Labeller Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436975 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Labeller Market Size

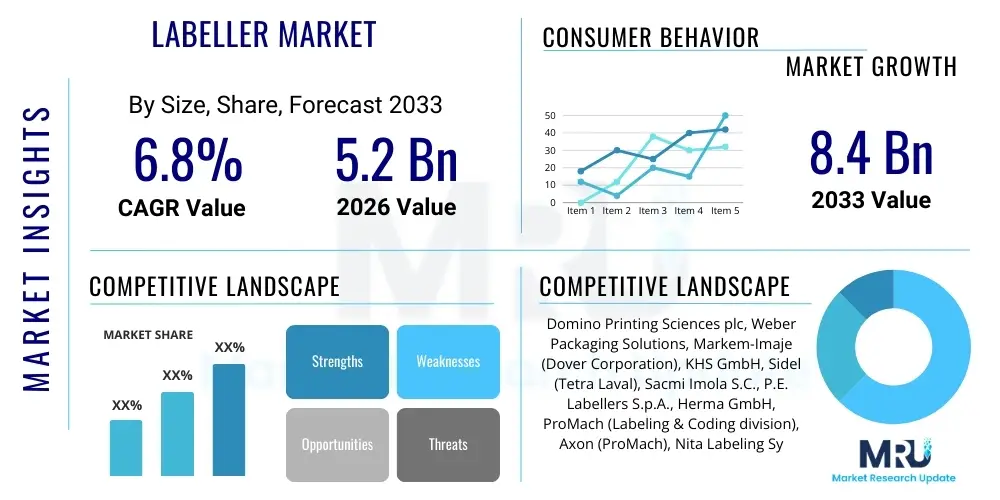

The Labeller Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $5.2 Billion in 2026 and is projected to reach $8.4 Billion by the end of the forecast period in 2033.

Labeller Market introduction

The Labeller Market encompasses a diverse range of automated and semi-automated machinery essential for applying pre-printed or print-on-demand labels to various products and packaging formats. These systems are critical components in modern production lines, facilitating brand identification, regulatory compliance, pricing, tracking, and consumer information dissemination. The primary products include pressure-sensitive labellers, sleeve labellers, wet-glue labellers, and print-and-apply systems, categorized further by application speed (low, medium, and high volume) and configuration (linear or rotary). The evolution of packaging complexity, coupled with the relentless demand for higher throughput, mandates continuous innovation in application precision and integration capabilities, making labellers indispensable assets across consumer goods, logistics, and healthcare sectors globally.

Major applications for high-speed labelling solutions reside within the Food and Beverage (F&B) industry, particularly for bottled water, carbonated drinks, and perishable goods, where accurate labeling ensures shelf life management and brand aesthetics are maintained under rigorous production schedules. The pharmaceutical sector represents another significant application area, driven by stringent regulatory requirements for serialization and track-and-trace capabilities, necessitating highly accurate and validated print-and-apply technologies for vials, cartons, and syringes. These advanced systems are instrumental in combating counterfeiting and ensuring global supply chain integrity. The benefits derived from deploying cutting-edge labellers include significant reductions in manual labor costs, increased production line efficiency, superior label placement accuracy, and enhanced inventory control through automated data capture.

Driving factors propelling the Labeller Market growth include the exponential expansion of the e-commerce sector, which mandates efficient, high-speed labeling for logistics and shipping packages, often requiring variable data printing capabilities. Furthermore, global legislative actions, such as mandatory nutrient labeling, traceability mandates in food supply chains, and unique device identification (UDI) requirements in medical devices, compel manufacturers to invest in advanced labeling infrastructure. The transition toward sustainable packaging materials, including thinner films and recycled content, also forces labeller manufacturers to develop specialized application technologies that can handle delicate or irregular surfaces without compromising adhesion or production speeds. This confluence of regulatory push and operational efficiency needs forms the foundational engine for sustained market expansion.

Labeller Market Executive Summary

The Labeller Market is characterized by robust growth, primarily fueled by global industrial automation trends and the escalating complexity of product traceability regulations. Business trends indicate a strong shift towards modular and integrated labelling solutions capable of seamless communication within broader Industry 4.0 frameworks, utilizing protocols such as OPC UA for real-time data exchange and performance monitoring. Key market players are concentrating on developing servo-driven, high-precision applicators that minimize downtime and simplify changeover processes, addressing the fast-changing demands of contract packaging organizations (CPOs) and large multinational manufacturers requiring flexibility. Investment in sophisticated vision inspection systems, integrated directly into the labeller, is becoming standard practice to ensure 100% label presence and data integrity verification, significantly mitigating compliance risks.

Regional trends highlight the Asia Pacific (APAC) region as the dominant growth engine, driven by massive investments in manufacturing infrastructure, rapid urbanization, and rising consumer spending power, particularly in economies like China and India. The stringent regulatory environment in North America and Europe continues to drive demand for highly compliant and validated machinery, particularly within the pharmaceutical and medical device sectors, where error rates must be virtually zero. European markets show a specific propensity for sustainable labelling equipment, favoring machines designed to handle biodegradable materials and offering reduced energy consumption. Latin America and the Middle East and Africa (MEA) are emerging markets, primarily adopting robust, cost-effective semi-automated and medium-speed solutions to meet burgeoning domestic industrial demands and initial export compliance requirements.

Segment trends underscore the accelerated adoption of print-and-apply labellers, essential for logistics and mass customization, offering flexibility in printing variable information like barcodes, expiration dates, and QR codes immediately prior to application. While pressure-sensitive labels remain the market leader due to their versatility and ease of use, the sleeve labelling segment is experiencing high growth, particularly in the beverage industry, due to the aesthetic appeal and 360-degree branding opportunities offered by full-body shrink sleeves. Technology advancements are also notable in the roll-fed/cut-and-stack label segment, with improved adhesives and application techniques maintaining competitiveness for high-volume, low-cost operations. Overall, the market trajectory favors high levels of automation, precision, and data connectivity across all machinery types.

AI Impact Analysis on Labeller Market

User inquiries regarding AI's impact on the Labeller Market frequently center on predictive maintenance, the integration of advanced machine vision for real-time quality assurance, and the optimization of operational throughput in dynamic environments. Users are particularly concerned with how AI-driven analytics can transition maintenance strategies from reactive or scheduled interventions to truly predictive ones, minimizing unplanned stoppages, which are costly in high-volume production. A significant area of interest is the deployment of deep learning models within vision systems to detect subtle, complex labelling defects—such as slight wrinkles, registration errors, or print quality degradation—that traditional rule-based systems often miss. Furthermore, manufacturers are exploring AI's role in optimizing line balance and recipe management, automatically adjusting labeller speeds and tension parameters based on upstream and downstream conditions and material variations, maximizing efficiency across diverse SKUs and materials.

The incorporation of Artificial Intelligence is fundamentally transforming the operational paradigm of advanced labelling machinery, moving them from static application devices to intelligent, self-optimizing stations within the production line. AI algorithms analyze historical performance data, environmental factors, and component wear indicators (like motor vibrations or thermal signatures) to predict potential component failure weeks in advance, scheduling maintenance precisely when it is necessary, thus achieving near-zero unplanned downtime. This capability drastically reduces the total cost of ownership (TCO) for manufacturers and ensures higher overall equipment effectiveness (OEE), providing a significant competitive advantage in markets characterized by tight margins and just-in-time manufacturing requirements. The self-learning nature of these systems allows labellers to continuously improve their efficiency over their operational lifespan.

Beyond predictive maintenance, AI is elevating quality control standards to unprecedented levels. Machine learning models, trained on millions of images of both perfect and defective labels, can achieve human-level accuracy in defect detection at high speeds, far exceeding the capabilities of manual inspection or basic optical sensors. These AI-powered vision systems can also interpret variable data printing (VDP) quality, instantly verifying serialized codes against databases, a critical function in pharmaceutical traceability. Moreover, AI is beginning to influence design optimization, simulating the performance of new application techniques or adhesive types under various production stresses, accelerating the development cycle for next-generation labelling equipment designed for complex, recyclable packaging formats.

- AI enables predictive maintenance, reducing unplanned downtime by anticipating component failures.

- Deep learning models enhance label quality inspection, detecting subtle defects like wrinkles and misregistration at high speed.

- Optimized recipe management allows labellers to autonomously adjust operating parameters based on real-time line conditions and material properties.

- AI-driven data analytics provide insights into operational bottlenecks and process variability, improving overall throughput.

- Automation of VDP validation and serialization checks ensures regulatory compliance and integrity of track-and-trace data.

- Autonomous robotic systems integration for non-standard labeling tasks, particularly in e-commerce fulfillment centers.

DRO & Impact Forces Of Labeller Market

The dynamic nature of the Labeller Market is influenced by a complex interplay of Drivers, Restraints, and Opportunities (DRO), collectively shaping the impact forces on investment and technological development. The primary drivers are the massive global growth of the packaged goods sector, particularly fueled by urbanization and rising disposable incomes in emerging markets, coupled with the stringent, non-negotiable regulatory demands for product information, traceability, and anti-counterfeiting measures across healthcare and food safety domains. Simultaneously, the persistent push towards factory automation and lean manufacturing principles compels industries to adopt high-speed, integrated labelling solutions to maximize efficiency and reduce labor reliance. These forces collectively exert a strong positive impact, dictating that investment in advanced, compliant machinery is mandatory for market participation.

Restraints, however, temper this growth trajectory. The high initial capital investment required for sophisticated, fully automated labelling systems, especially those incorporating servo technology and integrated vision inspection, can be prohibitive for small and medium-sized enterprises (SMEs). Furthermore, the technical complexity associated with integrating these advanced systems into existing legacy production lines, often requiring specialized skills for operation, maintenance, and troubleshooting, presents a significant barrier. Another notable restraint is the increasing variability in packaging materials, driven by sustainability goals, which introduces challenges related to label adhesion, material handling, and equipment versatility, requiring continuous, costly adjustments and material R&D to ensure reliable performance.

Opportunities within the market largely revolve around technological convergence and addressing sustainability imperatives. The opportunity for market penetration is strong in developing smart, connected labellers integrated with the Industrial Internet of Things (IIoT), enabling remote diagnostics, real-time OEE monitoring, and cloud-based data aggregation for fleet management. Moreover, the demand for flexible packaging and unique product personalization is creating opportunities for advanced digital printing and variable data labelling systems, capable of handling small batch sizes efficiently. Addressing environmental concerns through the development of equipment optimized for thin films, linerless labels (eliminating backing waste), and compostable materials represents a significant, forward-looking opportunity that will define market leadership in the coming decade. These forces create high impact, pressuring manufacturers toward specialized innovation and digital capabilities.

Segmentation Analysis

The Labeller Market is highly granular, segmented across several critical dimensions including technology type, application speed, end-user industry, and operational automation level. Understanding these segments is crucial for manufacturers to tailor product development and market strategies. The segmentation highlights the diverse needs of the global packaging industry, ranging from high-volume, standardized applications in beverages to low-volume, highly complex and regulated applications in specialized chemicals or medical diagnostics. Each segment requires specialized machinery designed to handle specific label formats, material substrates, and production environments, leading to a highly customized market offering dominated by application-specific solutions.

- By Technology Type:

- Pressure-Sensitive Labellers (PSL)

- Shrink Sleeve Labellers

- Wet Glue Labellers (Cut-and-Stack)

- Roll-Fed Labellers

- Print & Apply Labellers (P&A)

- RFID Labellers

- By Application Speed:

- Low Speed (Up to 100 products/min)

- Medium Speed (100–300 products/min)

- High Speed (Over 300 products/min)

- By Automation Level:

- Automatic Labellers

- Semi-Automatic Labellers

- Manual Labelling Systems

- By End-User Industry:

- Food and Beverage (F&B)

- Pharmaceuticals and Healthcare

- Cosmetics and Personal Care

- Chemicals and Industrial Products

- Logistics and E-commerce

- Automotive

Value Chain Analysis For Labeller Market

The Labeller Market value chain begins with upstream activities involving the sourcing and processing of raw materials, primarily specialized components like servo motors, electronic controls (PLCs), sensor technology, and structural metals. Key upstream suppliers include manufacturers of label materials (adhesives, substrates, release liners), which are critical inputs affecting the final machine design and performance. The quality and cost of these components directly impact the profitability and technological capability of the Original Equipment Manufacturers (OEMs). Effective management of the upstream segment is vital, particularly regarding the standardization of components and securing resilient supply chains for high-precision electronics, which have seen increased volatility and lead times recently.

The mid-stream segment is dominated by the Labeller OEMs, who specialize in machine design, precision engineering, assembly, software integration, and factory acceptance testing (FAT). These manufacturers focus heavily on research and development (R&D) to innovate application techniques, increase throughput, and integrate machine intelligence, often tailoring solutions for specific industry compliance requirements, such as pharmaceutical serialization standards. Distribution channels play a crucial role in market reach; large, multinational OEMs often utilize a mix of direct sales forces for strategic accounts and complex projects, alongside strong partnerships with specialized regional distributors and system integrators. Indirect channels, represented by distributors, provide localized technical support, spare parts inventory, and installation services, particularly in geographically dispersed or emerging markets, ensuring broad market coverage.

Downstream analysis focuses on the end-users and post-sales activities, which generate significant revenue through spare parts, service contracts, and consumable sales (e.g., label rolls and thermal transfer ribbons). End-users, including Consumer Packaged Goods (CPG) companies and contract packagers, rely heavily on reliable, long-term support for maintaining operational efficiency and compliance. After-sales service, encompassing predictive maintenance contracts, software updates, and training, is a major differentiator in this market. The effectiveness of the service network, whether direct from the OEM or through certified distributors, profoundly influences customer satisfaction and repeat business, effectively closing the value loop by providing crucial operational feedback for future product iterations.

Labeller Market Potential Customers

The primary customers for advanced labellers are enterprises operating high-volume, automated production environments that require precise and regulatory-compliant product identification. The Food and Beverage (F&B) sector constitutes the largest end-user segment, encompassing everything from major bottling corporations requiring rotary high-speed wet glue or roll-fed solutions to prepared meal manufacturers needing versatile pressure-sensitive systems for complex tray and lid applications. These customers prioritize speed, reliability, washdown capability, and ease of SKU changeover to accommodate rapid product cycles. Their purchasing decisions are critically dependent on minimizing OEE losses and ensuring complete regulatory adherence concerning nutritional and allergen information.

The Pharmaceutical and Healthcare industries represent the highest value segment, where the complexity and precision demands are paramount. Potential customers here include large pharmaceutical manufacturers, contract drug organizations (CDOs), and medical device producers. These entities require validated print-and-apply systems capable of complex serialization, handling small vials and ampoules, and integrating specialized vision systems for 2D data matrix verification and tamper evidence labeling. Investment in these sectors is driven less by cost and more by mandatory compliance with global track-and-trace legislation (e.g., UDI, EU FMD, DSCSA), where equipment validation documentation and software security are essential prerequisites for sale.

Additionally, the rapidly expanding Logistics and E-commerce sector forms a high-growth customer base, particularly for integrated print-and-apply systems designed for shipping cartons and fulfillment packets. As direct-to-consumer models proliferate, these customers require robust, industrial-grade systems that can handle continuous, high-speed, variable data printing, often integrated directly with warehouse management systems (WMS). Other significant potential customers include the Cosmetics industry, valuing aesthetic precision for high-end product presentation, and the Chemical sector, requiring durable, hazard-resistant labels applied precisely to drums and containers under challenging industrial conditions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $5.2 Billion |

| Market Forecast in 2033 | $8.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Domino Printing Sciences plc, Weber Packaging Solutions, Markem-Imaje (Dover Corporation), KHS GmbH, Sidel (Tetra Laval), Sacmi Imola S.C., P.E. Labellers S.p.A., Herma GmbH, ProMach (Labeling & Coding division), Axon (ProMach), Nita Labeling Systems, Fuji Seal International, Inc., Multi-Pack Solutions, Labelette Company, Accutek Packaging Equipment, CTM Labeling Systems, Etipack S.p.A., Trine Labeling Systems, Inline Labeling Equipment, Marel hf. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Labeller Market Key Technology Landscape

The current technology landscape in the Labeller Market is heavily influenced by the mandates of Industry 4.0, emphasizing connectivity, precision, and integration. Servo-driven application technology represents a core innovation, replacing traditional mechanical indexing systems. Servo motors offer unparalleled precision in label placement, highly repeatable operation, and the ability to adjust speed and tension digitally, which is crucial when handling delicate or irregular container shapes and thin film materials. This digital control architecture facilitates faster and simpler changeovers between different product formats, dramatically improving Overall Equipment Effectiveness (OEE) and minimizing waste associated with manual adjustments, making it the standard for high-speed automatic machinery in mature markets.

The integration of advanced optical inspection and machine vision systems, increasingly powered by AI and deep learning, is another transformative technology. These sophisticated systems utilize high-resolution cameras and pattern recognition algorithms to perform 100% verification of label quality, position, barcode readability (including 2D data matrices), and variable data accuracy at line speeds exceeding 500 products per minute. This level of verification is non-negotiable in pharmaceutical and high-value consumer goods packaging, ensuring both brand integrity and regulatory compliance. Furthermore, the adoption of Variable Data Printing (VDP) technologies, such as high-resolution thermal transfer overprinting (TTO) and inkjet systems, directly integrated into the labeller, allows for simultaneous printing and application of unique, serialized codes or customized marketing messages, enhancing supply chain visibility and personalized consumer engagement.

Looking forward, technologies focused on sustainability and product security are gaining momentum. Linerless labelling technology, which utilizes silicone-coated adhesive on the front of the label, eliminating the need for a backing liner, significantly reduces material waste and transportation costs—a major selling point in environmentally conscious regions. Simultaneously, the demand for smart packaging solutions is driving the integration of RFID (Radio Frequency Identification) and NFC (Near Field Communication) tag application systems into high-speed labellers. These systems allow for enhanced anti-counterfeiting measures, improved inventory management through item-level tracking, and enable sophisticated consumer interaction via smartphone scanning, merging physical product identification with digital informational ecosystems.

Regional Highlights

The global Labeller Market exhibits distinct regional dynamics driven by varying levels of industrial maturity, regulatory frameworks, and consumer market size. North America (NA) and Europe are characterized by high investment in sophisticated, automatic, and IIoT-enabled machinery, prioritizing maximum efficiency and adherence to rigorous health and safety standards. In North America, the rapid expansion of third-party logistics (3PLs) and the massive scale of the food processing industry necessitate robust Print & Apply systems for cartons and high-speed PSL for bottling. European demand is heavily skewed towards sustainable solutions, driving the adoption of linerless and energy-efficient servo-driven equipment, often mandated by strict environmental directives.

Asia Pacific (APAC) stands out as the fastest-growing region, contributing the largest share of market revenue growth, primarily due to expansive industrialization, increased foreign direct investment in manufacturing, and a burgeoning middle class demanding packaged goods. Countries like China, India, and Southeast Asian nations are rapidly automating their production lines, shifting from semi-automatic to medium-to-high-speed automatic labellers to handle mass production volumes. While cost-sensitivity remains a factor, regulatory harmonization and the export needs of major manufacturers are increasingly driving demand for globally compliant serialization and identification equipment, particularly in the pharmaceutical supply chains concentrated in this region.

Latin America (LATAM) and the Middle East and Africa (MEA) represent high-potential, yet developing, markets. Growth in LATAM is concentrated in Brazil and Mexico, focusing on the domestic demand for beverages and processed foods, leading to steady adoption of reliable, mid-range PSL and wet glue systems. The MEA region, particularly the GCC countries, is witnessing significant infrastructure investment in food security and pharmaceuticals, which generates demand for new, compliant labelling infrastructure. These regions generally favor robust, easy-to-maintain equipment and often enter the market through strategic partnerships with established global OEMs offering localized service and support structures.

- Asia Pacific (APAC): Dominant region driven by manufacturing output, urbanization, and rapid automation adoption in China and India; high demand for medium and high-speed packaging machinery.

- North America (NA): Focus on high-precision, IIoT-integrated solutions, strong demand from E-commerce logistics and pharmaceutical serialization compliance (DSCSA).

- Europe: Driven by strict environmental regulations and high labor costs, leading to high adoption of servo-driven, energy-efficient, and sustainable linerless labelling technology.

- Latin America (LATAM): Emerging market focused on local F&B production, gradual shift from semi-automatic to reliable automatic systems for regional distribution.

- Middle East and Africa (MEA): Growing investment in food processing and healthcare infrastructure, requiring compliance-focused equipment, particularly in GCC states.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Labeller Market.- Domino Printing Sciences plc

- Weber Packaging Solutions

- Markem-Imaje (Dover Corporation)

- KHS GmbH

- Sidel (Tetra Laval)

- Sacmi Imola S.C.

- P.E. Labellers S.p.A.

- Herma GmbH

- ProMach (Labeling & Coding division)

- Axon (ProMach)

- Nita Labeling Systems

- Fuji Seal International, Inc.

- Multi-Pack Solutions

- Labelette Company

- Accutek Packaging Equipment

- CTM Labeling Systems

- Etipack S.p.A.

- Trine Labeling Systems

- Inline Labeling Equipment

- Marel hf.

Frequently Asked Questions

Analyze common user questions about the Labeller market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of adopting linerless labelling systems?

Linerless labelling offers significant operational and environmental advantages by eliminating the silicone-coated backing paper (liner). This reduces material waste disposal costs, increases the number of labels per roll (minimizing changeovers and maximizing uptime), and decreases transportation requirements due aligning with corporate sustainability initiatives and enhancing overall line efficiency.

How is Industry 4.0 influencing the design and function of modern labellers?

Industry 4.0 drives the need for connectivity, integrating labellers with IIoT platforms via standardized protocols (e.g., OPC UA). This allows for real-time performance monitoring, remote diagnostics, automated data capture for compliance reporting, and predictive maintenance scheduling, transitioning machinery into smart, self-optimizing production assets.

Which end-user segment drives the highest demand for high-speed rotary labellers?

The Food and Beverage sector, specifically the high-volume bottling segment (water, soft drinks, beer), drives the highest demand for high-speed rotary labellers. These systems are essential for applying cut-and-stack, roll-fed, or PSL labels at throughput rates often exceeding 60,000 containers per hour, ensuring continuous, efficient line operation.

What is serialization and how do labellers support pharmaceutical compliance?

Serialization is the mandatory assignment of a unique identifier to individual saleable drug units. Labellers support pharmaceutical compliance by integrating high-resolution print-and-apply systems and validated machine vision inspection to accurately print and verify the 2D data matrix codes and human-readable data before application, satisfying global track-and-trace regulations like DSCSA and FMD.

What technical challenges are associated with labeling sustainable or recycled packaging materials?

Sustainable packaging, often made of thinner, softer, or post-consumer recycled (PCR) plastics, presents technical challenges regarding application precision and label adhesion. Labellers require specialized low-tension handling systems, precise vacuum controls, and optimized adhesive chemistries to ensure wrinkle-free application without damaging the delicate container substrate during high-speed operation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager