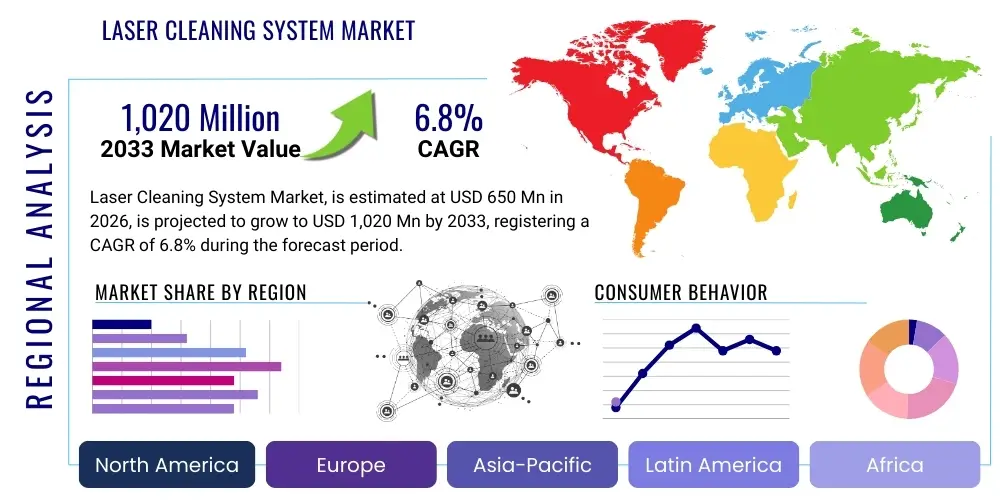

Laser Cleaning System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439144 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Laser Cleaning System Market Size

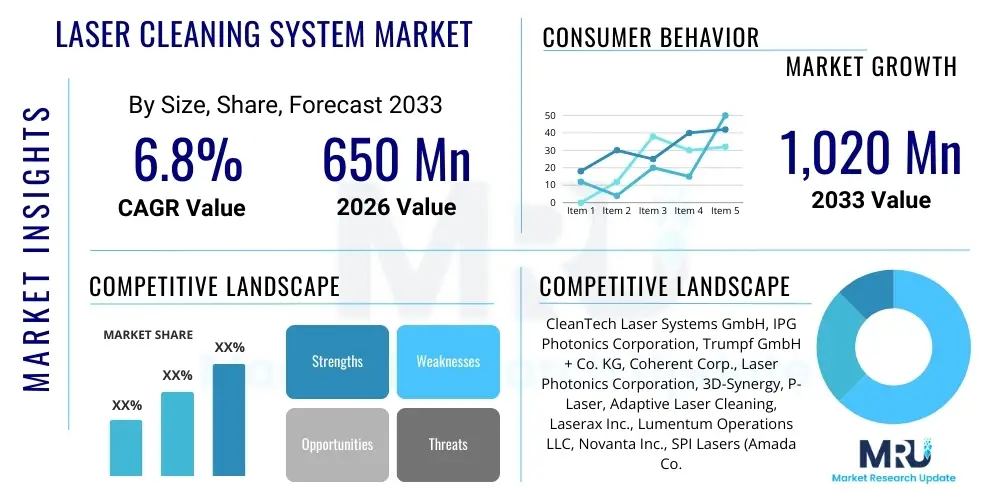

The Laser Cleaning System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 1,020 Million by the end of the forecast period in 2033.

Laser Cleaning System Market introduction

The Laser Cleaning System Market encompasses advanced industrial solutions utilizing high-intensity, short-pulse laser beams to remove contaminants, rust, paint, and oxidation layers from surfaces without causing damage to the underlying material. These systems leverage the principle of ablation, where the contaminant absorbs the laser energy and rapidly vaporizes or sublimes, offering a non-contact, environmentally superior alternative to traditional cleaning methods like sandblasting, chemical baths, and mechanical scrubbing. The technology is highly versatile, applicable across materials ranging from metals and plastics to composites and ceramics, providing precise control over the cleaning depth and area.

Major applications driving the adoption of laser cleaning technology include surface preparation in the automotive and aerospace industries for welding and bonding, mold cleaning in manufacturing, decontamination in cultural heritage preservation, and critical maintenance in nuclear and marine sectors. The inherent benefits—such as reduced secondary waste generation, improved operational safety by eliminating hazardous chemicals, and lower running costs compared to consumables-heavy alternatives—position laser cleaning as a cornerstone technology for modern, sustainable manufacturing processes. Furthermore, the rising demand for high-quality surface finishes and the need for precision cleaning in microelectronics contribute significantly to its expanding market penetration.

Key driving factors accelerating market growth include stringent environmental regulations necessitating eco-friendly cleaning solutions, technological advancements leading to more portable and higher-power laser systems, and the increasing automation across diverse industrial sectors. The shift toward Industry 4.0 principles emphasizes efficiency, precision, and minimal waste, areas where laser cleaning systems inherently excel. However, the initial capital investment associated with these sophisticated systems remains a limiting factor, particularly for Small and Medium-sized Enterprises (SMEs).

Laser Cleaning System Market Executive Summary

The Laser Cleaning System Market is poised for robust expansion, primarily fueled by the accelerating adoption of automated manufacturing processes and strict global mandates regarding industrial waste reduction. Business trends indicate a strong move toward integrated, high-power fiber laser solutions capable of continuous operation in harsh industrial environments, particularly within the automotive sector for paint stripping and welding preparation, and in the aerospace industry for component maintenance and protective coating removal. Key companies are focusing on developing compact, mobile, and user-friendly systems to lower the barrier to entry for smaller maintenance operations, alongside advanced software interfaces that allow for rapid customization of cleaning parameters for varied substrates.

Regionally, the market exhibits dominance by Asia Pacific (APAC) in terms of manufacturing capacity and consumption, driven by high volume electronics production and rapid industrialization in China, South Korea, and India. North America and Europe, while representing mature markets, are characterized by high value applications, stringent occupational safety requirements, and significant investment in R&D for specialized high-power and ultrafast pulse lasers used in critical infrastructure maintenance and high-precision tooling. The regulatory landscape in the West strongly favors non-chemical, low-emission technologies, further solidifying the market position of laser cleaning solutions in these areas.

Segment trends highlight the dominance of the high-power (greater than 100W) segment due to increased throughput demands in heavy industrial applications, while the pulsed fiber laser technology remains the preferred choice due to its high efficiency and minimal thermal impact on the substrate. The military and defense, along with the marine sector, are emerging as lucrative segments, requiring robust systems for specialized surface preparation and maintenance tasks, such as nuclear decontamination and ship hull cleaning. Segmentation growth is also observed in the robotics integration market, where laser cleaning heads are increasingly mounted onto robotic arms for fully automated, large-scale surface treatment operations.

AI Impact Analysis on Laser Cleaning System Market

Common user questions regarding AI's impact on laser cleaning often revolve around how artificial intelligence can improve process efficiency, ensure quality control, and enable greater autonomy in cleaning applications. Users are keen to understand if AI can compensate for variable surface contamination levels, predict component wear and maintenance needs of the system itself, and optimize laser parameters in real-time to prevent material damage. The core concerns address the complexity of integrating sophisticated AI algorithms with high-speed laser hardware and the necessary investment in sensing technologies (like high-speed cameras and spectroscopic analysis) required to feed data to the AI engine. This analysis reveals a consensus that AI is expected to transition laser cleaning from a predefined process into a highly adaptive, intelligent surface treatment solution, significantly enhancing precision and minimizing human intervention.

The integration of Artificial Intelligence (AI) and Machine Learning (ML) is rapidly transforming the laser cleaning system market by introducing capabilities for predictive maintenance, real-time quality assurance, and adaptive process control. AI algorithms can analyze sensor data (such as reflected light intensity, temperature changes, and plume analysis) captured during the cleaning process to instantly identify the type and thickness of contamination. This enables the system to dynamically adjust laser parameters—including pulse energy, repetition rate, and scanning speed—on a microsecond scale, ensuring optimal cleaning efficiency without compromising the structural integrity of the base material. This level of responsiveness is crucial for applications involving delicate or complex geometries.

Furthermore, AI-powered computer vision systems are deployed for automated defect detection and classification of the cleaned surface, confirming that regulatory or quality standards have been met immediately post-cleaning. ML models trained on vast datasets of cleaning scenarios can predict the required cleaning time and energy consumption based on initial surface scanning, optimizing resource allocation and reducing cycle times significantly. This intelligence not only enhances the performance of stationary industrial systems but is also vital for the successful deployment of autonomous, mobile laser cleaning robots used for large-scale infrastructure maintenance, providing a critical layer of operational efficiency and reliability.

- Real-time Parameter Optimization: AI adjusts laser pulse characteristics dynamically based on material feedback.

- Predictive Maintenance: ML algorithms forecast component failures, reducing downtime and operational costs.

- Automated Quality Assurance: Computer vision detects residual contamination or substrate damage instantly.

- Adaptive Trajectory Planning: AI optimizes the scanning path for complex geometries and uneven contamination.

- Enhanced Safety Protocols: AI monitors operational conditions to prevent hazardous beam reflections or overheating.

DRO & Impact Forces Of Laser Cleaning System Market

The dynamics of the Laser Cleaning System market are governed by robust drivers, significant restraints, and clear opportunities, resulting in powerful market impact forces. Key drivers include the global push for sustainable industrial practices and the increasing automation requirements across high-precision manufacturing sectors like automotive and aerospace. These drivers emphasize the non-contact nature, environmental friendliness, and superior precision of laser technology. Conversely, the high initial capital expenditure required for purchasing and integrating sophisticated laser systems, coupled with the necessity for highly trained personnel for operation and maintenance, act as substantial restraints, particularly affecting smaller organizations hesitant to transition away from established, cheaper chemical or abrasive methods. Opportunities abound in developing portable, lower-cost systems, expanding applications in the heritage restoration and medical device manufacturing fields, and integrating smart robotics and AI for fully autonomous solutions.

The major impact forces stem from regulatory pressure and technological evolution. Stringent environmental regulations in North America and Europe concerning Volatile Organic Compounds (VOCs) and abrasive dust emissions directly mandate the shift towards cleaner technologies, thus amplifying the attractiveness of laser cleaning. Concurrently, rapid advancements in solid-state laser technology, particularly the continuous development of higher-power, shorter-pulse fiber lasers, are constantly improving cleaning speeds and efficacy while simultaneously driving down the size and cost of the equipment over time. This technological momentum gradually mitigates the core restraint of high initial cost, making the technology more accessible to broader industrial applications and ensuring sustained market growth.

Furthermore, the competitive landscape is intensifying, forcing manufacturers to innovate rapidly, focusing on modular designs and enhanced user interfaces to maximize impact. While the high entry barrier concerning specialized knowledge remains an ongoing challenge, the long-term cost efficiencies related to reduced consumables, minimized waste disposal costs, and improved product quality solidify laser cleaning's strong value proposition. The balance between technological innovation (reducing system costs) and escalating regulatory demands (increasing market necessity) defines the current trajectory and overall positive impact forces within this specialized market.

Segmentation Analysis

The Laser Cleaning System Market is intricately segmented based on core technical specifications and application domains, providing a granular view of market dynamics. Key segments include power output (low, medium, high), reflecting the throughput requirements; technology (pulsed fiber laser, continuous wave laser), detailing the mechanism of action; application (surface preparation, paint removal, rust removal, mold cleaning), specifying the industrial task; and end-user industry (automotive, aerospace, marine, manufacturing), defining the market vertical. This segmentation allows stakeholders to target investment and product development efforts toward the most lucrative and rapidly evolving areas, such as high-power pulsed systems optimized for heavy industry or low-power systems designed for delicate cultural heritage restoration.

The dominance of high-power pulsed fiber lasers is evident across most industrial segments due to their superior capability to deliver high peak power necessary for rapid material ablation with minimal heat-affected zone (HAZ), crucial for maintaining material integrity. Within the end-user analysis, the automotive and aerospace industries consistently account for the largest market shares, driven by critical requirements for high-precision surface bonding and pre-welding treatment. The increasing complexity of materials used in modern manufacturing necessitates cleaning methods that are highly controllable and consistent, reinforcing the need for sophisticated laser solutions across all identified segments.

- By Power Output:

- Low Power (Up to 100W)

- Medium Power (101W to 500W)

- High Power (Above 500W)

- By Technology:

- Pulsed Fiber Laser

- Continuous Wave (CW) Laser

- Solid-State Laser

- By Application:

- Rust and Oxide Removal

- Paint and Coating Removal

- Surface Preparation (Pre-welding/Pre-bonding)

- Mold Cleaning

- Degreasing and Oil Removal

- Decontamination and Restoration

- By End-User Industry:

- Automotive

- Aerospace and Defense

- Manufacturing (Tooling and Molds)

- Marine

- Electronics and Semiconductors

- Cultural Heritage Restoration

Value Chain Analysis For Laser Cleaning System Market

The value chain of the Laser Cleaning System Market starts with upstream component suppliers responsible for manufacturing critical elements such as high-power fiber lasers, beam delivery systems (optics and scanners), and specialized control units. Innovation and quality assurance at this level are paramount, as the performance and reliability of the final system are intrinsically linked to the quality of the laser source and optics. Key suppliers of optical components and laser sources, particularly those specializing in short-pulse fiber technology, wield significant leverage in pricing and technology standardization. Consolidation or technological breakthroughs among these upstream players can rapidly affect the market price and capabilities of integrated laser cleaning units.

Midstream activities involve system integrators and Original Equipment Manufacturers (OEMs) who design, assemble, and customize the final cleaning systems. These companies are responsible for integrating the laser source with sophisticated beam steering mechanisms (such as galvanometers or robotic arms), developing application-specific software, and ensuring safety compliance (Class IV laser standards). Their competitive advantage lies in developing proprietary software algorithms for intelligent cleaning path optimization and providing modular, mobile, and robotic integration capabilities. Strong relationships with end-users enable integrators to design highly tailored solutions, essential given the diverse application requirements across industries like aerospace and tooling.

The downstream distribution channel involves direct sales teams, specialized distributors, and value-added resellers (VARs). Due to the high-value and technical complexity of laser cleaning systems, direct sales supported by comprehensive technical service and training are often favored, particularly for large industrial contracts. Indirect channels, primarily through local distributors, are crucial for market penetration in developing regions and for reaching smaller workshops and maintenance services. Effective after-sales support, including calibration, maintenance contracts, and technical consultation, forms a critical component of the downstream value proposition, ensuring high customer retention and reliable system uptime.

Laser Cleaning System Market Potential Customers

Potential customers for Laser Cleaning Systems are predominantly large-scale industrial operators and specialized maintenance service providers who require high precision, consistent quality, and environmentally compliant surface treatment methods. The primary buyers are manufacturers in sectors where surface integrity dictates product performance and safety, such as Tier 1 suppliers in the automotive industry needing precise pre-welding preparation, and MRO (Maintenance, Repair, and Overhaul) divisions in aerospace requiring non-destructive removal of thermal barrier coatings or paint from critical components. These end-users prioritize long-term operating cost reduction, minimal waste generation, and enhanced process reliability over initial equipment cost.

Beyond traditional manufacturing, emerging high-growth customer segments include foundries and mold makers, which utilize laser cleaning for rapid and non-abrasive removal of residues from injection molds, dramatically reducing downtime compared to traditional chemical or sandblasting techniques. Furthermore, governmental agencies and large infrastructure operators (marine shipping, nuclear power plants, military logistics) are significant potential buyers, especially for mobile and high-power systems designed for large-scale rust mitigation, hazardous material decontamination, and protective coating preparation. The versatility of the technology allows systems to address varied operational needs, from delicate precision cleaning of electronic components to heavy-duty industrial degreasing and paint stripping.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 1,020 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | CleanTech Laser Systems GmbH, IPG Photonics Corporation, Trumpf GmbH + Co. KG, Coherent Corp., Laser Photonics Corporation, 3D-Synergy, P-Laser, Adaptive Laser Cleaning, Laserax Inc., Lumentum Operations LLC, Novanta Inc., SPI Lasers (Amada Co. Ltd.), Maxphotonics Co., Ltd., Shenzhen Chuangxin Laser Equipment Co., Ltd., Wuhan Huagong Laser Engineering Co., Ltd., Han's Laser Technology Industry Group Co., Ltd., Advanced Laser Technology, Alaser GmbH, Reliant Laser, Laser Systems Europe. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Laser Cleaning System Market Key Technology Landscape

The technology landscape in the Laser Cleaning System Market is highly dynamic, centered primarily on the development and refinement of laser source types and beam delivery mechanisms. Pulsed fiber lasers remain the foundational technology, favored for their high peak power delivery at short pulse widths (nanoseconds to picoseconds), which facilitates efficient ablation of contaminants with minimal thermal interaction with the base material. Recent advancements focus on increasing the average power output of these pulsed lasers (moving above the 1000W threshold) to significantly enhance throughput for heavy industrial applications like ship hull cleaning and large-scale manufacturing surface preparation. Furthermore, the integration of advanced beam shaping optics, such as customized diffractive optical elements (DOEs) and homogenized beam profiles, ensures uniform energy distribution across the cleaning spot, mitigating the risk of hot spots and substrate damage.

A crucial technological trend involves the increasing sophistication of beam steering and motion control systems. High-speed galvanometer scanners, coupled with sophisticated robotic arms, are standard for automating the cleaning process across complex geometries. The emergence of handheld laser cleaning units, utilizing lower power levels for manual operations, has expanded market access for smaller maintenance operations and specialized tasks. These handheld systems depend heavily on safety interlocks and sophisticated distance sensing technology to ensure operator safety and maintain a precise working distance for optimal cleaning efficacy. Software control systems are simultaneously evolving, offering intuitive graphical user interfaces (GUIs) and comprehensive recipe management systems that allow operators to quickly switch between cleaning parameters tailored for different materials and contaminants.

Innovation is also evident in the monitoring and feedback mechanisms essential for smart laser cleaning. Technologies such as in-situ plasma spectroscopy and photothermal deflection sensing are being incorporated to provide real-time feedback on the cleaning progress, allowing AI-driven systems to confirm the complete removal of the targeted layer without reaching the substrate. Additionally, the increasing focus on modularity and portability, driven by customer demand for field applications, is leading to lighter, more robust cooling systems and power supplies capable of operating reliably in diverse environmental conditions. Continuous Wave (CW) lasers, while traditionally less precise for ablation, are finding niche applications in surface pre-treatment (like laser texturing) where thermal interaction is either acceptable or desired, though pulsed lasers overwhelmingly dominate the core cleaning segment.

Regional Highlights

The global Laser Cleaning System Market demonstrates distinct characteristics across major geographical regions, influenced by localized industrial intensity, environmental regulation severity, and technological adoption rates.

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market, primarily driven by mass manufacturing activities in China, Japan, South Korea, and India. The rapid expansion of the automotive, electronics, and heavy machinery sectors, coupled with government initiatives promoting automated and precise manufacturing processes (such as 'Made in China 2025'), fuels the demand. Low-cost system providers and intense competition characterize this region, with a strong focus on high-throughput solutions for general manufacturing and mold cleaning.

- North America: This region is a major contributor in terms of value, characterized by early adoption of high-power and highly specialized laser systems. Demand is concentrated in the aerospace and defense sectors (MRO, precise bonding preparation), critical infrastructure maintenance (nuclear, oil & gas), and high-end automotive production. The market is driven by strict regulatory standards for occupational safety and environmental protection, favoring technologically advanced, automated, and often AI-integrated cleaning solutions.

- Europe: Europe is a technologically mature market, highly driven by sustainability mandates and industrial quality standards. Germany, Italy, and France are key consumers, primarily in advanced manufacturing, tooling, and heritage restoration. The European market exhibits strong demand for medium to high-power fiber laser systems and is highly sensitive to ecological footprint, preferring non-chemical alternatives mandated by EU directives like REACH.

- Latin America (LATAM): LATAM is an emerging market, showing steady growth particularly in Brazil and Mexico, driven by foreign direct investment in automotive manufacturing and increasing modernization of infrastructure projects. Adoption is slower compared to North America due to higher import duties and initial cost sensitivity, focusing primarily on maintenance and repair applications.

- Middle East and Africa (MEA): The MEA region is witnessing gradual market expansion, primarily focused on the oil & gas industry (pipeline maintenance, surface preparation) and growing defense sectors. Investment is concentrated in countries like Saudi Arabia and UAE, aiming for modernization and efficiency in large-scale industrial assets.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Laser Cleaning System Market.- CleanTech Laser Systems GmbH

- IPG Photonics Corporation

- Trumpf GmbH + Co. KG

- Coherent Corp.

- Laser Photonics Corporation

- 3D-Synergy

- P-Laser

- Adaptive Laser Cleaning

- Laserax Inc.

- Lumentum Operations LLC

- Novanta Inc.

- SPI Lasers (Amada Co. Ltd.)

- Maxphotonics Co., Ltd.

- Shenzhen Chuangxin Laser Equipment Co., Ltd.

- Wuhan Huagong Laser Engineering Co., Ltd.

- Han's Laser Technology Industry Group Co., Ltd.

- Advanced Laser Technology

- Alaser GmbH

- Reliant Laser

- Laser Systems Europe

Frequently Asked Questions

Analyze common user questions about the Laser Cleaning System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of laser cleaning over traditional methods like sandblasting or chemical cleaning?

Laser cleaning is a non-contact, non-abrasive, and environmentally friendly process that generates minimal secondary waste, eliminating the need for hazardous chemicals or expensive consumables. It offers superior precision, minimal thermal impact (especially with pulsed lasers), and significantly reduces operational downtime compared to conventional methods.

How does the power output (W) of a laser cleaning system relate to its industrial application?

Higher power systems (500W+) are utilized for high-throughput, large-scale industrial applications requiring rapid material removal, such as paint stripping on automotive bodies or ship hull surface preparation. Lower power systems (below 100W) are suitable for precision tasks, delicate materials, and specialized applications like mold cleaning or cultural heritage restoration where material integrity is critical.

Is laser cleaning safe for the operator and the underlying material?

When operated correctly within mandated safety enclosures and protocols (typically Class IV systems), laser cleaning is safe for operators, eliminating exposure to harmful chemicals or abrasive dust. It is non-destructive to the substrate, provided the system is properly calibrated for the specific contamination and material, leveraging the high peak power and short pulse duration of fiber lasers to target only the surface layer.

Which industry currently drives the highest demand for laser cleaning systems globally?

The automotive industry is currently the largest end-user segment, utilizing laser cleaning extensively for surface preparation prior to welding, bonding, and coating applications, ensuring high structural integrity and quality finish. Aerospace, defense, and specialized manufacturing (tooling and molds) are also critical, high-value demand drivers.

What are the main constraints impacting the broader adoption of laser cleaning technology?

The primary constraints are the high initial capital investment required for purchasing advanced fiber laser sources and integrated robotic systems, which can be prohibitive for smaller enterprises. Additionally, the technology requires specialized technical expertise for installation, calibration, and optimal operation compared to simpler traditional cleaning methods.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager