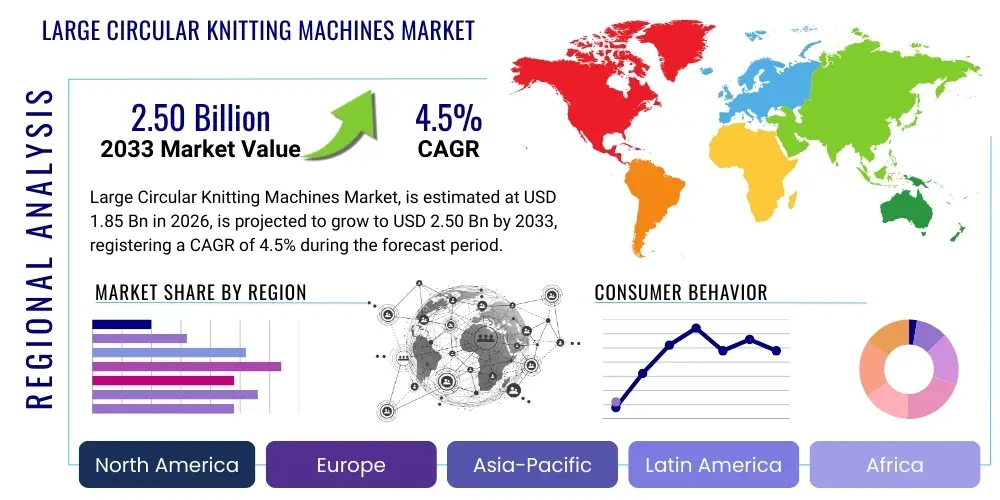

Large Circular Knitting Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436600 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Large Circular Knitting Machines Market Size

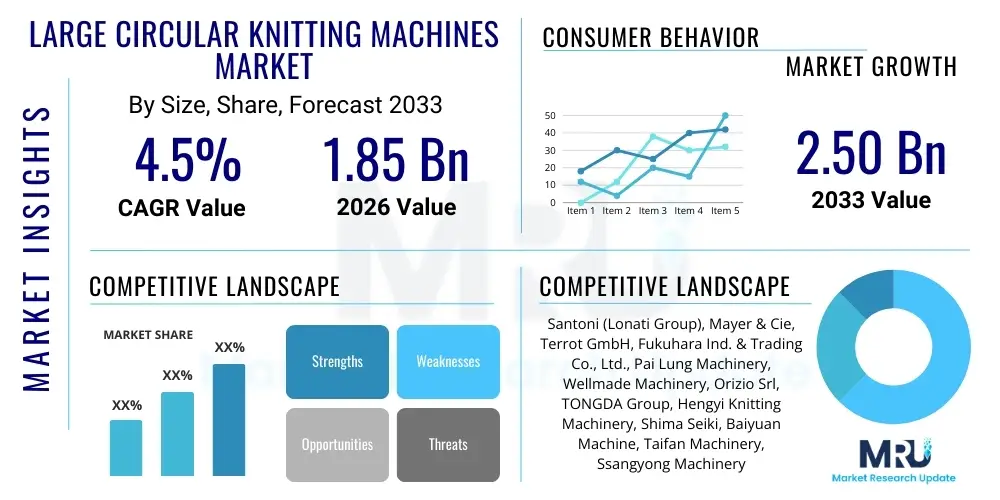

The Large Circular Knitting Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 2.50 Billion by the end of the forecast period in 2033.

Large Circular Knitting Machines Market introduction

Large Circular Knitting Machines (LCKMs) are high-efficiency, industrial-scale textile machinery critical for the mass production of tubular knitted fabrics. These machines are characterized by a large diameter cylinder and numerous feeders, enabling continuous, high-speed output of foundational textile structures such as single jersey, double knit (rib, interlock), terry, and fleece fabrics. The core product design emphasizes maximizing production throughput while ensuring pattern versatility and fabric quality consistency, utilizing complex cam and needle systems driven by precise electronic controls.

Major applications for LCKMs span the entire textile value chain, predominantly in the manufacture of apparel, including casual wear, activewear (due to the demand for seamless and stretchable fabrics), and intimate apparel. Beyond standard clothing, these machines are increasingly utilized in producing technical textiles for applications such as geotextiles, medical bandages, and automotive upholstery, demanding high durability and specific functional properties. The inherent efficiency of circular knitting, which minimizes cutting waste compared to weaving, combined with the versatility to handle diverse natural, synthetic, and specialty yarns, positions LCKMs as indispensable assets in modern textile manufacturing facilities globally.

Driving factors for the sustained market growth include the escalating global demand for comfortable and lightweight knitted apparel, fueled by urbanization and rising disposable incomes in emerging economies. Furthermore, the persistent pressure from the fast fashion industry to shorten production cycles necessitates investment in high-speed, reliable machinery like modern LCKMs. Technological advancements, particularly in automated fault detection, electronic needle selection for intricate patterning, and energy-saving motor systems, further enhance the attractiveness and operational cost-effectiveness of these advanced knitting solutions, compelling textile producers to upgrade older equipment.

Large Circular Knitting Machines Market Executive Summary

The Large Circular Knitting Machines market demonstrates robust business trends characterized by intense competition among European and Asian manufacturers, focusing primarily on innovation in electronic patterning capabilities and overall machine efficiency (OEE). Key business strategies involve expanding localized service networks, particularly in major production hubs like India, China, and Vietnam, and offering integrated software solutions for production monitoring and predictive maintenance. Companies are increasingly adopting modular designs, allowing customers to easily switch between different gauge settings and fabric types, thus enhancing the return on investment for end-users. Consolidation activities remain sporadic, but partnerships focused on technology sharing, particularly related to digitalization and automation features, are gaining prominence as manufacturers strive to differentiate their offerings in a highly competitive capital equipment sector.

Regional trends indicate that the Asia Pacific region, led by China and India, remains the dominant market, driven by massive domestic consumption and its status as the world’s leading textile manufacturing hub for exports. While manufacturing capacity in Western markets has stabilized or declined, demand in the Americas and Europe is shifting towards high-specification, technologically advanced machines capable of producing specialty fabrics (e.g., sustainable materials, highly technical sportswear). Investment growth is notably strong in Southeast Asia and parts of Africa, where manufacturers are seeking to capitalize on lower operational costs and preferential trade agreements, driving demand for cost-effective yet reliable medium-to-large diameter machines.

Segmentation trends highlight the increasing dominance of the Electronic Jacquard segment due to the industry’s need for rapid pattern changes and complex designs, offering superior flexibility compared to mechanical alternatives. Within application segments, the Sportswear and Technical Textiles categories are exhibiting the fastest growth rates, demanding high-gauge, finer-diameter machines that offer superior stability for synthetic yarns and complex stitch structures. The Single Knit machine category retains the largest volume share due to its versatility and foundational role in basic apparel production, but Double Knit machines are expanding their market share, driven by increasing demand for structure fabrics like interlock, rib, and specialized spacer fabrics used in automotive and furniture applications.

AI Impact Analysis on Large Circular Knitting Machines Market

Analysis of common user questions reveals significant interest in the immediate and future applications of Artificial Intelligence (AI) and Machine Learning (ML) within circular knitting operations. End-users frequently inquire about the feasibility of integrating AI systems for real-time defect detection, asking how these systems compare to traditional human inspection in terms of speed and accuracy, particularly for subtle flaws like sinker lines or yarn slubs. A major theme is production optimization; users seek models that can predict optimal feeder speeds, yarn tension adjustments, and maintenance schedules based on historical operational data, thereby minimizing costly machine downtime and maximizing fabric output quality and consistency. Furthermore, there is growing curiosity regarding AI’s potential in pattern generation and optimizing complex stitch structures for specific performance requirements (e.g., moisture wicking, compression).

The prevailing concerns center around the required data infrastructure, the cost of retrofitting existing high-value machinery with necessary sensor arrays and edge computing capabilities, and the expertise needed to manage and train these sophisticated algorithms. Users understand that while AI promises enhanced efficiency, the implementation barrier, especially for smaller textile mills, remains substantial. Manufacturers, in response, are focusing on developing proprietary, cloud-based AI platforms that offer subscription models, democratizing access to predictive analytics and remote diagnostics. This shift towards smart manufacturing integrates seamlessly with the trend of Industry 4.0 adoption, positioning AI not just as an optimization tool but as a foundational element for future circular knitting machine design and operation.

Ultimately, the impact of AI is expected to redefine operational excellence in the LCKM market. By leveraging machine vision for quality control and ML algorithms for predictive maintenance and parameter optimization, AI promises to significantly elevate Overall Equipment Effectiveness (OEE) scores across the industry. This technological convergence will enable textile producers to meet the ever-increasing demands for customization, faster time-to-market, and higher quality standards while simultaneously reducing reliance on highly variable manual interventions, securing a more predictable and sustainable manufacturing process.

- AI-driven real-time fabric defect detection replacing manual inspection processes.

- Predictive maintenance schedules based on ML analysis of vibration and temperature data, drastically reducing unplanned downtime.

- Optimization of knitting parameters (speed, tension, stitch length) for maximum quality and efficiency.

- Automated pattern adjustment and fault correction based on sensor feedback.

- Enhanced supply chain integration by optimizing production flow based on real-time inventory and order data.

- Reduced material waste through improved process control and minimization of defective output.

- Energy consumption optimization through AI management of motor speeds and climate control systems in the production environment.

DRO & Impact Forces Of Large Circular Knitting Machines Market

The Large Circular Knitting Machines Market is fundamentally influenced by a complex interplay of Drivers (D), Restraints (R), Opportunities (O), and Impact Forces. The primary driver remains the robust and sustained global demand for knitted apparel, particularly activewear and innerwear, which rely heavily on high-speed circular knitting for production efficiency. This is augmented by continuous advancements in machine technology, offering higher gauges, increased speeds, and enhanced automation capabilities that necessitate cyclical equipment upgrades across the textile industry. However, the market faces significant restraints, chiefly the substantial initial capital investment required for these sophisticated machines, which creates high barriers to entry for smaller textile manufacturers and replacement cycle inertia. Furthermore, geopolitical instability affecting global trade routes and raw material costs (especially steel and electronic components) introduces supply chain volatility, directly impacting manufacturing costs and delivery timelines for machinery manufacturers.

Significant opportunities are emerging from the growing global focus on sustainable manufacturing, pushing manufacturers toward developing machines optimized for recycled yarns, reduced energy consumption, and lower water usage (e.g., through reduced lubrication systems). The expansion into specialized technical textiles—such as those used in aerospace, medical implants, and performance filtration—represents a high-value niche market requiring specialized LCKMs with precise control mechanisms and durability for handling unconventional materials like carbon fiber or glass fiber blends. The integration of advanced digital technologies, including the Industrial Internet of Things (IIoT) and AI-based diagnostics, further presents an opportunity to deliver value-added services and recurring revenue streams through software and remote monitoring packages, shifting the business model from pure hardware sales to integrated solutions provision.

The market is constantly shaped by key impact forces that determine the rate and direction of growth. Regulatory pressures concerning labor practices and environmental standards force manufacturers to innovate towards automation and sustainability, increasing the competitive necessity for highly compliant, advanced machinery. Competitive intensity is high, particularly between established European leaders renowned for precision engineering and rapidly innovating Asian firms offering aggressive pricing and customizable solutions, driving down overall component costs while accelerating the pace of feature integration. Moreover, shifting consumer preferences towards customized and short-run production cycles necessitate machine flexibility and rapid changeover capabilities, placing a premium on electronic patterning systems and advanced control software that can quickly adapt production parameters.

Segmentation Analysis

The Large Circular Knitting Machines Market is extensively segmented based on machine type, diameter, gauge, application, and end-user base, reflecting the diverse requirements of the global textile industry. Analyzing these segments provides critical insights into manufacturing specialization and the varying investment patterns across different geographical and functional textile sectors. Machine type segmentation, for instance, distinguishes between single knit and double knit configurations, reflecting fundamental differences in fabric structure capabilities, with double knit machines gaining traction due to the complexity and structure required for interlock and rib fabrics demanded by premium apparel markets. Gauge segmentation, categorized typically as fine, medium, and coarse, dictates the fineness of the fabric produced, linking directly to the type of end-product, where fine gauge (e.g., E30 and above) dominates high-end fashion and technical textile production.

Diameter segmentation is crucial as it determines the width of the fabric tube and thus, the primary target market, ranging from smaller diameters used for specialized seamless garments to large diameters (over 30 inches) dedicated to broad fabric rolls for cut-and-sew operations. Application-based segmentation further clarifies market demand drivers, separating generic apparel manufacturing from high-growth sectors like sportswear, which requires specialized features such as spandex plating and superior tension control, and technical textiles, which emphasize reliability and material compatibility. Understanding these interconnected segmentations allows machine manufacturers to align their research and development efforts with specific, high-growth niche areas and tailor marketing strategies to address the distinct technical needs of various end-user categories, ensuring maximum market penetration and optimized product portfolios.

- By Machine Type:

- Single Knit Circular Knitting Machines (Jersey, Fleece, Terry)

- Double Knit Circular Knitting Machines (Interlock, Rib, Jacquard)

- High-Speed Jacquard Machines (Electronic and Mechanical)

- By Diameter Size:

- Less than 30 Inches

- 30 Inches to 34 Inches

- Greater than 34 Inches

- By Gauge (Needle Density):

- Fine Gauge (E28 and above)

- Medium Gauge (E18 to E26)

- Coarse Gauge (Below E18)

- By Application:

- Apparel (Casual Wear, Intimate Apparel)

- Sportswear and Activewear

- Home Textiles (Bedding, Upholstery)

- Technical Textiles (Medical, Automotive, Industrial)

- By Automation Level:

- Fully Automated

- Semi-Automated

Value Chain Analysis For Large Circular Knitting Machines Market

The value chain for the Large Circular Knitting Machines market begins with the upstream segment, dominated by specialized component suppliers. These suppliers provide critical, high-precision elements essential for machine function, including high-speed precision needles (which must withstand constant mechanical stress), sinkers, cams, yarn feeders, and sophisticated electronic components like servo motors, PLCs (Programmable Logic Controllers), and HMI (Human-Machine Interface) screens. The quality and longevity of the final machine are heavily reliant on the metallurgical precision and reliability of these upstream components. Key competitive advantages are secured through exclusive sourcing agreements or vertical integration, particularly regarding electronic needle selection mechanisms which determine the machine’s patterning versatility and speed. Fluctuations in the global price of specialty metals (like tungsten and high-grade steel) and electronic chips significantly impact the cost structure of LCKM manufacturers, requiring stringent inventory and risk management strategies.

The core midstream activity involves the actual manufacturing and assembly of the circular knitting machines. Leading manufacturers perform intensive R&D to optimize machine speed, energy efficiency, and operational stability. This stage encompasses the integration of mechanical frames with complex electronic control systems and proprietary knitting software. Post-production, the distribution channel becomes critical. Distribution is typically dual-mode: direct sales and service for major global textile groups or national accounts, where close technical consultation and customized machine specifications are required; and indirect sales through highly specialized, technically proficient local agents or distributors in emerging markets. These indirect partners provide essential localized inventory holding, customs clearance, localized maintenance, spare parts supply, and rapid technical support, which is critical given the complexity and size of the capital equipment.

Downstream analysis focuses on the end-users—large-scale textile mills and garment manufacturers who utilize the machinery to produce knitted fabrics. The final stages involve the consumption and maintenance of the LCKMs, requiring a steady supply of spare parts (e.g., needles, cylinders), ongoing technical support, and periodic software updates. The profitability of the downstream segment is directly linked to the machine’s reliability (uptime) and efficiency (throughput). The growing market for after-sales services, including predictive maintenance contracts and operational training, is becoming a key revenue driver for LCKM manufacturers, creating a high-value feedback loop that informs future R&D efforts. This entire chain is increasingly digitized, with manufacturers leveraging IIoT connectivity to monitor machine performance remotely, ensuring optimal operations for their global client base.

Large Circular Knitting Machines Market Potential Customers

Potential customers for Large Circular Knitting Machines are predominantly concentrated within the industrialized textile manufacturing sector, encompassing a wide array of entities that require high-volume production of knitted fabric rolls. The primary buyers are large, integrated textile mills (both spinning and knitting operations) focused on mass production for domestic and international retail supply chains. These customers prioritize high machine uptime, robust throughput capacity, and low operational costs, often purchasing multiple units simultaneously to equip expansive factory floors. Their purchasing decisions are heavily influenced by the machines' energy consumption ratings, the reliability of the electronic components, and the manufacturer's ability to provide comprehensive, global technical support and rapid spare parts delivery.

A rapidly expanding customer segment includes specialized contract manufacturers (CMs) and vertically integrated garment manufacturers (VIGMs) who cater directly to major global apparel brands (e.g., Nike, Adidas, H&M). These buyers frequently require advanced LCKMs, particularly those with electronic jacquard capabilities, to produce complex, short-run designs and specialized fabrics (like high-performance synthetics or sustainable blends) demanded by fast fashion and activewear markets. For VIGMs, the ability of the machine to seamlessly integrate into their overall production workflow, often involving automation of downstream processes like fabric inspection and cutting, is a crucial purchasing criterion, favoring machines with robust Industry 4.0 compatibility and data export features.

Furthermore, niche markets represent significant potential customers, including technical textile manufacturers focusing on non-apparel applications such as automotive seating fabric, medical textiles (bandages, compression wear), and specialized industrial filtration materials. These buyers demand machines engineered for high tension and stability when handling unconventional materials, prioritizing precision and durability over sheer speed. Lastly, academic and vocational textile research institutions occasionally constitute a minor, yet influential, customer base, purchasing advanced, often customized LCKMs for experimental purposes and training future textile engineers, thereby influencing long-term brand preference within the industry.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.50 Billion |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Santoni (Lonati Group), Mayer & Cie, Terrot GmbH, Fukuhara Ind. & Trading Co., Ltd., Pai Lung Machinery, Wellmade Machinery, Orizio Srl, TONGDA Group, Hengyi Knitting Machinery, Shima Seiki, Baiyuan Machine, Taifan Machinery, Ssangyong Machinery, Cixing Group, Keumyong Machinery |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Large Circular Knitting Machines Market Key Technology Landscape

The technological landscape of the Large Circular Knitting Machines market is defined by continuous pursuit of higher speeds, increased pattern flexibility, and integration into digital manufacturing ecosystems (Industry 4.0). Central to modern LCKMs is the sophisticated implementation of electronic needle selection technology, particularly the fully electronic jacquard system. This allows for individual control over hundreds or thousands of needles per revolution, enabling instantaneous switching between complex patterns, vastly reducing downtime associated with mechanical cam changes, and supporting the mass customization trend prevalent in the apparel industry. Servo motor technology drives precision and efficiency, offering superior control over cylinder rotation and yarn feeding compared to traditional mechanical drives, which significantly reduces energy consumption while maintaining high knitting speeds, addressing both operational cost and sustainability requirements.

Advancements in yarn feeding and tension control systems are also critical elements. Modern LCKMs incorporate precision electronic yarn storage feeders and sophisticated sensors that monitor and dynamically adjust yarn tension in real-time. This level of control is essential for managing delicate or specialty yarns, such as elastane or recycled polyester, ensuring uniform stitch formation, minimizing yarn breakage, and preventing costly fabric defects. The integration of advanced human-machine interfaces (HMIs) featuring intuitive, large touchscreens allows operators to monitor thousands of critical knitting parameters, perform detailed diagnostics, and upload complex design files quickly, thereby streamlining the overall operational management process and reducing reliance on specialized mechanical expertise.

Furthermore, machine manufacturers are heavily investing in IIoT connectivity and integrated software solutions. Contemporary machines are equipped with embedded sensors that transmit operational data—such as speed, temperature, vibration, energy usage, and output metrics—to centralized cloud platforms. This connectivity facilitates predictive maintenance routines, remote diagnostics, and detailed OEE analysis, enabling manufacturers to optimize their entire production fleet across multiple geographical locations. The push towards sustainable knitting involves innovations in lubrication systems, minimizing oil usage and ensuring clean fabric output, as well as developing frame stability technologies to handle increasing speeds without compromising needle and cylinder longevity, solidifying the market's focus on long-term efficiency and reduced environmental impact.

Regional Highlights

Regional dynamics within the Large Circular Knitting Machines market are highly fragmented, reflecting global shifts in textile manufacturing capacity, labor costs, and consumer markets. Each major geographical area presents a unique blend of demand drivers and competitive challenges, compelling manufacturers to adapt their sales and support strategies locally.

- Asia Pacific (APAC): Dominates the global market in terms of installed base and ongoing capacity expansion. Countries like China, India, Vietnam, and Bangladesh serve as the primary global textile production centers, driving massive demand for both high-speed basic machines and advanced electronic jacquard models. The regional growth is fueled by strong governmental support for the textile sector, competitive labor costs, and a vast, rapidly expanding domestic consumer base demanding knitted apparel. Manufacturers in this region prioritize capacity, operational reliability, and competitive pricing, often demanding quick amortization periods for capital investments.

- Europe: Characterized by high demand for specialized, high-gauge, and technologically advanced LCKMs. European textile manufacturers focus on high-value products, including premium fashion, innovative sportswear, and technical textiles. The market prioritizes energy efficiency, automation (due to high labor costs), and superior precision engineering. Key manufacturing centers in Germany and Italy remain crucial hubs for innovation, setting global standards for machine quality and integration of Industry 4.0 solutions, often exporting these high-end machines globally.

- North America: A mature market where demand is largely focused on replacement of aging machinery and highly specialized applications, particularly technical textiles (automotive, medical) and high-end niche apparel. Domestic production, though smaller than APAC, demands highly efficient, automated machines to maintain competitiveness against imported goods. Investment decisions are heavily weighted towards software integration, efficiency guarantees, and long-term service agreements to ensure minimal operational disruption.

- Latin America: Showing moderate growth, driven by key markets such as Brazil and Mexico, which possess established textile industries catering to regional consumer demand. Market growth is sensitive to macroeconomic stability and trade agreements. Demand tends to favor robust, reliable machinery with a balanced approach between cost and automation features, supporting vertically integrated domestic apparel production.

- Middle East and Africa (MEA): Emerging as a future growth frontier, especially in countries like Turkey, Egypt, and Ethiopia, which are establishing textile parks to leverage low labor costs and strategic geographical positioning for export. The demand here is centered on acquiring foundational large-scale capacity, leading to significant uptake of medium-technology, reliable LCKMs, with a growing appetite for training and technical support services.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Large Circular Knitting Machines Market.- Santoni (Lonati Group)

- Mayer & Cie

- Terrot GmbH

- Fukuhara Ind. & Trading Co., Ltd.

- Pai Lung Machinery

- Wellmade Machinery

- Orizio Srl

- TONGDA Group

- Hengyi Knitting Machinery

- Shima Seiki

- Baiyuan Machine

- Taifan Machinery

- Ssangyong Machinery

- Cixing Group

- Keumyong Machinery

- Mec-Mor Srl

- Jingwei Textile Machinery

- Unitex Textile Corporation

- Precision Fukuhara

- Tianjin Light Industry Machinery

Frequently Asked Questions

Analyze common user questions about the Large Circular Knitting Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected CAGR for the Large Circular Knitting Machines Market?

The Large Circular Knitting Machines Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 4.5% during the forecast period from 2026 to 2033, driven by increasing global textile demand and technological innovation in machinery efficiency.

Which machine type segment dominates the Large Circular Knitting Machines Market?

The Single Knit Circular Knitting Machines segment currently holds the largest volume share due to its versatility and high production speed, forming the backbone of basic apparel and casual wear fabric manufacturing worldwide.

How is Industry 4.0 impacting circular knitting operations?

Industry 4.0 significantly impacts operations through the integration of IIoT connectivity and AI, enabling predictive maintenance, real-time quality control via machine vision, and optimized production scheduling, drastically improving Overall Equipment Effectiveness (OEE).

Which geographical region represents the highest growth potential for LCKMs?

The Asia Pacific (APAC) region, specifically China, India, and Southeast Asia, presents the highest growth potential, primarily driven by large-scale capacity expansion, robust domestic consumption, and its dominant position as a global export manufacturing hub.

What are the primary restraints affecting market growth?

The major restraints include the substantial initial capital investment required for high-precision, automated LCKMs, which limits adoption by smaller firms, and supply chain volatility affecting the cost and availability of critical components like electronic chips and precision steel parts.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager