Kraft Paper Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433615 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Kraft Paper Machines Market Size

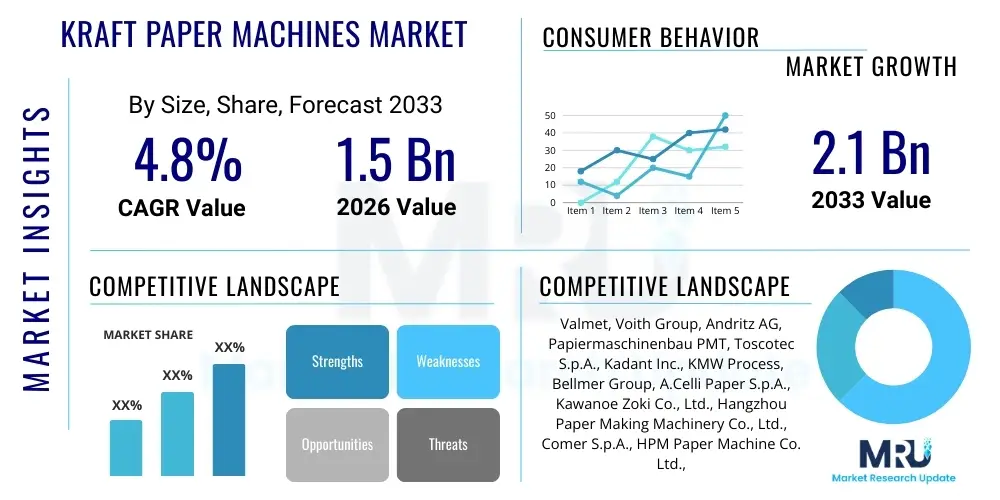

The Kraft Paper Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.1 Billion by the end of the forecast period in 2033.

Kraft Paper Machines Market introduction

The Kraft Paper Machines Market encompasses the design, manufacturing, installation, and maintenance of specialized industrial equipment utilized for producing various grades of kraft paper, which is known for its high tensile strength and durability. Kraft paper is manufactured primarily from chemical pulp produced in the kraft process, allowing it to utilize a wider range of raw materials, including sustainable forestry products and recycled content. The machinery involved ranges from stock preparation systems and headboxes to complex drying sections, reelers, and finishing equipment. These machines are engineered for high-speed operation and continuous production, catering to the massive global demand for sustainable packaging solutions.

Major applications of the resulting kraft paper include corrugated board for shipping containers, industrial sacks and bags, wrapping paper, and multiwall bags used in construction and food industries. The inherent strength and biodegradability of kraft paper make it a preferred material over plastic in many jurisdictions globally, driving consistent investment in new machine installations and capacity upgrades, particularly in high-growth packaging sectors. The market is significantly influenced by global trade volumes, e-commerce proliferation, and tightening environmental regulations that favor fiber-based materials.

Kraft Paper Machines Market Executive Summary

The global Kraft Paper Machines market exhibits robust growth driven by accelerating global demand for sustainable and biodegradable packaging materials, heavily influenced by the expansion of the e-commerce sector and stringent governmental policies restricting single-use plastics. Business trends indicate a strong focus on high-capacity and energy-efficient machinery, incorporating advanced automation systems and digitalization capabilities (Industry 4.0 standards) to minimize operational costs and optimize production quality. Key manufacturers are prioritizing modular designs that allow for easy integration of upgrades, such as specialized coating or calendering units, enhancing the versatility of the produced paper grades.

Regionally, the Asia Pacific (APAC) stands out as the primary growth engine, fueled by massive industrialization, rapid urbanization, and significant capacity expansions in countries like China, India, and Southeast Asian nations striving to meet domestic and export packaging requirements. Conversely, established markets in North America and Europe are characterized by modernization and replacement cycles, emphasizing machines capable of utilizing high levels of recycled fiber content and implementing advanced water and energy recovery systems to comply with demanding sustainability targets. The competitive landscape is moderately consolidated, dominated by a few global technology leaders who invest heavily in R&D to deliver state-of-the-art machine technologies.

In terms of segmentation, high-speed machines (above 1000 m/min) and wide-format machines (above 5 meters) are witnessing increased adoption due to economies of scale sought by major paper manufacturers. The End-Use segment is overwhelmingly dominated by containerboard production for corrugated packaging, although the demand for specialty kraft paper machines for liquid packaging board and sack kraft remains steady. The trend across all segments points towards enhanced operational visibility and predictive maintenance, making digital integration a crucial differentiator for new equipment purchases.

AI Impact Analysis on Kraft Paper Machines Market

Common user questions regarding AI in the Kraft Paper Machines Market revolve around how machine learning can enhance production efficiency, reduce energy consumption, and improve product consistency without significant downtime. Users frequently inquire about the feasibility and ROI of integrating AI systems for predictive failure analysis on critical components like drying rolls and press sections, as well as optimizing fiber usage and chemical dosing in the wet end. There is also considerable interest in AI-driven process control loops that adapt dynamically to variations in raw material quality (especially recycled pulp), ensuring consistent output despite input heterogeneity. The core concern centers on the initial investment cost, data security, and the need for specialized IT expertise to manage these complex systems, balancing innovation against operational stability.

AI's influence is transforming traditional papermaking operations from reactive maintenance to proactive, highly optimized manufacturing environments. By employing sophisticated algorithms, AI platforms analyze vast datasets generated by thousands of sensors embedded throughout the machine—monitoring temperature, vibration, moisture profiles, and operational speeds. This analysis identifies subtle patterns indicative of equipment wear or process drift long before human operators detect issues, enabling targeted maintenance interventions. This capability dramatically reduces unplanned downtime, which is extremely costly in continuous-process industries like papermaking.

Furthermore, AI plays a pivotal role in optimizing energy management and raw material utilization. Machine learning models can accurately predict the energy required for drying based on real-time pulp moisture and speed, dynamically adjusting steam and heat inputs, leading to substantial energy savings. In quality control, AI-driven visual inspection systems, integrated with high-speed cameras, can detect defects (like holes, streaks, or inconsistencies) in the paper web instantly, allowing for immediate corrective adjustments to the machine's operational parameters, thereby ensuring higher finished product quality and reducing waste.

- AI-Driven Predictive Maintenance: Reduces unplanned downtime and extends component lifespan by analyzing real-time sensor data.

- Process Optimization: Utilizes machine learning to fine-tune speed, temperature, and chemical dosing for energy efficiency and consistency.

- Enhanced Quality Control: AI vision systems perform instantaneous defect detection on the paper web, improving product consistency.

- Supply Chain Forecasting: AI models assist mills in forecasting pulp demand and managing inventory efficiently based on production schedules.

- Energy Consumption Reduction: Dynamic optimization of drying and pressing sections based on predictive models of moisture content.

DRO & Impact Forces Of Kraft Paper Machines Market

The Kraft Paper Machines Market is propelled significantly by the global shift towards environmentally conscious packaging, constrained by substantial capital investment requirements, and presented with opportunities through technological advancements in high-yield fiber processing. The interplay of these forces dictates market trajectory: sustainability demands accelerate machine adoption, high costs necessitate careful strategic investment planning, and continuous innovation enables manufacturers to meet stricter production criteria efficiently. The predominant impact force remains the ever-increasing global consumption of packaged goods driven by population growth and economic development, inextricably linking the market's success to global logistics and e-commerce expansion.

Drivers: Environmental mandates and consumer preferences for sustainable packaging strongly favor durable, biodegradable kraft paper, forcing investments in new capacity. The explosive growth of the e-commerce sector globally requires massive volumes of corrugated boxes and filler materials, maintaining consistently high demand for containerboard production machinery. Furthermore, technological leaps enhancing machine speed and width allow papermakers to achieve unprecedented economies of scale, making new investments economically attractive despite high costs.

Restraints: The primary restraint is the extremely high capital expenditure required for installing or significantly upgrading a large-scale kraft paper machine, often running into hundreds of millions of USD, posing significant barriers to entry and expansion for smaller or mid-sized players. Another crucial restraint is the inherent volatility in raw material (pulpwood) prices and energy costs, which directly impacts the profitability of the final paper producers, sometimes delaying planned machinery investments. Additionally, the increasing complexity of modern machines necessitates highly specialized technical expertise for operation and maintenance, limiting adoption in regions lacking adequate skilled labor pools.

Opportunities: Significant opportunities exist in developing highly efficient machines optimized for processing recycled or alternative fibers (e.g., bamboo, agro-waste), catering to regions with limited virgin pulp resources. Emerging markets in Africa and Latin America present greenfield investment opportunities as they seek to localize their packaging production capabilities. Furthermore, the integration of advanced digitalization (IoT, AI) into machines offers paper producers the chance to optimize energy intensity and water usage, turning sustainability compliance into a competitive operational advantage.

- Drivers: Global sustainability push; E-commerce expansion; Increased consumer preference for fiber-based packaging; Technological advancements in high-speed machinery.

- Restraints: High initial capital expenditure; Volatility in raw material and energy prices; Need for highly specialized operational expertise; Long project implementation cycles.

- Opportunity: Focus on recycled fiber utilization technologies; Untapped growth in emerging markets; Integration of sophisticated digital and AI solutions for efficiency.

- Impact Forces: Strong positive impact from environmental regulations; Moderate positive impact from technological innovation; High pressure from global competition requiring efficiency.

Segmentation Analysis

The Kraft Paper Machines Market is meticulously segmented based on key operational and structural parameters, allowing for detailed market analysis tailored to specific industrial needs and production objectives. The primary segmentation criteria include machine type, defining the fundamental technology utilized (e.g., Fourdrinier, Twin-Wire), which directly influences dewatering efficiency and paper formation quality. Further segregation occurs based on machine capacity, measured in tones per day (TPD) or meters per minute (m/min), differentiating between small, medium, and high-speed units suitable for various scale operations. The market analysis also critically segments the industry by end-use application, reflecting whether the produced paper targets containerboard, sack kraft, or specialty packaging, as each requires unique machine configurations and features.

Analyzing the market across these dimensions reveals distinct trends: Twin-wire technology is increasingly preferred for high-volume containerboard production due to its superior formation characteristics at high speeds, while modernized Fourdrinier machines often serve medium-capacity specialty paper needs. Geographically, segments focusing on lower-to-medium capacity machines are prevalent in developing nations initiating their paper manufacturing base, whereas industrialized nations overwhelmingly prioritize the largest, highest-capacity equipment to maintain cost competitiveness on a global scale. This segmentation framework assists stakeholders in precisely identifying high-growth niches and formulating strategic investment plans aligning with prevailing operational standards and end-user requirements.

- By Machine Type:

- Fourdrinier Machines

- Twin-Wire Machines

- Crescent Former Machines (less common for traditional kraft)

- By Machine Capacity (Speed):

- Low Speed (Under 500 m/min)

- Medium Speed (500 – 1000 m/min)

- High Speed (Above 1000 m/min)

- By End-Use Application:

- Containerboard (Linerboard and Fluting/Corrugating Medium)

- Sack Kraft Paper (Cement, Chemicals, Food Bags)

- Specialty Kraft Paper (Liquid Packaging Board, Release Liner)

- Wrapping and Converting Paper

- By Fiber Input:

- Virgin Fiber Machines

- Recycled Fiber (RCF) Machines

Value Chain Analysis For Kraft Paper Machines Market

The value chain for the Kraft Paper Machines market is intricate, commencing significantly upstream with the suppliers of highly specialized components and raw materials crucial for machine construction. This upstream segment includes global providers of high-precision steel alloys, specialized ceramics for dewatering elements, and advanced electronic and automation components (e.g., PLCs, sensors, drives). The effectiveness and reliability of the final paper machine are heavily dependent on the quality and synchronization of these specialized inputs. Key upstream activities involve intensive R&D to develop durable, corrosion-resistant materials capable of withstanding the harsh chemical and thermal stress inherent in the papermaking process. Strong, strategic relationships with these component suppliers are vital for machine manufacturers to ensure cost control and maintain competitive lead times for complex projects.

The core of the value chain involves the midstream activities—the design, engineering, and final assembly of the paper machines by Original Equipment Manufacturers (OEMs). This stage is highly knowledge-intensive, requiring extensive civil, mechanical, and process engineering expertise. OEMs integrate the specialized components into massive, customized machine lines. Distribution channels are predominantly direct, involving direct sales teams and technical experts who engage directly with large integrated paper mills and pulp producers globally. Given the bespoke nature of the machinery and the high investment involved, indirect sales through third-party distributors are extremely rare, reserved generally for aftermarket spare parts and minor auxiliary equipment.

Downstream, the paper machines are installed at the customer's site (paper mills). The downstream value capture focuses heavily on aftermarket services, including installation supervision, commissioning, operator training, process optimization consulting, and continuous supply of spare parts and critical consumables (e.g., fabrics, felts, chemicals). The final end-users—the paper manufacturers—then convert the finished kraft paper into final products like corrugated boxes or industrial bags. The success of the machine manufacturer is intrinsically linked to the operational efficiency and profitability achieved by the downstream paper producer, making long-term service contracts a significant revenue stream within the total value chain.

Kraft Paper Machines Market Potential Customers

Potential customers for Kraft Paper Machines are primarily large-scale entities operating within the global pulp and paper industry who require high-volume, reliable production capacity for packaging and industrial applications. The most significant customer base comprises vertically integrated pulp and paper companies that manage everything from sustainable forestry resources to final product conversion, requiring the largest, highest-capacity machines to feed their extensive converting operations. These large conglomerates frequently engage in significant capacity expansions or greenfield projects in emerging economies, driven by the need to secure regional supply chains and achieve maximum economies of scale in containerboard production. Their buying decisions are heavily influenced by machine speed, operational lifespan, and proven reliability metrics.

A secondary, yet crucial, customer segment includes independent corrugated packaging manufacturers and specialized sack producers. While they may not require the absolute highest speeds, they seek machines optimized for specific niche applications, such as high-strength sack kraft or specialty bleached kraft for food contact materials. These customers often focus on RCF (Recycled Fiber) machines, particularly in regions with strong governmental emphasis on circular economy practices. Their purchasing criteria often prioritize flexibility in utilizing varying input materials and quick changeover capabilities between different paper grades. Capital availability and governmental incentives for sustainable manufacturing play a decisive role in their investment timing and scale.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.1 Billion |

| Growth Rate | 4.8% ( Include CAGR Word with % Value ) |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Valmet, Voith Group, Andritz AG, Papiermaschinenbau PMT, Toscotec S.p.A., Kadant Inc., KMW Process, Bellmer Group, A.Celli Paper S.p.A., Kawanoe Zoki Co., Ltd., Hangzhou Paper Making Machinery Co., Ltd., Comer S.p.A., HPM Paper Machine Co. Ltd., Shandong Sun Paper Industry Joint Stock Co., Ltd., Leizhan International Paper Machinery Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Kraft Paper Machines Market Key Technology Landscape

The technological landscape within the Kraft Paper Machines market is undergoing rapid evolution, heavily focused on enhancing operational efficiency, minimizing resource consumption, and maximizing output quality under Industry 4.0 paradigms. A primary technological advancement involves the integration of sophisticated digitalization features, including the Industrial Internet of Things (IIoT), extensive sensor networks, and advanced automation controls (e.g., Distributed Control Systems - DCS). These technologies enable real-time monitoring of every phase of the papermaking process, from stock preparation consistency to final winding density, ensuring tight control and rapid optimization. This shift towards smart manufacturing facilitates remote diagnostics, predictive maintenance scheduling, and dynamic process adjustments, dramatically improving overall equipment effectiveness (OEE) and reducing operational variability.

Another crucial area of innovation lies in the drying section, which accounts for the vast majority of energy consumption in the papermaking process. Modern machines utilize advanced drying techniques such as specialized high-efficiency steam systems, infrared drying units, and improved heat recovery systems to reduce the energy footprint significantly. Furthermore, machine builders are focusing on developing innovative shoe press technologies and advanced forming sections (like gap formers or hybrid formers) that maximize dewatering mechanically before the sheet enters the thermal drying phase. These mechanical improvements are critical for reducing moisture content efficiently, leading to faster machine speeds and lower energy demands per ton of paper produced, directly addressing the pressure of rising global energy costs.

The drive towards sustainable input materials has also spurred technological development in the stock preparation and forming sections. Modern kraft paper machines are designed with highly efficient screening and cleaning systems to handle increased percentages of recycled fiber or non-wood fibers (like bagasse), ensuring high-quality paper formation even with lower-grade input materials. Additionally, machine suppliers are integrating advanced coating and calendering technologies directly into the machine line, enabling the production of specialized, high-surface-quality kraft papers (e.g., for packaging applications requiring high printability) in a single, continuous process, thereby enhancing product diversification opportunities for paper manufacturers.

Regional Highlights

The global demand for kraft paper machines is geographically diverse, yet profoundly concentrated in regions undergoing rapid industrial and demographic expansion, alongside established markets focused on sustainability and modernization.

- Asia Pacific (APAC): APAC dominates the market both in terms of new installations (greenfield projects) and capacity expansion. Countries like China, India, and Indonesia are witnessing unprecedented growth in domestic and export-oriented packaging sectors, making this region the largest consumer of new high-speed containerboard and sack kraft machines. Government initiatives promoting sustainable packaging and rapid urbanization further bolster market activity.

- Europe: Europe represents a mature market characterized primarily by replacement and upgrade investments rather than greenfield construction. The focus here is rigorously placed on efficiency, digitalization, and maximum utilization of recycled fiber (RCF) content, driven by the EU’s strict environmental mandates (e.g., the Circular Economy Action Plan). European manufacturers seek advanced technology to reduce energy and water consumption and enhance specialty paper production capabilities.

- North America: Similar to Europe, North America is a mature market where investment is primarily directed toward modernizing aging infrastructure and expanding capacity for brown kraft linerboard to serve the dominant e-commerce logistics sector. There is significant technological focus on automation and incorporating advanced sensor technology to optimize large-scale, high-speed operations.

- Latin America (LATAM): LATAM, particularly Brazil and Chile, is critical due to its abundant, sustainably managed virgin fiber resources. Investment often targets machines capable of processing high-quality virgin pulp for export-grade linerboard, focusing on speed and robust operational stability.

- Middle East and Africa (MEA): This region is an emerging market for kraft paper machines, with investment concentrated in developing paper capacity to reduce reliance on imports. Projects are often greenfield, aimed at meeting growing domestic consumer and construction demands, particularly in packaging and industrial sack applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Kraft Paper Machines Market.- Valmet

- Voith Group

- Andritz AG

- Papiermaschinenbau PMT

- Toscotec S.p.A.

- Kadant Inc.

- KMW Process

- Bellmer Group

- A.Celli Paper S.p.A.

- Kawanoe Zoki Co., Ltd.

- Hangzhou Paper Making Machinery Co., Ltd.

- Comer S.p.A.

- HPM Paper Machine Co. Ltd.

- Shandong Sun Paper Industry Joint Stock Co., Ltd.

- Leizhan International Paper Machinery Co. Ltd.

- Fujian Light Industry Machinery & Equipment Co., Ltd.

- Recard S.p.A.

- Changsha Xingyuan Paper Machinery Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Kraft Paper Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is driving the current demand for new Kraft Paper Machines?

The primary drivers are the accelerated global shift towards sustainable, fiber-based packaging solutions, mandated by environmental regulations, and the explosive volume growth in the e-commerce sector requiring massive quantities of corrugated containerboard.

How does AI technology benefit the operation of modern Kraft Paper Machines?

AI technology significantly improves operational efficiency and cost control by enabling predictive maintenance, optimizing complex process variables (like drying energy and fiber consistency), and enhancing real-time quality control through computer vision systems.

Which region currently leads the global market for new machine installations?

The Asia Pacific (APAC) region, driven by countries such as China and India, leads the market for new installations and capacity expansion, supported by rapid industrialization and high domestic demand for packaging materials.

What are the most crucial technological advancements in machine design?

Key advancements include high-efficiency drying sections (reducing energy consumption), integrated digitalization (Industry 4.0/IIoT), and improved forming technologies (Twin-Wire) that allow for higher speeds and better utilization of recycled fibers.

What is the main challenge faced by potential investors in this market?

The most significant challenge is the extremely high initial capital investment required for large-scale, high-capacity kraft paper machines, alongside the high operational costs associated with energy consumption and raw material volatility.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager