Laboratory Coating Machine Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440626 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Laboratory Coating Machine Market Size

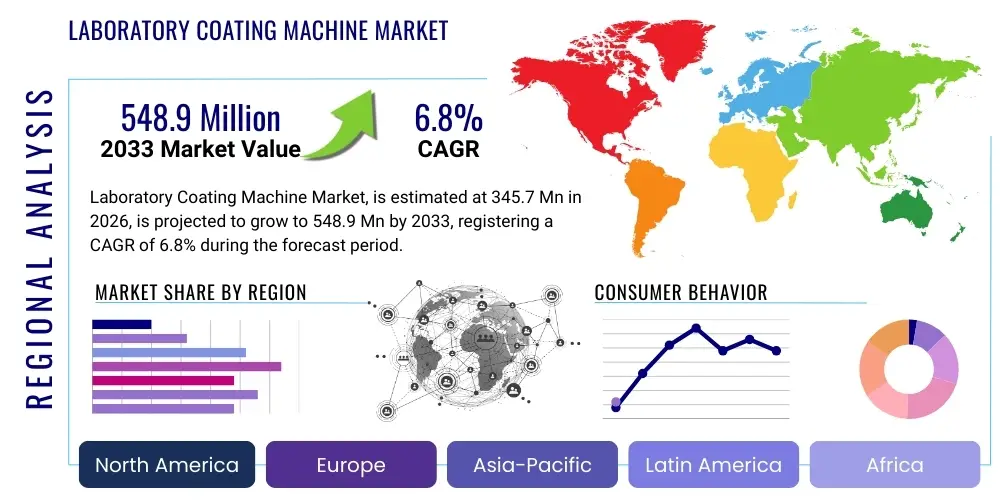

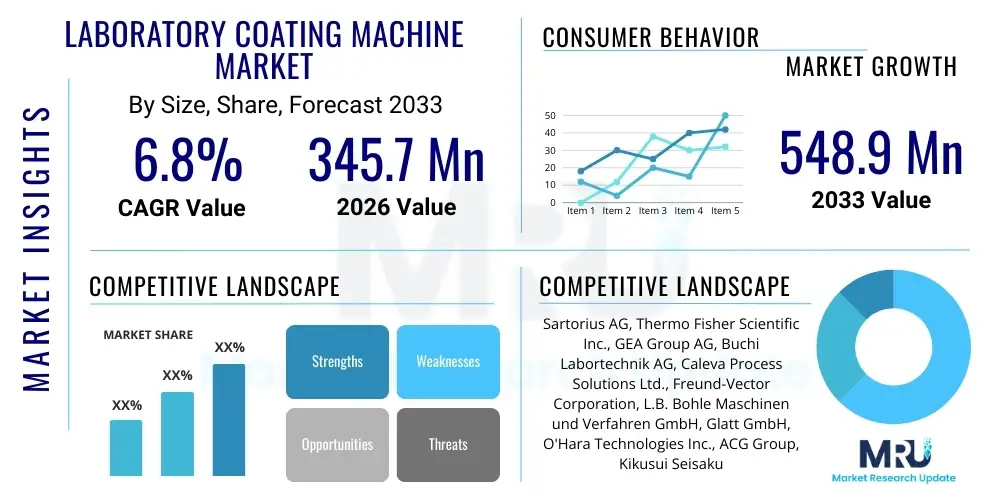

The Laboratory Coating Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 345.7 Million in 2026 and is projected to reach USD 548.9 Million by the end of the forecast period in 2033. This robust growth trajectory is primarily driven by escalating research and development activities across various industries, particularly pharmaceuticals, biotechnology, and advanced materials. The increasing demand for precise and reproducible coating processes in laboratory settings, coupled with technological advancements in machine capabilities, significantly contributes to this expansion.

The market's valuation reflects the critical role laboratory coating machines play in developing and optimizing new formulations, drug delivery systems, and functional materials. As industries continue to prioritize innovation and product differentiation, the investment in sophisticated laboratory equipment capable of handling intricate coating requirements becomes imperative. This sustained demand from both established research institutions and emerging biotech startups underpins the market's consistent upward trend, positioning it as a vital segment within the broader laboratory equipment landscape.

Laboratory Coating Machine Market introduction

The Laboratory Coating Machine Market encompasses the design, manufacturing, and distribution of specialized equipment used for applying thin layers of material onto substrates in a controlled laboratory environment. These machines are crucial for various applications, including drug formulation, material science research, and product development, allowing for precise control over coating thickness, uniformity, and composition. The primary objective is to replicate and optimize industrial coating processes on a smaller scale, facilitating experimentation and parameter refinement before large-scale production. This includes techniques such as film coating, tablet coating, spray coating, and dip coating, tailored to specific research needs.

Major applications for laboratory coating machines span across the pharmaceutical, biotechnology, chemical, and food and beverage industries. In pharmaceuticals, they are indispensable for developing enteric coatings, sustained-release formulations, and taste masking for tablets and pellets. Biotechnology leverages these machines for creating biocompatible coatings on medical devices or for encapsulation purposes. In material science, they enable the creation of functional surfaces for advanced electronics, protective layers, or catalyst supports. The benefits of using these machines include enhanced product stability, improved bioavailability, precise dose control, extended shelf life, and the ability to impart specific functional properties to materials, all achievable with high reproducibility and efficiency.

Driving factors for the growth of this market include the global surge in pharmaceutical R&D spending, the increasing complexity of drug formulations requiring advanced coating solutions, and the growing demand for personalized medicine and specialized material coatings. Furthermore, the push for automation in laboratories to improve efficiency and reduce human error, coupled with stringent regulatory requirements demanding highly controlled and documented processes, further propels the adoption of sophisticated laboratory coating machines. The continuous development of novel materials and the need for their surface modification for enhanced performance also act as significant market accelerators.

Laboratory Coating Machine Market Executive Summary

The Laboratory Coating Machine Market is experiencing significant momentum, driven by a confluence of evolving business trends, robust regional growth, and distinct segmental shifts. Business trends indicate a strong emphasis on automation and digitalization within laboratory environments, fostering demand for smart, integrated coating solutions that offer remote monitoring, data logging, and predictive maintenance capabilities. There is also a notable trend towards customization, with manufacturers offering modular systems and specialized coating techniques to cater to niche research applications and increasingly complex material requirements. The imperative for faster R&D cycles and cost-efficiency further drives the adoption of advanced, high-throughput laboratory coating machines across various industries, pushing innovation in design and functionality.

Regionally, North America and Europe continue to dominate the market due to their mature pharmaceutical and biotechnology sectors, substantial R&D investments, and advanced research infrastructure. However, the Asia Pacific region is rapidly emerging as a high-growth market, propelled by expanding contract research organizations (CROs), increasing government support for scientific research, and a burgeoning pharmaceutical manufacturing base, particularly in countries like China and India. Latin America, the Middle East, and Africa are also expected to witness steady growth as healthcare infrastructure improves and industrialization gains pace, leading to greater demand for localized R&D capabilities and associated laboratory equipment.

Segmentation trends highlight a growing preference for automatic and semi-automatic machines over manual variants, reflecting the industry's move towards higher precision, reproducibility, and reduced manual intervention. In terms of application, the pharmaceutical and biotechnology sectors remain the largest end-users, driven by continuous innovation in drug delivery systems and biologics. However, the advanced materials and chemical industries are showing accelerated adoption, utilizing these machines for developing functional coatings, nanoparticles, and specialty chemicals. Within the technology landscape, continuous coating processes and integration with analytical instruments are gaining traction, signaling a future where laboratory coating machines are integral components of fully automated, intelligent research workflows.

AI Impact Analysis on Laboratory Coating Machine Market

Users frequently inquire about how Artificial Intelligence (AI) and Machine Learning (ML) could transform the functionality and efficiency of laboratory coating machines. Common questions revolve around AI's role in process optimization, predictive maintenance, data analysis, and the development of novel coating formulations. There is significant interest in how AI can enhance precision and reproducibility, reduce experimental errors, and accelerate R&D timelines, ultimately leading to faster market introduction of new products. Concerns often surface regarding the initial investment required for AI integration, the complexity of implementation, and the need for specialized data science skills within traditional laboratory settings. Users also expect AI to facilitate real-time adaptive process control and to unlock new possibilities for personalized and high-performance coatings, moving beyond conventional trial-and-error methodologies.

The integration of AI into laboratory coating machines is anticipated to be a transformative force, enabling unprecedented levels of control, efficiency, and discovery. AI algorithms can analyze vast datasets generated during coating experiments, identifying optimal parameters that might be missed by human operators. This capability extends to predicting coating performance based on input variables, thereby significantly reducing the number of physical trials required and accelerating the formulation development process. Beyond process optimization, AI can contribute to equipment longevity by monitoring machine health, predicting potential failures, and scheduling proactive maintenance, minimizing downtime and operational costs.

Furthermore, AI-driven systems can provide invaluable insights into the complex interactions between coating materials, substrates, and processing conditions, leading to a deeper understanding of coating mechanisms. This advanced analytical capability is particularly critical for developing highly specialized coatings for new-generation pharmaceuticals, medical devices, and advanced materials where precision and novel functionalities are paramount. The ability of AI to adapt and learn from continuous operation also paves the way for intelligent, self-optimizing coating systems that can autonomously adjust parameters to achieve desired outcomes, marking a significant leap forward in laboratory automation and research efficacy.

- AI-driven optimization of coating parameters: Enhances precision and reproducibility, reducing experimental variability.

- Predictive maintenance capabilities: Utilizes machine learning to anticipate equipment failures, minimizing downtime and repair costs.

- Automated data analysis and interpretation: Processes large volumes of experimental data to identify trends and insights faster than manual methods.

- Accelerated formulation development: AI algorithms can suggest optimal coating formulations and processes, shortening R&D cycles.

- Real-time adaptive process control: Enables machines to adjust coating parameters dynamically in response to environmental or material changes.

- Enhanced quality control: AI vision systems can detect defects and ensure coating uniformity with high accuracy.

- Personalized coating solutions: Facilitates the development of highly customized coatings tailored to specific application requirements.

- Integration with LIMS and ELN systems: Improves data integrity, traceability, and overall laboratory workflow efficiency.

- Simulation and virtual prototyping: Allows for virtual testing of coating processes, reducing the need for costly physical experiments.

- Knowledge discovery: AI can uncover hidden correlations between material properties and coating outcomes, advancing scientific understanding.

DRO & Impact Forces Of Laboratory Coating Machine Market

The Laboratory Coating Machine Market is shaped by a dynamic interplay of drivers, restraints, and opportunities, collectively forming the impact forces that dictate its growth trajectory. Key drivers include the ever-increasing investment in pharmaceutical and biotechnology research and development, necessitating advanced equipment for drug formulation and delivery system innovation. The rising demand for specialized and functional coatings across various industries, from medical devices to advanced electronics, further propels market expansion. Moreover, the global shift towards automation and digital integration in laboratory settings, aimed at improving efficiency, reproducibility, and data management, significantly boosts the adoption of sophisticated coating machines. Stringent regulatory standards for product quality and process control also compel manufacturers and researchers to invest in precise and reliable laboratory coating solutions.

However, the market faces several notable restraints. The high initial capital investment associated with acquiring advanced laboratory coating machines can be a significant barrier for smaller research institutions and emerging companies, particularly in developing regions. The operational complexity and the requirement for highly skilled personnel to operate and maintain these sophisticated machines also pose challenges, potentially increasing operational costs and limiting widespread adoption. Furthermore, the rapid pace of technological change necessitates continuous upgrades and training, adding to the overall cost burden. Supply chain disruptions, often exacerbated by global events, can also impact manufacturing and delivery timelines, creating market volatility.

Despite these challenges, substantial opportunities exist for market growth and innovation. The expansion of personalized medicine and regenerative therapies opens new avenues for customized coating applications, requiring novel laboratory solutions. Emerging economies present vast untapped potential, driven by improving healthcare infrastructure, increasing R&D spending, and growing industrialization. Technological advancements, particularly in areas like continuous manufacturing, nanotechnology, and artificial intelligence, offer opportunities for developing next-generation coating machines that are more efficient, versatile, and intelligent. Collaboration between academic institutions, industry players, and technology providers can accelerate innovation, leading to solutions that address current market gaps and unlock future growth prospects.

Segmentation Analysis

The Laboratory Coating Machine Market is comprehensively segmented to provide a detailed understanding of its diverse landscape and to identify specific growth drivers and challenges within each category. This segmentation allows for targeted market strategies and highlights areas of significant investment and innovation. The primary dimensions for segmentation include machine type, application area, and operational scale, each reflecting distinct user needs and technological requirements. By analyzing these segments, stakeholders can gain critical insights into market dynamics, competitive positioning, and future opportunities.

- By Type:

- Automatic Laboratory Coating Machines: Offer high precision, reproducibility, and minimal human intervention, often integrated with automated control systems.

- Semi-Automatic Laboratory Coating Machines: Provide a balance between automation and manual control, suitable for diverse research needs and budget constraints.

- Manual Laboratory Coating Machines: Cost-effective and straightforward, primarily used for basic research or smaller-scale experimental work.

- By Application:

- Pharmaceutical Industry: Dominant segment, driven by drug formulation, taste masking, controlled release, and enteric coating development.

- Biotechnology Industry: Used for coating medical devices, cell encapsulation, and bio-functionalization of surfaces.

- Chemical Industry: Applied in catalyst development, polymer coatings, and specialty chemical synthesis.

- Food & Beverage Industry: For nutritional supplements, flavor encapsulation, and protective coatings on food products.

- Others (Academic Research, Material Science, Cosmetics): Includes diverse research applications in universities, R&D labs, and cosmetic product development.

- By Scale:

- Benchtop Laboratory Coating Machines: Compact, ideal for small-scale experiments, feasibility studies, and academic research.

- Pilot Scale Laboratory Coating Machines: Larger capacity, used for process optimization, scale-up studies, and clinical trial material production.

- Production Scale Laboratory Coating Machines (Small-scale Production Units): Bridge the gap between pilot and full commercial production, offering higher throughput for early commercialization or specialized batches.

Value Chain Analysis For Laboratory Coating Machine Market

The value chain for the Laboratory Coating Machine Market is a complex ecosystem encompassing various stages, from raw material sourcing to end-user application and after-sales support. Upstream analysis involves the procurement of specialized components such as precision pumps, spray nozzles, control systems, drying elements, and high-grade stainless steel for machine fabrication. Key suppliers include manufacturers of electronic components, specialized alloys, and automation software. The quality and availability of these components directly impact the final product's performance, reliability, and cost-effectiveness. Strong relationships with reliable suppliers are crucial for maintaining consistent production quality and managing supply chain risks, ensuring that the core technological elements meet the stringent requirements of laboratory environments.

Midstream activities primarily involve the design, engineering, assembly, and rigorous testing of the laboratory coating machines. Manufacturers invest heavily in research and development to innovate coating technologies, improve user interfaces, and integrate advanced features like automation and data logging. This stage also includes compliance with various international standards and regulations, particularly for machines destined for pharmaceutical and medical device applications. Manufacturing processes emphasize precision engineering, cleanroom assembly where necessary, and comprehensive quality control checks to ensure optimal performance, durability, and safety of the equipment. Efficient production processes and lean manufacturing principles are often adopted to optimize costs and shorten lead times.

Downstream analysis focuses on distribution channels, sales, and post-sales services. Direct channels involve manufacturers selling directly to large pharmaceutical companies, research institutions, and government laboratories, often with dedicated sales teams providing specialized support. Indirect channels include distributors, resellers, and channel partners who help extend market reach, especially in diverse geographic regions or to smaller clients. These partners often provide local support, installation, and initial training. After-sales services, including maintenance contracts, spare parts availability, technical support, and user training, are critical for customer satisfaction and long-term relationships. Both direct and indirect distribution strategies are employed to ensure broad market penetration and comprehensive customer service, adapting to regional market dynamics and customer preferences.

Laboratory Coating Machine Market Potential Customers

The potential customer base for laboratory coating machines is highly diverse, spanning multiple high-growth industries that rely on precision coating for product development, quality enhancement, and research innovation. Pharmaceutical and biotechnology companies represent the largest segment of end-users. These organizations utilize laboratory coating machines extensively for the R&D of novel drug formulations, including controlled-release tablets, enteric-coated capsules, and taste-masked active pharmaceutical ingredients. Furthermore, the burgeoning field of biologics and gene therapy requires advanced coating solutions for medical devices, diagnostic tools, and cell encapsulation techniques. Their demand is driven by the continuous need to improve drug efficacy, patient compliance, and product stability, all while adhering to rigorous regulatory standards.

Beyond the life sciences, the chemical industry is a significant consumer, using these machines for developing new catalysts, creating functional polymer coatings, and synthesizing specialty chemicals with enhanced properties. Research institutions, including universities and government-funded laboratories, are also key buyers. They employ laboratory coating machines for fundamental scientific research, material characterization, and the exploration of new coating applications across a multitude of disciplines, ranging from nanotechnology to surface engineering. The educational sector also uses these machines for training future scientists and engineers in advanced material processing techniques, ensuring a continuous pipeline of skilled professionals.

Moreover, the food and beverage industry increasingly utilizes laboratory coating machines for developing nutritional supplements, probiotics, and functional food ingredients. These applications often focus on flavor encapsulation, moisture barrier creation, or enhancing the shelf life of sensitive components. The medical device industry is another critical end-user, requiring precise coatings for implants, surgical instruments, and diagnostic strips to improve biocompatibility, deliver active agents, or modify surface properties. The electronics sector also presents a growing customer segment, using laboratory coaters to develop protective layers, conductive coatings, or anti-reflective films for various components, showcasing the wide-ranging applicability and essential nature of these specialized machines across modern industrial and scientific landscapes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 345.7 Million |

| Market Forecast in 2033 | USD 548.9 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sartorius AG, Thermo Fisher Scientific Inc., GEA Group AG, Buchi Labortechnik AG, Caleva Process Solutions Ltd., Freund-Vector Corporation, L.B. Bohle Maschinen und Verfahren GmbH, Glatt GmbH, O'Hara Technologies Inc., ACG Group, Kikusui Seisakusho Ltd., Dott. Bonapace & C. S.r.l., IMA S.p.A., Romaco Holding GmbH, Sejong Pharmatech Co., Ltd., Key International, Inc., Union Process, Inc., Nicomac S.r.l., Shanghai Keshun Pharmaceutical Machinery Co., Ltd., Votsch Industrietechnik GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Laboratory Coating Machine Market Key Technology Landscape

The technology landscape for the Laboratory Coating Machine Market is characterized by continuous innovation aimed at enhancing precision, efficiency, and versatility. Core to these advancements are sophisticated coating techniques that ensure uniform and reproducible film deposition. This includes various spray coating methods, which use atomizers to create fine droplets for even application on tablets or powders, and dip coating, where substrates are immersed in a liquid coating solution for creating uniform layers on complex geometries. Additionally, spin coating is often employed for very thin, highly uniform films on flat substrates, particularly in material science and electronics research. The evolution of these techniques focuses on minimizing material waste, improving film integrity, and enabling multi-layer coating capabilities for complex formulations.

Process control systems are integral to the modern laboratory coating machine. These systems incorporate advanced sensors and automation software, often utilizing Human-Machine Interfaces (HMIs) and Supervisory Control and Data Acquisition (SCADA) systems, to monitor and regulate critical parameters such as spray rate, air pressure, temperature, humidity, and pan speed in real-time. This level of control is paramount for achieving consistent product quality and for adhering to strict regulatory requirements in industries like pharmaceuticals. The integration of data acquisition capabilities allows for comprehensive process documentation and analysis, which is vital for R&D, process optimization, and troubleshooting, thereby enhancing the overall efficiency and scientific rigor of experimental work.

Furthermore, drying technologies play a crucial role in the coating process, as efficient solvent removal is necessary to achieve stable and durable coatings without damaging the substrate. Innovations include the use of infrared (IR) drying, hot air drying, and vacuum drying, each optimized for different solvents and heat-sensitive materials. There is a growing trend towards the integration of advanced automation and robotics for automated sample loading, unloading, and cleaning, significantly reducing manual labor and potential contamination risks. The development of advanced analytical tools, such as in-line spectroscopy and particle size analyzers, integrated directly into the coating process, allows for real-time quality control and feedback loops, leading to self-optimizing systems. This comprehensive technological ecosystem ensures that laboratory coating machines remain at the forefront of precision manufacturing and material development.

Regional Highlights

- North America: This region holds a significant share of the Laboratory Coating Machine Market, primarily driven by robust investments in pharmaceutical and biotechnology research, particularly in the United States. The presence of numerous global pharmaceutical giants, well-established research institutions, and a strong culture of innovation contribute to sustained demand. Stringent regulatory frameworks by bodies like the FDA necessitate high-precision, reproducible coating processes, further boosting adoption. The region is also at the forefront of adopting advanced laboratory automation and digitalization, which spurs demand for technologically sophisticated coating machines. Canada also contributes to the market with its growing biotech sector and government funding for R&D.

- Europe: Europe represents another dominant market, characterized by a strong pharmaceutical industry, particularly in countries like Germany, Switzerland, and the UK. Significant R&D expenditure by both public and private entities, coupled with supportive government policies for life sciences and advanced manufacturing, fuels market growth. The region's emphasis on high-quality manufacturing standards and continuous process improvement drives the demand for reliable and efficient laboratory coating machines. Academic excellence and collaborative research initiatives across the continent further bolster the market for advanced laboratory equipment.

- Asia Pacific (APAC): The APAC region is projected to exhibit the highest growth rate, making it a pivotal market for laboratory coating machines. This surge is attributed to the rapid expansion of the pharmaceutical and biotechnology sectors in countries such as China, India, Japan, and South Korea. Increasing healthcare expenditure, a rising prevalence of chronic diseases, and a growing focus on drug discovery and development are key drivers. Furthermore, the region is witnessing a significant influx of foreign investment in R&D and manufacturing capabilities, alongside a burgeoning contract research and manufacturing organization (CRO/CMO) sector. Local governments are also promoting scientific research and technological innovation, creating a fertile ground for market expansion.

- Latin America: This region is experiencing steady growth in the Laboratory Coating Machine Market, primarily driven by improving healthcare infrastructure and increasing investments in pharmaceutical manufacturing, especially in Brazil and Mexico. The rising demand for generic drugs and the local production initiatives are stimulating the adoption of laboratory equipment for R&D and quality control. While smaller in market size compared to North America and Europe, the region offers emerging opportunities as its economies stabilize and industrialization progresses, leading to increased research activities and product development.

- Middle East and Africa (MEA): The MEA region is expected to demonstrate modest but consistent growth. This growth is largely influenced by government initiatives aimed at diversifying economies away from oil, leading to increased investments in healthcare, pharmaceutical manufacturing, and scientific research, particularly in Gulf Cooperation Council (GCC) countries. The development of new research hubs and academic institutions also contributes to the rising demand for modern laboratory equipment. However, factors such as political instability and varying levels of economic development across the region can present challenges to market expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Laboratory Coating Machine Market.- Sartorius AG

- Thermo Fisher Scientific Inc.

- GEA Group AG

- Buchi Labortechnik AG

- Caleva Process Solutions Ltd.

- Freund-Vector Corporation

- L.B. Bohle Maschinen und Verfahren GmbH

- Glatt GmbH

- O'Hara Technologies Inc.

- ACG Group

- Kikusui Seisakusho Ltd.

- Dott. Bonapace & C. S.r.l.

- IMA S.p.A.

- Romaco Holding GmbH

- Sejong Pharmatech Co., Ltd.

- Key International, Inc.

- Union Process, Inc.

- Nicomac S.r.l.

- Shanghai Keshun Pharmaceutical Machinery Co., Ltd.

- Votsch Industrietechnik GmbH

Frequently Asked Questions

What are the primary applications of laboratory coating machines?

Laboratory coating machines are primarily used in pharmaceutical R&D for developing drug formulations like controlled-release tablets and enteric coatings, in biotechnology for medical device coatings and cell encapsulation, in material science for functional surface modification, and in the food industry for encapsulation and protective layers. They enable precise and reproducible application of thin films for various product development and research purposes.

How does AI impact the Laboratory Coating Machine Market?

AI significantly impacts this market by optimizing coating parameters, enabling predictive maintenance, accelerating formulation development through data analysis, and facilitating real-time adaptive process control. It enhances precision, reduces experimental errors, and shortens R&D cycles, leading to more efficient and innovative coating solutions.

What factors drive the growth of the Laboratory Coating Machine Market?

Key growth drivers include increasing R&D investments in pharmaceuticals and biotechnology, the rising demand for advanced and functional materials requiring specialized coatings, the ongoing trend towards laboratory automation for enhanced efficiency, and stringent regulatory requirements that mandate precise and reproducible coating processes.

What are the main types of laboratory coating machines available?

The market primarily offers three types: Automatic machines, which provide high precision and minimal human intervention; Semi-Automatic machines, offering a balance of control and automation; and Manual machines, which are cost-effective for basic or small-scale research. The choice depends on the required precision, throughput, and budget.

Which regions are leading the Laboratory Coating Machine Market?

North America and Europe currently lead the market due to their established pharmaceutical and biotechnology industries and high R&D spending. However, the Asia Pacific region is expected to show the fastest growth, driven by expanding healthcare sectors and increasing investments in research and manufacturing capabilities in countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager