Laser Protective Eyewear Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439285 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Laser Protective Eyewear Market Size

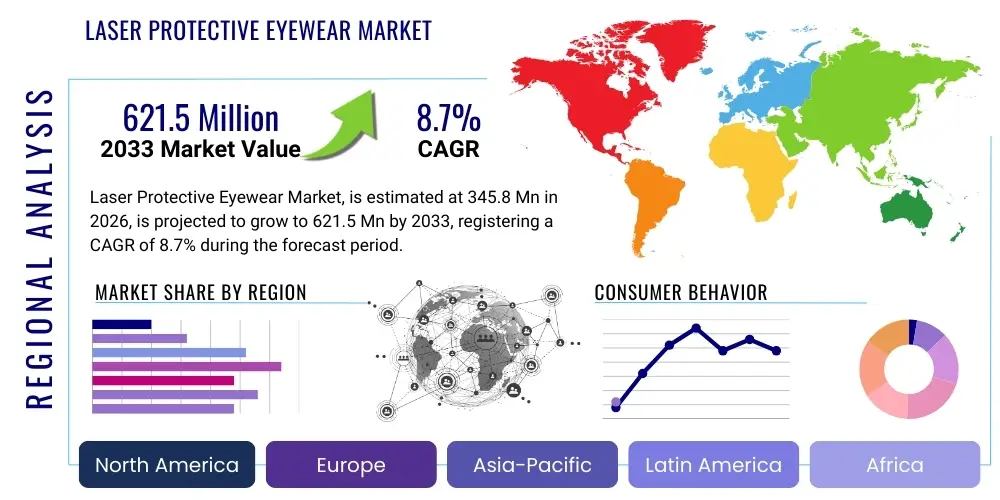

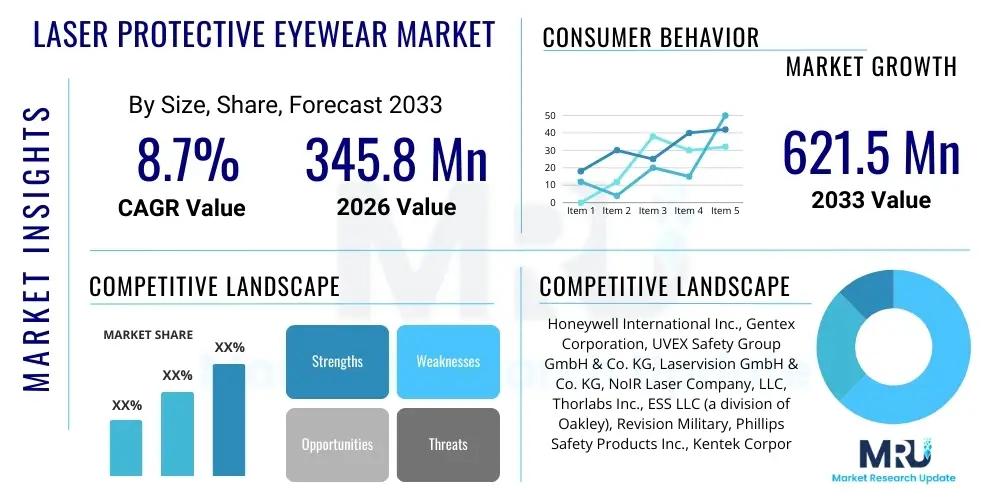

The Laser Protective Eyewear Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.7% between 2026 and 2033. The market is estimated at USD 345.8 million in 2026 and is projected to reach USD 621.5 million by the end of the forecast period in 2033.

Laser Protective Eyewear Market introduction

Laser protective eyewear encompasses a specialized range of personal protective equipment designed to safeguard the eyes from the potentially harmful effects of laser radiation. These devices are engineered with specific optical densities and wavelength absorption characteristics, ensuring that hazardous laser light is attenuated to safe levels before reaching the user's retina. The core function of this eyewear is to provide comprehensive protection against direct beam exposure, diffuse reflections, and accidental misfires across a spectrum of laser types, including those used in industrial, medical, military, and research applications. The global increase in the deployment of lasers across diverse industries, driven by their precision, efficiency, and versatility in manufacturing, healthcare, and defense, directly underpins the escalating demand for robust eye safety solutions.

The product portfolio within the laser protective eyewear market ranges from basic spectacles and goggles to advanced face shields, each tailored to specific operational environments and laser parameters. Benefits of using high-quality laser protective eyewear extend beyond mere compliance with safety regulations; they include preventing permanent eye damage, reducing the risk of costly workplace accidents, and ensuring continuous operational safety and productivity. The ongoing advancements in laser technology, leading to more powerful and diverse laser systems, necessitate a parallel evolution in protective eyewear to meet increasingly stringent safety standards. This constant innovation in laser applications, coupled with a heightened global awareness of occupational safety, acts as a primary driving factor for market expansion, compelling industries to adopt and upgrade their laser safety protocols and equipment.

Major applications for laser protective eyewear span a wide array of sectors. In manufacturing, it is indispensable for personnel operating laser cutting, welding, and marking machines, ensuring protection against intense reflections and stray beams. Within healthcare, surgeons and medical professionals rely on specialized eyewear during laser-assisted surgeries, dermatological treatments, and ophthalmological procedures where precision is paramount and ocular exposure must be meticulously controlled. Research and development laboratories, academic institutions, and military operations also represent significant application areas where precise laser use, often involving high-power or experimental systems, demands rigorous and often custom eye protection. The inherent precision and power of lasers, while beneficial, pose significant risks if proper protective measures, such as the use of certified laser eyewear, are not meticulously observed. Therefore, the market is continually driven by the imperative to protect human vision from both chronic and acute laser-induced injuries, aligning with global occupational health and safety protocols and fostering a culture of preventative safety.

Laser Protective Eyewear Market Executive Summary

The Laser Protective Eyewear Market is characterized by robust growth, propelled by the pervasive integration of laser technology across various industrial, medical, and scientific domains. Key business trends include a strong emphasis on product innovation, focusing on lighter materials, enhanced comfort, broader spectral protection, and improved visibility. Manufacturers are increasingly adopting advanced manufacturing techniques and exploring smart eyewear solutions that incorporate digital functionalities for real-time hazard assessment, such as automatic tinting or laser detection warnings. Strategic partnerships and collaborations between eyewear manufacturers and laser system providers are also becoming prevalent, aiming to offer integrated safety solutions and expand market reach. Furthermore, the market is seeing a trend towards customization, where eyewear is tailored to specific laser wavelengths and power outputs used in particular applications, moving beyond generic protection to provide optimized safety solutions.

Regionally, North America and Europe continue to dominate the market due to stringent safety regulations, a high concentration of advanced manufacturing industries, and significant investments in healthcare and defense sectors that heavily utilize laser technologies. However, the Asia Pacific region is rapidly emerging as a high-growth market, driven by the rapid industrialization, expansion of manufacturing bases, increasing adoption of medical lasers, and growing awareness regarding workplace safety in countries like China, India, and Japan. Latin America and the Middle East & Africa regions are also showing promising growth, albeit from a smaller base, as industrial and medical sectors in these areas continue to develop and implement modern laser technologies, leading to a rising demand for protective solutions as safety standards begin to catch up with technological adoption.

Segmentation trends within the market highlight the growing prominence of specialized eyewear categories. The industrial application segment remains the largest, driven by the widespread use of lasers in various manufacturing processes, but medical and research segments are exhibiting the fastest growth rates due to increasing laser-based procedures and intensified R&D activities in photonics and quantum technologies. By material, polycarbonate frames with specialized absorption dyes or reflective coatings are widely adopted for their balance of protection, comfort, and cost-effectiveness, while glass-based optics are favored for high-power laser applications requiring superior optical clarity and damage resistance. The demand for prescription laser safety eyewear is also on the rise, catering to individuals who require vision correction alongside laser protection, underscoring a trend towards more inclusive, user-centric product development and a recognition of diverse workforce needs.

AI Impact Analysis on Laser Protective Eyewear Market

User inquiries concerning AI's influence on the Laser Protective Eyewear Market often revolve around how artificial intelligence can significantly enhance safety, improve design, and optimize manufacturing processes. Common questions explore the potential for AI-driven smart features, such as real-time laser detection and automatic attenuation adjustments based on identified laser parameters, or AI's role in predicting material degradation and improving spectral filtering accuracy through advanced simulations. Users are also keen to understand if AI can personalize eyewear solutions more effectively by analyzing biometric data and usage patterns, or even automate the design and rapid prototyping of new protective materials with optimal optical properties. The overarching themes reflect an expectation that AI will lead to more proactive, intelligent, and highly customized laser safety solutions, moving beyond passive protection to active hazard mitigation, improved ergonomic design, and a significantly enhanced user experience within dynamic laser environments. There is also considerable interest in AI's capacity to streamline supply chains, enhance market forecasting, and ensure consistent product quality.

- AI-driven material development: Utilizing machine learning algorithms to predict and design novel filtering materials with improved absorption properties, lighter weight, and enhanced broadband protection capabilities, accelerating R&D cycles.

- Smart eyewear integration: Embedding AI sensors and processors for real-time detection of laser exposure, wavelength identification, power measurement, and providing immediate alerts to users or connected safety systems.

- Personalized fit and prescription optimization: AI algorithms for precise facial mapping, anthropometric analysis, and seamless integration of complex prescriptions, ensuring optimal comfort, fit, and comprehensive protective coverage for diverse users.

- Predictive maintenance for eyewear: AI analyzing historical usage data, environmental conditions, and material properties to predict potential filter fatigue or frame degradation, prompting timely replacement or preventative maintenance.

- Automated quality control: AI-powered vision systems and robotic inspection tools for highly accurate and rapid assessment of manufactured eyewear, ensuring consistent optical density, coating integrity, and compliance with stringent safety standards.

- Supply chain optimization: AI for advanced demand forecasting, optimizing inventory management, streamlining logistics, and improving the efficiency of distribution channels for laser protective eyewear globally.

- Enhanced training and simulation: AI-driven virtual reality or augmented reality platforms for immersive training simulations, educating users on proper eyewear selection, laser hazard zones, and best practices for laser safety protocols.

- Robotics in manufacturing: AI guiding advanced robotic systems for precision assembly, intricate coating applications, and high-volume lens fabrication, improving consistency, reducing waste, and enhancing manufacturing efficiency.

- Customization at scale: AI enabling the efficient and cost-effective production of highly customized eyewear solutions to meet diverse end-user requirements, specific laser specifications, and ergonomic preferences without incurring prohibitive costs.

DRO & Impact Forces Of Laser Protective Eyewear Market

The Laser Protective Eyewear Market is significantly shaped by a confluence of driving forces, restraining factors, and emerging opportunities, all operating within a dynamic competitive landscape influenced by various impact forces. The primary drivers include the escalating adoption of laser technologies across diverse industries such as manufacturing, healthcare, and telecommunications, alongside increasingly stringent occupational safety regulations enforced by governmental and international bodies. This widespread integration of lasers, driven by their precision and efficiency, coupled with a heightened global awareness of potential ocular hazards, creates a foundational and expanding demand for effective protective solutions. Technological advancements in laser systems, which lead to more powerful, versatile, and often novel laser types, further necessitate continuous innovation in protective eyewear to ensure adequate and compliant safety measures. Additionally, the growing investment in research and development activities involving lasers, particularly in advanced materials and quantum technologies, contributes significantly to the market's expansion by creating new applications and risks.

However, the market also faces several notable restraints that can temper its growth. The high cost associated with advanced, specialized laser protective eyewear, particularly for broadband or customizable solutions with complex optical densities, can be a significant barrier to adoption for smaller enterprises or in developing regions with budget constraints. A persistent lack of comprehensive awareness regarding specific laser safety requirements among end-users, or widespread misconceptions about the necessity and efficacy of specialized eyewear, can also impede market growth and lead to underutilization of critical safety equipment. Furthermore, the inherent complexities involved in accurately selecting the correct eyewear for a multitude of laser wavelengths, power levels, and operating conditions can sometimes lead to user confusion or improper selection, posing unaddressed safety risks and potentially impacting market trust. The ongoing challenge of balancing optimal optical density with clear visible light transmission and user comfort, especially for prolonged wear, also presents a persistent design and engineering constraint that manufacturers continuously strive to overcome through material science innovations.

Opportunities within this market are substantial and primarily driven by the development of novel materials that offer superior protection, lighter weight, improved visual clarity, and enhanced durability. The integration of smart features, such as electronic light filters with dynamic response times, real-time laser detection systems, and augmented reality overlays providing critical safety information, represents a significant avenue for innovation and market differentiation. Expanding applications of lasers into new, high-growth sectors, such as quantum computing, advanced additive manufacturing, and sophisticated medical diagnostics, will create fresh and specialized demand for protective eyewear. Moreover, the growing trend of personalized protective equipment, including bespoke prescription laser safety glasses that cater to individual vision needs, serves to broaden the user base and enhance compliance. Impact forces, such as the moderate bargaining power of buyers due to specialized product needs and the imperative for certified protection, the increasing bargaining power of suppliers for advanced raw materials and proprietary filter technologies, and the relatively low threat of substitutes for purpose-built certified protective eyewear, contribute to a stable market structure. While the threat of new entrants is moderate, requiring significant R&D investment, regulatory compliance, and brand reputation, competitive rivalry remains high among established players, driving continuous innovation, product diversification, and market segmentation.

Segmentation Analysis

The Laser Protective Eyewear Market is meticulously segmented to reflect the diverse applications, technological specifications, and user requirements that characterize this specialized industry. Understanding these segments is crucial for analyzing market dynamics, identifying growth opportunities, and developing targeted strategies for product development and market penetration. The segmentation primarily considers factors such as the physical type of eyewear, the specific materials used in their construction, the primary absorption mechanism, the specific laser applications they are designed for, and the end-user industries that ultimately utilize them. This multi-faceted approach allows for a granular view of market trends, revealing distinct preferences and demands across different operational environments and user groups.

The inherent variations in laser wavelengths, power levels, and operating conditions necessitate a wide array of protective solutions, each with unique specifications. For instance, a medical professional using a low-power therapeutic laser during a dermatological procedure will require different eyewear specifications—potentially favoring comfort and a wider field of view—than an industrial technician operating a high-power cutting laser, who prioritizes robust impact resistance and precise optical density. Similarly, the choice of material for the lens and frame significantly impacts the eyewear's optical density, visible light transmission, comfort, and long-term durability. End-user industries, ranging from precision manufacturing to advanced scientific research, also dictate the specific design and functional requirements, influencing everything from frame style and ergonomic considerations to advanced lens coatings and compatibility with other personal protective equipment. Analyzing these distinct segments provides a comprehensive framework for market participants to innovate and tailor their offerings, ensuring optimal safety, regulatory compliance, and user satisfaction in an ever-evolving technological landscape.

- By Type:

- Goggles: Designed for full peripheral protection, often with a tighter seal against the face.

- Spectacles: Resembling conventional eyeglasses, offering comfort and a wider field of vision, typically for lower-risk environments.

- Face Shields: Providing broader facial protection against laser radiation, debris, and splashes, suitable for higher-risk applications.

- Custom/Prescription Eyewear: Tailored to individual vision requirements, integrating corrective lenses with laser protection.

- By Material:

- Polycarbonate Lenses: Widely used for their impact resistance, lightweight nature, and ability to be infused with specific absorbing dyes.

- Glass Lenses: Preferred for high-power laser applications due to superior optical clarity, scratch resistance, and higher damage threshold, often with dielectric coatings.

- Mineral Glass Lenses: A specific type of glass offering excellent clarity and chemical resistance, suitable for demanding environments.

- Acrylic Lenses: Lighter than glass, but generally less resistant to high power, often used for specific wavelength absorption.

- Hybrid Materials: Combinations designed to leverage benefits of multiple materials, such as polycarbonate with specialized coatings.

- By Absorption Type:

- Absorptive: Lenses containing dyes or pigments that absorb specific laser wavelengths.

- Reflective: Lenses with dielectric coatings that reflect specific laser wavelengths.

- Hybrid/Combination: Utilizing both absorptive and reflective properties for broad-spectrum or multi-wavelength protection.

- By Application:

- Industrial Manufacturing (Laser Cutting, Welding, Marking, Engraving, Additive Manufacturing)

- Medical & Healthcare (Dermatology, Ophthalmology, Surgery, Dental, Aesthetics, Diagnostic Imaging)

- Research & Development (Laboratories, Universities, Quantum Computing, Photonics Experimentation)

- Military & Defense (Laser Rangefinders, Targeting Systems, Directed Energy Weapons, Communication)

- Telecommunications & IT (Fiber Optic Installation, Maintenance, Data Center Operations)

- Aesthetics & Beauty (Hair Removal, Skin Rejuvenation, Tattoo Removal)

- By End-User Industry:

- Healthcare Sector (Hospitals, Clinics, Private Practices)

- Manufacturing Sector (Automotive, Aerospace, Electronics, Heavy Industry)

- Defense & Aerospace (Military Branches, Defense Contractors, Space Agencies)

- Education & Academia (Universities, Technical Colleges, Research Institutions)

- Electronics & Semiconductor (Micro-fabrication, Chip Manufacturing, Quality Control)

- Construction & Automotive (Laser Leveling, Autonomous Vehicle Sensor Development, Production Lines)

Value Chain Analysis For Laser Protective Eyewear Market

The value chain for the Laser Protective Eyewear Market begins with upstream activities involving the sourcing and processing of highly specialized raw materials, which are foundational to the protective capabilities of the final product. This includes manufacturers of high-quality optical polymers such as polycarbonate, various types of glass (e.g., mineral glass, borosilicate), and specific organic dyes, inorganic pigments, or metallic coatings that provide the necessary optical density and wavelength-specific absorption or reflection properties. Key players at this initial stage are specialized chemical companies, advanced glass manufacturers, and material science firms that develop cutting-edge filter technologies. The quality, purity, and precise formulation of these raw materials are paramount, directly influencing the protective capabilities, optical clarity, durability, and ergonomic properties of the final eyewear. Innovation at this upstream stage, particularly in developing new broadband filters or lighter, more robust materials with enhanced scratch resistance, can significantly impact the downstream product offerings and overall market competitiveness, dictating performance benchmarks.

Moving downstream, the value chain encompasses the intricate manufacturing, precision assembly, and diverse distribution of the finished laser protective eyewear. Manufacturers transform these specialized raw materials into highly engineered lenses and frames, often incorporating sophisticated coating processes using vacuum deposition, precision cutting using CNC machinery, and ergonomic assembly techniques. This stage includes rigorous quality control measures and extensive testing to ensure strict compliance with international safety standards such as EN 207/208 (Europe), ANSI Z136.1 (USA), and ISO standards, which are critical for market acceptance and user safety. Once manufactured and certified, the products are distributed through various channels to effectively reach end-users. Direct distribution typically involves manufacturers selling directly to large industrial clients, defense contractors, major healthcare systems, or research institutions that require bulk orders or highly customized solutions. This channel allows for closer customer relationships and direct feedback loops.

Indirect distribution, on the other hand, relies on an extensive network of specialized distributors, wholesalers, and dedicated safety equipment retailers who possess expertise in laser safety products and serve a broader range of smaller businesses, independent research labs, and individual professionals. E-commerce platforms are also gaining significant prominence as a convenient and accessible indirect channel, offering wider product accessibility and streamlined purchasing processes for a global customer base. The efficiency and reliability of these distribution channels are critical for ensuring that specialized eyewear reaches the correct end-users promptly, given the specific and often urgent safety requirements associated with laser operations. Both direct and indirect models play a vital role in the market, with a growing trend towards hybrid approaches that combine the benefits of direct engagement and customization with the extensive market penetration and reach of indirect partners. After-sales support, including comprehensive education on proper eyewear selection, maintenance, and periodic inspection and recertification, also forms a crucial part of the value chain, ensuring the continued efficacy of the protective equipment and fostering long-term customer satisfaction and loyalty.

Laser Protective Eyewear Market Potential Customers

The potential customers for the Laser Protective Eyewear Market are highly diverse, encompassing a broad spectrum of industries and professional roles where lasers are regularly employed, from low-power alignment tools to high-power industrial cutting systems. These end-users are primarily driven by the imperative to comply with stringent occupational safety regulations, prevent severe and often irreversible ocular injuries, and ensure a consistently safe working environment for their personnel. Key segments include manufacturing facilities that utilize lasers for precision cutting, welding, engraving, marking metals, plastics, and other advanced materials. Workers in these dynamic environments, ranging from machine operators and technicians to quality control inspectors and maintenance staff, require robust eye protection tailored to the specific laser types, power outputs, and beam delivery systems of their equipment. The expansion of advanced manufacturing techniques, such as additive manufacturing (3D printing with lasers) and micro-machining, continues to broaden and diversify this crucial customer base.

Another highly significant customer segment is the healthcare industry, including hospitals, specialized clinics, and private practices, where lasers are integral to a wide array of medical procedures. Ophthalmologists, dermatologists, surgeons across various specialties, dentists, and cosmetic practitioners depend critically on specialized laser protective eyewear during laser eye surgery, advanced skin treatments, dental procedures, and various surgical interventions where precision laser application is key. The increasing global adoption of minimally invasive laser surgeries, diagnostic laser systems, and aesthetic laser treatments directly translates into a consistently growing demand from this vital sector. Research and academic institutions, including university laboratories, national research facilities, and corporate R&D centers, constitute another crucial customer group. Scientists, engineers, and students working with experimental lasers, advanced spectroscopy, quantum computing setups, or sophisticated optical systems require precise and often custom eyewear to protect against a wide range of wavelengths and power levels during experimentation, development, and groundbreaking research.

Furthermore, the military and defense sector represents a critical end-user, requiring highly specialized laser protective eyewear for personnel operating laser rangefinders, target designators, directed energy weapons, and advanced optical communication systems in demanding operational environments. The highly dynamic, unpredictable, and often hazardous nature of military applications necessitates eyewear that is not only highly protective against a broad spectrum of laser threats but also exceptionally durable, comfortable for extended wear, and fully compatible with other personal protective equipment (PPE) such as helmets and night-vision devices. Other burgeoning customer segments include the telecommunications industry, where lasers are extensively used in fiber optic installations, testing, and maintenance, and the rapidly growing aesthetics and beauty industry for procedures like laser hair removal, skin rejuvenation, and tattoo removal. Essentially, any professional environment where lasers are present, from low-power laboratory setups to high-power industrial or military systems, represents a potential customer for specialized laser protective eyewear, underscoring the market's extensive reach and the universal, unwavering need for effective, certified eye safety solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 345.8 million |

| Market Forecast in 2033 | USD 621.5 million |

| Growth Rate | 8.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Honeywell International Inc., Gentex Corporation, UVEX Safety Group GmbH & Co. KG, Laservision GmbH & Co. KG, NoIR Laser Company, LLC, Thorlabs Inc., ESS LLC (a division of Oakley), Revision Military, Phillips Safety Products Inc., Kentek Corporation, Sperian Protection (now part of Honeywell), Fendall (now part of Honeywell), Rockwell Laser Industries, Inc., Beamproof (part of Dantec Dynamics A/S), Globalsun Optical (GSUN), Metamaterial Inc., Newport Corporation (a MKS Instruments Brand), LEONI AG (formerly LASER COMPONENTS GmbH), Protection Lasers S.A., Optosigma Corporation, Kimberly-Clark Corporation, 3M Company, Melles Griot (now part of IDEX Health & Science LLC), Roshield GmbH, Elvex Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Laser Protective Eyewear Market Key Technology Landscape

The key technology landscape of the Laser Protective Eyewear Market is characterized by continuous innovation in material science, optical engineering, and increasingly, smart integration, all driven by the evolving demands and capabilities of modern laser technology. At its core, the technology relies on developing highly specialized filtering mechanisms within the eyewear lenses. This involves the precise use of advanced polymer formulations, particularly polycarbonate, which can be custom-compounded and impregnated with specific organic dyes that selectively absorb particular laser wavelengths. For higher power applications or those requiring superior optical clarity and thermal stability, mineral glass lenses are employed, often featuring sophisticated dielectric coatings that are precisely engineered to reflect specific laser wavelengths while transmitting visible light. These multi-layer thin-film coatings are designed to provide high optical density (OD) at the hazardous wavelengths without significantly compromising light transmission in the visible spectrum, thus maintaining good vision and color recognition for the user.

Beyond the fundamental absorption and reflection technologies, significant advancements are being made in developing broadband filters that offer comprehensive protection across a wider range of laser wavelengths, directly addressing the growing challenge of multi-wavelength laser systems used in complex research and industrial settings. There is also a nascent but promising focus on photochromic and electro-optic technologies, which allow for dynamic adjustment of optical density in response to changing laser conditions or real-time detection of laser firing. While still largely in the research and development phase for widespread commercial use in protective eyewear, these smart technologies promise a future where eyewear can proactively adapt in real-time to unforeseen laser exposures or variable operating environments, significantly enhancing user safety and flexibility. The integration of augmented reality (AR) capabilities into protective eyewear, for instance, could provide users with critical real-time information about laser parameters, hazard zones, or operational instructions directly within their field of view, enhancing both safety and operational efficiency.

Manufacturing processes also represent a crucial aspect of the technology landscape, with precision injection molding for polycarbonate frames and lenses, as well as advanced vacuum deposition and sputtering techniques for reflective filters, being central to producing high-performance eyewear. The ability to produce lightweight, comfortable, and ergonomically designed frames that accommodate various facial structures and integrate seamlessly with other personal protective equipment (PPE) such as respirators or hard hats, is a key technological challenge that drives material and design innovation. Furthermore, the development of eyewear that is fully compatible with prescription lenses, either through integrated inserts or direct prescription fabrication, is an important area of focus to cater to a broader user base and ensure uncompromised vision alongside superior laser protection. Ongoing research into novel materials such as quantum dots, plasmonic structures, or other nanomaterials that offer tunable absorption properties, improved spectral filtering efficiency, and enhanced damage thresholds indicates the future direction of technological innovation, aiming for superior protection with enhanced user experience, versatility, and long-term durability in an increasingly laser-centric world.

Regional Highlights

- North America: A mature and dominant market characterized by exceptionally stringent safety regulations (e.g., ANSI Z136.1), high adoption rates of advanced laser technologies across robust industrial and medical sectors, and significant investments in research and development. The United States leads the region due to its expansive manufacturing base, advanced healthcare infrastructure, and a strong defense industry, all of which are major consumers of laser technology and protective eyewear. Canada also contributes significantly with its growing industrial applications and a strong emphasis on occupational safety, driving steady demand for high-quality protective solutions.

- Europe: Another key and highly influential market driven by comprehensive safety directives (e.g., EN 207/208, CE certification), well-established manufacturing industries, and a strong cultural and regulatory focus on occupational health and safety. Germany, France, and the UK are prominent players with substantial R&D activities in laser technology and photonics, coupled with strong regulatory compliance and a demand for high-performance, certified eyewear. Eastern European countries are also seeing increased adoption as industrial sectors modernize and align with EU safety standards, leading to expanding market opportunities.

- Asia Pacific (APAC): The fastest-growing market globally, propelled by rapid industrialization, the expansion of manufacturing hubs in economic powerhouses like China, India, Japan, and South Korea, and increasing investments in advanced healthcare infrastructure and scientific research. The region's large population and burgeoning middle class also contribute to the rising demand for laser-based aesthetic and medical treatments, further driving the need for protective eyewear. Government initiatives promoting industrial safety and the transfer of advanced manufacturing technologies from Western economies further fuel market expansion.

- Latin America: An emerging market with growing industrial sectors, particularly in economic leaders like Brazil and Mexico, leading to increased demand for laser protective eyewear as industries modernize and adopt more advanced manufacturing processes. Investments in infrastructure, automotive manufacturing, and medical technology are steadily expanding the market, though regulatory frameworks for laser safety are still developing and being implemented in some areas, presenting both challenges and long-term growth potential.

- Middle East and Africa (MEA): This region is experiencing nascent growth, primarily driven by significant investments in infrastructure development, the burgeoning oil and gas sector, and the expansion of the healthcare sector, particularly in countries like UAE and Saudi Arabia. Awareness of occupational safety and health standards is increasing, slowly but surely driving the adoption of personal protective equipment, including specialized laser eyewear, as industrial and medical capabilities advance and global safety practices are integrated.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Laser Protective Eyewear Market.- Honeywell International Inc.

- Gentex Corporation

- UVEX Safety Group GmbH & Co. KG

- Laservision GmbH & Co. KG

- NoIR Laser Company, LLC

- Thorlabs Inc.

- ESS LLC (a division of Oakley)

- Revision Military

- Phillips Safety Products Inc.

- Kentek Corporation

- Sperian Protection (now part of Honeywell)

- Fendall (now part of Honeywell)

- Rockwell Laser Industries, Inc.

- Beamproof (part of Dantec Dynamics A/S)

- Globalsun Optical (GSUN)

- Metamaterial Inc.

- Newport Corporation (a MKS Instruments Brand)

- LEONI AG (formerly LASER COMPONENTS GmbH)

- Protection Lasers S.A.

- Optosigma Corporation

- Kimberly-Clark Corporation

- 3M Company

- Melles Griot (now part of IDEX Health & Science LLC)

- Roshield GmbH

- Elvex Corporation

- Spectra-Physics (a MKS Instruments Brand)

- EKSPLA UAB

Frequently Asked Questions

What is laser protective eyewear?

Laser protective eyewear comprises specialized glasses, goggles, or face shields designed to absorb or reflect specific laser wavelengths, reducing their intensity to safe levels and preventing eye damage during laser operation.

Why is laser protective eyewear important?

It is crucial for preventing severe and irreversible eye injuries, such as retinal burns or cataracts, from accidental or intentional exposure to hazardous laser radiation, ensuring compliance with safety regulations and protecting worker health.

How do I choose the right laser protective eyewear?

Selection depends on the laser's wavelength, optical density (OD), and power/energy. Always refer to the laser's specifications, applicable safety standards, and consult a certified laser safety officer to ensure proper protection.

What are the key materials used in laser protective eyewear lenses?

Common materials include polycarbonate for its impact resistance and customizable dye absorption, and glass for superior optical clarity and high-power laser resistance, often enhanced with specialized dielectric coatings.

What industries commonly use laser protective eyewear?

Key industries include industrial manufacturing (laser cutting, welding, marking), medical (surgery, dermatology, ophthalmology), research and development, military and defense, and telecommunications, wherever lasers are actively utilized in professional settings.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager