Kit Packers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432103 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Kit Packers Market Size

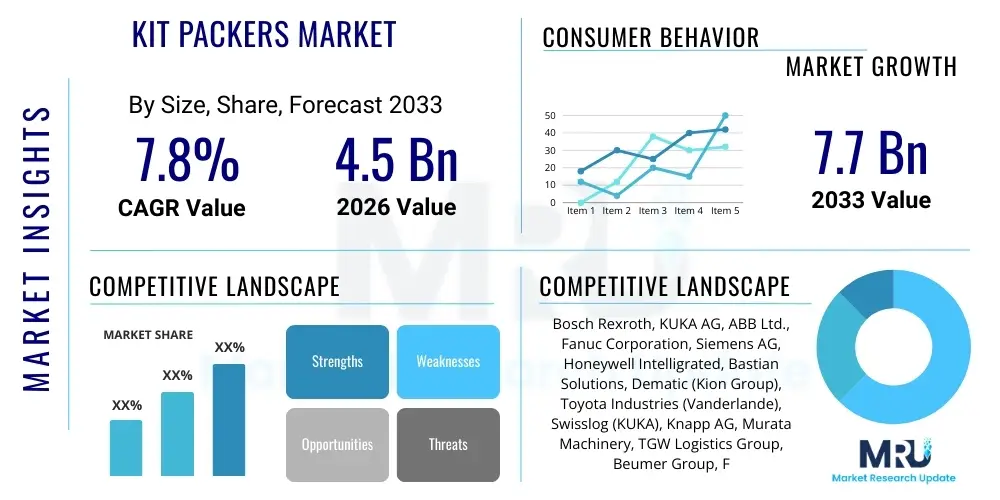

The Kit Packers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 7.7 Billion by the end of the forecast period in 2033. This robust growth trajectory is primarily driven by the escalating demand for streamlined assembly operations, particularly across the automotive, healthcare, and electronics manufacturing sectors where Just-In-Time (JIT) inventory management and custom production runs are becoming standard operating procedure. The need for precise component grouping, reduced labor costs associated with manual kitting, and minimizing errors in complex product assemblies are key factors underpinning this expansive market valuation.

Market expansion is significantly influenced by geographical diversification, with rapid industrialization in emerging economies such as China, India, and Southeast Asian nations fueling investments in advanced automated kitting systems. Furthermore, the push towards digitalization in manufacturing, exemplified by Industry 4.0 initiatives, encourages the integration of smart kitting solutions that incorporate robotics, vision systems, and sophisticated material handling technologies. These systems enhance throughput efficiency and traceability, appealing strongly to high-mix, low-volume manufacturers seeking competitive advantages through operational excellence. The shift from bulk handling to precise, customized packaging solutions ensures components reach the point of use quickly and accurately, mitigating supply chain bottlenecks.

Kit Packers Market introduction

The Kit Packers Market encompasses the entire ecosystem of equipment, services, and software dedicated to assembling pre-packaged kits containing multiple components required for a specific manufacturing, assembly, or maintenance task. These kits significantly improve production efficiency by eliminating the need for operators to individually pick parts, reducing setup times, and ensuring all necessary components are available at the point of use. Major applications span critical industries including automotive (for sub-assembly parts), aerospace (for maintenance and repair operations), medical devices (surgical trays and procedure packs), and consumer electronics (DIY assembly sets). The primary benefits derived from adopting kit packing solutions include inventory shrinkage reduction, enhanced quality control through automated verification, substantial labor cost savings, and improved assembly line throughput. Driving factors include the increasing complexity of modern products, the rising adoption of lean manufacturing principles across global supply chains, and the imperative for error reduction in high-value component handling, which necessitates specialized, highly reliable packing and verification machinery.

Kit Packers Market Executive Summary

The global Kit Packers Market is experiencing dynamic shifts, characterized by increasing automation and software integration designed to support flexible manufacturing environments. Key business trends include the strong preference for modular and scalable automated kitting systems that can adapt quickly to evolving product designs and volume fluctuations. Manufacturers are increasingly prioritizing vendors who offer end-to-end kitting solutions encompassing both picking and packing technology coupled with robust inventory management software. Regionally, Asia Pacific (APAC) dominates the growth trajectory due to burgeoning manufacturing bases, especially in automotive and semiconductor fabrication, necessitating high-speed, precision kitting operations. North America and Europe, while mature, are focusing on adopting highly sophisticated robotic kitting for specialized, high-mix applications, prioritizing quality and traceability over pure volume.

Segment trends indicate that the robotics and automation segment, specifically those utilizing collaborative robots (cobots) for flexible kitting tasks, is witnessing the highest growth. Application-wise, the healthcare and pharmaceutical sectors are showing accelerated adoption rates, driven by stringent regulatory requirements for sterile kitting and procedural pack precision. In terms of components, vision systems and AI-powered sorting technologies are becoming standard inclusions to ensure 100% kit accuracy, thereby minimizing downstream assembly errors. The competitive landscape is becoming increasingly consolidated, with major automation providers acquiring specialized kitting technology companies to offer comprehensive solutions, reinforcing the market’s pivot towards integrated, smart factory ecosystems.

AI Impact Analysis on Kit Packers Market

User queries regarding AI's influence on the Kit Packers Market frequently revolve around automation capabilities, predictive maintenance, and quality assurance. Common questions include: "How can AI reduce kitting errors?" "Will machine learning optimize inventory levels for kitting operations?" and "What is the role of computer vision in verifying kit completeness?" The analysis reveals that users are highly concerned with leveraging AI to move beyond simple mechanical automation toward intelligent decision-making within kitting systems. Key themes summarize to a high expectation that AI will deliver near-perfect accuracy, dynamically adjust kitting schedules based on real-time assembly line demand, and autonomously troubleshoot equipment failures. There is also significant interest in using large language models (LLMs) to optimize complex Bill of Materials (BOM) management for highly customized kits, minimizing human intervention and maximizing production fluidity.

The integration of artificial intelligence is fundamentally transforming the capabilities and efficiency of kit packing operations. AI-driven vision systems, for instance, are employed for instantaneous component identification and verification, ensuring that every kit adheres precisely to the required specifications, even when dealing with minute or similar-looking parts. This capability far surpasses traditional sensor-based verification, significantly reducing human error and improving quality control throughput. Furthermore, machine learning algorithms are being utilized for predictive inventory management, analyzing historical kitting data, upstream supply chain signals, and downstream production schedules to forecast component demand accurately. This predictive capacity minimizes stockouts while optimizing warehouse space usage and reducing working capital requirements associated with excess inventory.

- Enhanced Quality Control: AI vision systems perform instantaneous defect detection and component recognition, ensuring 100% kit accuracy regardless of part similarity or complexity.

- Predictive Maintenance: Machine learning models analyze operational data from kit packing machinery to predict potential failures, scheduling maintenance proactively and maximizing system uptime.

- Dynamic Scheduling: AI algorithms optimize kitting sequences in real-time based on fluctuating production line demands, materials availability, and logistics constraints (AEO: dynamic production optimization).

- Inventory Optimization: ML models forecast precise component needs, balancing JIT requirements with supply lead times to reduce excess inventory holding costs.

- Robotic Pathfinding: AI optimizes the movement and gripping strategies of robotic arms in automated kitting cells, increasing picking speed and efficiency.

- Complex Kit Configuration: Utilizing LLMs and expert systems to manage and validate complex Bill of Materials (BOMs) for high-mix, custom kitting scenarios.

DRO & Impact Forces Of Kit Packers Market

The Kit Packers Market is fundamentally driven by the global adoption of lean manufacturing philosophies, which prioritize waste reduction and efficiency maximization. The increasing complexity and diversification of modern product lines (high-mix, low-volume production) necessitate highly organized and precise component management, making kitting an indispensable strategy. Restraints primarily involve the high initial capital investment required for sophisticated automated kitting systems, particularly for Small and Medium-sized Enterprises (SMEs), alongside the technical complexity associated with integrating these systems into legacy manufacturing environments. Opportunities are abundant, especially in the expansion of kitting services into emerging sectors like electric vehicle (EV) manufacturing and personalized medicine, which demand extreme precision and traceability. The primary impact force is technological advancement, where the convergence of robotics, AI, and advanced material handling drives operational performance benchmarks upward, simultaneously addressing the restraints related to cost and complexity over the long term, pushing the market towards more scalable and affordable modular solutions.

A detailed examination of drivers highlights the growing labor scarcity and rising operational costs in industrialized nations, making automation in kitting a financial necessity rather than a mere efficiency enhancement. Furthermore, regulatory compliance in highly sensitive sectors, particularly medical devices and aerospace, mandates impeccable traceability and error-free assembly, which kitting systems intrinsically provide. Conversely, the market faces constraints related to standardization; the highly customized nature of many kits means that system implementation often requires extensive software integration and specialized tooling, increasing deployment time and complexity. Another restraint is the potential vulnerability of highly automated systems to software glitches or cyber threats, necessitating robust cybersecurity protocols for connected kitting infrastructure.

The most compelling opportunities reside in developing rental or subscription-based models (Kitting-as-a-Service, or KaaS), lowering the entry barrier for smaller manufacturers. Moreover, sustainable packaging mandates are creating demand for kit packing solutions that utilize eco-friendly, yet durable, materials, presenting a niche for innovation. The impact forces are multifaceted, involving market consolidation among equipment providers, rapid evolution of sensory and vision technology allowing for the accurate handling of microscopic parts, and strong governmental support for automation in manufacturing supply chains post-pandemic, reinforcing resilience and localized production capabilities.

Segmentation Analysis

The Kit Packers Market segmentation provides critical insights into the various technologies, components, applications, and regional dynamics shaping the industry landscape. The market is primarily segmented based on the level of automation (manual, semi-automatic, fully automatic), the components used (hardware, software, services), the end-use industry, and the type of material handled. Fully automated kitting systems, incorporating advanced robotics and integrated conveyor systems, are expected to exhibit the highest growth rate due to their superior efficiency, throughput, and ability to operate continuously in complex manufacturing settings, aligning perfectly with Industry 4.0 paradigms. The software segment is also crucial, encompassing warehouse management systems (WMS) and manufacturing execution systems (MES) that orchestrate the kitting process, ensuring seamless integration with the broader supply chain ecosystem and providing real-time operational visibility.

From an end-use perspective, the automotive industry traditionally holds the largest market share, leveraging kitting for crucial tasks like engine assembly and interior component grouping, which demands precise sequence delivery. However, the healthcare and pharmaceutical sector is rapidly expanding its share, fueled by the demand for sterile surgical kits, personalized medication packs, and diagnostic test kits, where accuracy and cleanliness are non-negotiable regulatory requirements. Technology segmentation highlights the increasing adoption of specialized picking technologies, including Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), which transport components between storage areas and the kitting station, enhancing internal logistics flexibility. Analyzing these segments is vital for stakeholders to tailor investment strategies towards high-potential areas such as high-precision, small-part kitting demanded by the electronics sector.

- By Type of Automation:

- Manual Kitting

- Semi-Automatic Kitting

- Fully Automatic Kitting (Highest Growth)

- By Component:

- Hardware (Robotics, Conveyors, Dispensers, Vision Systems)

- Software (WMS Integration, MES, Optimization Tools)

- Services (Installation, Maintenance, Training)

- By Application:

- Automotive

- Aerospace and Defense

- Electronics and Semiconductors

- Healthcare and Pharmaceuticals

- E-commerce and Retail

- General Manufacturing

- By End Product Type:

- Standard Kits

- Customized/Configurable Kits

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Kit Packers Market

The value chain for the Kit Packers Market begins with upstream activities involving component suppliers, primarily focused on sourcing specialized industrial automation hardware such as high-precision robots, sophisticated sensors, and industrial computers necessary for control systems. These suppliers must adhere to stringent quality and reliability standards, as the performance of the kitting system hinges entirely on the quality of its foundational machinery. Software developers, another key upstream component, focus on creating the proprietary algorithms and integration platforms (WMS/MES connectors) that enable the physical kitting machinery to communicate effectively with enterprise resource planning (ERP) systems and manage complex Bill of Materials (BOMs) efficiently. The competitive advantage at this stage often lies in innovation related to robotic dexterity and software interface user-friendliness, reducing implementation friction for end-users.

Midstream activities involve the core kitting system integrators and manufacturers who design, assemble, and configure the customized kitting solutions. These firms combine hardware and software components tailored to specific industry needs, whether it be sterile kitting for medical procedures or high-volume kitting for automotive production lines. The distribution channel is crucial, often leveraging a mix of direct sales teams for large, complex, multi-million dollar projects and indirect channels, such as specialized regional distributors or third-party logistics (3PL) providers, who offer Kitting-as-a-Service (KaaS) models. Direct distribution allows for deep customization and post-installation support, critical for complex automated lines, while indirect channels provide market reach and localized service capabilities, particularly beneficial in emerging markets.

Downstream activities center on the end-users (manufacturers, logistics firms) and the subsequent maintenance and service ecosystem. Ongoing technical support, software updates, and predictive maintenance services are essential to maximize the return on investment (ROI) for kitting systems. Furthermore, the relationship between the kitting solution provider and the end-user is often long-term, focused on continuous process improvement and expansion of kitting capabilities as the end-user's product portfolio evolves. Efficiency gains and proven cost reductions achieved at the point of assembly, driven by accurate and timely kit delivery, represent the final value realization point in this intricate chain, heavily influencing future technology procurement decisions by major market participants.

Kit Packers Market Potential Customers

Potential customers for the Kit Packers Market span a wide array of industrial and commercial entities that rely on efficient component assembly and standardized procedure execution. The primary end-users are large-scale manufacturers operating complex assembly lines, notably within the Automotive sector, including Tier 1 suppliers and Original Equipment Manufacturers (OEMs) who require sequenced component kits delivered directly to the assembly cell (AEO: sequenced delivery kitting). These customers utilize kitting to maintain the stringent quality control standards and high production speeds demanded by modern vehicle manufacturing. Similarly, the Aerospace and Defense industries represent significant customers, needing highly reliable kitting for maintenance, repair, and overhaul (MRO) operations where component traceability and precision are matters of regulatory and operational safety.

A rapidly growing customer base includes companies in the Healthcare and Pharmaceutical domain. Hospitals, medical device manufacturers, and diagnostic firms rely on kit packers for sterile surgical procedure trays, customized dosage packaging, and test kits, prioritizing sterility, documentation, and compliance with Good Manufacturing Practice (GMP). Furthermore, the burgeoning E-commerce and Retail sector, driven by increasing consumer demand for personalized products and Subscription Box services, constitutes a key demographic. These organizations leverage kitting systems to efficiently package varied combinations of consumer goods, requiring flexible, high-throughput systems capable of managing thousands of unique SKUs daily.

In addition to traditional manufacturing, third-party logistics (3PL) providers and contract packaging organizations (CPOs) are substantial buyers. These firms offer kitting services as a core part of their outsourced supply chain management offering, serving multiple clients across different industries. For these service providers, modularity, scalability, and rapid reconfiguration capabilities are critical purchasing criteria. Ultimately, any organization facing the challenges of high labor costs, high inventory error rates, or complex product assembly stands as a potential customer, seeking kitting solutions to achieve operational streamlining and verifiable process improvement across their entire production lifecycle.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 7.7 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch Rexroth, KUKA AG, ABB Ltd., Fanuc Corporation, Siemens AG, Honeywell Intelligrated, Bastian Solutions, Dematic (Kion Group), Toyota Industries (Vanderlande), Swisslog (KUKA), Knapp AG, Murata Machinery, TGW Logistics Group, Beumer Group, Fives Group, SSI Schaefer, Grenzebach Group, JBT Corporation, Daifuku Co., Ltd., Witron Logistik. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Kit Packers Market Key Technology Landscape

The technology landscape for the Kit Packers Market is rapidly evolving, driven by the shift towards fully automated and intelligent manufacturing environments. Central to this evolution is the deployment of highly dexterous robotic systems, including multi-axis industrial robots and collaborative robots (cobots), which are essential for handling diverse component shapes and weights with high precision. Cobots, in particular, are gaining traction due to their ability to work safely alongside human operators, providing flexibility in semi-automatic kitting environments and enabling quick setup changes for high-mix production. Furthermore, advanced gripper technology, utilizing soft robotics and vacuum suction combined with rapid tool changers, ensures that the kitting system can seamlessly transition between packaging fragile electronic parts and heavy mechanical components without manual recalibration, significantly boosting system versatility and minimizing downtime.

Vision systems and sensor technologies represent another critical technological pillar. High-resolution 2D and 3D cameras, often integrated with AI-powered image processing software, are used for precise part identification, orientation, and quality verification within the kitting cell. This level of verification is paramount in preventing faulty or incorrect components from being included in a kit, thereby ensuring downstream assembly success. The development of sophisticated sensors also facilitates real-time monitoring of component weight and dimensions, adding an extra layer of quality control. The ability of these systems to interpret slight variances in components allows the kitting process to adapt dynamically, addressing common challenges related to manufacturing tolerances and component batch variability.

Beyond physical hardware, the rise of sophisticated software solutions is shaping the landscape. Modern kitting systems rely heavily on integrated Manufacturing Execution Systems (MES) and Warehouse Management Systems (WMS) to coordinate inventory flow, prioritize kit creation based on production line needs, and maintain a complete digital audit trail for traceability. The implementation of digital twin technology is also emerging, allowing manufacturers to simulate kitting operations and optimize layouts virtually before physical deployment, thereby reducing commissioning time and risk. Moreover, the adoption of industrial internet of things (IIoT) frameworks ensures that all kitting machinery is connected, providing continuous data streams for operational analytics, predictive maintenance scheduling, and overall equipment effectiveness (OEE) monitoring, transitioning kitting from a logistics task to a strategic, data-driven operational asset.

Regional Highlights

The global Kit Packers Market demonstrates varied growth patterns and maturity levels across different geographical regions, heavily influenced by local manufacturing intensity, labor costs, and technological adoption rates. North America, characterized by high labor costs and a strong focus on advanced automation and high-value manufacturing (aerospace, medical devices), represents a mature yet continually innovating market. The emphasis here is on precision kitting, traceability, and the integration of highly complex, software-driven systems that utilize AI and robotic vision. The growth in North America is driven by the reshoring trend, pushing domestic manufacturers to invest in automation to remain competitive globally, focusing particularly on flexible, scalable solutions that support high-mix assembly lines.

Europe, similar to North America, showcases maturity but with a significant push toward sustainable and efficient manufacturing practices, championed by the German and Scandinavian markets. The European market leads in the adoption of collaborative robotics (cobots) for kitting, integrating these flexible solutions into existing production layouts to enhance worker productivity and ergonomics. Regulations governing worker safety and the stringent quality demands of the automotive and pharmaceutical industries in countries like Germany, France, and Switzerland drive continuous investment in highly certified and validated kitting processes. The focus is on implementing modular systems that minimize energy consumption and material waste, aligning with strict EU environmental directives, making resource efficiency a key purchasing criterion.

Asia Pacific (APAC) is projected to be the fastest-growing region, dominated by the massive manufacturing bases in China, Japan, South Korea, and emerging economies like India and Vietnam. This growth is spurred by rapid industrialization, increasing foreign direct investment in manufacturing facilities, and the sheer volume of production across electronics, automotive components, and consumer goods. While Japan and South Korea focus on ultra-high-speed, precision kitting for semiconductors and high-tech assembly, China and Southeast Asia are witnessing explosive demand for scalable, cost-effective automated kitting solutions to replace traditionally manual processes and handle increasing export volumes. Government initiatives promoting factory modernization and infrastructure development further accelerate the adoption of automated kit packing machinery across the region.

- North America (NA): Focus on AI-integrated kitting, high-precision handling for aerospace and medical, and adoption of kitting for complex defense components. Driven by high labor costs and reshoring initiatives.

- Europe (EU): Strong growth in collaborative robotics adoption, emphasis on sustainable kitting practices, and regulatory-driven quality control in pharma and automotive sectors.

- Asia Pacific (APAC): Highest volume growth driven by China, India, and ASEAN countries; significant investment in automated systems for electronics and mass-market automotive parts manufacturing.

- Latin America (LATAM): Moderate growth, primarily localized in Brazil and Mexico, focusing on optimizing existing manufacturing operations through semi-automatic kitting and material handling upgrades.

- Middle East & Africa (MEA): Nascent market primarily driven by large-scale infrastructure projects and emerging domestic automotive assembly plants, demanding basic kitting solutions and associated services.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Kit Packers Market.- Bosch Rexroth

- KUKA AG

- ABB Ltd.

- Fanuc Corporation

- Siemens AG

- Honeywell Intelligrated

- Bastian Solutions

- Dematic (Kion Group)

- Toyota Industries (Vanderlande)

- Swisslog (KUKA)

- Knapp AG

- Murata Machinery

- TGW Logistics Group

- Beumer Group

- Fives Group

- SSI Schaefer

- Grenzebach Group

- JBT Corporation

- Daifuku Co., Ltd.

- Witron Logistik

Frequently Asked Questions

Analyze common user questions about the Kit Packers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary financial benefit of implementing automated kit packing systems?

The primary financial benefit is the substantial reduction in operational expenditure through minimized labor costs, decreased inventory errors (shrinkage), and improved line efficiency, leading to faster assembly throughput and higher overall production quality.

How does kitting support the principles of Lean Manufacturing?

Kitting directly supports Lean principles by eliminating the waste associated with searching for parts, reducing excess inventory near assembly stations, and ensuring Just-In-Time (JIT) material delivery, streamlining the overall value stream.

Which technological innovation is currently driving the most significant market growth?

The most significant market growth is driven by the integration of AI-powered vision systems and collaborative robotics (cobots), enabling highly accurate, flexible, and scalable kitting operations that can adapt to high-mix, low-volume production demands.

What are the main challenges for Small and Medium-sized Enterprises (SMEs) entering the automated kitting market?

SMEs primarily face challenges related to the high initial capital investment required for fully automated systems and the technical complexity involved in integrating advanced kitting software with existing legacy ERP/WMS platforms.

Is the Kit Packers Market seeing demand for sustainable packaging solutions?

Yes, driven by consumer and regulatory pressure, there is increasing demand across all sectors, particularly e-commerce and retail, for kitting solutions that incorporate sustainable, recyclable, or biodegradable packaging materials while maintaining structural integrity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager