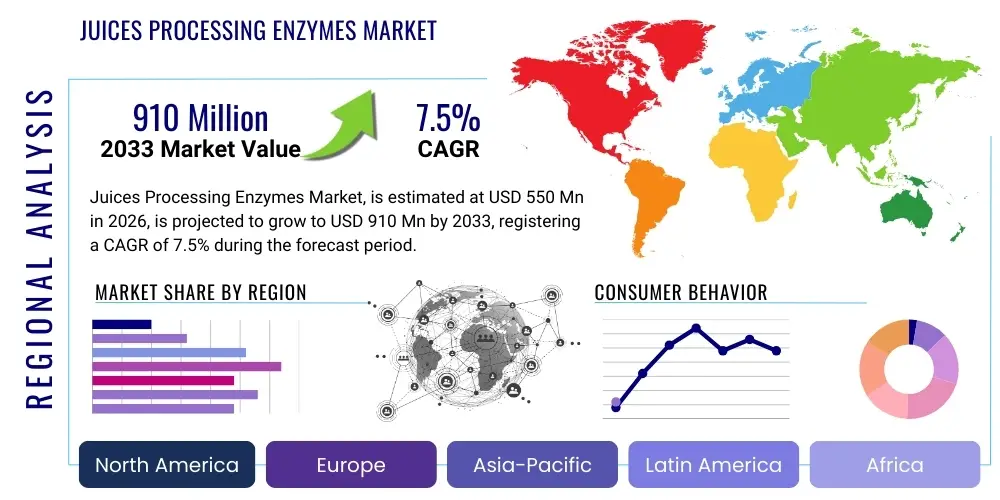

Juices Processing Enzymes Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435313 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Juices Processing Enzymes Market Size

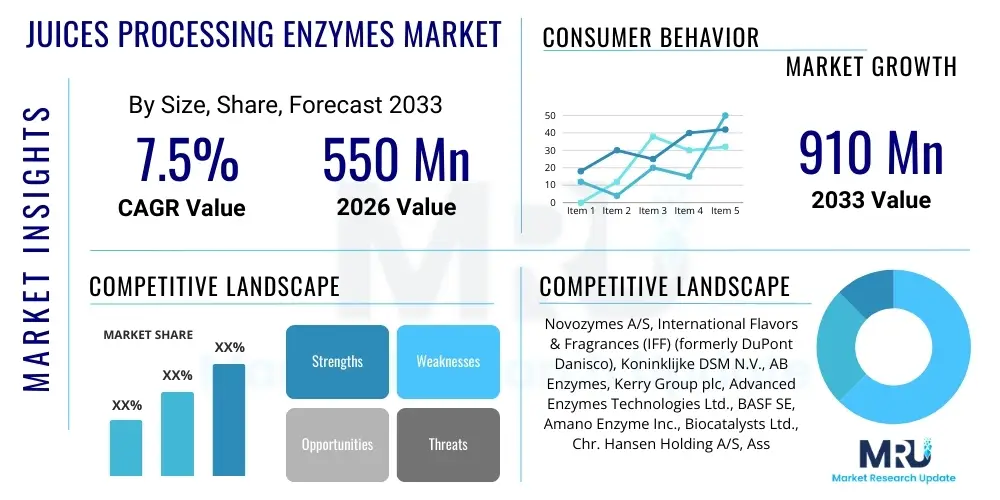

The Juices Processing Enzymes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 910 Million by the end of the forecast period in 2033.

Juices Processing Enzymes Market introduction

The global market for Juices Processing Enzymes involves the systematic application of highly specific biocatalysts across the industrial manufacturing landscape of fruit and vegetable beverages. These specialized enzymes are indispensable modern tools that address critical operational challenges inherent in transforming raw produce into shelf-stable, aesthetically appealing juice products. Enzymes, predominantly derived through controlled microbial fermentation, are engineered to target and hydrolyze structural components of plant cell walls and intercellular substances, such as pectin, cellulose, and starch. This targeted biochemical action is central to maximizing the extraction efficiency of juice from the solid fruit matrix, a process known as maceration, leading directly to reduced raw material wastage and enhanced economic viability for producers across all scales of operation. The commercial success of these enzymes is fundamentally tied to their capacity to significantly improve the physical properties of the juice mash, leading to superior final product characteristics and optimization of downstream processing steps, such as ultrafiltration and evaporation.

Product categories within this market range from single, high-purity enzymes like polygalacturonases (a type of pectinase) to sophisticated, multi-component enzyme blends specifically designed to tackle complex fruit matrices, such as those found in tropical fruits or highly starchy varieties like pears or unripe bananas. The primary objective is twofold: functional enhancement and process optimization. Functionally, enzymes ensure the final juice achieves the required standard of clarity, preventing the formation of cloudy haze caused by colloidal particles, and ensuring stable coloration and flavor profiles. Operationally, enzyme treatments drastically lower the viscosity of the juice, which is a major constraint in high-volume industrial processing, thereby speeding up subsequent physical separation steps like sedimentation, centrifugation, and, most critically, membrane filtration. The application of enzyme technology thus allows manufacturers to meet stringent market demands for high-quality juice consistency and rapid production cycles, which traditional thermal methods struggle to achieve without detrimental impact on flavor and nutrition.

Key benefits driving the sustained adoption of these processing aids include maximizing the extractable juice volume, often resulting in yield increases of 5-15% depending on the fruit type, and substantial energy savings achieved through shorter filtration times and reduced need for intensive thermal treatments. Furthermore, the use of enzymes contributes to a cleaner product profile, as they are often preferred over chemical clarification agents, supporting the clean label trend. The underlying market drivers are deeply rooted in changing global consumer preferences, specifically the growing appetite for premium, minimally processed, and functional beverages that retain the natural flavor and nutritional integrity of the raw ingredients. As global standards for food safety and traceability become stricter, and manufacturers face mounting pressure to optimize their environmental footprint, the enzymatic approach—being inherently gentler and more targeted—positions itself as the superior and sustainable method for modern juice production, ensuring continuous market proliferation and technological advancement in biochemical catalysis.

Juices Processing Enzymes Market Executive Summary

The Juices Processing Enzymes Market is exhibiting robust expansion, underpinned by crucial business trends emphasizing technological customization and supply chain integration. Leading enzyme manufacturers are heavily investing in research and development to develop thermostable, highly concentrated enzyme preparations optimized for specific juice matrices, minimizing dosage requirements and ensuring high efficacy under diverse operational temperatures and pH conditions globally. A significant business trend involves the shift towards providing comprehensive technical consulting alongside enzyme supply, positioning vendors as integrated solution providers rather than mere chemical input suppliers. This approach facilitates better integration of enzymatic steps within highly automated juice lines, reducing adoption barriers for processors and securing long-term supply contracts, particularly with large multinational beverage corporations keen on process standardization and efficiency maximization across their global facilities, driving value beyond the physical product itself.

Regional dynamics illustrate a divergence in growth momentum, with emerging economies in the Asia Pacific (APAC) driving market volume growth, while mature markets like North America and Europe focus on value-added segments and premiumization. The APAC surge is fundamentally linked to increased per capita consumption of packaged juices, rapid expansion of domestic beverage industries, and significant governmental focus on reducing post-harvest losses, making yield improvement technologies paramount. Conversely, European growth is characterized by a demand for premium, clean-label enzyme sourcing, often requiring non-GMO verified microbial strains and strict adherence to sustainability metrics. This regional specialization dictates distinct marketing and R&D strategies, requiring global enzyme suppliers to tailor their product portfolios to meet differing regulatory and consumer demands across geographic boundaries effectively, leading to intense competition based on technical support and compliance capabilities.

Segmentation analysis reveals the continued dominance of Pectinase, which remains the cornerstone of clear juice and concentrate production, due to the ubiquity of pectin in fruit structure and its profound effect on viscosity. However, the fastest-growing segment trend points toward the increased adoption of complex enzyme blends—often incorporating Amylase for starch removal and Cellulase for improved pressing—to efficiently process challenging or mixed raw materials, thereby broadening the application scope beyond traditional fruit juices into vegetable and functional beverage bases. Application trends indicate a strong rise in enzyme use within the juice concentrate sector, where viscosity reduction is crucial for energy-efficient evaporation and subsequent transport. This executive summary highlights a market characterized by high technical specificity, geographically diverse demand drivers, and a steady move toward integrated, customized biochemical solutions designed to meet the dual industry requirements of maximizing efficiency and improving final product quality in the global juice industry.

AI Impact Analysis on Juices Processing Enzymes Market

The integration of Artificial Intelligence (AI) and Machine Learning (ML) technologies is fundamentally reshaping the operational and innovation landscape of the Juices Processing Enzymes Market. A prevalent concern among industry stakeholders, frequently reflected in user questions, focuses on how AI can manage the inherent variability of natural agricultural inputs—the core challenge for juice processing. Manufacturers are keen to utilize predictive analytics to correlate raw fruit quality metrics, such as ripeness, pectin content, sugar levels, and geographic origin, with optimal enzyme cocktail formulation and dosage requirements. This application of AI moves the industry beyond static, generalized processing protocols toward dynamic, batch-specific enzymatic treatment, ensuring consistent final product quality regardless of upstream feedstock fluctuations, thereby minimizing costly reprocessing, reducing waste, and mitigating quality deviations that can severely impact brand reputation and profitability.

AI's influence is profoundly felt in the domain of bio-manufacturing, specifically optimizing the complex fermentation processes required to produce high-purity, industrial-grade enzymes. Advanced Machine Learning algorithms are employed to analyze vast and complex datasets generated by bioreactors, including precise metrics on temperature profiles, nutrient feeding rates, dissolved oxygen levels, and real-time growth kinetics of enzyme-producing microorganisms. This high-precision computational control allows manufacturers to construct highly accurate digital twins of the fermentation process, enabling them to simulate and predict the optimal control sequence to maximize the titre (concentration) and activity of the target enzymes. This significantly lowers overall production costs, enhances the reliability of the enzyme supply chain, and ensures high batch-to-batch consistency, which are critical performance indicators for the downstream juice processing industry that demands reliable and uniform performance.

Looking forward, the most transformative application of AI resides in directed evolution and computational enzyme design, often referred to as enzyme engineering 2.0. Traditional enzyme discovery is time-consuming and relies heavily on empirical testing and random mutagenesis. Generative AI models and deep learning tools, however, can predict the three-dimensional structure, stability, activity, and substrate specificity of novel enzyme variants before they are synthesized in a laboratory setting. This capability drastically accelerates the discovery cycle for highly customized enzymes tailored to non-traditional substrates or extreme processing conditions, such as the ultra-low pH required for processing high-acid fruits or the higher temperatures necessary for rapid concentrate production. By simulating and screening millions of potential molecular structures digitally, AI facilitates the creation of proprietary, bespoke enzyme solutions that offer manufacturers a substantial competitive edge in product differentiation and process efficiency, ensuring the technological frontier of the market is increasingly driven by sophisticated digital tools and biological data science.

- Optimization of Fermentation Yield: AI uses multivariate analysis of bioreactor data to fine-tune microbial growth environments, maximizing enzyme titre and purity while substantially reducing production variance and energy input.

- Predictive Quality Control: Machine learning models analyze complex raw fruit composition data (e.g., polysaccharide, tannin, and starch profiles) to automate enzyme dosage recommendations, guaranteeing consistent juice quality metrics like clarity and viscosity.

- Accelerated Enzyme Discovery: Computational biology and generative AI predict novel enzyme structures and activity profiles, drastically reducing the R&D timeline for new highly specific, robust biocatalysts tailored for specific fruit matrices.

- Supply Chain Optimization: AI integrates global raw material forecasts with internal production schedules, enabling predictive ordering and ensuring just-in-time delivery of fresh enzymes, critical due to the biological nature and shelf-life limitations of the product.

- Real-time Process Monitoring: Implementation of smart sensors and AI analytics within juice processing lines detects deviations in parameters like viscosity or clarification rates instantly, enabling automated, minute-by-minute adjustments to enzyme injection systems.

- Minimization of Waste: Optimized enzymatic hydrolysis ensures maximum extraction efficiency from fruit mash, reducing solid waste volumes and improving environmental sustainability metrics for juice manufacturers worldwide.

DRO & Impact Forces Of Juices Processing Enzymes Market

The proliferation of Juices Processing Enzymes is primarily driven by the imperative to increase operational efficiency in the highly competitive global beverage sector, alongside strong consumer preferences for natural products. Key drivers include the exponential growth in consumer demand for 100% natural, high-purity, and minimally processed juices, necessitating gentle enzymatic clarification over harsher thermal or chemical methods to preserve sensitive nutrients, antioxidants, and original flavor compounds. Furthermore, the economic pressure on juice manufacturers to maximize extraction yield from expensive fruit raw materials, coupled with volatile raw material costs, acts as a significant catalyst. Enzymes offer a sophisticated, cost-effective solution by substantially improving the efficacy of pressing and reducing the required filtration time, thus contributing directly to lower energy consumption and faster processing cycles, which are vital metrics for large-scale industrial operations aiming for global price competitiveness and sustainable manufacturing practices.

However, market expansion is constrained by several critical factors that necessitate careful risk management. The most prominent restraint is the relatively high upfront cost of highly specialized, standardized enzyme preparations compared to conventional processing aids, which poses a significant barrier, particularly for small and medium-sized regional producers who operate under tight budgetary constraints and may lack the necessary specialized equipment for optimal enzyme application and recovery. Technical challenges also exist, including the extreme sensitivity of enzymes to non-optimal processing conditions (pH, temperature) and the necessity for highly customized enzyme cocktails to account for the enormous variability in fruit composition based on cultivar, harvest year, and geographical origin. Educating the industry workforce on precise enzyme handling and application protocols further adds operational complexity and acts as a minor barrier to seamless adoption across all demographics of juice producers, particularly in developing regions.

Opportunities for market acceleration are abundant, centered around the rapid evolution of the functional beverage segment, which includes cold-pressed juices, functional water infusions, and plant-based dairy alternatives like oat or almond milk, where enzymes play a crucial role in extraction and modification. The demand for cold-pressed juices and nutraceutical extracts offers significant avenues for enzyme suppliers to develop bespoke solutions, particularly enzymes targeting cellulose and hemicellulose for enhanced fiber and nutrient extraction. Furthermore, technological leaps in enzyme immobilization—binding the biocatalyst to an inert matrix for reusability—present a practical pathway to reducing the effective cost per unit of processed juice, making enzymatic processing economically viable across a broader range of applications and aligning with corporate sustainability mandates. Focusing research and development on novel enzyme sources (e.g., extremophiles) can also improve thermal stability and expand the functional range of enzymes, representing a substantial future growth opportunity.

The collective impact forces shaping the market are intensely focused on sustainability and technical precision, pushing the industry toward a higher level of specialization. The regulatory force demanding 'clean label' and transparent sourcing acts as a powerful motivator for manufacturers to adopt enzyme technology, which is perceived favorably by consumers and regulatory bodies compared to synthetic chemicals. Concurrently, the force of technical specialization drives core R&D, pushing manufacturers toward developing synergistic, proprietary enzyme blends that address specific processing bottlenecks, like dealing with starch haze in high-starch fruit concentrates or improving the color intensity and stability of berry juices. Successfully leveraging these high-impact forces requires enzyme companies to maintain leadership in biotechnology patents, offer robust technical support, and ensure transparent, compliant supply chains globally, reinforcing the irreversible shift toward biochemical processing efficiency.

Segmentation Analysis

Segmentation analysis of the Juices Processing Enzymes Market is essential for understanding the specific dynamics of supply and demand based on biochemical function and industrial application, reflecting the heterogeneous nature of the global juice industry. The classification by enzyme type directly reflects the molecular problem being solved within the juice matrix. Pectinases, which hydrolyze pectin—the key structural component, gelling agent, and primary cause of cloudiness—command the largest market segment due to their universal necessity in producing clarified fruit juices and concentrates, such as apple and grape juice, where rapid viscosity reduction and clarification are paramount objectives. Following Pectinase, Amylase is critical for degrading starch, especially important in processing starchy fruits or concentrates where residual starch can lead to undesirable haze formation post-bottling, impacting visual quality. The relative size and growth of these segments are heavily influenced by prevailing global fruit processing volumes and the technological maturity of regional juice industries.

The segmentation by source highlights the industry's predominant reliance on microbiological manufacturing due to factors of consistency and scalability. Enzymes derived from microorganisms, primarily specific strains of fungi (like Aspergillus niger) and bacteria, dominate the market overwhelmingly due to their genetic adaptability, high-yield production capabilities through optimized fermentation, and consistency of supply irrespective of agricultural seasonality. This microbial segment benefits significantly from lower production costs, enhanced purity profiles, and the ability to genetically engineer strains for superior performance and thermal stability, offering a reliable, high-performing alternative to traditional plant or animal-sourced enzymes. While plant-sourced enzymes (e.g., papain or bromelain) hold niche applications for specific protein hydrolysis or debittering in certain juices, regulatory preference, ethical sourcing concerns, and economic viability overwhelmingly favor microbially produced enzymes, cementing the microorganism source segment as the fundamental backbone of industrial supply globally.

Segmentation by application clearly demarcates usage patterns across the beverage landscape and highlights areas of accelerated demand. The production of clear fruit juices and juice concentrates represents the highest volume application segment, where efficient clarification and viscosity reduction directly translate into superior market value, reduced logistics costs (due to higher concentration efficiency), and enhanced aesthetic appeal. However, the fastest growth is anticipated in the utilization of enzymes within the vegetable juice and functional beverage categories. In vegetable juice processing, cellulases and hemicellulases are gaining significant traction as they are essential for breaking down rigid plant cell structures, thereby maximizing extraction yield and improving the textural consistency and nutritional release of fibrous vegetable blends. This application shift reflects manufacturers' strategic alignment with consumer trends favoring nutrient-rich, functional ingredient incorporation, necessitating customized enzymatic tools for extraction and modification beyond simple clarification requirements.

- By Type:

- Pectinase: Dominant segment, used universally for clarification, viscosity reduction, and improved filtration in fruit juices (e.g., apple, grape, citrus).

- Amylase: Crucial for degrading starch, particularly in starchy fruit processing and concentrates, preventing starch haze formation during storage and cooling.

- Cellulase: Utilized for enhanced maceration, significantly increasing juice yield, especially valuable for berries, tropical fruits, and fibrous vegetables with rigid cell walls.

- Protease: Niche application, used for reducing protein-tannin hazes, improving stability, and specific debittering of certain juice varieties.

- Others (e.g., Glucanase, Lipase): Emerging applications in processing specialized extracts, managing specific flavor compounds, and improving stability in complex functional blends.

- By Source:

- Microorganism (Fungi, Bacteria): Highest market share due to cost-effectiveness, purity, consistency, and ability for genetic optimization and large-scale industrial production.

- Plant: Smaller segment, used for specific flavor or texture modification (e.g., Papain, Bromelain), often limited by supply chain complexity.

- Animal: Minimal market share, often constrained by stringent regulatory oversight, ethical considerations, and lack of specificity for most juice applications.

- By Application:

- Fruit Juices (Apple, Grape, Citrus, Berries): Largest volume consumer, driven by standard clarification, yield, and filtration requirements.

- Vegetable Juices: High growth area, requiring complex enzyme mixes for extraction maximization and modulation of texture and viscosity in functional blends.

- Juice Concentrates: Critical application for reducing viscosity prior to evaporation, directly impacting energy consumption and logistics costs.

- Nectars and Smoothies: Used primarily for controlled viscosity reduction, improving mouthfeel, and preventing sedimentation or phase separation over time.

Value Chain Analysis For Juices Processing Enzymes Market

The upstream segment of the Juices Processing Enzymes value chain is heavily concentrated among specialized biotechnology companies that possess core competencies in microbial genetics, molecular biology, and precision fermentation. This initial stage involves the scientific discovery, screening, and selection of robust microbial strains (e.g., fungi, bacteria) capable of hyper-expressing the required enzymes, such as highly active pectinases or specific amylases. Value is profoundly added here through proprietary knowledge concerning high-throughput strain improvement, optimization of complex fermentation media nutrients, and advanced sterile fermentation techniques in large-scale bioreactors, ensuring consistent high-purity and predictable enzyme activity. The high initial capital investment and demanding technical barrier to entry in biotechnology manufacturing mean that this upstream stage is controlled by a limited number of global leaders, who derive substantial competitive value from their intellectual property, patented strains, and economies of scale, setting the essential quality benchmarks and base cost structure for the entire market.

The midstream phase encompasses post-fermentation recovery, rigorous purification, stabilization, and formulation into commercial products. After extraction and purification, the enzyme solution must be carefully stabilized, often concentrated, and accurately formulated into final commercial formats, which may be liquid or standardized powders. Standardization is paramount in this market; enzymes are typically sold based on their measured activity unit (e.g., Pectolytic Units) rather than mere weight, requiring precise quality control, specialized assay development capabilities, and certification. Distribution channels are highly critical and specialized due to the biological nature of the product, often requiring strict temperature control (cold chain logistics) to maintain enzyme efficacy and shelf stability during transit to juice manufacturers globally. Direct distribution, involving dedicated technical sales teams, is preferred for major juice processors, offering customized formulations and on-site technical assistance to troubleshoot integration into complex, high-throughput processing lines, fostering strong supplier-customer relationships.

The downstream segment centers entirely on the application and final consumption within juice production facilities worldwide. Here, the enzyme’s true economic and functional value is realized through quantifiable operational benefits: demonstrable increases in juice yield, significant reduction in energy costs derived from faster filtration, and improved final product characteristics such as superior clarity, enhanced flavor retention, and color stability. Potential customers, or end-users, meticulously assess value based on the cost-to-benefit ratio, calculating yield increases and processing time savings against the enzyme expenditure. Effective utilization requires specialized in-plant equipment (e.g., precise dosing pumps, continuous mixing tanks) and skilled technical operators. Therefore, the profitability and success of the entire value chain are intrinsically linked to the successful integration and optimization of the enzyme’s performance in the processor’s plant, solidifying the importance of technical application support provided by upstream suppliers to ensure optimal downstream results and consistent high-quality juice output that meets global market demands.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 910 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Novozymes A/S, International Flavors & Fragrances (IFF) (formerly DuPont Danisco), Koninklijke DSM N.V., AB Enzymes, Kerry Group plc, Advanced Enzymes Technologies Ltd., BASF SE, Amano Enzyme Inc., Biocatalysts Ltd., Chr. Hansen Holding A/S, Associated British Foods plc (ABF), Specialty Enzymes and Biotechnologies, Lallemand Inc., Puratos Group, Jiangsu Boli Bioproducts Co., Ltd., Sunson Industry Group Co., Ltd., Enzyme Development Corporation (EDC), Sichuan Initiative Biotechnology Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Juices Processing Enzymes Market Key Technology Landscape

The technological sophistication of the Juices Processing Enzymes Market is rapidly advancing, moving far beyond simple single-enzyme application towards integrated biochemical systems. The foundational technology remains the precise control of large-scale microbial fermentation, specifically submerged fermentation (SmF), which is continually optimized using advanced sensors, automated control systems, and predictive modeling (often AI-assisted) to maximize the economic yield, purity, and activity of the biocatalyst. Crucial advancements are focused on strain engineering using modern biotechnology techniques like CRISPR/Cas9 to enhance the resilience of enzyme-producing organisms, resulting in enzymes that exhibit superior thermal stability and functional efficacy across a broader range of high and low pH levels encountered in diverse fruit types, thereby widening their industrial utility and simplifying the application process for manufacturers globally.

A paramount technological trend involves the development of proprietary multi-enzyme systems, often termed 'enzyme cocktails,' which represent the high-value segment of the market. These systems are scientifically engineered to achieve synergistic effects by carefully combining different enzyme classes—such as high-activity pectinases, specific cellulases, and starch-targeting amylases—in precise, proprietary ratios. The integrated goal is to simultaneously address multiple processing issues, such as increasing juice extraction yield from the mash, rapidly breaking down haze-causing colloidal particles, and efficiently reducing viscosity, all in one integrated step. This approach leads to exponential gains in processing throughput compared to sequential, single-enzyme treatments. This customized blending technology allows suppliers to offer highly specialized solutions tailored specifically for regional or complex fruit types, such as enzymes optimized for high-tannin berry juices or robust solutions designed for tropical fruit pulps containing dense fibrous and starchy structures, thereby driving market value through technical differentiation.

Further innovation is concentrated on the deployment of advanced enzyme application methods, notably enzyme immobilization and enhanced downstream separation technologies. Enzyme immobilization involves chemically or physically binding the enzyme to a solid, inert support material, allowing the biocatalyst to be used continuously in a flow reactor system and easily recovered and reused multiple times. While currently challenged by high initial costs and complexity, immobilization technology promises a significant reduction in enzyme usage costs and aligns perfectly with corporate sustainability goals by minimizing biological waste. Concurrently, the increasing efficiency of ultrafiltration and microfiltration membranes necessitates equally precise enzymatic pretreatment; technology developments now focus on creating enzymes that hydrolyze colloidal materials into optimally sized, filterable particles that maximize membrane flux rates, efficiently preventing fouling and reducing the substantial energy and maintenance costs associated with industrial membrane filtration processes, ensuring a holistic approach to process optimization.

Regional Highlights

The market landscape for Juices Processing Enzymes demonstrates distinct regional dynamics rooted in local agricultural output, consumption culture, and regulatory stringency. Asia Pacific (APAC) represents the focal point of future growth, propelled by robust economic expansion and significant demographic shifts. Countries such as China, India, and Vietnam are witnessing exponential growth in the demand for packaged juices as urbanization accelerates and disposable incomes rise, leading to a greater reliance on convenience and processed foods. The necessity to process vast and often highly variable quantities of tropical and regional fruits, coupled with governmental focus on reducing significant post-harvest waste, drives strong adoption of yield-maximizing enzymes like cellulases and specific pectinases. Regional processors are rapidly modernizing their infrastructure, adopting enzyme technology to compete effectively in lucrative global juice concentrate export markets, solidifying APAC’s role as the market leader in volume growth trajectory and investment in cutting-edge enzyme applications.

Europe holds a commanding position as a mature, value-driven market, distinguished by its high regulatory standards and strong consumer preference for transparent, 'clean label' food processing methods. The application of enzymes in Europe is characterized by precision and technological maturity, particularly in the production of premium clear juices (grape, apple) and high-quality cider and wine production, where achieving absolute clarity, stable coloration, and preventing sedimentation are critical quality metrics. European demand emphasizes enzymes sourced from verified non-GMO microbial strains and requires suppliers to possess robust certification and traceability protocols adhering strictly to EU regulations. Furthermore, the region’s focus on circular economy principles and sustainable production strongly encourages the adoption of enzymes for fruit waste valorization and energy-efficient processing, sustaining strong demand for highly optimized, environmentally conscious enzymatic solutions within a deeply quality-focused market environment.

North America maintains significant market dominance, driven by the entrenched presence of global beverage headquarters and a highly diversified consumer base demanding exotic, functional, and health-focused beverages, including cold-pressed and high-fiber smoothies. Enzyme use here is concentrated on maximizing processing efficiency across highly complex and diverse product lines, from standardized orange juice concentrate to complex vegetable-fruit smoothies. The market is highly technologically advanced, rapidly integrating AI-driven process optimization systems and utilizing sophisticated, customized enzyme cocktails for enhanced extraction and stabilization in challenging products like pulp-rich cold-pressed juices that require precise viscosity control. Latin America, rich in natural fruit resources (citrus, mango, pineapple), is a significant emerging market where enzyme adoption is increasing as local producers transition from traditional methods to advanced industrial processing, aimed at enhancing production yield and consistency necessary to access lucrative international export channels and satisfy a rapidly growing domestic packaged juice market.

- North America: Focus on functional beverages, high adoption of customized enzyme blends, integration of AI for process control, and large-scale, standardized usage in concentrated citrus and apple juice processing.

- Europe: Driven by stringent quality and clean label requirements; high enzyme usage in premium clear juices, wine clarification, and sustainable fruit waste reduction processes, emphasizing non-GMO sourcing.

- Asia Pacific (APAC): Fastest growing region; high demand due to urbanization, increased packaged juice consumption, and heavy investment in fruit concentrate manufacturing and yield maximization for diverse tropical fruits.

- Latin America (LATAM): Emerging market potential fueled by vast tropical fruit availability, increasing industrialization of local processors, and strategic investment to meet international export quality standards and satisfy domestic demand.

- Middle East & Africa (MEA): Growth driven by rising consumer affluence, increased consumption of imported juices, and nascent development of local beverage bottling and processing infrastructure, demanding standardized enzyme solutions for product consistency.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Juices Processing Enzymes Market.- Novozymes A/S

- International Flavors & Fragrances (IFF) (formerly DuPont Danisco)

- Koninklijke DSM N.V.

- AB Enzymes

- Kerry Group plc

- Advanced Enzymes Technologies Ltd.

- BASF SE

- Amano Enzyme Inc.

- Biocatalysts Ltd.

- Chr. Hansen Holding A/S

- Associated British Foods plc (ABF)

- Specialty Enzymes and Biotechnologies

- Sunson Industry Group Co., Ltd.

- Puratos Group

- Lallemand Inc.

- Jiangsu Boli Bioproducts Co., Ltd.

- Sichuan Initiative Biotechnology Co., Ltd.

- Enzyme Development Corporation (EDC)

Frequently Asked Questions

Analyze common user questions about the Juices Processing Enzymes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of enzymes in juice processing, particularly concerning yield and viscosity?

The primary function is to enhance operational efficiency and final product quality by hydrolyzing structural plant components like pectin and cellulose. Pectinase and Cellulase specifically break down these cell wall components, drastically reducing the viscosity of the juice mash, which maximizes the release of juice during pressing and significantly speeds up downstream filtration and clarification processes.

How does enzyme technology contribute to achieving "clean label" status in beverages?

Enzymes are generally classified as processing aids, not functional ingredients, in the final juice product across most major global markets (EU, US). Since they are either removed by filtration or deactivated by subsequent processing steps (like pasteurization) and leave no active residue, their use is compliant with consumer demand for clean and transparent product labels.

Which factors pose the most significant restraints to global market growth and widespread adoption?

The most significant restraints include the relatively high production cost of specialized, high-purity enzyme preparations compared to conventional alternatives, the operational complexity arising from the need to develop customized enzyme cocktails to manage high variability in raw fruit quality, and the necessity for specialized cold chain logistics and technical expertise for effective application and storage.

Why is the Asia Pacific region projected to exhibit the highest growth rate in enzyme adoption?

APAC's high growth rate is driven by robust urbanization, rapidly increasing consumer demand for packaged and processed juices, and the strategic necessity for local processors to adopt modern enzymatic methods to maximize yield from complex regional tropical fruits and ensure product quality consistency for both domestic markets and competitive international export channels.

What major role does AI play in optimizing the enzyme production and application processes?

AI's role is transformative, primarily by optimizing the complex industrial fermentation process through predictive analytics to maximize enzyme yield and purity. It also accelerates R&D by using generative models to computationally design novel enzyme structures with enhanced stability and substrate specificity, drastically shortening the time needed to bring customized, high-performance solutions to market.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager