Lateral Hydraulic Damper Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432306 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Lateral Hydraulic Damper Market Size

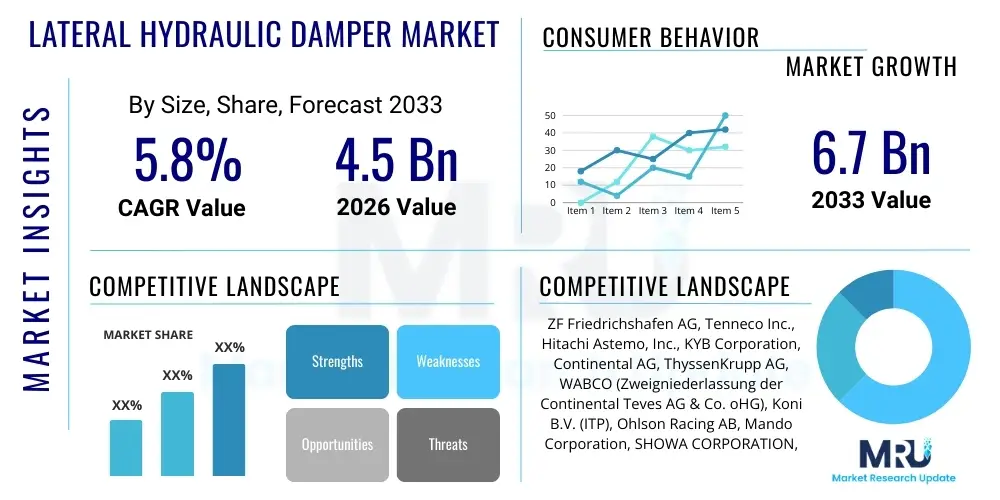

The Lateral Hydraulic Damper Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.5 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033.

Lateral Hydraulic Damper Market introduction

The Lateral Hydraulic Damper Market encompasses specialized shock absorption systems predominantly utilized in railway rolling stock, heavy commercial vehicles, and select industrial machinery to manage complex lateral forces, ensuring stability, minimizing wear, and enhancing passenger comfort. These critical components are designed to control horizontal motion (yaw, sway, and truck hunting phenomena) which is particularly prominent in high-speed rail applications and challenging terrains. By utilizing hydraulic fluid displacement through calibrated valves and orifices, lateral dampers effectively dissipate kinetic energy generated by external disturbances or track irregularities, thereby maintaining operational safety and extending the lifespan of bogie components and track infrastructure.

The core functionality of a lateral hydraulic damper revolves around its ability to provide variable damping resistance tailored to specific vehicle loads and operational speeds. In railway systems, they are often installed between the car body and the bogie or between the primary and secondary suspension stages, acting as a crucial interface for vibration mitigation. Key applications extend beyond traditional rail to include advanced magnetic levitation (maglev) systems and specialized military vehicles requiring superior stability under dynamic loading conditions. The engineering challenge lies in balancing stiff damping characteristics necessary for controlling high-frequency oscillations with smooth damping needed for optimal ride quality across diverse operational environments.

Market growth is substantially driven by global investments in high-speed rail networks, increasing urbanization demanding sophisticated public transportation, and stringent regulatory requirements pertaining to vehicle stability and safety standards across transportation sectors. Furthermore, the inherent benefits—such as reduction in wheel and rail wear, minimized noise and vibration levels, and superior control during curve negotiation—cement the lateral hydraulic damper's position as an indispensable component in modern transportation systems. The ongoing material science advancements and integration of smart sensing technologies are further evolving the product landscape, promising enhanced performance and predictive maintenance capabilities.

Lateral Hydraulic Damper Market Executive Summary

The Lateral Hydraulic Damper Market is currently witnessing robust expansion fueled primarily by substantial global investments in railway infrastructure, particularly the rapid deployment of high-speed rail and metro systems across Asia Pacific and Europe. Business trends indicate a strong move toward lightweight materials, intelligent damping systems incorporating sensors and electronic controls, and a focus on dampers designed for extreme temperature resilience and extended maintenance cycles, responding directly to operator demands for lower Total Cost of Ownership (TCO). Strategic partnerships between damper manufacturers and major rolling stock original equipment manufacturers (OEMs) are crucial business drivers, focusing on co-development tailored to specific train and track specifications.

Regionally, Asia Pacific maintains market dominance, driven by massive governmental expenditure on rail modernization in China, India, and Japan, which are aggressively expanding intercity and urban transit capabilities. Europe also presents a mature, high-value segment, characterized by stringent safety regulations and a continuous push for cross-border high-speed connectivity, emphasizing advanced, high-performance damper solutions. North America, while slower in high-speed rail adoption, exhibits significant demand in the heavy-duty freight and specialized military vehicle segments, requiring robust and durable lateral damping solutions tailored for heavy axle loads and demanding operational environments.

Segmentation trends highlight the supremacy of the rail vehicle application segment, specifically in high-speed trains, where safety and comfort requirements necessitate the highest quality of lateral damping mechanisms. Technology-wise, double-acting dampers remain the core offering, though the integration of adaptive and semi-active damping technologies represents the fastest growing sub-segment, promising real-time adjustment capability. End-use industries such as construction and mining machinery are also demonstrating increased uptake, recognizing the value of lateral stability in enhancing operational efficiency and component longevity in harsh off-highway applications.

AI Impact Analysis on Lateral Hydraulic Damper Market

Common user questions regarding AI's influence often center on its ability to enhance predictive maintenance, optimize damper performance in real-time, and streamline manufacturing processes. Users are keenly interested in whether AI algorithms can predict component failure more accurately than traditional monitoring systems, thus minimizing costly unplanned downtime, particularly in critical high-speed rail applications. Furthermore, there is significant inquiry into how AI-driven analysis of operational data (speed, load, track conditions) can lead to the design of truly adaptive, semi-active dampers that adjust fluid dynamics instantaneously, moving beyond fixed or manually adjustable settings. The consensus expectation is that AI integration will shift the market focus from merely selling hardware to providing comprehensive, data-driven stability management solutions, requiring manufacturers to develop new competencies in data science and software integration.

- AI facilitates advanced predictive maintenance by analyzing sensor data (temperature, pressure, vibration) to forecast potential damper failures before they occur.

- Generative design AI optimizes the internal fluid dynamics and mechanical structure of dampers, leading to lighter, more efficient, and application-specific designs.

- Machine learning algorithms enable semi-active and active damping systems to adjust parameters instantaneously based on real-time track and vehicle dynamics, maximizing stability and comfort.

- AI enhances quality control in manufacturing by autonomously inspecting components and identifying microscopic defects, ensuring compliance with stringent safety standards.

- Supply chain optimization is achieved through AI forecasting of material needs and demand fluctuations, reducing lead times and inventory costs.

DRO & Impact Forces Of Lateral Hydraulic Damper Market

The Lateral Hydraulic Damper Market is primarily driven by accelerating global urbanization, which mandates greater investment in high-capacity, high-speed rail networks across Asia and Europe, creating persistent demand for high-performance vibration control components. However, this growth is significantly restrained by the high initial capital investment required for installing advanced damping systems and the long maintenance and replacement cycles inherent to quality components, which limit continuous replacement revenue streams. Opportunities emerge through the untapped potential in retrofitting older freight rolling stock with modern lateral stability solutions to meet enhanced safety mandates, coupled with diversification into heavy-duty electric vehicles (EVs) where managing high battery weight distribution requires sophisticated lateral control. These market forces are consistently shaped by stringent government safety regulations and the relentless pressure from rail operators to reduce operational costs and enhance energy efficiency, compelling manufacturers to innovate constantly in material science and smart technology integration.

Segmentation Analysis

The Lateral Hydraulic Damper Market is comprehensively segmented based on the mechanism type, the primary application, the materials used in construction, and the end-use industry utilizing the product. This detailed segmentation allows stakeholders to analyze specific market dynamics, identify high-growth niches, and tailor product development strategies effectively. The core differentiation often lies between single-acting and double-acting hydraulic designs, where double-acting, providing resistance in both extension and compression, dominates performance-critical sectors like high-speed rail. Application analysis demonstrates that the rail vehicle segment, encompassing high-speed trains and metros, remains the most lucrative segment due to high technical specifications and safety demands. Material advancements, particularly the use of specialized aluminum alloys and composites, are crucial for reducing unsprung mass and enhancing fuel efficiency in transportation sectors, influencing purchasing decisions significantly. Understanding these interlinked segments is vital for forecasting regional demand and competitive positioning.

- By Type:

- Single-Acting Damper

- Double-Acting Damper

- Telescopic Damper

- Non-Telescopic Damper

- By Application:

- Rail Vehicles

- High-Speed Trains

- Locomotives

- Metros and Trams

- Automotive

- Commercial Vehicles

- Heavy-Duty Trucks

- Industrial Machinery

- Aerospace and Defense

- Rail Vehicles

- By Material:

- Steel Alloys (Standard and High-Tensile)

- Aluminum Alloy

- Composite Materials (for lightweight applications)

- By End-Use Industry:

- Railway and Transportation

- Construction and Mining

- Automotive Manufacturing

- Infrastructure Development

Value Chain Analysis For Lateral Hydraulic Damper Market

The value chain for the Lateral Hydraulic Damper Market starts upstream with the procurement of highly specialized raw materials, primarily high-grade steel, precision-machined aluminum alloys, and specialized hydraulic fluids and sealing components. Success at this stage relies heavily on securing reliable suppliers capable of meeting stringent quality specifications and traceability standards, especially for components used in safety-critical rail applications. Core manufacturing involves precision engineering, sophisticated welding techniques, and rigorous testing protocols to ensure component reliability and longevity under extreme stress, where leading manufacturers integrate advanced robotics and automation to maintain consistency and efficiency in production volumes.

The midstream focuses on component assembly and specialized calibration, where the hydraulic characteristics (damping curves) are meticulously tailored to specific client requirements, often collaborating closely with rolling stock OEMs or heavy truck manufacturers. Distribution channels are highly critical and typically bifurcated: direct distribution dominates the initial equipment market (OEM sales), involving long-term supply contracts and highly technical sales support; indirect distribution utilizes specialized railway parts distributors and authorized service centers for the aftermarket (MRO) segment, providing rapid access to spare parts and repair services globally. Maintaining robust intellectual property protection for proprietary valve designs and hydraulic systems is also a key competitive element throughout this middle stage.

Downstream activities center on installation, post-sale service, and performance monitoring. Direct engagement with end-users, such as rail operators or fleet managers, allows manufacturers to gather crucial real-world performance data, feeding back into R&D for continuous product improvement and adaptation. The aftermarket sales of spare parts, seals, and specialized fluids constitute a significant and profitable stream, requiring manufacturers to ensure global availability and standardized replacement procedures. Successful participation in the downstream segment necessitates a global service network capable of quick deployment and highly technical field support, ensuring that critical infrastructure remains operational with minimal downtime, thereby enhancing customer loyalty and long-term contract security.

Lateral Hydraulic Damper Market Potential Customers

The primary customers for Lateral Hydraulic Dampers are large-scale operators and manufacturers within the global transportation infrastructure sector, particularly those involved in high-speed and heavy-load movement where stability is paramount. The dominant customer segment comprises Rolling Stock Original Equipment Manufacturers (OEMs) such as Alstom, Siemens Mobility, CRRC, and Stadler Rail, who integrate these dampers directly into new train bogie assemblies, requiring customized, high-volume supply contracts and intense co-development efforts to meet specific vehicle dynamic models. These OEMs demand components that comply with stringent international railway standards (e.g., UIC, CEN) and offer guaranteed performance for periods often exceeding 30 years.

A secondary, yet highly lucrative customer base is the Aftermarket and Maintenance, Repair, and Overhaul (MRO) segment, consisting of national railway operators (e.g., Deutsche Bahn, SNCF, Indian Railways), public transit authorities, and specialized overhaul workshops. These entities require replacement units, spare parts, and specialized diagnostic services to maintain their existing fleets, focusing on minimizing Mean Time Between Failures (MTBF) and maximizing operational availability. Given the long lifespan of rail assets, MRO demand provides a stable, ongoing revenue stream, often prioritizing quick turnaround times and compatibility with legacy systems over the absolute lowest initial cost.

Beyond rail, significant potential lies within the Commercial Vehicle and Construction/Mining sectors. Customers here include manufacturers of heavy-duty commercial trucks, specialized military vehicles, and large off-highway machinery (such as excavators, cranes, and specialized transporters) requiring enhanced stability to manage heavy loads, high centers of gravity, and severe operating vibrations. For these industrial applications, the emphasis is placed on ruggedness, resistance to contamination, and extreme durability in adverse environmental conditions, often necessitating different design parameters than those used in passenger rail.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.5 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ZF Friedrichshafen AG, Tenneco Inc., Hitachi Astemo, Inc., KYB Corporation, Continental AG, ThyssenKrupp AG, WABCO (Zweigniederlassung der Continental Teves AG & Co. oHG), Koni B.V. (ITP), Ohlson Racing AB, Mando Corporation, SHOWA CORPORATION, Meritor, Inc. (Cummins), Gabriel India Limited, Sachs (ZF), Bilstein (ThyssenKrupp), BOSCH Rexroth, Shanghai Railway Damper Co., Ltd., China South Industries Group Corporation (CSGC), Alstom, Siemens Mobility. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Lateral Hydraulic Damper Market Key Technology Landscape

The technological landscape of the Lateral Hydraulic Damper Market is continuously evolving, moving toward systems that offer greater adaptability, reduced maintenance, and superior performance, particularly at high speeds. The fundamental technology remains based on viscous fluid damping, utilizing hydraulic oil forced through precisely engineered valves and orifices to dissipate vibrational energy. However, manufacturers are increasingly adopting advanced sealing technologies, such as low-friction elastomers and magnetic fluid seals, to minimize internal leakage and operational wear, thereby extending the service interval of the dampers, which is a critical operational parameter for rail operators seeking to reduce downtime and maintenance costs significantly.

A major area of innovation involves the shift from passive to semi-active and active damping systems. Semi-active dampers, often incorporating Magneto-Rheological (MR) fluids or solenoid-controlled valves, allow for instantaneous adjustment of damping force in response to real-time sensor inputs regarding track geometry and vehicle speed. This capability optimizes both high-speed stability and low-speed comfort, providing a versatile solution superior to traditional passive setups. While fully active systems, which require external power input to generate forces, are technologically sophisticated and offer ultimate control, their higher complexity, cost, and power requirements currently limit their widespread adoption primarily to niche, high-performance applications.

Further technological advancements include the integration of sophisticated monitoring systems, such as embedded Inertial Measurement Units (IMUs) and wireless telemetry systems, which allow continuous data collection on damper performance, temperature, and internal pressures. This data, often analyzed using cloud-based platforms and AI algorithms, enables highly accurate condition-based monitoring and predictive maintenance strategies. Furthermore, material science plays a crucial role, with research focused on utilizing lightweight, high-strength composite materials for housing and mounting components to reduce unsprung mass, thereby improving suspension response characteristics and overall vehicle efficiency and maneuverability, especially in applications where energy consumption is critical.

Regional Highlights

The global Lateral Hydraulic Damper Market exhibits distinct growth patterns and maturity levels across key geographical regions, largely dictated by infrastructure investment cycles, technological adoption rates, and regulatory mandates regarding transportation safety.

- Asia Pacific (APAC): APAC is the epicenter of market growth, primarily fueled by massive infrastructure development programs, especially in China and India. China's relentless expansion of its high-speed rail network (HSR) and urban metro systems drives immense demand for lateral dampers, positioning it as the largest consumer globally. Other nations like Japan and South Korea, possessing mature and technologically advanced rail systems, focus on replacement and upgrade cycles, demanding components with the highest precision and reliability. The region’s rapid urbanization ensures sustained demand for the foreseeable future.

- Europe: Europe represents a technologically mature market characterized by stringent safety and environmental regulations (TSI standards) and a dense, interconnected high-speed rail network (e.g., TGV, ICE). Demand here is focused on high-specification, reliable, long-life dampers, and there is a significant push toward integrating semi-active technologies for enhanced cross-border performance optimization. Key countries like Germany, France, and Italy are leading innovators, often requiring complex, customized solutions tailored to specific rolling stock designs.

- North America: This region's demand is dominated by the heavy-haul freight rail sector and specialized commercial vehicles, prioritizing ruggedness, durability, and resistance to extreme temperature variations. While passenger rail development is slower compared to APAC or Europe, the immense volume and weight carried by US and Canadian freight trains necessitate extremely robust lateral damping solutions to manage high dynamic loading and minimize track wear. Military applications also form a vital, high-value niche in this region.

- Latin America (LATAM) and Middle East & Africa (MEA): These regions are emerging markets showing high growth potential linked to new urban transit projects (metros) and regional infrastructure modernization efforts (e.g., railway links in the GCC countries). While the market size is currently smaller, increasing investment in railway privatization and urban mass transit systems is expected to accelerate the adoption of lateral dampers, particularly standard, cost-effective solutions in the short term, with a gradual transition to more sophisticated products.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Lateral Hydraulic Damper Market.- ZF Friedrichshafen AG

- Tenneco Inc.

- Hitachi Astemo, Inc.

- KYB Corporation

- Continental AG

- ThyssenKrupp AG

- WABCO (Zweigniederlassung der Continental Teves AG & Co. oHG)

- Koni B.V. (ITP)

- Ohlson Racing AB

- Mando Corporation

- SHOWA CORPORATION

- Meritor, Inc. (Cummins)

- Gabriel India Limited

- Sachs (ZF)

- Bilstein (ThyssenKrupp)

- BOSCH Rexroth

- Shanghai Railway Damper Co., Ltd.

- China South Industries Group Corporation (CSGC)

- Alstom

- Siemens Mobility

Frequently Asked Questions

Analyze common user questions about the Lateral Hydraulic Damper market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a lateral hydraulic damper in railway applications?

The primary function of a lateral hydraulic damper is to control and dampen horizontal movements—specifically yaw, sway, and hunting instability—between the car body and the bogie or between bogies, ensuring operational safety, minimizing component wear, and maximizing passenger comfort, particularly on curved tracks or at high speeds.

How do semi-active lateral dampers differ from passive dampers?

Passive dampers offer fixed damping characteristics based on mechanical design. Semi-active dampers utilize integrated sensors and electronic controls (often with MR fluids or adjustable valves) to instantly modify damping resistance in real-time based on vehicle speed, load, and track conditions, thus optimizing performance dynamically.

Which region currently dominates the demand for lateral hydraulic dampers?

Asia Pacific (APAC), particularly driven by extensive government investments in high-speed rail and urban metro network expansion in countries like China and India, dominates the current global demand for lateral hydraulic dampers due to high volume requirements and new infrastructure projects.

What are the main restraints impacting market growth?

Key restraints include the high initial cost associated with manufacturing and implementing advanced, high-precision hydraulic systems and the inherently long operational lifespan of quality dampers, which reduces the frequency of replacement demand in the highly durable rail and heavy-duty sectors.

What role does predictive maintenance play in the lateral damper market?

Predictive maintenance, often powered by AI analyzing sensor data, plays a crucial role by enabling operators to monitor damper health, anticipate component failure, and schedule maintenance proactively, thereby minimizing unplanned operational downtime and significantly reducing Total Cost of Ownership (TCO).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager