Laser Safety Protection Eyewear Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435839 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Laser Safety Protection Eyewear Market Size

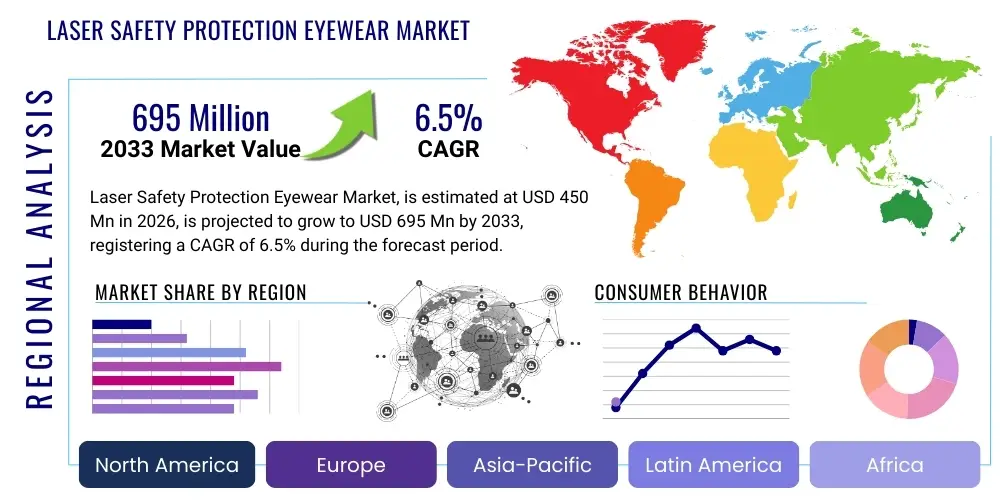

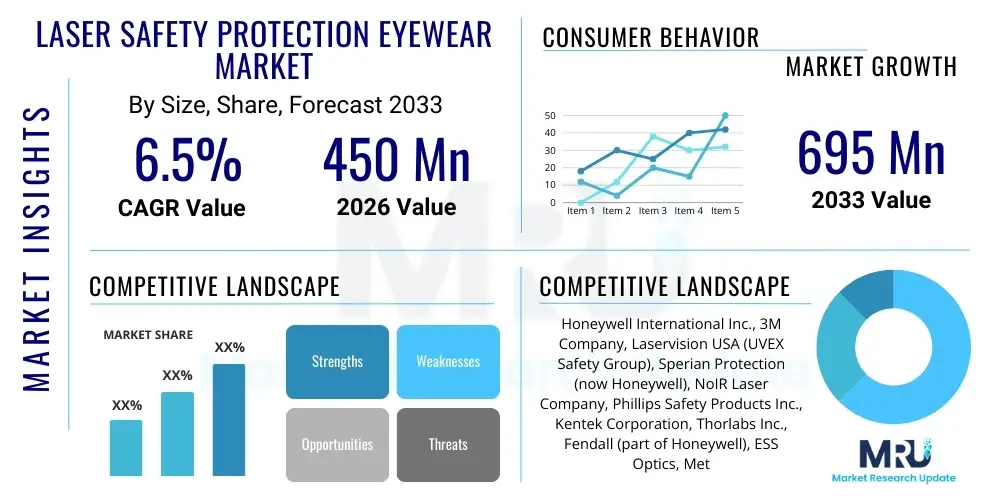

The Laser Safety Protection Eyewear Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 695 Million by the end of the forecast period in 2033.

Laser Safety Protection Eyewear Market introduction

The Laser Safety Protection Eyewear Market encompasses specialized personal protective equipment (PPE) designed to shield the eyes from the harmful effects of direct or scattered laser radiation across various wavelengths. These critical safety devices, often mandated by strict governmental and occupational safety regulations, utilize specific materials and filter technologies—such as absorbing dyes embedded in polycarbonate or glass, or thin-film dielectric coatings—to ensure the Optical Density (OD) required for safe operation. The core functionality is to attenuate hazardous laser light energy to non-damaging levels while maintaining sufficient Visible Light Transmittance (VLT) to allow the user to perform tasks effectively and safely.

The primary applications driving the demand for laser safety eyewear span across industrial manufacturing, particularly in welding, cutting, and marking processes; medical aesthetics and surgery, where high-power lasers are standard tools; and advanced scientific research, including fields like spectroscopy, physics, and defense. The increasing global deployment of high-power laser systems in automated industrial environments, coupled with the rapid expansion of non-invasive medical procedures utilizing high-precision lasers, fundamentally underpins the market's robust growth trajectory. Furthermore, regulatory bodies worldwide, such as the Occupational Safety and Health Administration (OSHA) in the US and equivalent European agencies, continually update standards, necessitating continuous product innovation and compliance.

Key benefits derived from utilizing compliant laser safety eyewear include the prevention of acute and chronic ocular injuries, ranging from corneal burns and retinal damage to cataracts, thereby ensuring worker safety and reducing organizational liability. Driving factors fueling market expansion include technological advancements in laser output power and efficiency, the proliferation of fiber lasers and ultrafast pulsed lasers requiring broader wavelength coverage in eyewear, and heightened awareness among professionals regarding laser hazards. The complexity inherent in selecting the correct protective eyewear, based on laser wavelength, mode, power/energy, and maximum permissible exposure (MPE) levels, necessitates expert consultation and specialized product lines, contributing to the value proposition of market players.

Laser Safety Protection Eyewear Market Executive Summary

The Laser Safety Protection Eyewear Market is characterized by steady technological evolution driven by the need to protect against increasingly powerful and diverse laser sources. Business trends indicate a strong move toward customization and lightweight design, addressing user comfort and compliance issues. Manufacturers are focusing on developing hybrid technologies that combine absorption and reflection properties to achieve superior optical density across broad spectral bands, particularly important in research environments where multiple laser systems are utilized simultaneously. Furthermore, consolidation within the market is observed as major PPE providers acquire specialized laser safety manufacturers to integrate high-margin, niche products into their broader safety portfolios. Supply chain resilience, ensuring the availability of specialized optical materials and dyes, remains a critical operational consideration.

Regionally, Asia Pacific (APAC) is positioned as the fastest-growing market segment, driven primarily by massive investments in industrial automation, electronics manufacturing, and rapidly expanding healthcare infrastructure, especially in China, South Korea, and India. North America and Europe currently represent the largest revenue share, underpinned by stringent occupational safety standards and a high concentration of advanced scientific research facilities and established medical device markets. In these developed regions, the emphasis is shifting toward replacing older, less compliant eyewear and adopting smart safety glasses integrated with monitoring technology. The Middle East and Africa (MEA) and Latin America are showing emergent growth, fueled by infrastructure development projects and increasing adoption of aesthetic laser treatments.

Segment trends reveal that the use of polycarbonate eyewear continues to dominate due to its impact resistance and lightweight nature, although specialized glass filters are essential for extremely high-power continuous-wave (CW) lasers or environments requiring perfect clarity. By application, the industrial sector maintains the largest share, owing to the widespread adoption of laser processing in automotive and aerospace manufacturing. However, the medical segment is exhibiting the highest growth rate, fueled by the demand for highly precise protection required during ophthalmology, dermatology, and complex surgical procedures. The rising trend of using disposable or single-use protective film over standard glasses for aesthetic applications is also a noteworthy segment development impacting material choices.

AI Impact Analysis on Laser Safety Protection Eyewear Market

Common user questions regarding AI’s impact on laser safety eyewear frequently revolve around two main themes: personalization and compliance verification. Users inquire whether AI can analyze individual user metrics (such as facial geometry and ambient light conditions) and specific laser operational data to recommend or even dynamically adjust the optimal protective filter. Another significant concern relates to how AI can be integrated into manufacturing processes to enhance quality control, ensuring zero defects in critical optical filters, or utilized in smart safety systems to predict potential laser exposure breaches before they occur. There is an expectation that AI and Machine Learning (ML) algorithms will move the industry beyond static protection to intelligent, responsive safety solutions, integrating the eyewear into a broader smart PPE ecosystem and automating complex compliance reporting.

AI is beginning to influence the market by enhancing predictive maintenance systems in laser manufacturing facilities, which indirectly lowers the risk of accidental high-energy exposure, subsequently influencing the required specifications of safety eyewear. More directly, AI-powered image processing is being applied during the quality inspection phase of specialized filter coatings. This ensures ultra-precise deposition of dielectric layers and the uniform distribution of absorbing dyes, verifying that the optical density across the lens surface is consistent and meets stringent ANSI or EN standards. This level of automated quality assurance is vital given the critical safety function of the product, minimizing human error in detection of micro-defects that could compromise protection.

Furthermore, the future integration of AI involves developing 'smart' safety eyewear. These devices may use miniature sensors and ML models to instantly recognize the wavelength, power, and operational state of nearby laser sources. This data can be processed in real-time to alert the wearer if they are utilizing non-compliant eyewear for a detected laser, or even dynamically adjust the liquid crystal display (LCD) protection layers, offering a flexible defense mechanism against multi-wavelength environments. This evolution moves the eyewear from a passive safety tool to an active, connected safety component, significantly improving operational safety and compliance adherence in complex industrial and research settings.

- AI-driven Quality Control: Enhanced precision in coating inspection and defect detection of optical filters.

- Predictive Compliance: ML models used in smart eyewear to recommend optimal protection based on real-time environmental laser hazards.

- Personalized Fit and Design: AI algorithms optimize ergonomic design and lens curvature based on detailed facial scanning data, improving seal and comfort.

- Manufacturing Optimization: ML techniques streamline the chemical processes for dye inclusion in polymers, ensuring consistent optical density (OD) yield.

- Automated Reporting: Smart eyewear integrated with AI systems automatically logs compliance usage hours and potential near-miss incidents for regulatory audits.

DRO & Impact Forces Of Laser Safety Protection Eyewear Market

The Laser Safety Protection Eyewear Market is strongly shaped by mandatory regulations, rapid technological shifts in laser systems, and end-user behavior regarding compliance. The primary driver is the stringent enforcement of occupational safety standards across key industrialized nations, which necessitates the use of certified eyewear whenever Class 3B or Class 4 lasers are in operation. Opportunities lie in the unmet demand for highly customized, lighter, and more comfortable eyewear, particularly in fields requiring extended wear, such as prolonged surgical procedures or industrial monitoring. However, a significant restraint is the prevalent lack of awareness in certain emerging markets regarding the severity of laser hazards and the frequent non-compliance or use of improperly specified protection, often driven by cost considerations.

The key impact forces dictating the market structure resemble Porter’s Five Forces. The threat of new entrants is moderate; while manufacturing polycarbonate frames is relatively easy, the technical expertise required for producing certified, high-OD optical filters (especially specialized glass or multi-layered dielectric coatings) creates a high barrier to entry. Buyer bargaining power is significant, particularly from large industrial procurement groups and global research institutions that demand customized solutions, high volume discounts, and adherence to specific regulatory certifications (e.g., CE, ANSI Z136.1). Supplier power is moderate to high, concentrated among specialized chemical and material providers who supply unique absorbing dyes and precision optical materials crucial for high-performance filters, leading to tight control over input costs.

The intensity of competitive rivalry is high, characterized by continuous innovation aimed at improving VLT without compromising OD, and a strong focus on ergonomic design features such as ventilation, anti-fog coatings, and peripheral vision enhancement. Substitution threat is low; while engineering controls (like beam enclosures and interlocks) are preferred safety measures, eyewear remains the essential last line of defense, making its role irreplaceable in most operational scenarios. Technological advances, particularly in diode lasers and fiber optics, continually force manufacturers to update their product lines to cover new, hazardous wavelengths, driving constant product lifecycle turnover and sustaining market dynamism.

Segmentation Analysis

The Laser Safety Protection Eyewear Market is broadly segmented based on technology type, material composition, laser type, and end-use application. Understanding these segments is crucial for manufacturers to target specific industrial, medical, or research niches that possess unique safety requirements, such as protection against pulsed vs. continuous wave lasers, or the need for specific optical characteristics. The technological distinction between absorption-based and reflection-based filtration methods dictates the primary performance characteristics and cost structure of the protective lenses. Meanwhile, application-specific requirements, such as those in military/defense or specialized research, necessitate highly tailored and certified products, ensuring market specialization.

- By Technology Type:

- Absorption Filters (Dye-based, typically polycarbonate or glass)

- Reflective Filters (Dielectric coated, utilizing thin films)

- Hybrid Filters (Combining absorption and reflection)

- By Material Type:

- Polycarbonate

- Glass

- Ceramic

- By Laser Type/Wavelength Coverage:

- CO2 Laser (10600 nm)

- Nd:YAG Laser (1064 nm)

- Diode Lasers (800-980 nm)

- Excimer Lasers (UV wavelengths)

- Visible Lasers (400-700 nm)

- By Application:

- Industrial (Cutting, Welding, Marking, Alignment)

- Medical (Aesthetics, Surgery, Ophthalmology)

- Research and Development (R&D)

- Military and Defense

- Education and Laboratories

Value Chain Analysis For Laser Safety Protection Eyewear Market

The value chain for laser safety eyewear is highly specialized, beginning with the upstream supply of raw materials, predominantly precision optical polymers (polycarbonate) and specialized optical glass. Manufacturers rely heavily on chemical suppliers for proprietary laser-absorbing dyes and high-purity metal oxides used in dielectric coatings. The critical phase involves complex manufacturing processes, including injection molding, precision coating application (often in cleanroom environments), and rigorous testing to achieve certified optical density. Intellectual property surrounding unique dye formulations and coating methodologies is a significant source of competitive advantage in this upstream segment.

The midstream phase focuses on assembly, frame production, and quality assurance. Unlike conventional eyewear, laser safety protection requires certification under international standards (e.g., EN 207/208 in Europe, ANSI Z136.1 in North America), necessitating documented traceability and compliance testing for every batch. Distribution channels play a vital role in reaching niche end-users. Direct channels are often utilized for large industrial clients, government defense contracts, and specialized R&D facilities, allowing for tailored specifications and direct technical support regarding Maximum Permissible Exposure (MPE) calculations and usage guidelines.

Indirect channels primarily utilize specialized safety equipment distributors and medical supply retailers. These distributors often maintain stock of standard, commonly used protective eyewear models and provide regional support. The downstream market involves extensive post-sale services, including recalibration checks, guidance on cleaning and maintenance (crucial as surface scratches can compromise OD), and mandatory training for end-users on selecting the correct protection. The high value associated with ensuring zero-defect protection against potentially blinding hazards means the value chain places paramount importance on quality verification and expert technical consultation throughout the distribution and final usage stages.

Laser Safety Protection Eyewear Market Potential Customers

Potential customers for laser safety protection eyewear are defined by sectors utilizing high-power lasers that necessitate strict adherence to safety protocols for personnel protection. The largest consumer base resides within the industrial manufacturing sector, encompassing automotive assembly lines, aerospace component fabrication, semiconductor manufacturing, and specialized metal processing plants where laser welding, cutting, and ablation systems are integral to production efficiency and quality. These buyers prioritize durability, consistent optical quality, and compatibility with other PPE, such as hard hats or respirators.

The medical and healthcare sector represents a high-growth segment, driven by ophthalmologists, dermatologists performing aesthetic procedures (hair removal, tattoo removal), and surgical teams employing laser scalpels. These customers require extremely high precision, lightweight design for long procedures, and often need multiple specific filters (e.g., specialized lenses for patient protection during eye surgery). Compliance with strict hospital infection control standards and the need for sterile or easy-to-clean materials are primary purchase criteria for medical buyers.

Furthermore, research and academic institutions, including university science departments, national laboratories, and private R&D centers, constitute a crucial customer base. These environments frequently employ complex, multi-wavelength laser setups (e.g., femtosecond pulsed lasers, tunable dye lasers), demanding versatile and specialized eyewear that offers broad-spectrum protection with maximum visible light transmission to facilitate delicate experimental work. The defense and military sector, utilizing high-power laser systems for ranging, target acquisition, and directed energy applications, also represents a premium customer segment requiring rugged, high-performance protection that meets military specifications for environmental resilience and optical clarity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 695 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Honeywell International Inc., 3M Company, Laservision USA (UVEX Safety Group), Sperian Protection (now Honeywell), NoIR Laser Company, Phillips Safety Products Inc., Kentek Corporation, Thorlabs Inc., Fendall (part of Honeywell), ESS Optics, Metamaterial Inc., LaseReflex GmbH, Melles Griot, Global Laser Safety, R&D Vision Ltd., Laser Mechanisms Inc., DEWALT Safety, Trotec Laser GmbH, Innovative Optics Inc., Hellma GmbH & Co. KG. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Laser Safety Protection Eyewear Market Key Technology Landscape

The technology landscape of laser safety eyewear is defined by innovations in materials science and optical coating techniques, focused on maximizing Visible Light Transmittance (VLT) while achieving the necessary high Optical Density (OD) for specific wavelengths. Absorption technology, utilizing specialized organic dyes or metal ion-doped glass, remains the dominant method for wide-field protection due to its cost-effectiveness and robustness against scratches, as the protection is embedded throughout the material. Recent advancements in polycarbonate absorption filters include the development of multi-wavelength dyes that can cover broader or non-traditional laser spectral ranges (e.g., complex mixtures of near-infrared and visible lines), addressing the needs of multi-laser research environments.

Reflective technology, based on thin-film dielectric coatings, is crucial for ultra-high power continuous wave (CW) lasers, as reflection dissipates heat more effectively than absorption, which can lead to thermal damage in the lens material. Innovations in this area focus on developing highly durable, multi-layer coatings using nanotechnology, offering razor-edge spectral cutoff filters that are extremely precise. Hybrid filters, combining a reflective coating on the exterior surface for initial high-power attenuation and an absorption dye substrate for secondary protection, represent the cutting edge, offering superior protection against beam misalignment and accidental direct exposure while maintaining reasonable VLT.

Emerging technologies include photochromic or electronically switchable filters, although these are still primarily in the R&D phase for high-power laser use. The goal is to develop smart eyewear that can dynamically adjust its OD in response to a sudden exposure or change in laser operating parameters. Furthermore, advancements in 3D printing and digital manufacturing are allowing for the creation of perfectly fitted, custom frames, resolving the common industry challenge of ensuring a complete peripheral seal to prevent laser light bypass, a critical factor for compliance and maximum safety.

Regional Highlights

- North America (NA): NA holds a significant market share, primarily driven by stringent enforcement of ANSI Z136 series standards and a high concentration of sophisticated defense, aerospace, and medical laser manufacturers. The US market dominates, characterized by rapid adoption of advanced surgical laser systems and extensive government spending on high-energy laser research. Demand is high for custom-fit and certified high-OD products.

- Europe: Europe is a mature market heavily influenced by the harmonization of safety standards under the CE marking (EN 207/208). Germany and the UK are key contributors, largely due to their robust automotive manufacturing sectors utilizing laser welding and cutting, alongside significant pharmaceutical and research R&D investment. Focus is on ergonomic compliance and integrating safety eyewear into overall protective gear systems.

- Asia Pacific (APAC): APAC is the fastest-growing region, fueled by the aggressive expansion of industrial automation, semiconductor manufacturing, and consumer electronics production in countries like China and South Korea. Increased foreign direct investment in localized manufacturing facilities brings advanced laser technology, necessitating localized production of safety eyewear and driving high volume demand for standardized, reliable protection.

- Latin America (LATAM): Growth in LATAM is driven by expanding industrial capabilities, particularly in Brazil and Mexico, and the rising popularity of aesthetic laser clinics in major urban centers. The market often lags slightly behind NA and Europe in regulatory stringency but is rapidly catching up, leading to growing demand for internationally compliant entry-level and mid-range protective solutions.

- Middle East and Africa (MEA): MEA represents an emergent market, with increasing adoption linked to major infrastructure projects, oil and gas processing (utilizing laser measurement systems), and developing healthcare facilities, particularly in the UAE and Saudi Arabia. The market primarily relies on imports of certified European and US-manufactured protective equipment, with an increasing focus on localized technical support.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Laser Safety Protection Eyewear Market.- Honeywell International Inc.

- 3M Company

- Laservision USA (UVEX Safety Group)

- Sperian Protection (now Honeywell)

- NoIR Laser Company

- Phillips Safety Products Inc.

- Kentek Corporation

- Thorlabs Inc.

- Fendall (part of Honeywell)

- ESS Optics

- Metamaterial Inc.

- LaseReflex GmbH

- Melles Griot

- Global Laser Safety

- R&D Vision Ltd.

- Laser Mechanisms Inc.

- DEWALT Safety

- Trotec Laser GmbH

- Innovative Optics Inc.

- Hellma GmbH & Co. KG

Frequently Asked Questions

Analyze common user questions about the Laser Safety Protection Eyewear market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Laser Safety Eyewear Market?

The primary driver is the global increase in the use of high-power industrial and medical laser systems, combined with stringent governmental occupational safety regulations (such as ANSI Z136.1 and EN 207) mandating the use of certified protective eyewear to prevent severe ocular damage.

How do absorption filters differ fundamentally from reflective filters?

Absorption filters use dyes or specialized material embedded throughout the lens to absorb laser energy, offering robust, wide-field protection. Reflective filters use thin, multi-layer dielectric coatings to reflect the hazardous wavelength, typically used for ultra-high power lasers where heat dissipation is critical.

Which end-use application segment accounts for the largest market share?

The Industrial segment holds the largest market share, driven by the widespread application of high-power lasers in manufacturing processes such as cutting, welding, drilling, and marking across the automotive, aerospace, and electronics industries.

What is Optical Density (OD) and why is it crucial for laser safety eyewear selection?

Optical Density (OD) is a logarithmic measure of the attenuation capacity of the filter, quantifying how much the laser light intensity is reduced. A higher OD value signifies greater protection, and selecting the correct OD is crucial as it must correspond precisely to the specific laser’s wavelength and power output to ensure compliance with Maximum Permissible Exposure (MPE) limits.

How is the market addressing the issue of comfort and compliance for long-duration use?

Manufacturers are addressing comfort through advanced ergonomic design, utilizing lightweight polycarbonate materials, developing anti-fog coatings, and offering custom-fit frames based on 3D scanning, significantly improving user compliance by making extended wear more tolerable.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager