Laser Particle Size Analyzer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433232 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Laser Particle Size Analyzer Market Size

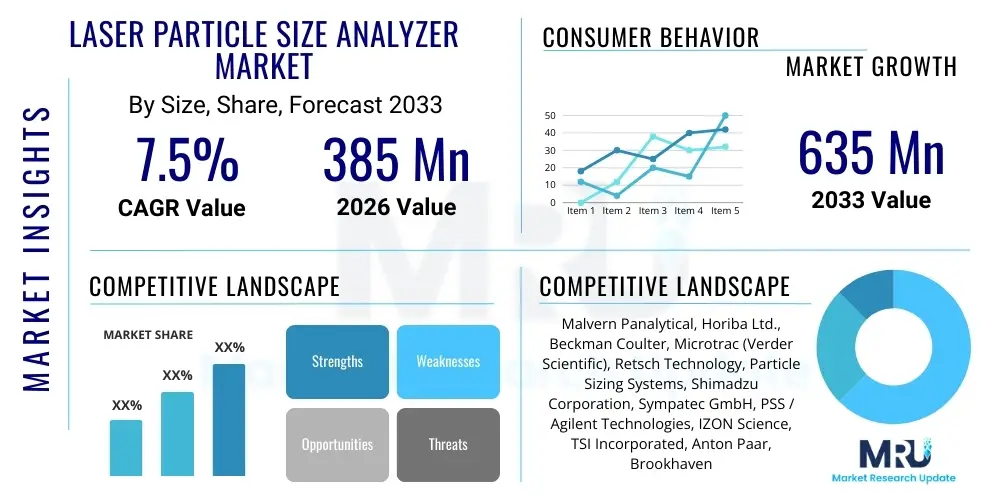

The Laser Particle Size Analyzer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at $385 Million USD in 2026 and is projected to reach $635 Million USD by the end of the forecast period in 2033.

Laser Particle Size Analyzer Market introduction

The Laser Particle Size Analyzer Market encompasses instruments designed to accurately measure the particle size distribution of various materials, ranging from sub-nanometer to millimeter scales. These analyzers primarily utilize advanced optical principles, most notably laser diffraction and dynamic light scattering (DLS), to characterize powders, emulsions, aerosols, and suspensions. The necessity for precise particle characterization is paramount across numerous high-value industries, including pharmaceuticals for bioavailability and drug delivery optimization, advanced materials manufacturing for quality control, and chemical processing for optimizing product performance. The fundamental principle of these systems involves illuminating a sample with a laser beam and analyzing the resulting light scatter pattern, which is then correlated back to the particle size distribution through sophisticated mathematical models (e.g., Mie theory or Fraunhofer approximation).

Product description highlights the sophisticated integration of laser technology, fluidics, and advanced computational software within these devices. Modern laser particle size analyzers offer high-throughput capabilities, automation, and compliance with stringent regulatory standards (like FDA and ISO). Major applications span quality assurance, research and development (R&D), process control, and troubleshooting across sectors demanding nanoscale precision. The intrinsic benefits include high accuracy, reproducibility, non-destructive analysis, and the ability to measure a wide range of materials quickly and efficiently. These instruments are indispensable tools for ensuring that manufactured products meet necessary specifications regarding texture, reactivity, stability, and therapeutic efficacy.

Driving factors for market expansion are closely tied to increasing global R&D investments, particularly in nanotechnology, biotechnology, and personalized medicine. Regulatory pressures demanding finer control over product attributes, such as particle size uniformity in drug formulations or cement fineness in construction materials, further propel demand. The shift towards automated and in-line particle size analysis systems, which allow for real-time monitoring and feedback control in manufacturing processes, is a significant technological catalyst. Furthermore, the growing complexity of engineered materials and the resultant need for ultra-precise characterization techniques ensure sustained market growth over the forecast period.

Laser Particle Size Analyzer Market Executive Summary

The Laser Particle Size Analyzer Market demonstrates robust growth, primarily driven by increasing applications in high-growth sectors such as pharmaceuticals, biotechnology, and advanced ceramics manufacturing. Business trends indicate a strong focus on developing hybrid instruments that combine multiple measurement techniques (e.g., DLS and electrophoresis) to provide comprehensive material characterization, moving away from single-technique platforms. Key market players are concentrating on strategic mergers, acquisitions, and collaborations to expand their geographical reach and enhance their technological portfolios, particularly in software integration for data interpretation and compliance documentation. The competitive landscape is also witnessing a shift towards offering specialized services, including method development and contract analysis, supplementing equipment sales.

Regional trends reveal that North America and Europe currently dominate the market share, attributed to established R&D infrastructure, high expenditure on life sciences, and stringent quality control regulations in manufacturing. However, the Asia Pacific (APAC) region is poised for the fastest growth, fueled by rapid industrialization, burgeoning pharmaceutical manufacturing capabilities, and significant governmental investment in scientific research, particularly in China and India. The demand in APAC is increasingly focused on cost-effective, high-throughput instruments suitable for large-scale quality control operations, while mature markets emphasize high-precision instruments for fundamental research.

Segment trends highlight the dominance of the laser diffraction technology segment due to its versatility, wide measurement range, and robustness in industrial environments. However, the dynamic light scattering (DLS) segment is experiencing accelerated growth, driven by the expanding field of nanotechnology and the need to characterize small particles (below 1 micrometer), such as liposomes, proteins, and quantum dots. In terms of end-users, the pharmaceutical and biotechnology segment remains the largest revenue contributor, consistently driving demand for compliant, validated analytical instrumentation necessary for drug development and regulatory submissions.

AI Impact Analysis on Laser Particle Size Analyzer Market

Common user questions regarding AI’s influence typically center on how artificial intelligence can streamline data processing, enhance measurement accuracy, and integrate particle size data with broader quality control systems (Industry 4.0). Users are primarily concerned with whether AI can eliminate the need for manual setup and interpretation, especially in complex polymodal distributions or unstable suspensions where standard algorithms struggle. Expectations involve AI enabling predictive maintenance of instrumentation, optimizing sample preparation protocols automatically, and accelerating R&D cycles through faster, more reliable data correlation with material performance outcomes. The core theme is leveraging AI to transform raw optical data into actionable manufacturing intelligence with minimal human intervention, thereby reducing operational variability and increasing measurement throughput.

- AI-powered data interpretation and anomaly detection, significantly improving the accuracy of distribution modeling for complex or aggregated samples.

- Predictive analytics for optimizing instrument performance and scheduling maintenance, minimizing downtime and calibration drift.

- Automated method development (AMD) utilizing machine learning algorithms to select optimal dispersants, stirring rates, and measurement parameters, reducing human error.

- Integration of particle size data into digital twins and smart manufacturing platforms (Industry 4.0) for real-time process control and feedback loops.

- Enhanced image analysis capabilities, particularly when coupled with static or dynamic imaging systems, classifying particle shapes and structures based on deep learning models.

- Improved quality assurance and compliance by rapidly cross-referencing measured particle data against historical batch performance and regulatory standards.

DRO & Impact Forces Of Laser Particle Size Analyzer Market

The dynamics of the Laser Particle Size Analyzer Market are governed by a complex interplay of internal and external forces. Drivers include the global expansion of nanotechnology and personalized medicine, which necessitate precise characterization of fine particles. Increased stringency in regulatory guidelines, particularly in the pharmaceutical and food and beverage sectors, mandates the use of highly accurate, validated measurement techniques. Furthermore, the relentless pursuit of product innovation across materials science, requiring sophisticated tools for analyzing novel compounds and complex formulations, acts as a primary catalyst for market growth. Technological advancements, such as the miniaturization of sensors and the incorporation of advanced software for data handling, also fuel adoption.

Restraints, conversely, pose significant challenges to market expansion. The high initial capital investment required for purchasing and installing advanced laser particle size analyzers, particularly those offering wide size ranges and high automation, can be prohibitive for small and medium-sized enterprises (SMEs) and academic institutions with limited budgets. Operational restraints include the complex requirements for calibration and validation, demanding highly skilled technical personnel. Furthermore, challenges related to sample preparation, where errors can severely impact measurement accuracy, remain a significant impediment, often requiring extensive user training and standardization.

Opportunities for market players are abundant in emerging economies, where industrialization is accelerating and local regulatory standards are tightening. The demand for portable and robust systems for field testing and remote quality control offers a lucrative niche. Moreover, developing instruments capable of in-line, real-time measurements directly within manufacturing environments provides a substantial opportunity for process analytical technology (PAT) integration. The strongest impact force is the necessity for quality assurance and control (QA/QC); in regulated industries, the absence of particle size data means the inability to release products, making these instruments mission-critical, thereby ensuring stable demand regardless of short-term economic fluctuations. Conversely, the restraint posed by high acquisition cost exerts a negative drag, particularly in price-sensitive regions.

Segmentation Analysis

The Laser Particle Size Analyzer Market is comprehensively segmented based on technology, measurement range, end-user industry, and geographical region, reflecting diverse application needs and technical requirements across the global economy. Understanding these segments is crucial for market participants to tailor product development and strategic marketing efforts. The technology segment distinguishes between methods based on their underlying physical principles and is foundational to the instrument's capabilities. Measurement range categorization addresses the specific particle sizes the analyzer is optimized to measure, ranging from nanosized drug carriers to micron-sized mineral powders. End-user classification reveals the primary demand drivers, showing significant investment from research institutions versus high-volume manufacturing facilities.

- By Technology:

- Laser Diffraction (LD)

- Dynamic Light Scattering (DLS)

- Nanoparticle Tracking Analysis (NTA)

- Static Light Scattering (SLS)

- Integrated Technologies (Hybrid Systems)

- By Measurement Range:

- Nanoscale (Typically below 1 µm)

- Microscale (1 µm to 1,000 µm)

- Broad Scale (Systems covering nano to millimeter range)

- By End-User Industry:

- Pharmaceutical and Biotechnology (Drug Formulation, Vaccines, API)

- Chemical and Polymer (Paints, Coatings, Plastics)

- Food and Beverage (Emulsions, Texturization, Additives)

- Materials Science and Engineering (Ceramics, Metals, Batteries)

- Mining and Minerals

- Academic Research and Government Laboratories

Value Chain Analysis For Laser Particle Size Analyzer Market

The value chain for the Laser Particle Size Analyzer Market begins with upstream activities focused on the procurement and manufacturing of highly specialized components. This includes securing high-quality, stable solid-state lasers (e.g., HeNe or diode lasers), precision optical elements (lenses, detectors, and filters), and sophisticated fluidic control systems necessary for sample dispersion. Key upstream challenges involve maintaining ultra-precise component quality to ensure measurement accuracy and managing the supply chain for specialized sensors and high-speed data acquisition boards. Component suppliers often need to meet specific quality certifications (e.g., ISO 9001) given the sensitive nature of the analytical instrumentation.

The central manufacturing stage involves the assembly, integration, and calibration of the optomechanical systems, fluidics, and control electronics. This phase is highly proprietary, requiring significant intellectual property regarding alignment procedures and advanced software algorithms for data inversion (converting scattering data into size distributions). Following manufacturing, distribution channels play a critical role. Direct distribution is common for high-end, complex instruments sold to large pharmaceutical and research organizations, where direct technical support and customized installation are paramount. Indirect distribution utilizes authorized regional distributors and third-party sales agents, particularly beneficial for reaching smaller clients or expanding into geographically diverse markets like Latin America and Southeast Asia.

The downstream segment focuses on post-sale activities, including installation, calibration, validation services (crucial for regulated environments like pharma), ongoing maintenance, and technical training. This service revenue stream constitutes a significant portion of the total market value and builds long-term customer loyalty. Specialized training ensures end-users can correctly prepare samples and interpret complex data, directly impacting the instrument's utility. The overall efficiency and profitability of the value chain are increasingly dependent on the rapid deployment of software updates and remote diagnostic capabilities to minimize service costs and maximize instrument uptime for the end-user.

Laser Particle Size Analyzer Market Potential Customers

Potential customers, or end-users, for Laser Particle Size Analyzers are characterized by their stringent requirements for material homogeneity and particle size control, recognizing that particle characteristics directly influence product efficacy, stability, and processing behavior. The primary and most lucrative customer base resides in the pharmaceutical industry, particularly companies engaged in developing generic drugs, novel drug delivery systems (e.g., nanosuspensions, microcapsules), and biopharmaceuticals. For these users, particle size analysis is a mandatory step for Investigational New Drug (IND) applications and quality control throughout the manufacturing lifecycle, ensuring compliance with pharmacopoeial standards and optimal therapeutic performance.

Beyond pharmaceuticals, the chemical and polymer sectors represent a massive user base. These customers utilize analyzers to control the size of pigments, fillers, specialty chemicals, and polymer beads, which dictate properties such as opacity, viscosity, abrasion resistance, and surface finish. Manufacturers of advanced materials, including those developing battery electrodes, catalytic converters, and high-performance ceramics, are also critical customers. Their reliance stems from the direct relationship between particle morphology and final material performance, such as energy density in batteries or structural integrity in composites.

Furthermore, academic and governmental research institutions constitute a steady demand segment, primarily purchasing high-precision DLS and NTA systems for fundamental research in areas like colloidal science, toxicology, and environmental studies. The food and beverage industry also employs these analyzers to optimize the texture and stability of emulsions, flavor systems, and powdered ingredients. These diverse customer groups prioritize instruments that offer high reliability, verifiable accuracy, and sophisticated software capable of handling diverse sample matrices and reporting formats essential for their specialized applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $385 Million USD |

| Market Forecast in 2033 | $635 Million USD |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Malvern Panalytical, Horiba Ltd., Beckman Coulter, Microtrac (Verder Scientific), Retsch Technology, Particle Sizing Systems, Shimadzu Corporation, Sympatec GmbH, PSS / Agilent Technologies, IZON Science, TSI Incorporated, Anton Paar, Brookhaven Instruments, Micromeritics Instrument Corporation, Bettersize Instruments Ltd., L.O.T.-Oriel, K-FEE, CILAS, Occhio, Fritsch GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Laser Particle Size Analyzer Market Key Technology Landscape

The technological landscape of the Laser Particle Size Analyzer Market is dominated by two core techniques: Laser Diffraction (LD) and Dynamic Light Scattering (DLS). Laser Diffraction, also known as static light scattering, is the workhorse of industrial particle sizing, characterized by its wide measurement range, rapid analysis time, and robustness. LD instruments measure the angular distribution of light scattered by particles passing through a laser beam, utilizing advanced detectors and optical geometry (e.g., Fourier optics). Recent technological advancements in LD focus on improving dry powder dispersion units, enhancing software algorithms for better handling of non-spherical particles, and extending the lower detection limit towards the sub-micron range, thereby increasing its applicability across various quality control processes.

Dynamic Light Scattering (DLS), conversely, is the preferred method for characterizing nanoparticles, macromolecules, and materials in suspension, typically operating in the 1 nm to 10 µm range. DLS measures the Brownian motion of particles in a fluid and uses the Stokes-Einstein equation to correlate particle movement speed with size. The technological focus in DLS development involves improving sensitivity to allow measurement of very dilute samples, incorporating specialized cells for high-temperature or high-pressure analysis, and integrating Phase Analysis Light Scattering (PALS) capabilities for zeta potential measurement, providing comprehensive colloidal stability data. Furthermore, integrating DLS systems with flow analysis methods allows for continuous monitoring in flow-through systems.

Emerging technologies, such as Nanoparticle Tracking Analysis (NTA) and Single Particle Counting methods, are gaining prominence, particularly in the rapidly growing field of exosome research and viral vector characterization in biotech. NTA tracks the movement of individual nanoparticles frame-by-frame, providing highly detailed number-weighted size distributions, which is advantageous over the intensity-weighted distributions provided by standard DLS. The market is also seeing a shift toward multimodal instruments that combine LD, DLS, and sometimes static imaging, offering users a single platform capable of analyzing the full spectrum of particle sizes and morphologies, enhancing data robustness and reducing the need for multiple instruments in a single laboratory setting.

Regional Highlights

- North America: This region holds a leading market share, driven by high R&D expenditure in the U.S., particularly within the pharmaceutical, nanotechnology, and advanced materials sectors. The presence of major global manufacturers and a well-established regulatory framework requiring precise analytical validation contribute significantly to market maturity and high demand for sophisticated, automated systems. Adoption of Process Analytical Technology (PAT) tools is highest here, ensuring continuous investment in advanced in-line analyzers.

- Europe: Characterized by strong growth, particularly in Germany (automotive, chemical) and the UK (life sciences), Europe exhibits high demand for robust, compliant instrumentation. European regulations, such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), necessitate extensive particle characterization for safety documentation, providing a sustained market driver. Focus remains on innovation in green chemistry and materials recycling, demanding precise sizing tools.

- Asia Pacific (APAC): Expected to register the highest Compound Annual Growth Rate (CAGR) during the forecast period. This rapid expansion is attributed to massive government investments in R&D in China and South Korea, coupled with the rapid expansion of generic drug manufacturing and fine chemical production in India and Southeast Asia. The region is increasingly adopting western quality control standards, resulting in a surge in demand for reliable and moderately priced analytical instruments for QA/QC labs.

- Latin America: This region is an emerging market, primarily driven by expanding pharmaceutical manufacturing and increasing infrastructure projects (cement, mining). Market growth is steady but sensitive to economic stability and import duties, leading to a preference for cost-effective instruments with strong local service support. Brazil and Mexico are the primary centers of demand.

- Middle East and Africa (MEA): Growth in MEA is specialized, driven by investments in the petrochemical and oil & gas sectors (slurry and catalyst characterization) and the increasing development of local pharmaceutical production hubs in countries like Saudi Arabia and the UAE. Market penetration is gradually increasing as educational institutions and industrial research capabilities are strengthened, requiring fundamental analytical tools.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Laser Particle Size Analyzer Market.- Malvern Panalytical

- Horiba Ltd.

- Beckman Coulter

- Microtrac (Verder Scientific)

- Retsch Technology

- Particle Sizing Systems

- Shimadzu Corporation

- Sympatec GmbH

- PSS / Agilent Technologies

- IZON Science

- TSI Incorporated

- Anton Paar

- Brookhaven Instruments

- Micromeritics Instrument Corporation

- Bettersize Instruments Ltd.

- L.O.T.-Oriel

- K-FEE

- CILAS

- Occhio

- Fritsch GmbH

Frequently Asked Questions

Analyze common user questions about the Laser Particle Size Analyzer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Laser Diffraction (LD) and Dynamic Light Scattering (DLS) technologies?

Laser Diffraction (LD) measures the intensity of scattered light at various angles to determine the size distribution of particles generally ranging from 0.1 µm to 3,000 µm, ideal for powders and suspensions. Dynamic Light Scattering (DLS) measures the Brownian motion of particles in suspension to calculate size distribution, primarily effective for very small particles (typically 1 nm to 10 µm) and macromolecules.

In which end-user industry are Laser Particle Size Analyzers most critically utilized?

The pharmaceutical and biotechnology industry is the most critical end-user, utilizing these analyzers extensively for quality control (QC), research and development (R&D), and regulatory compliance, particularly in optimizing drug delivery systems, ensuring API uniformity, and characterizing vaccine components.

How does AI technology enhance the performance of modern Laser Particle Size Analyzers?

AI improves analyzer performance by enabling sophisticated data interpretation, particularly for complex polymodal or aggregated samples, automating method development, and facilitating integration into real-time Process Analytical Technology (PAT) systems for enhanced manufacturing control and predictive maintenance.

What major factors are restraining the growth of the Laser Particle Size Analyzer Market, especially for smaller businesses?

The primary restraints include the high initial capital investment required for advanced, highly automated systems and the necessity for highly trained technical personnel for complex sample preparation, calibration, and method validation processes, posing a barrier to entry for smaller enterprises and academic labs.

Which geographical region is projected to exhibit the fastest growth in the Laser Particle Size Analyzer Market through 2033?

The Asia Pacific (APAC) region, particularly driven by rapid industrialization, massive investments in nanotechnology R&D, and the burgeoning pharmaceutical manufacturing sectors in countries like China and India, is forecasted to achieve the highest Compound Annual Growth Rate (CAGR).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager