Laser Coding and Marking Equipment Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440683 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Laser Coding and Marking Equipment Market Size

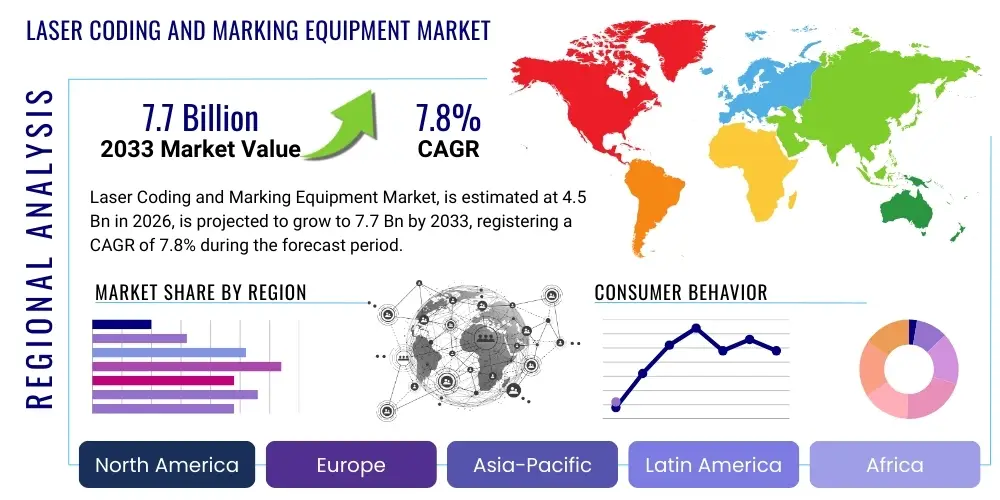

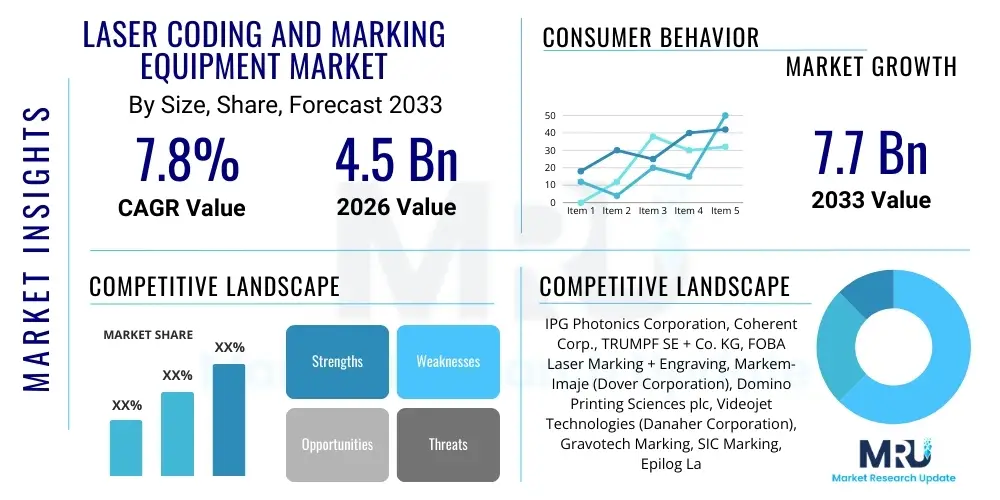

The Laser Coding and Marking Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 7.7 Billion by the end of the forecast period in 2033. This robust growth is underpinned by the increasing demand for high-precision, permanent, and efficient product identification across various industries, driven by stringent regulatory compliance and brand protection initiatives. The shift towards automation and smart manufacturing processes further accelerates the adoption of advanced laser marking technologies, ensuring traceability and quality control throughout the supply chain.

Laser Coding and Marking Equipment Market introduction

The Laser Coding and Marking Equipment Market encompasses a broad spectrum of advanced systems utilized for engraving, marking, and coding products with identifying information such as serial numbers, barcodes, QR codes, date codes, and logos. These systems employ various laser technologies, including CO2, Fiber, and UV lasers, each suited for specific material types and application requirements. The core function of these machines is to create durable, high-contrast, and tamper-proof marks directly onto product surfaces, eliminating the need for labels or inks in many cases.

Major applications of laser coding and marking equipment span across diverse industries, including automotive, aerospace, electronics, medical devices, packaging, and food and beverage. In the automotive sector, lasers mark components for traceability and safety, while in electronics, they are crucial for circuit board and semiconductor identification. The medical device industry relies on laser marking for UDI (Unique Device Identification) compliance and sterilization resistance, ensuring patient safety and regulatory adherence. Packaging applications benefit from high-speed, crisp coding on various substrates, from plastic to glass.

The primary benefits of adopting laser coding and marking solutions include superior mark quality and permanence, high processing speeds, reduced operational costs due to consumable-free operation, enhanced product aesthetics, and increased automation capabilities. These systems offer unparalleled precision, allowing for intricate designs and micro-marking on delicate components. Driving factors for market growth include the escalating demand for product traceability and anti-counterfeiting measures, the global push towards automation and Industry 4.0, increasing regulatory pressures for serialization, and the continuous innovation in laser technology leading to more versatile and cost-effective solutions for a wider range of materials.

Laser Coding and Marking Equipment Market Executive Summary

The Laser Coding and Marking Equipment Market is experiencing dynamic shifts, characterized by significant business trends that underscore its growth trajectory. Key among these is the escalating demand for integrated solutions that seamlessly fit into automated production lines, reflecting the broader industrial shift towards Industry 4.0. Companies are increasingly investing in sophisticated laser systems to achieve higher throughput, reduce human error, and enhance overall operational efficiency. Furthermore, there is a strong trend towards customization and flexibility, with manufacturers seeking modular laser systems that can be easily adapted to varying product lines and marking requirements, addressing the diverse needs of end-user industries. The emphasis on sustainable manufacturing practices also favors laser marking, given its consumable-free nature and reduced environmental footprint compared to traditional methods.

Regional trends reveal distinct patterns of adoption and growth. Asia Pacific continues to emerge as the dominant market, propelled by rapid industrialization, expansion of manufacturing hubs in countries like China, India, and Vietnam, and significant investments in the electronics, automotive, and medical device sectors. North America and Europe, while mature markets, are experiencing growth driven by stringent regulatory frameworks for product traceability, advanced manufacturing initiatives, and a strong focus on high-value, precision-engineered products. Latin America and the Middle East & Africa are nascent but rapidly growing markets, with increasing industrial development and diversification leading to greater adoption of advanced marking technologies, particularly in the packaging and consumer goods industries.

Segmentation trends highlight the increasing prominence of fiber laser technology due to its versatility, efficiency, and capability to mark a wide array of materials, from metals to certain plastics, making it highly suitable for industrial applications. UV lasers are gaining traction for heat-sensitive materials and applications requiring ultra-fine marking without material degradation. In terms of application, the packaging and food & beverage industries are significant consumers, driven by expiration dating, batch coding, and regulatory compliance, while the automotive and electronics sectors continue to drive demand for highly precise and permanent part identification. The service segment, encompassing maintenance, spare parts, and customization, is also growing, as companies seek to maximize the lifespan and efficiency of their laser marking investments, ensuring continuous operation and optimized performance.

AI Impact Analysis on Laser Coding and Marking Equipment Market

The integration of Artificial Intelligence (AI) into the Laser Coding and Marking Equipment Market is set to revolutionize operational efficiency, precision, and predictive capabilities. Users are increasingly concerned with how AI can automate complex marking tasks, optimize laser parameters for different materials, and enhance quality control to minimize errors and rework. There is a strong expectation that AI will lead to smarter, more adaptive marking systems that can identify product variations, adjust marking patterns on the fly, and even anticipate maintenance needs. Concerns often revolve around the initial investment costs, the complexity of integrating AI into existing infrastructure, and the need for specialized skills to manage these advanced systems, alongside data privacy and security implications, particularly in highly regulated industries.

Users anticipate that AI will significantly improve decision-making processes within manufacturing environments by providing real-time analytics on marking quality, throughput, and system performance. This data-driven approach is expected to unlock new levels of efficiency, allowing manufacturers to achieve higher production yields and reduce waste. Furthermore, the potential for AI to facilitate greater customization and personalization in marking operations, moving beyond static patterns to adaptive, intelligent marking based on individual product attributes or batch requirements, is a key area of interest. This predictive and adaptive capability promises to transform how products are identified and tracked throughout their lifecycle, from manufacturing to end-of-life.

Ultimately, the overarching theme among users is the desire for AI to create a self-optimizing, highly reliable, and intelligent laser marking ecosystem. This includes not only advanced capabilities in marking itself but also in supply chain integration, where AI-powered traceability solutions can provide end-to-end visibility. The market expects AI to transition laser coding and marking from a purely operational task to a strategic tool that contributes significantly to product quality, brand reputation, and overall manufacturing intelligence. The focus is on leveraging AI to drive greater autonomy, precision, and cost-effectiveness, ensuring competitive advantage in a rapidly evolving industrial landscape.

- Predictive Maintenance: AI algorithms analyze sensor data from laser systems to predict potential equipment failures, enabling proactive maintenance and minimizing downtime, thereby extending machine lifespan and improving operational continuity.

- Quality Control and Inspection: AI-powered vision systems can inspect marked codes in real-time, detecting imperfections, verifying readability, and ensuring compliance with quality standards at high speeds, significantly reducing defect rates.

- Parameter Optimization: Machine learning models can automatically adjust laser power, speed, and focus settings based on material type, thickness, and desired mark quality, leading to optimal results and reduced material waste.

- Adaptive Marking: AI enables laser systems to adapt marking patterns or content based on real-time product variations or specific batch requirements, enhancing flexibility and customization for diverse production runs.

- Robotics and Automation Integration: AI facilitates seamless integration of laser marking equipment with robotic arms and automated production lines, allowing for intelligent pick-and-place, positioning, and marking processes, boosting automation levels.

- Data Analytics and Traceability: AI processes vast amounts of marking data to provide comprehensive traceability insights, improving supply chain visibility, anti-counterfeiting measures, and regulatory compliance.

- User Interface Enhancement: AI-driven interfaces can offer intuitive controls, guided troubleshooting, and intelligent recommendations, simplifying operation for diverse skill levels and reducing training time.

- Energy Efficiency: AI optimization can fine-tune laser operations to consume less energy while maintaining high performance, contributing to sustainable manufacturing practices and reducing operational costs.

- Material Identification: Advanced AI vision systems can identify unknown materials and suggest optimal laser settings, expanding the versatility of existing equipment without manual intervention.

- Smart Factory Integration: AI acts as a central intelligence layer, allowing laser marking systems to communicate and coordinate with other smart factory components, creating a highly efficient and interconnected manufacturing ecosystem.

DRO & Impact Forces Of Laser Coding and Marking Equipment Market

The Laser Coding and Marking Equipment Market is significantly propelled by several powerful drivers. Paramount among these is the escalating global demand for product traceability and serialization across various industries, driven by both consumer safety concerns and stringent regulatory mandates. Industries such as pharmaceuticals, medical devices, automotive, and food & beverage are increasingly required to implement comprehensive tracking systems to combat counterfeiting, ensure product authenticity, and facilitate efficient recall processes. Laser marking provides a permanent, high-contrast, and machine-readable identification that meets these demanding requirements, making it an indispensable tool for compliance and brand protection. Furthermore, the continuous advancements in laser technology, leading to more versatile, compact, and energy-efficient systems, are broadening the applicability of these solutions to a wider range of materials and industrial environments, thereby fueling market expansion.

However, the market also faces considerable restraints. The relatively high initial capital investment required for sophisticated laser coding and marking equipment, especially for high-power or specialized laser types like UV lasers, can be a significant barrier for small and medium-sized enterprises (SMEs) with limited budgets. Additionally, the need for skilled operators and maintenance personnel to handle and optimize these advanced systems poses a challenge, particularly in regions with a shortage of technical expertise. The complexity of integrating laser marking systems into existing diverse production lines, which may vary significantly across industries and facilities, can also present implementation hurdles and require significant customization efforts, adding to overall project costs and timelines. The challenge of marking certain highly reflective or transparent materials effectively without specialized coatings or pre-treatment also limits universal application.

Despite these challenges, substantial opportunities exist within the market. The burgeoning growth of emerging economies, characterized by rapid industrialization and increasing manufacturing output, presents vast untapped potential for laser marking adoption. As these regions modernize their production capabilities and strive for higher quality and global competitiveness, the demand for efficient and permanent marking solutions will naturally rise. Moreover, the accelerating trend towards automation and Industry 4.0 initiatives globally creates a fertile ground for integrated, smart laser marking systems that can communicate with other factory devices and leverage data analytics for process optimization. The continuous innovation in laser sources, beam steering technologies, and software capabilities, including the integration of AI and machine learning for predictive maintenance and automated quality control, will further unlock new applications and enhance the value proposition of these systems, driving future market growth and diversification across various end-user sectors.

Segmentation Analysis

The Laser Coding and Marking Equipment Market is comprehensively segmented based on various criteria to provide a detailed understanding of its dynamics, adoption patterns, and growth opportunities across different industry verticals and technological preferences. This segmentation includes analysis by laser type, which highlights the prevalent technologies used; by end-user industry, which showcases the diverse applications and demand drivers; and by application type, outlining specific marking needs. Additionally, regional segmentation provides insights into geographical market trends and regulatory impacts. Each segment offers unique characteristics and growth potentials, reflecting the multifaceted nature of the industrial marking landscape and the tailored solutions required to meet specific operational and regulatory demands.

- By Laser Type:

- Fiber Laser

- CO2 Laser

- UV Laser

- Green Laser

- Diode Laser

- Excimer Laser

- By End-User Industry:

- Automotive

- Aerospace and Defense

- Electronics and Semiconductors

- Medical Devices

- Pharmaceuticals

- Packaging

- Food and Beverage

- Industrial (General Manufacturing, Tools, etc.)

- Plastics and Polymers

- Textile and Apparel

- Jewelry and Engraving

- Solar Energy

- Others (e.g., Construction, Research)

- By Application Type:

- Product Identification

- Serialization and Traceability

- Anti-Counterfeiting

- Branding and Aesthetics

- Date and Batch Coding

- Barcoding and QR Coding

- Direct Part Marking (DPM)

- Micro-Marking

- Deep Engraving

- Surface Etching

- Annealing

- Foaming/Color Change

- By Offering:

- Hardware (Systems)

- Software

- Services (Installation, Maintenance, Training, Customization)

Value Chain Analysis For Laser Coding and Marking Equipment Market

The value chain for the Laser Coding and Marking Equipment Market begins with upstream activities focused on the research, development, and manufacturing of core components. This includes specialized laser sources (fiber, CO2, UV, green, etc.), beam delivery systems (galvanometers, optics, mirrors), control electronics, power supplies, and specialized software. Suppliers in this segment invest heavily in R&D to enhance laser efficiency, beam quality, and component durability. Key players in the upstream segment are often niche technology companies that specialize in producing high-performance laser emitters and optical systems, which are then integrated into complete marking solutions. The quality and innovation at this stage are critical, as they directly influence the performance, reliability, and cost-effectiveness of the final laser marking equipment.

Moving downstream, the value chain involves the assembly, integration, and customization of these components into complete laser coding and marking systems by equipment manufacturers. These manufacturers often develop proprietary software interfaces and mechanical designs to optimize the marking process for various applications and materials. This stage also includes rigorous testing, quality assurance, and certification to meet industry standards and regulatory requirements. Distribution channels play a crucial role here, connecting manufacturers with end-users. Direct sales channels are common for large industrial clients or complex, custom installations, where direct technical consultation and support are paramount. Indirect channels, such as distributors, value-added resellers (VARs), and system integrators, are prevalent for reaching a broader market, particularly for standardized or smaller-scale systems, providing localized support and faster delivery.

The final stages of the value chain involve aftermarket services and end-user adoption. Post-sales services, including installation, operator training, maintenance, calibration, and provision of spare parts, are vital for ensuring the long-term performance and customer satisfaction. Direct interaction with end-users is often maintained through dedicated service teams or authorized service partners. End-users span across diverse manufacturing sectors, each with unique marking requirements. The effectiveness of the distribution channel directly impacts market penetration and customer reach, while robust after-sales support ensures continued customer loyalty and optimal equipment operation throughout its lifecycle. This entire chain emphasizes the importance of collaboration between component suppliers, equipment manufacturers, and service providers to deliver comprehensive and reliable marking solutions.

Laser Coding and Marking Equipment Market Potential Customers

The potential customer base for Laser Coding and Marking Equipment is incredibly diverse, encompassing nearly every manufacturing sector that requires permanent, high-quality, and precise product identification. At the forefront are industries with stringent regulatory requirements for traceability and anti-counterfeiting, such as pharmaceuticals and medical devices. Manufacturers in these sectors are mandated to implement Unique Device Identification (UDI) and serialization, making laser marking an indispensable tool for compliance, patient safety, and managing complex supply chains. These end-users prioritize reliability, precision for micro-marking, and the ability to mark a variety of substrates, including plastics, metals, and ceramics, often in sterile or cleanroom environments.

Another significant segment of potential customers includes the automotive and aerospace industries. Within these sectors, laser marking is critical for component identification, ensuring traceability from raw material to finished vehicle or aircraft. Parts like engine components, electronic control units, chassis parts, and aerospace structural elements require durable marks that can withstand harsh operating conditions, extreme temperatures, and chemical exposure. Manufacturers here seek robust systems capable of Direct Part Marking (DPM) on various metals and engineering plastics, often integrating with automated production lines for high-volume marking, emphasizing speed, accuracy, and integration capabilities.

Furthermore, the electronics and semiconductor industries represent a rapidly growing customer segment, utilizing laser marking for PCBs, integrated circuits, connectors, and casings to provide serialization, branding, and functional marking without damaging sensitive components. The food and beverage and packaging industries are also key buyers, driven by the need for date codes, batch numbers, and branding on a wide array of packaging materials like plastic, glass, and flexible films, where high-speed, consumable-free marking is highly advantageous for operational efficiency and environmental reasons. General manufacturing, tools, and consumer goods sectors also regularly leverage laser marking for branding, product information, and quality control, demonstrating the broad appeal and utility of these advanced marking technologies across the global industrial landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 7.7 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | IPG Photonics Corporation, Coherent Corp., TRUMPF SE + Co. KG, FOBA Laser Marking + Engraving, Markem-Imaje (Dover Corporation), Domino Printing Sciences plc, Videojet Technologies (Danaher Corporation), Gravotech Marking, SIC Marking, Epilog Laser, Han's Laser Technology Industry Group Co., Ltd., Telesis Technologies, Inc., Mecco, Trotec Laser GmbH, Keyence Corporation, HGTECH, LaserStar Technologies Corporation, Datalogic S.p.A., Universal Laser Systems, Inc., REA JET (REA Elektronik GmbH) |

| Regions Covered | North America (U.S., Canada, Mexico), Europe (Germany, UK, France, Italy, Spain, Rest of Europe), Asia Pacific (China, India, Japan, South Korea, Australia, Southeast Asia, Rest of APAC), Latin America (Brazil, Argentina, Rest of Latin America), Middle East, and Africa (MEA) (UAE, Saudi Arabia, South Africa, Rest of MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Laser Coding and Marking Equipment Market Key Technology Landscape

The technological landscape of the Laser Coding and Marking Equipment Market is characterized by continuous innovation and diversification, driven by the need for greater precision, speed, material versatility, and integration capabilities. At the core of these systems are various types of laser sources, each optimized for specific applications. Fiber lasers, for instance, are highly favored for their excellent beam quality, long operational life, and efficiency in marking metals and certain plastics. They operate at infrared wavelengths, offering high power output and flexibility for both surface marking and deeper engraving, making them a staple in automotive, electronics, and general industrial manufacturing.

CO2 lasers, operating at far-infrared wavelengths, remain dominant for marking organic materials such as wood, paper, glass, ceramics, and many plastics, including those used in packaging and food & beverage industries. Recent advancements in CO2 laser technology have focused on improving pulse control and beam stability, allowing for cleaner, faster marks and expanding their application to more challenging materials. UV lasers, known as "cold lasers," are gaining significant traction for marking heat-sensitive materials like medical plastics, circuit boards, and delicate electronic components. Their shorter wavelength provides extremely fine spot sizes and minimal heat-affected zones (HAZ), enabling high-contrast, precise marks without material degradation, which is critical for micro-marking and sensitive applications.

Beyond laser sources, the technological landscape also encompasses advanced beam delivery systems, such as high-speed galvanometer scanners, which enable rapid and precise positioning of the laser beam across the marking area. Sophisticated control software, often featuring intuitive graphical user interfaces and CAD/CAM integration, allows for complex marking designs, real-time parameter adjustments, and seamless integration with existing factory automation systems. Furthermore, the integration of vision systems and artificial intelligence (AI) is a burgeoning trend, enhancing quality control through automated inspection, optimizing marking parameters, and enabling predictive maintenance. This holistic technological ecosystem ensures that laser coding and marking equipment remains at the forefront of industrial identification solutions, continually evolving to meet emerging manufacturing challenges and regulatory demands.

Regional Highlights

- North America: A mature market characterized by early adoption of advanced manufacturing technologies, stringent regulatory requirements for product traceability in aerospace, medical devices, and automotive sectors, and a strong focus on high-value, precision manufacturing. The U.S. leads in R&D and implementation of cutting-edge laser solutions.

- Europe: Driven by robust industrial bases in Germany, Italy, and France, with a significant emphasis on quality, efficiency, and environmental sustainability. Strict EU regulations for product safety and serialization in pharmaceuticals and food & beverage fuel demand, alongside strong automotive and general manufacturing sectors.

- Asia Pacific (APAC): The largest and fastest-growing market, propelled by rapid industrialization, burgeoning manufacturing sectors (electronics, automotive, consumer goods) in China, India, Japan, and South Korea, and increasing investments in automation and smart factories. Competitive manufacturing landscapes drive demand for cost-effective and high-speed marking solutions.

- China: Dominates the APAC market due to its massive manufacturing output, significant domestic demand for industrial equipment, and increasing focus on upgrading manufacturing capabilities with advanced laser technologies. Local manufacturers contribute to intense competition and innovation.

- India: Experiencing substantial growth in manufacturing, particularly in automotive, electronics, and packaging sectors. Rising awareness of product quality and traceability, coupled with government initiatives like "Make in India," boosts adoption of laser marking solutions.

- Japan: A leader in advanced manufacturing and precision engineering, driving demand for high-quality, reliable, and technologically sophisticated laser marking equipment, especially in electronics, automotive, and semiconductor industries.

- South Korea: Known for its strong electronics and automotive industries, exhibiting high adoption rates of advanced laser marking systems for precision and efficiency in high-volume production.

- Latin America: An emerging market with growing industrialization, particularly in Brazil and Mexico, driven by foreign investments in automotive, food & beverage, and packaging. Increasing demand for efficient marking solutions to improve local manufacturing competitiveness.

- Middle East and Africa (MEA): A developing market witnessing increased investments in infrastructure and diversification of economies beyond oil, leading to growth in manufacturing, particularly in packaging, construction, and nascent automotive industries, stimulating demand for industrial marking equipment.

- Southeast Asia: Countries like Vietnam, Thailand, and Indonesia are becoming significant manufacturing hubs, attracting foreign direct investment and driving the need for modern production technologies, including laser coding and marking systems, to meet global supply chain standards.

- Canada: Strong ties with the U.S. market, focusing on specific niche industries such as aerospace, automotive components, and medical devices, with a consistent demand for high-precision marking solutions.

- Australia: Stable demand from manufacturing sectors, mining equipment, and food processing industries, with a focus on durability and compliance for identification and traceability.

- Germany: A technology leader in laser manufacturing, driving innovation in laser sources and integrated marking systems for its robust automotive, machinery, and industrial goods sectors.

- United Kingdom: Growing demand from packaging, aerospace, and medical sectors, with an emphasis on R&D for advanced marking applications and smart factory integration.

- France: Significant market share in luxury goods, automotive, and aerospace industries, requiring high aesthetic quality and precision from laser marking equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Laser Coding and Marking Equipment Market.- IPG Photonics Corporation

- Coherent Corp.

- TRUMPF SE + Co. KG

- FOBA Laser Marking + Engraving

- Markem-Imaje (Dover Corporation)

- Domino Printing Sciences plc

- Videojet Technologies (Danaher Corporation)

- Gravotech Marking

- SIC Marking

- Epilog Laser

- Han's Laser Technology Industry Group Co., Ltd.

- Telesis Technologies, Inc.

- Mecco

- Trotec Laser GmbH

- Keyence Corporation

- HGTECH

- LaserStar Technologies Corporation

- Datalogic S.p.A.

- Universal Laser Systems, Inc.

- REA JET (REA Elektronik GmbH)

Frequently Asked Questions

What is laser coding and marking equipment and how does it work?

Laser coding and marking equipment utilizes focused laser beams to create permanent, high-contrast marks on various product surfaces without contact. It works by directing a high-intensity light beam onto a material, causing a chemical or physical change such as ablation, engraving, annealing, foaming, or color change. Different laser types (fiber, CO2, UV) are chosen based on the material (metals, plastics, glass, organics) and the desired marking effect, providing superior precision, speed, and durability compared to traditional methods. The process is controlled by sophisticated software that translates digital designs into precise laser movements.

Which industries are the primary users of laser coding and marking equipment?

The primary users of laser coding and marking equipment span a wide array of industries including automotive for component traceability, electronics and semiconductors for intricate circuit board and component identification, medical devices and pharmaceuticals for UDI and serialization compliance, and packaging and food & beverage for date, batch, and anti-counterfeiting codes. Other significant sectors include aerospace and defense, general industrial manufacturing, tools, plastics, and even jewelry engraving. These industries rely on laser technology for its permanence, precision, and ability to meet stringent regulatory and quality standards.

What are the key advantages of laser marking over traditional marking methods?

Laser marking offers several significant advantages over traditional methods like ink jet printing or stamping. These include superior mark permanence, as laser marks are resistant to abrasion, chemicals, and extreme temperatures, ensuring long-term traceability. It is a consumable-free process, reducing operational costs and environmental impact by eliminating inks, solvents, and labels. Laser marking provides exceptional precision, allowing for micro-marking and intricate designs on delicate components. Additionally, it offers high-speed processing for efficient production lines, is non-contact, preventing product damage, and enhances overall product aesthetics and brand integrity through clean, crisp marks.

How is AI impacting the future of the laser coding and marking equipment market?

AI is profoundly impacting the future of the laser coding and marking market by enabling smarter, more efficient, and autonomous systems. AI-powered vision systems enhance real-time quality control and defect detection, ensuring flawless marks. Machine learning algorithms optimize laser parameters automatically for different materials and desired effects, reducing setup times and material waste. Furthermore, AI facilitates predictive maintenance, anticipating equipment failures before they occur, thus minimizing downtime. It also enables adaptive marking, allowing systems to adjust to product variations on the fly, and contributes to seamless integration into broader Industry 4.0 smart factory ecosystems, driving greater automation, precision, and cost-effectiveness.

What factors are driving the growth of the laser coding and marking equipment market?

The growth of the laser coding and marking equipment market is primarily driven by the increasing global demand for product traceability and anti-counterfeiting measures, especially due to stringent regulatory compliance in sectors like pharmaceuticals and medical devices. The accelerating adoption of automation and Industry 4.0 initiatives in manufacturing processes worldwide also fuels demand for integrated, high-speed marking solutions. Additionally, continuous technological advancements in laser sources, beam steering, and software capabilities are making these systems more versatile and efficient, expanding their application across a wider range of materials and industries, coupled with the rising focus on sustainable, consumable-free manufacturing.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Laser Coding and Marking Equipment Market Size Report By Type (Fiber Laser, CO2 Laser, UV Laser, Others (YAG Laser, etc.)), By Application (Automotive, Aerospace, Machine Tool, Electronics & Microelectronics, Medical, Packaging, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Industrial Laser Coding and Marking Equipment Market Statistics 2025 Analysis By Application (Automotive, Aerospace, Machine Tool), By Type (Fiber Laser, CO2 Laser, UV Laser), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Laser Coding and Marking Equipment Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Fiber Laser, CO2 Laser, UV Laser, Others), By Application (Automotive, Aerospace, Machine Tool, Electronics & Microelectronics, Medical, Packaging, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager