense segments. These established markets emphasize adherence to stringent safety certifications (e.g., ISO 13849, SIL standards) for industrial controls, necessitating continuous product refinement and certification efforts by market players.

Segment trends underscore the dominance of the Industrial Machinery application segment, encompassing material handling, earthmoving, and factory automation. Within the technology types, contactless joysticks, particularly utilizing Hall Effect sensing, are anticipated to witness the highest Compound Annual Growth Rate (CAGR), reflecting the market's shift away from components susceptible to physical degradation. Furthermore, the three-axis segment is expanding rapidly, primarily due to its necessity in complex remote vehicle operations and sophisticated crane controls that require simultaneous proportional movement across multiple planes. The OEM channel remains the largest revenue generator, although the aftermarket segment is seeing consistent growth driven by replacement needs and technological upgrades in existing fleets of heavy equipment.

AI Impact Analysis on Joystick Handle Market

User inquiries regarding AI's influence on the Joystick Handle Market center predominantly on themes related to autonomy versus manual override, predictive maintenance integration, and the evolution of the human-machine interface (HMI). Users frequently question whether the rise of fully autonomous systems will render traditional joystick handles obsolete, or if AI integration will simply enhance their functionality through adaptive control algorithms and predictive input assistance. Key concerns revolve around data processing at the edge—how joysticks can integrate local AI processors to filter or refine operator inputs for smoother machine response—and the deployment of AI for health monitoring of the joystick components itself, predicting potential failures before they occur in critical systems. Expectations include AI-enhanced ergonomics where the joystick dynamically adjusts sensitivity or haptic feedback based on operator fatigue or complex task requirements, ensuring operational continuity and precision.

- AI enhances input filtering and adaptive control, refining raw operator inputs for smoother machine movements, particularly in remote or variable load applications.

- Predictive maintenance algorithms use internal joystick sensor data (e.g., wear patterns, temperature fluctuations) to forecast component failure, drastically reducing unplanned downtime in industrial machinery.

- Integration of AI at the HMI level allows for contextual awareness, enabling the joystick system to adjust sensitivity or resistance based on the current machine state or operational complexity.

- AI supports the development of semi-autonomous control modes, allowing operators to use the joystick for high-level command while AI manages fine-tuning and stabilization (e.g., load balancing in cranes).

- Increased data output requirements: Joysticks must now reliably transmit high-frequency telemetry data necessary for AI training and real-time operational analysis.

- AI accelerates the development of advanced haptic feedback systems, providing operators with intelligent, real-time warnings or directional guidance through tactile stimuli.

DRO & Impact Forces Of Joystick Handle Market

The Joystick Handle Market is significantly influenced by a dynamic interplay of Drivers, Restraints, and Opportunities (DRO), which collectively shape the competitive landscape and growth trajectory. The primary driver is the pervasive trend of automation and remote operation across heavy industries, including construction, mining, and agriculture, necessitating reliable and high-precision proportional controls. This is compounded by stringent regulatory safety standards that favor highly reliable, certified control components, often pushing adoption toward non-contact technologies. The major restraint is the high initial cost associated with advanced, custom-engineered joystick handles, particularly those designed for extreme environments or sophisticated aerospace applications, which can restrict uptake in price-sensitive emerging markets. Additionally, the proliferation of sophisticated touch-screen interfaces and alternative control methods presents a minor threat. However, substantial opportunities exist in the ongoing development of electric vehicles and autonomous machinery, where joysticks are critical for manual override and precise docking/loading functions, alongside the expansion of medical robotics requiring extremely precise, tactile feedback controls.

These DRO elements are moderated by several high-impact forces. The technological impact force is robust, driven by the shift from potentiometers to Hall Effect and fiber optic sensing, substantially increasing product lifespan and accuracy. The competitive impact force is moderate but intensifying, with key players focusing on proprietary sensor technology and software integration (e.g., diagnostics, configuration tools) to differentiate their offerings. Economically, global infrastructure spending heavily influences demand, particularly for construction and earthmoving equipment joysticks. The regulatory environment imposes a significant impact force, particularly in Europe and North America, where compliance with functional safety standards (ISO 13849, IEC 61508) is mandatory, requiring specialized engineering and testing, thereby raising barriers to entry for new competitors.

Consequently, the market demonstrates resilience, with opportunities in customization and niche high-reliability segments outweighing the general constraints posed by cost and alternative interfaces. Strategic investment in research and development centered on improved sealing (IP69K), material science for extreme temperature operation, and integration with high-speed fieldbus systems (CANopen, EtherCAT) are critical strategies for maintaining competitive advantage. The market is thus defined by the balance between meeting industrial ruggedness requirements and integrating the precision demanded by high-tech applications like surgical robotics and sophisticated defense systems.

Segmentation Analysis

The Joystick Handle Market segmentation provides a granular view of market structure, allowing stakeholders to identify key growth areas and technology adoption trends across various end-user industries. The market is primarily segmented based on the type of sensing technology used (contact vs. contactless), the number of operational axes, the application industry, and the channel of sale. The technological split is crucial, indicating a clear trend toward non-contact solutions due to demands for maintenance-free operation and extended life cycles. Application analysis highlights the critical role of joysticks in capital equipment industries where precision control directly impacts operational safety and productivity, while regional analysis pinpoints geographical areas experiencing maximum adoption based on infrastructure investment levels and industrial maturity. Understanding these segments is vital for targeted product development and market entry strategies.

- By Type (Sensing Technology):

- Potentiometer Joysticks (Resistive Sensing)

- Hall Effect Joysticks (Contactless Magnetic Sensing)

- Contactless Joysticks (Including Inductive and Optic Sensors)

- By Axis:

- 1-Axis Joysticks

- 2-Axis Joysticks

- 3-Axis Joysticks (Including twist or Z-axis functionality)

- By Application:

- Industrial Machinery (Material Handling, Factory Automation)

- Construction Equipment (Excavators, Cranes, Loaders)

- Aerospace & Defense (Flight Simulators, UAV/Drone Control, Ground Support)

- Medical Devices (Surgical Robots, Imaging Systems)

- Marine and Offshore Equipment

- Consumer Electronics (High-end Gaming Peripherals)

- By End-Use Channel:

- OEM (Original Equipment Manufacturers)

- Aftermarket/Replacement

Value Chain Analysis For Joystick Handle Market

The value chain for the Joystick Handle Market is complex, beginning with highly specialized upstream suppliers of core electronic components and concluding with system integrators and end-user deployment. Upstream activities involve sourcing high-grade materials, including specialized polymers, ruggedized alloys, and critical electronic components such as custom ICs, high-precision magnetic sensors (for Hall Effect types), potentiometers, and microcontrollers. The competitiveness at this stage relies heavily on reliable component supply and maintaining extremely tight tolerances necessary for proportional control accuracy. Key suppliers must adhere to quality certifications relevant to industrial and aerospace sectors (e.g., AS9100 or ISO 9001). Manufacturing, the central value addition step, involves precision assembly, rigorous calibration, integration of software stacks (firmware), and compliance testing for environmental robustness (IP ratings) and functional safety.

Downstream activities focus heavily on sales, distribution, and comprehensive aftermarket support. The distribution channel is bifurcated into direct sales to large Original Equipment Manufacturers (OEMs) and indirect sales through specialized industrial distributors and system integrators. Direct sales provide the benefit of close collaboration on custom designs and integration into proprietary machine control architectures. Conversely, indirect channels leverage distributor networks to reach smaller users and manage the higher-volume aftermarket replacement segment. System integrators play a vital role, often modifying standard joystick handles or bundling them with larger control panels and software solutions before delivery to the final end-user, thereby adding application-specific value.

The direct channel dominates revenue for high-specification, custom joystick handles utilized in aerospace and heavy equipment, where long-term contracts and technical collaboration are essential. The indirect channel, however, is crucial for capturing the robust aftermarket demand driven by standard replacement cycles in construction and material handling sectors. Efficiency in logistics, speed of delivery, and technical training for distributor staff are critical factors influencing success in the indirect channel. Furthermore, the provision of robust technical documentation, troubleshooting guides, and immediate parts availability defines competitive success in the downstream market segment, ensuring system uptime for mission-critical applications.

Joystick Handle Market Potential Customers

The primary end-users and buyers of joystick handles are centered around industries requiring precise, durable, and reliable human-machine interfaces for complex machinery operations. This includes global Original Equipment Manufacturers (OEMs) specializing in heavy machinery such as Caterpillar, Komatsu, Volvo Construction Equipment, and Liebherr, who integrate these controls into excavators, cranes, and specialized mining vehicles. Beyond construction, the aerospace and defense sectors are critical customers, including major players like Boeing, Airbus, and defense contractors, utilizing high-reliability joysticks for aircraft cockpits, flight simulation equipment, and remote weapon systems. These end-users prioritize certification, longevity, and adherence to stringent industry standards like DO-160 and military specifications.

A rapidly expanding customer base includes manufacturers of advanced medical devices, particularly those involved in minimally invasive surgery (MIS) and diagnostic imaging systems. Surgical robotics firms require specialized, extremely sensitive, and ergonomic joysticks for remote manipulation of surgical tools, where nanometer-level precision and intuitive tactile feedback are mandatory. In the industrial realm, automation companies and system integrators serving factory automation, warehousing (AGVs, forklifts), and material handling systems constitute a substantial and recurring customer segment. These buyers prioritize integration capabilities, especially compatibility with industrial networks (CAN, Profibus), and standardized mounting options for ease of maintenance and system upgrade.

Lastly, the aftermarket segment represents continuous demand, encompassing maintenance, repair, and overhaul (MRO) service providers, as well as equipment rental fleets and independent owner-operators. These buyers seek reliable, readily available replacement units that match or exceed the performance specifications of the original component. The purchasing decision in this segment is driven by cost-effectiveness, quick delivery times, and compatibility with a wide range of legacy equipment. Therefore, successful market penetration requires addressing both the bespoke needs of high-value OEMs and the efficiency and volume requirements of the broad aftermarket distribution network.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.25 Billion |

| Market Forecast in 2033 | $2.10 Billion |

| Growth Rate | 7.6% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Apem, Curtiss-Wright, Eaton, Meggitt, P-Q Controls, J.R. Merritt Controls, Inc., Sure Grip Controls Inc., CTI Electronics, Safran S.A., Alps Alpine Co., Ltd., Elobau GmbH & Co. KG, Bosch Rexroth AG, Parker Hannifin Corporation, Honeywell International Inc., Sensata Technologies, Penny & Giles Controls Ltd., OMRON Corporation, CH Products (A division of APEM), Boshoku Automotive Interiors, Kavlico Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Joystick Handle Market Key Technology Landscape

The technology landscape of the Joystick Handle Market is rapidly evolving, driven primarily by the need for enhanced durability, higher precision, and integration capabilities with digital control systems. The shift from traditional potentiometric sensing, which relies on physical contact and is susceptible to wear, towards contactless technologies is the most significant technological trend. Hall Effect sensing dominates the high-end industrial and mobile equipment sectors. This technology uses magnetic fields to determine handle position, providing infinite mechanical life, exceptional repeatability, and high resistance to environmental ingress, vibration, and shock, making it ideal for harsh operating conditions like those found in mining or offshore environments. The advancements in magnet material science and sensor resolution continually push the boundaries of achievable proportional accuracy.

Another crucial technological development involves the integration of advanced communication protocols directly into the joystick handle's internal electronics. Modern industrial joystick handles are increasingly featuring embedded microcontrollers that support industrial fieldbus standards such as CANopen, J1939 (for mobile machinery), and increasingly, EtherCAT or PROFINET for faster deterministic control in complex factory automation systems. This integration simplifies wiring harnesses, enables diagnostic feedback directly from the handle (e.g., health status, input integrity checks), and allows for sophisticated system calibration and configuration via software. Furthermore, ergonomic design improvements, leveraging computer-aided design (CAD) and simulation, are focusing on modular grip customization and integration of multi-function tactile switches (rockers, push buttons, and scroll wheels) directly into the handle top, optimizing operator workflow.

The future technology trajectory points toward enhanced haptic feedback systems and sensor fusion. Haptic technology allows the joystick to communicate operational status, warnings, or limits back to the operator through programmable resistance, vibration, or force feedback, significantly improving safety and operational awareness in remote control applications. Sensor fusion involves combining data from the primary position sensor with secondary sensors (e.g., accelerometers, gyroscopes) within the handle to provide advanced input stabilization and situational context to the control system. Moreover, the focus on achieving higher safety integrity levels (SIL) through redundant sensing elements and self-monitoring diagnostics embedded in the firmware is essential for applications in functional safety critical domains, such as safety-rated cranes or nuclear plant controls.

Regional Highlights

- Asia Pacific (APAC): APAC represents the fastest-growing region, driven primarily by massive governmental investments in infrastructure (roads, railways, ports), rapid urbanization, and corresponding growth in the construction and material handling sectors, particularly in China, India, and Southeast Asian nations. The region is characterized by high volume manufacturing and increasing domestic demand for construction machinery OEMs seeking cost-effective yet reliable joystick solutions. Furthermore, the burgeoning electric vehicle and robotics markets in countries like Japan and South Korea provide specialized demand for advanced, compact control systems.

- North America: This region maintains a significant market share, characterized by high adoption rates of advanced, high-precision joystick handles in the aerospace, defense, and oil & gas sectors. The U.S. remains the largest consumer, driven by continuous military modernization programs and robust industrial automation mandates. Market focus here is heavily skewed toward certified products (MIL-SPEC, FAA standards) and contactless technologies (Hall Effect) that guarantee long-term reliability and compliance with stringent operational safety regulations.

- Europe: Europe is a mature but highly innovative market, dominated by adherence to strict functional safety standards (e.g., Machinery Directive, ISO 13849). Demand is strong from Germany, France, and the UK, particularly within advanced factory automation, heavy construction, and marine vessel control systems. European OEMs often demand highly customized, ergonomic solutions with integrated network connectivity (CANopen is highly prevalent), emphasizing sustainable manufacturing practices and energy efficiency in components.

- Latin America (LATAM): Growth in LATAM is closely tied to commodity cycles, particularly mining and agricultural activities in Brazil, Chile, and Mexico. While adoption of advanced joysticks is increasing, the market is highly cost-sensitive. Demand primarily targets durable, standard industrial joysticks for mobile equipment fleets, with slower penetration of high-end contactless technologies compared to North America or Europe.

- Middle East and Africa (MEA): This region is witnessing steady growth fueled by mega-infrastructure projects, particularly in the UAE and Saudi Arabia. The extreme environmental conditions (high heat, dust) mandate the use of highly ruggedized, sealed joystick handles (high IP ratings). The market size remains comparatively smaller but offers high-value opportunities in niche areas such as oil exploration and port handling logistics, which demand mission-critical control solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Joystick Handle Market.- Apem

- Curtiss-Wright

- Eaton

- Meggitt

- P-Q Controls

- J.R. Merritt Controls, Inc.

- Sure Grip Controls Inc.

- CTI Electronics

- Safran S.A.

- Alps Alpine Co., Ltd.

- Elobau GmbH & Co. KG

- Bosch Rexroth AG

- Parker Hannifin Corporation

- Honeywell International Inc.

- Sensata Technologies

- Penny & Giles Controls Ltd.

- OMRON Corporation

- CH Products (A division of APEM)

- Boshoku Automotive Interiors

- Kavlico Corporation

Frequently Asked Questions

Analyze common user questions about the Joystick Handle market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical advantage of Hall Effect joysticks over potentiometer-based joysticks?

The primary advantage of Hall Effect joysticks is their contactless operation, meaning they use magnetic sensing instead of physical resistance elements. This eliminates mechanical wear and tear, resulting in significantly extended operational life, superior reliability, and consistent performance, particularly in high-duty cycle industrial and aerospace applications, reducing maintenance requirements substantially.

Which industry segment drives the highest demand for joystick handles globally?

The Industrial Machinery and Construction Equipment segment drives the highest volume demand for joystick handles. This is due to the mandatory requirement for precise proportional control in heavy machinery such as cranes, excavators, forklifts, and loaders, where the joystick serves as the essential human-machine interface controlling complex hydraulic or electric drive systems.

How does the rise of autonomous vehicles affect the market for industrial joystick handles?

While full autonomy reduces continuous manual input needs, it increases the demand for highly reliable, certified joystick handles designed for manual override, emergency control, and fine-tuning operations. Joysticks are crucial for maintaining safety integrity levels (SIL) and ensuring human intervention capability in semi-autonomous and fully autonomous heavy equipment.

What role does CAN bus integration play in modern joystick handle technology?

CAN bus (Controller Area Network) integration is vital as it allows the joystick handle to communicate digitally with the machine's primary control unit using a standardized protocol. This enables enhanced diagnostics, simplified wiring, and highly configurable output signals, improving system responsiveness and reducing installation complexity across diverse mobile machinery platforms (J1939, CANopen).

Which geographic region is projected to experience the fastest growth rate for joystick handle adoption?

Asia Pacific (APAC), particularly driven by expansive infrastructure projects and rapid industrialization in countries like China and India, is projected to exhibit the fastest Compound Annual Growth Rate (CAGR). This regional growth is supported by increasing mechanization, automation adoption, and rising regional OEM manufacturing capabilities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager