Laser Micro Perforation Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432706 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Laser Micro Perforation Market Size

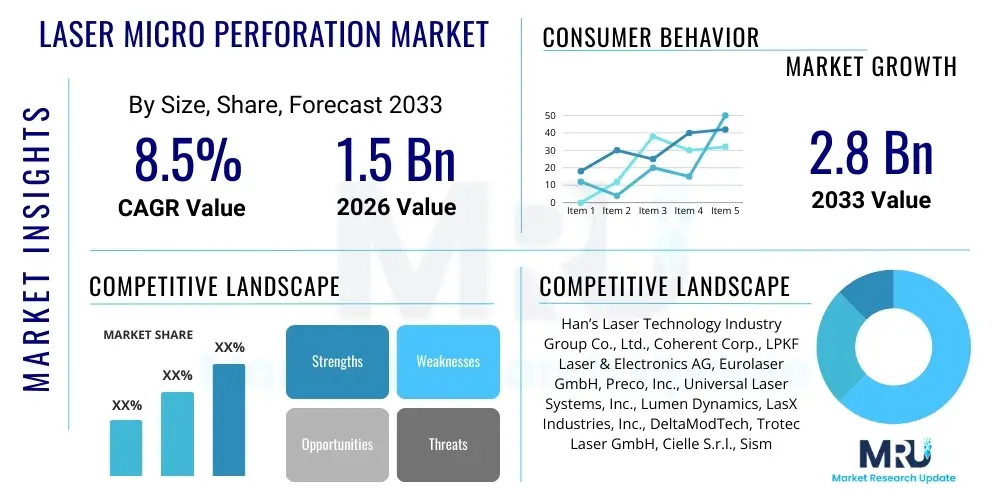

The Laser Micro Perforation Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. This sophisticated industrial process market is estimated at USD 1.5 Billion in 2026 and is strategically projected to reach USD 2.8 Billion by the end of the forecast period in 2033. The robust growth trajectory is underpinned by increasing demand for enhanced packaging solutions that require modified atmospheric properties and the proliferation of high-precision manufacturing across the medical and electronics sectors. Market valuation reflects the continuous technological advancements in laser sources, specifically the adoption of ultrafast lasers that offer superior precision and efficiency.

The calculation of market size incorporates revenue generated from the sale of laser micro perforation systems, including CO2, fiber, and UV laser sources, along with associated software and maintenance services. This growth is not merely volumetric but also qualitative, driven by the shift from traditional mechanical perforation techniques to non-contact laser methods. Furthermore, the rising regulatory focus on sustainable and biodegradable packaging materials necessitates micro perforation capabilities to control gas and moisture exchange, positioning the technology as an indispensable tool for extending product shelf life, particularly in the fresh produce industry.

Geographic diversification of manufacturing bases, especially in the Asia Pacific region, significantly contributes to the escalating market value. Investments in fully automated, high-throughput laser systems for flexible packaging production lines are key financial indicators influencing the market forecast. The steady integration of laser micro perforation into highly specialized applications, such as transdermal drug delivery patches and advanced electronic filters, solidifies its critical role in high-value manufacturing processes, thereby ensuring sustained revenue expansion through 2033.

Laser Micro Perforation Market introduction

Laser micro perforation is a high-precision manufacturing technique involving the creation of extremely small, highly uniform holes or pores in various materials, typically ranging from a few micrometers up to hundreds of micrometers in diameter. This non-contact process utilizes concentrated laser energy—most commonly from CO2, fiber, or UV lasers—to ablate the material surface with exceptional accuracy and speed. The primary objective is to modify the gas permeability, breathability, filtration properties, or visual appearance of the substrate without compromising its structural integrity. This technology is crucial across industries demanding meticulous control over material properties, offering a distinct advantage over traditional mechanical punching methods which often introduce structural stress or lack the necessary fine resolution.

The major applications of laser micro perforation span a diverse array of high-growth sectors. In the food packaging industry, it is fundamental for Modified Atmosphere Packaging (MAP), ensuring optimal gas exchange (primarily oxygen and carbon dioxide) to preserve freshness and delay spoilage of fresh produce. Beyond packaging, the technology is vital in the medical sector for producing surgical textiles, micro-fluidic devices, and transdermal patches requiring controlled release rates. Furthermore, the electronics industry leverages micro perforation for specialized filtering and venting applications in sensitive components, while the automotive and construction industries utilize it for airbag venting systems and advanced membrane materials that require precise air flow characteristics.

Key driving factors propelling market expansion include the global shift towards sustainable and functional packaging solutions, demanding increased shelf life and reduced food waste. The inherent benefits of laser technology—such as high processing speed, minimal material damage, operational flexibility, and the ability to process intricate patterns on heat-sensitive materials—make it economically compelling compared to conventional techniques. Moreover, continuous innovation in laser source efficiency and beam delivery systems, coupled with stringent quality standards in healthcare and automotive manufacturing, consistently fuels the adoption of sophisticated laser micro perforation systems worldwide, ensuring their pervasive influence across modern manufacturing landscapes.

Laser Micro Perforation Market Executive Summary

The Laser Micro Perforation Market is characterized by vigorous technological integration and expansive application growth, driven primarily by the global emphasis on extending product shelf life and achieving high-precision material processing. Business trends indicate a robust investment cycle focusing on automation and high-speed processing capabilities, particularly utilizing ultrafast pulsed lasers (picosecond and femtosecond) to enhance quality control and throughput while minimizing heat-affected zones (HAZ). Key players are strategically focusing on vertical integration, offering tailored system solutions that combine advanced optics, motion control, and proprietary software to meet stringent industry standards, especially in pharmaceutical packaging and specialty films manufacturing. The competitive landscape is evolving towards specialized service models, where providers offer contract perforation services alongside equipment sales, catering to smaller enterprises lacking significant capital investment.

Regional trends highlight the Asia Pacific (APAC) region as the dominant market in terms of volume and growth potential, fueled by rapidly expanding manufacturing bases in packaging, automotive, and consumer electronics in countries like China, India, and South Korea. North America and Europe maintain significant market shares, characterized by early adoption of high-end, highly automated systems driven by strict regulatory requirements for food safety and medical device production, prioritizing UV and excimer laser technologies for extremely fine perforations. Latin America and the Middle East & Africa (MEA) are emerging regions, witnessing steady growth as flexible packaging manufacturers in these territories upgrade their facilities to meet international quality standards and serve modern retail chains requiring advanced preservation techniques.

Segment trends underscore the dominance of the flexible packaging application segment, closely followed by filtration and medical device manufacturing. By material type, polymer films and paper & paperboard represent the largest segments, reflecting the high demand from the food and tobacco industries. Technology segmentation shows a strong migration towards fiber and UV lasers due to their improved efficiency and capability for micromachining delicate materials, though CO2 lasers remain the workhorse for high-speed processing of macro-perforation and larger hole patterns on thick films. The increasing complexity of materials, including multilayer films and biodegradable plastics, mandates continuous segment-specific innovation in laser wavelength selection and processing parameters to ensure optimal perforation quality and consistency across diverse material compositions.

AI Impact Analysis on Laser Micro Perforation Market

User queries regarding the impact of Artificial Intelligence (AI) on the Laser Micro Perforation Market frequently revolve around topics such as enhanced process control, predictive maintenance, defect detection accuracy, and optimization of laser parameters for novel materials. Users seek confirmation on whether AI can significantly reduce material wastage, improve yield rates, and handle the variability inherent in high-speed manufacturing environments. The core themes coalesce around the potential for AI-driven systems to move beyond simple automation into true intelligent manufacturing, leveraging machine learning algorithms to autonomously adjust laser power, pulse duration, and scanning speed in real-time based on live sensor feedback regarding material thickness, composition variations, and environmental factors. Concerns often center on the initial cost and complexity of integrating AI vision systems and data infrastructure into existing perforation equipment.

The integration of AI, particularly through Computer Vision and Machine Learning (ML), is revolutionizing the quality control aspect of laser micro perforation. Traditional systems relied on statistical sampling, but AI-powered inline inspection systems can analyze 100% of the perforated material at production speeds, detecting microscopic defects, inconsistencies in hole diameter, and pattern deviations with unparalleled accuracy. ML models trained on vast datasets of perforation images can instantaneously differentiate acceptable quality from defects, drastically reducing the possibility of non-conforming product reaching the customer. This capability is paramount in high-stakes applications like medical packaging and specialized electronics, where zero-defect manufacturing is a prerequisite for regulatory compliance and operational safety.

Furthermore, AI algorithms are critical for optimizing the operational efficiency and predictive maintenance of advanced laser systems. ML models analyze operational data—including laser source temperature, power fluctuations, coolant flow rates, and beam alignment metrics—to predict potential component failures well before they occur. This proactive approach minimizes unscheduled downtime, extending the lifespan of expensive optical components and ensuring maximal equipment utilization. In terms of process optimization, AI-driven parameter tuning allows manufacturers to rapidly establish the optimal settings when switching between different substrate materials or product specifications, saving significant time during setup and reducing the need for extensive manual testing, thus accelerating time-to-market for new packaging designs.

- AI-enhanced Vision Systems: Enables 100% real-time defect inspection and micro-hole quality assessment at high production speeds.

- Predictive Maintenance: Machine Learning analyzes operational telemetry to forecast component failure (e.g., optics degradation), maximizing uptime.

- Autonomous Parameter Optimization: AI algorithms adjust laser power, pulse frequency, and scanning speed based on live material sensing and desired hole geometry.

- Reduced Material Waste: Improved control and instant feedback loop minimizes scrap associated with process drift or material inconsistencies.

- Throughput Maximization: AI identifies and eliminates bottlenecks in the production line, optimizing the flow of material for peak efficiency.

DRO & Impact Forces Of Laser Micro Perforation Market

The dynamics of the Laser Micro Perforation Market are dictated by a compelling set of Drivers, Restraints, and Opportunities (DRO), collectively forming the fundamental Impact Forces shaping its trajectory. The primary driver is the exponentially increasing global demand for Modified Atmosphere Packaging (MAP) technology in the food industry, necessitated by the need to combat global food waste and extend the market reach of fresh produce. Simultaneously, technological advancements in laser sources, specifically the commercial viability of high-power, high-speed fiber and solid-state lasers, offer significant efficiency gains and cost reductions compared to older CO2 laser systems, accelerating their deployment across diverse manufacturing environments. These positive forces establish a strong foundation for sustained market growth.

However, the market faces significant Restraints that temper its expansion. The initial capital investment required for high-precision laser micro perforation equipment is substantial, posing a barrier to entry, particularly for Small and Medium Enterprises (SMEs). Furthermore, operating advanced laser systems requires highly skilled technicians for maintenance, calibration, and optimization, leading to challenges related to specialized workforce availability and associated labor costs. Another constraint involves the complex interaction between laser energy and diverse material compositions, where achieving consistent, high-quality micro perforations on multilayer, composite, or sensitive biodegradable films requires extensive research and customized process development, often resulting in prolonged integration periods and steep learning curves for end-users.

Significant Opportunities exist for market participants to capitalize on emerging trends. The most promising opportunity lies in the rapid development and commercialization of biodegradable and sustainable packaging materials, which require unique, laser-specific perforation techniques to maintain desired barrier properties and decomposition rates. The expansion of the medical devices sector, demanding ultra-precise micro-machining for micro-fluidics, drug delivery patches, and surgical implants, represents a high-value niche market. Additionally, the proliferation of Internet of Things (IoT) sensors and connected devices requires advanced venting and filtration, providing a continuous stream of specialized application needs that only laser micro perforation can effectively address, thereby widening the technology’s industrial footprint and diversifying revenue streams.

The impact forces indicate a market characterized by high technical barrier to entry but significant long-term reward. Drivers related to global sustainability goals and technological leaps in laser efficiency exert strong upward pressure on market adoption. Conversely, the high investment cost and the necessity for specialized expertise act as counter-forces, slowing broader market penetration. The overwhelming opportunities in specialized high-precision sectors, particularly medical and advanced packaging, suggest that strategic innovators focusing on user-friendly, fully automated systems with integrated AI quality control will capture the largest market share, mitigating the impact of capital constraints through demonstrated return on investment (ROI) in quality and productivity.

Segmentation Analysis

The Laser Micro Perforation Market is segmented comprehensively based on Technology, Material, Application, and End-User, reflecting the diverse industrial requirements and technical specifications of the process. This segmentation allows for precise market sizing and strategic targeting by vendors, as the optimal laser system is highly dependent on the target material and the required hole geometry. The technology segment, which includes CO2, Fiber, UV, and Excimer lasers, dictates the achievable precision and material compatibility; for instance, UV lasers are preferred for fine, non-thermal processing of organic polymers and sensitive films, while CO2 lasers dominate high-speed, cost-effective macro-perforation in thick paperboard or certain plastic films.

The application segmentation is particularly critical, showcasing the versatility of the technology, with Packaging (both flexible and rigid) constituting the largest market share due to ubiquitous demand for shelf-life extension and moisture control. Medical applications, including transdermal patches and surgical non-wovens, command a premium due to the stringent quality requirements and regulatory hurdles associated with manufacturing these critical components. The segmentation by material highlights the market's shift towards handling complex, multi-layered polymer films which are increasingly used in advanced packaging, demanding sophisticated beam delivery systems capable of perforating one layer without damaging the underlying structure or causing material fusion.

Understanding these segments is essential for strategic planning. Equipment manufacturers often specialize in specific laser types or application areas—for example, focusing exclusively on high-throughput CO2 systems for tobacco tipping paper or specializing in precision UV systems for flexible printed electronics. The continuous evolution of materials in the End-User sectors, such as the introduction of new bio-plastics in the Food & Beverage industry or exotic polymers in the Automotive sector for advanced filtration systems, constantly redefines the performance metrics required from laser micro perforation equipment, ensuring continuous innovation remains a mandatory aspect of sustaining market relevance.

- Technology:

- CO2 Laser Micro Perforation

- Fiber Laser Micro Perforation

- UV Laser Micro Perforation

- Excimer Laser Micro Perforation

- Material:

- Polymer Films (e.g., PET, PP, PE)

- Paper & Paperboard

- Foils & Metals

- Textiles and Non-Wovens

- Composite Materials

- Application:

- Packaging (Flexible Packaging, Rigid Packaging, Tobacco Tipping Paper)

- Filtration and Screening

- Medical Devices and Healthcare (e.g., Transdermal Patches, Surgical Drapes)

- Electronics and Displays

- Automotive Components (e.g., Airbag Vents)

- Consumer Goods

- End-User Industry:

- Food & Beverage Industry

- Healthcare and Pharmaceutical Industry

- Industrial Manufacturing

- Consumer Goods

- Chemical and Petrochemical Industry

Value Chain Analysis For Laser Micro Perforation Market

The value chain of the Laser Micro Perforation Market begins with upstream activities focused on the manufacturing and supply of critical components. This includes the highly specialized production of laser sources (e.g., CO2 tubes, fiber laser engines, solid-state lasers, and UV sources), sophisticated optical components (mirrors, lenses, beam expanders), and high-speed galvanometric scanners necessary for beam steering. Key raw material suppliers also provide the necessary gases, cooling systems, and specialized control electronics. Manufacturers in this upstream segment typically require high R&D investment and possess significant intellectual property regarding laser physics and optical engineering, making this a high-value, concentrated segment of the chain. Competition is intense among core laser manufacturers who must continuously drive down costs while increasing power efficiency and beam quality.

The midstream of the value chain is dominated by System Integrators and Original Equipment Manufacturers (OEMs) who assemble the components into fully functional micro perforation machines, integrating motion control systems, sophisticated Human-Machine Interfaces (HMIs), and proprietary process control software. These entities customize systems based on the end-user's material requirements, required throughput, and desired perforation geometry. Distribution channels for these high-value capital goods are typically direct, involving extensive consultation, installation, and technical training provided by the OEM. Indirect distribution, involving specialized regional distributors or agents, is sometimes utilized in markets requiring local support, although the complexity of the machinery often necessitates a strong direct technical sales presence from the manufacturer.

Downstream activities involve the Contract Manufacturing and End-User segments. Contract perforation service providers offer specialized services to companies that cannot justify the capital expenditure of purchasing their own laser system, particularly small-to-mid-sized packaging converters or specialty product manufacturers. The final link is the End-Users—Food & Beverage, Healthcare, and Electronics companies—who utilize the perforated materials in their final product assembly. The value chain is highly integrated, as machine reliability and precision directly impact the quality and safety standards required by the downstream users. Efficiency gains achieved through technological advancement upstream translate directly into cost savings and quality improvements at the end-user level, creating strong feedback loops for continuous system improvement.

Laser Micro Perforation Market Potential Customers

Potential customers for laser micro perforation technology are primarily sophisticated manufacturers and processors operating in industries where gas exchange, filtration, or high-precision material modification is critical to product performance and safety. The largest customer base resides within the packaging conversion sector, specifically companies involved in producing flexible films, pouches, and wraps for perishable goods. These end-users, including major global packaging corporations and specialized regional converters, require high-speed, reliable systems to create Modified Atmosphere Packaging (MAP) solutions that extend the shelf life of produce, meats, and processed foods, directly addressing critical retail supply chain demands and global food waste reduction initiatives.

Another high-value segment of potential buyers includes pharmaceutical and medical device manufacturers. These customers require ultra-precise micro-machining capabilities for manufacturing drug delivery patches (transdermal systems), sterile surgical barrier fabrics, and diagnostic components where hole geometry and consistency are non-negotiable and strictly regulated. The demand here is for highly controlled systems, often utilizing UV or excimer lasers, that can process bio-compatible materials without inducing thermal damage or introducing contaminants. For these customers, the investment decision is driven by regulatory compliance, process validation capabilities, and the need for micron-level accuracy rather than simply throughput maximization, justifying the higher costs associated with advanced laser technology.

Industrial manufacturers, particularly those in the automotive, filtration, and electronics sectors, also constitute a significant pool of potential customers. Automotive suppliers utilize laser micro perforation for producing components like airbag venting panels and specialized acoustic materials. Filtration companies require the technology for creating fine-mesh screens and membrane filters used in water purification and air quality control systems, where pore size distribution and density are paramount to performance. These diverse buyers seek customization, system reliability, and robust service agreements, valuing the laser's ability to process materials that are often challenging for mechanical techniques, such as brittle ceramics or ultra-thin metallic foils.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.8 Billion |

| Growth Rate | CAGR 8.5% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Han’s Laser Technology Industry Group Co., Ltd., Coherent Corp., LPKF Laser & Electronics AG, Eurolaser GmbH, Preco, Inc., Universal Laser Systems, Inc., Lumen Dynamics, LasX Industries, Inc., DeltaModTech, Trotec Laser GmbH, Cielle S.r.l., Sisma S.p.A., GF Machining Solutions (Agie Charmilles), Synova S.A., 3D-Micromac AG, TRUMPF GmbH + Co. KG, FOBA Laser Marking + Engraving, ROFIN-SINAR Technologies, and Suzhou Delphi Laser Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Laser Micro Perforation Market Key Technology Landscape

The technological landscape of the laser micro perforation market is characterized by a continuous evolution towards higher power, shorter pulse durations, and better beam control, aimed at maximizing throughput while minimizing the Heat Affected Zone (HAZ). Current market domination is shared primarily by three laser types: CO2, Fiber, and UV lasers. CO2 lasers, operating in the infrared spectrum (around 10.6 µm), remain the most cost-effective solution for high-speed, large-area perforation on materials like paper, thick films, and textiles, valued for their high power output and reliability in continuous industrial processes. However, their relatively long wavelength limits achievable spot size and precision, making them unsuitable for micron-level perforations or heat-sensitive materials.

The proliferation of fiber and solid-state lasers represents a significant technological shift. Fiber lasers (typically 1.0 µm) offer excellent efficiency and beam quality, making them suitable for moderate to high-precision micro perforation in foils, thin metals, and certain polymers. More critically, the growing adoption of UV lasers (e.g., Nd:YAG tripled, operating at 355 nm) and excimer lasers provides the capability for "cold ablation," where the shorter wavelength allows for higher energy absorption by organic materials and minimal thermal interaction. This cold processing capability is essential for delicate applications, such as micro-fluidics manufacturing and perforation of multi-layer flexible substrates where layers must be perforated selectively without fusing or distorting adjacent materials, driving their necessity in the medical and electronics segments.

Looking ahead, the market is increasingly incorporating advanced system architectures and ultrafast laser technology. Picosecond and femtosecond lasers, while still premium in price, are gaining traction for applications demanding sub-micron precision and absolute minimal HAZ, such as manufacturing high-performance filters or drilling complex hole patterns for specialized sensors. Furthermore, integration technologies such as high-speed galvanometer scanners, advanced vision systems for real-time monitoring, and proprietary processing software that compensates for material variations are becoming standard offerings. These integrated systems facilitate seamless automation, improve process validation, and allow for on-the-fly adjustment of perforation parameters, defining the competitive edge in the high-end industrial micro perforation sector.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand and technological preferences within the Laser Micro Perforation Market, reflecting differences in manufacturing complexity, regulatory environments, and prevailing consumer demands. North America, driven by rigorous food safety standards and a highly sophisticated medical device manufacturing sector, is a key market, focusing heavily on adopting high-precision, low-HAZ UV and excimer laser systems. The region emphasizes automated quality control and process validation, leading to higher average spending per system compared to other geographies. Demand is strongest in advanced packaging for specialized pharmaceutical and medical products, alongside high-end flexible food packaging solutions that prioritize minimal waste and extended shelf life, driving the demand for specialized perforation contract services.

Europe stands as another mature and technologically advanced market, distinguished by strict environmental regulations and a strong commitment to reducing plastic use and promoting circular economy initiatives. This focus translates into high demand for laser systems capable of efficiently perforating new biodegradable and bio-plastic materials without compromising their structural integrity or thermal stability. Countries like Germany and Italy, with strong traditions in industrial automation and machine building, act as major hubs for both manufacturing the laser systems and their deployment across diverse applications including automotive component manufacturing and high-speed tobacco processing. The regional strategy involves continuous innovation in system efficiency and integration into Industry 4.0 frameworks.

The Asia Pacific (APAC) region is forecasted to exhibit the highest growth rate during the projection period, primarily fueled by the rapid expansion of the food and beverage industry, coupled with the massive scale of manufacturing in consumer electronics and textiles. Countries like China, India, and Japan are investing heavily in modernizing their packaging infrastructure to meet growing domestic consumption and stringent export standards. While initial adoption often focuses on high-throughput, cost-effective CO2 and fiber laser systems for flexible packaging, there is a burgeoning demand for advanced UV lasers in electronics and specialized textile manufacturing. This market is characterized by high volume, price sensitivity, and a fast pace of technology assimilation, making it the central engine for overall market volume growth.

- North America: Focus on high-precision medical, pharmaceutical packaging, and advanced filtration; preference for UV and Excimer cold ablation technologies.

- Europe: Driven by strict environmental regulations and sustainability targets; high adoption of systems compatible with bio-plastics and advanced materials; strong automation and Industry 4.0 integration.

- Asia Pacific (APAC): Leading market for volume growth; dominant demand from flexible packaging, electronics, and textiles; significant investment in high-throughput CO2 and Fiber laser systems; increasing need for local technical support and system integration services.

- Latin America: Emerging market focusing on modernizing packaging infrastructure for fresh produce exports; gradual adoption of cost-effective CO2 and entry-level fiber laser systems.

- Middle East & Africa (MEA): Growth driven by expanding local food production and modern retail chains; targeted adoption in specialized industrial and filtration applications; often reliant on imported technology and service expertise.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Laser Micro Perforation Market.- Han’s Laser Technology Industry Group Co., Ltd.

- Coherent Corp.

- LPKF Laser & Electronics AG

- Eurolaser GmbH

- Preco, Inc.

- Universal Laser Systems, Inc.

- Lumen Dynamics

- LasX Industries, Inc.

- DeltaModTech

- Trotec Laser GmbH

- Cielle S.r.l.

- Sisma S.p.A.

- GF Machining Solutions (Agie Charmilles)

- Synova S.A.

- 3D-Micromac AG

- TRUMPF GmbH + Co. KG

- FOBA Laser Marking + Engraving

- ROFIN-SINAR Technologies (Part of Coherent)

- IPG Photonics Corporation

- Suzhou Delphi Laser Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Laser Micro Perforation market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary benefit of laser micro perforation over mechanical punching?

The primary benefit is superior precision and consistency, allowing for micron-level hole sizes and complex patterns without creating mechanical stress, material deformation, or contamination typical of contact punching methods, ensuring material integrity and higher yields.

Which laser technology is best suited for perforating heat-sensitive biodegradable packaging films?

UV lasers (typically 355 nm) and Excimer lasers are best suited for heat-sensitive and biodegradable films. These lasers utilize 'cold ablation,' minimizing the Heat Affected Zone (HAZ) and preventing thermal degradation, fusion, or structural distortion of the delicate polymer materials.

How does laser micro perforation contribute to extending the shelf life of food products?

It enables Modified Atmosphere Packaging (MAP) by creating precisely controlled micro-pores that regulate the exchange of gases (oxygen and carbon dioxide) and moisture vapor, maintaining an optimal internal atmosphere that slows down the ripening or decay process of fresh produce and perishable goods.

What are the main technical challenges in adopting high-speed laser micro perforation systems?

Key technical challenges include the significant initial capital expenditure for advanced systems, the necessity for high-level expertise in optics and process control, and the difficulty in achieving consistent perforation quality across rapidly moving, variable-thickness multilayer materials.

Is AI integration standard in modern laser micro perforation equipment?

While not universally standard across all entry-level systems, AI integration, specifically in the form of machine vision and learning algorithms for real-time quality inspection and predictive maintenance, is rapidly becoming a standard feature in high-end, high-throughput industrial perforation equipment to ensure zero-defect output.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager