Leaf Spring Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439719 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Leaf Spring Market Size

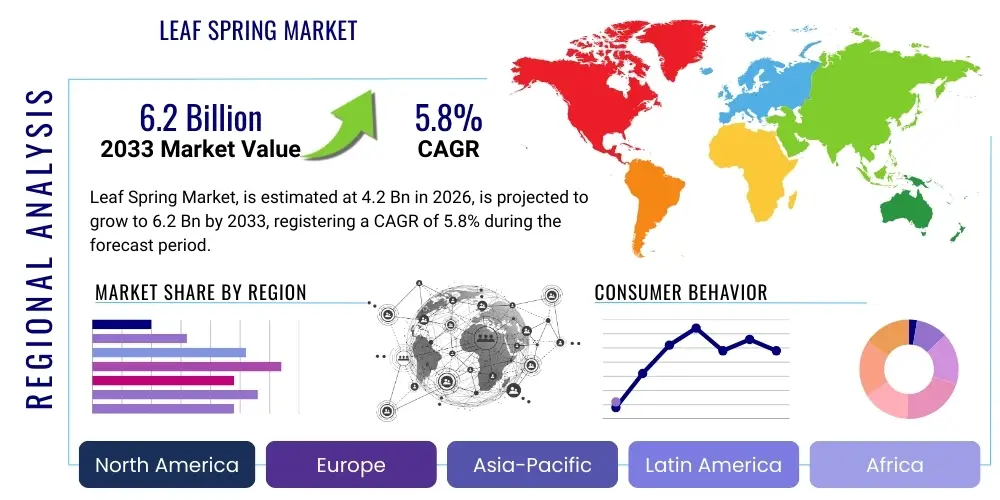

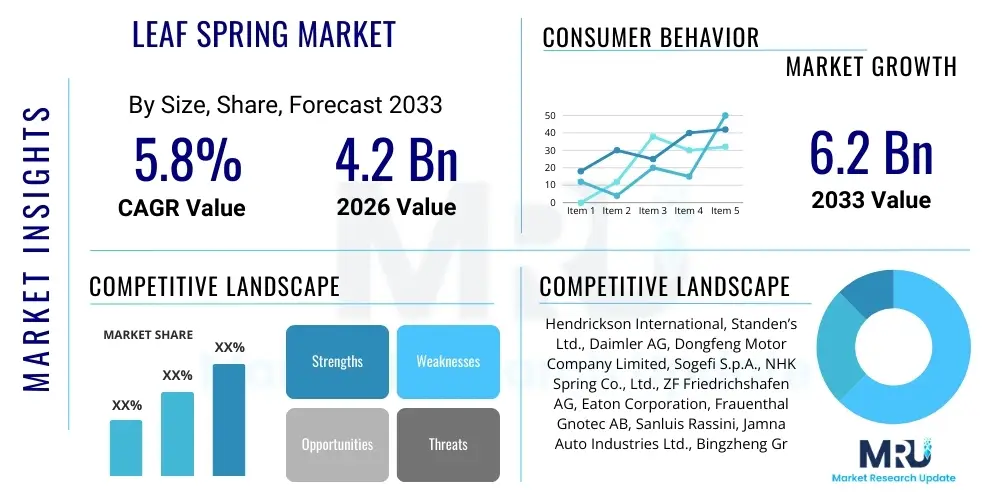

The Leaf Spring Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.2 Billion in 2026 and is projected to reach USD 6.2 Billion by the end of the forecast period in 2033.

Leaf Spring Market introduction

The leaf spring market is a critical segment within the automotive and industrial suspension systems, providing essential support, absorbing shocks, and maintaining vehicle stability. Characterized by its robust design and reliability, the leaf spring is a time-tested component predominantly used in heavy-duty vehicles such as trucks, buses, commercial vans, and trailers, as well as increasingly in certain passenger and off-road vehicles. Its primary function is to dampen vibrations and distribute load evenly, ensuring a smoother ride and enhanced vehicle control, particularly under heavy loads or challenging terrains.

Major applications of leaf springs span across original equipment manufacturing (OEM) for new vehicle production and the aftermarket for replacement and upgrades. Benefits include high load-carrying capacity, durability, simplicity in design, and relative cost-effectiveness compared to more complex suspension systems. The market is significantly driven by global automotive production trends, especially in the commercial vehicle sector, and infrastructure development projects that necessitate heavy transportation. Innovations in material science, such as the adoption of composite leaf springs, are also influencing market dynamics by offering lighter, more fuel-efficient, and corrosion-resistant alternatives.

Leaf Spring Market Executive Summary

The Leaf Spring Market is currently experiencing a period of moderate but steady growth, underpinned by robust demand from the global commercial vehicle industry and significant infrastructure development across emerging economies. Business trends indicate a shift towards advanced manufacturing techniques and the integration of lightweight materials, driven by stringent emission regulations and the ongoing pursuit of fuel efficiency. Manufacturers are increasingly focusing on automation and precision engineering to enhance product quality and consistency, while also exploring opportunities in specialized applications such as off-highway vehicles and electric commercial vehicles.

Regional trends highlight the Asia Pacific as the dominant market, propelled by rapid industrialization, urbanization, and a burgeoning automotive manufacturing base, particularly in China and India. North America and Europe demonstrate a mature market with stable demand, primarily driven by replacement cycles and the adoption of advanced suspension technologies for improved performance and comfort. Segment-wise, traditional multi-leaf steel springs continue to hold a substantial share due to their proven reliability and cost-effectiveness, though composite leaf springs are gaining traction due to their weight reduction benefits and superior fatigue life, particularly in new vehicle designs. The aftermarket segment remains vital, fueled by the extensive existing fleet of commercial vehicles requiring periodic maintenance and upgrades, ensuring sustained demand for leaf spring components.

AI Impact Analysis on Leaf Spring Market

User questions regarding AI's impact on the leaf spring market often revolve around how artificial intelligence might influence manufacturing processes, material optimization, supply chain efficiency, and even the design of traditional components. Key themes emerge around the potential for predictive maintenance leveraging AI analytics to extend leaf spring lifespan, the role of AI in quality control during production, and its application in optimizing vehicle suspension systems for specific performance characteristics. There is also interest in how AI could facilitate the development of next-generation leaf spring materials and designs, though concerns about data security and the high investment required for AI implementation are frequently raised.

- AI-driven predictive maintenance for vehicle suspension systems, extending leaf spring lifespan and reducing unplanned downtime.

- Optimization of manufacturing processes through AI, leading to enhanced precision, reduced waste, and improved production efficiency for leaf springs.

- AI-assisted material science research for developing lighter, stronger, and more durable composite leaf springs.

- Supply chain optimization using AI for demand forecasting, inventory management, and logistics, ensuring timely availability of leaf spring components.

- Integration of AI in quality control systems for automated inspection of leaf springs, ensuring adherence to stringent quality standards.

- Potential for AI to analyze real-world driving data to inform and refine leaf spring designs for various vehicle types and operational conditions.

DRO & Impact Forces Of Leaf Spring Market

The Leaf Spring Market is influenced by a complex interplay of Drivers, Restraints, and Opportunities, collectively forming the Impact Forces that shape its trajectory. Key drivers include the consistent growth in commercial vehicle production worldwide, driven by expanding logistics, e-commerce, and construction sectors, which heavily rely on vehicles equipped with leaf spring suspensions. Robust infrastructure development, particularly in emerging economies, further fuels the demand for heavy-duty trucks and trailers, directly impacting market growth. The inherent durability, high load-bearing capacity, and cost-effectiveness of leaf springs also serve as fundamental drivers, ensuring their continued preference in many applications.

However, the market faces significant restraints. The increasing adoption of alternative suspension systems, such as air suspensions, particularly in premium commercial vehicles and modern passenger cars, presents a competitive challenge. Additionally, the fluctuating prices of raw materials, primarily steel, can impact manufacturing costs and profit margins. Environmental regulations pushing for vehicle lightweighting and improved fuel efficiency also pose a restraint, as traditional steel leaf springs are heavier, driving research into lighter alternatives that may incur higher initial costs. Opportunities within the market primarily stem from the ongoing innovation in composite leaf springs, which address weight and corrosion concerns, offering a pathway for market expansion into new vehicle segments. The growing demand for electric commercial vehicles, which require robust yet weight-optimized suspension systems, also presents a substantial opportunity for innovative leaf spring solutions. Furthermore, the burgeoning aftermarket segment for replacement and upgrade of existing vehicle fleets ensures a consistent revenue stream.

Segmentation Analysis

The Leaf Spring Market is comprehensively segmented to provide granular insights into its diverse components and applications. Understanding these segments is crucial for identifying specific market dynamics, consumer preferences, and growth opportunities. The primary segmentation approaches typically involve categorizing leaf springs by material type, product type, vehicle type, and end-use application, each influencing market share and technological advancements.

By dissecting the market through these various lenses, stakeholders can pinpoint lucrative niches, assess competitive landscapes, and formulate targeted strategies. For instance, the distinction between steel and composite leaf springs highlights the ongoing shift towards advanced materials, while vehicle type segmentation reveals the core markets driving demand. End-use application further clarifies whether demand originates from original equipment manufacturers or the robust aftermarket sector, offering different strategic considerations for market participants.

- By Material Type:

- Steel Leaf Spring (Multi-leaf, Mono-leaf)

- Composite Leaf Spring (Fiberglass, Carbon Fiber Reinforced)

- By Product Type:

- Multi-leaf Spring

- Mono-leaf Spring

- Parabolic Leaf Spring

- By Vehicle Type:

- Commercial Vehicles (Heavy-duty Trucks, Light Commercial Vehicles, Buses, Trailers)

- Passenger Cars

- Off-Highway Vehicles (Agricultural Machinery, Construction Equipment)

- By End-Use Application:

- OEM (Original Equipment Manufacturer)

- Aftermarket

Value Chain Analysis For Leaf Spring Market

The value chain for the Leaf Spring Market encompasses a series of interconnected activities, from raw material sourcing to the final distribution to end-users, highlighting the flow of value creation. Upstream analysis involves the procurement of key raw materials, primarily high-grade steel alloys and, increasingly, advanced composite materials like fiberglass and carbon fibers. This stage also includes the manufacturing of specialized components such as spring steel bars or composite laminates, which are crucial for the primary production of leaf springs. Relationships with steel mills and material suppliers are critical, as material quality directly impacts the performance and durability of the final product.

Downstream analysis focuses on the manufacturing processes, including forging, heat treatment, bending, assembly, and quality control, transforming raw materials into finished leaf springs. This stage involves complex engineering and precision to meet stringent automotive standards. The distribution channel plays a pivotal role, covering both direct and indirect sales. Direct channels primarily serve Original Equipment Manufacturers (OEMs), where leaf springs are integrated directly into new vehicle assembly lines through long-term supply contracts. Indirect channels cater to the aftermarket, involving a network of distributors, wholesalers, retailers, and service centers that supply replacement parts to independent workshops and end-consumers. The efficiency of these channels, coupled with strong logistics, is essential for market reach and customer satisfaction.

Leaf Spring Market Potential Customers

Potential customers and end-users of leaf springs are diverse, primarily spanning the automotive and heavy machinery industries. The largest segment of buyers comprises Original Equipment Manufacturers (OEMs) in the commercial vehicle sector, including manufacturers of heavy-duty trucks, light commercial vehicles (LCVs), buses, and trailers. These OEMs integrate leaf springs directly into their new vehicle production lines, requiring high-volume, quality-assured components that meet precise specifications for performance, durability, and safety standards. Their purchasing decisions are driven by cost-efficiency, technological advancements, and supplier reliability.

Beyond OEMs, the aftermarket represents a substantial customer base. This includes independent garages, repair shops, fleet owners, and individual vehicle owners who require replacement leaf springs due to wear and tear, damage, or for upgrade purposes. Demand in the aftermarket is influenced by the size and age of the existing vehicle fleet, driving patterns, road conditions, and the availability of reliable replacement parts. Additionally, manufacturers of off-highway vehicles such as agricultural machinery, construction equipment, and mining vehicles also constitute a significant customer segment, valuing the robustness and load-bearing capabilities of leaf springs for their demanding operational environments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.2 Billion |

| Market Forecast in 2033 | USD 6.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hendrickson International, Standen’s Ltd., Daimler AG, Dongfeng Motor Company Limited, Sogefi S.p.A., NHK Spring Co., Ltd., ZF Friedrichshafen AG, Eaton Corporation, Frauenthal Gnotec AB, Sanluis Rassini, Jamna Auto Industries Ltd., Bingzheng Group, Qingdao Hengli Industry Co., Ltd., Weweler-Colaert, Emco Industries Limited, Mota, IFC Composite GmbH, BPW Bergische Achsen KG, Shandong Futian Automobile Co., Ltd., Zhejiang Sanli Suspension Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Leaf Spring Market Key Technology Landscape

The technological landscape of the Leaf Spring Market is undergoing a steady evolution, driven by the persistent demand for enhanced performance, reduced weight, and improved durability in vehicle suspension systems. Traditionally dominated by multi-leaf steel springs, manufacturing techniques have advanced significantly to include sophisticated heat treatment processes, shot peening, and precision forming to increase fatigue life and load-bearing capacity. The development of mono-leaf and parabolic leaf springs represents a key technological refinement, offering better ride comfort and reduced inter-leaf friction compared to conventional multi-leaf designs, catering to specific vehicle performance requirements.

A major technological shift is the increasing adoption of composite materials, primarily fiberglass and carbon fiber reinforced polymers, in the production of leaf springs. These composite leaf springs offer substantial weight reduction (up to 70% compared to steel), leading to improved fuel efficiency, reduced emissions, and enhanced vehicle dynamics. They also exhibit superior corrosion resistance and a higher strength-to-weight ratio, contributing to longer service life. Research and development efforts are further focused on integrating smart materials and sensor technologies into leaf spring designs for real-time monitoring of stress, load, and fatigue, enabling proactive maintenance and optimizing suspension performance under varying conditions. Advances in CAD/CAM and simulation tools are also crucial, allowing for precise design optimization and virtual testing before physical prototyping, accelerating product development cycles.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market due to the robust growth in automotive manufacturing, particularly commercial vehicles, in countries like China, India, and Japan. Rapid industrialization, urbanization, and significant infrastructure development projects in the region continuously drive demand for heavy-duty transportation solutions. The expanding logistics and e-commerce sectors further contribute to the high production and sales of trucks and buses, making APAC a pivotal market for leaf spring manufacturers.

- North America: A mature market characterized by steady demand from both OEM and aftermarket segments. Stringent regulations regarding vehicle safety, emissions, and fuel efficiency encourage the adoption of advanced leaf spring technologies, including composite materials. The presence of major commercial vehicle manufacturers and a large existing fleet requiring maintenance and replacement parts ensures consistent market activity.

- Europe: Exhibits stable growth, driven by a focus on technological innovation, quality, and environmental sustainability. European manufacturers are at the forefront of developing lightweight and durable composite leaf springs to comply with stringent emission norms and enhance vehicle performance. The region's robust logistics industry and high standards for commercial vehicle fleets sustain demand for advanced suspension components.

- Latin America: Experiences moderate growth, influenced by economic conditions and investment in infrastructure projects. Brazil and Mexico are key markets, with significant automotive production capabilities. Demand is primarily driven by the commercial vehicle sector and the need for durable suspension systems capable of handling varied road conditions.

- Middle East and Africa (MEA): Emerging markets with growth potential, particularly in countries investing in infrastructure and logistics. The expansion of mining, construction, and transportation sectors in parts of Africa and the GCC countries fuels the demand for heavy-duty vehicles and their components, including leaf springs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Leaf Spring Market.- Hendrickson International

- Standen’s Ltd.

- Daimler AG

- Dongfeng Motor Company Limited

- Sogefi S.p.A.

- NHK Spring Co., Ltd.

- ZF Friedrichshafen AG

- Eaton Corporation

- Frauenthal Gnotec AB

- Sanluis Rassini

- Jamna Auto Industries Ltd.

- Bingzheng Group

- Qingdao Hengli Industry Co., Ltd.

- Weweler-Colaert

- Emco Industries Limited

- Mota

- IFC Composite GmbH

- BPW Bergische Achsen KG

- Shandong Futian Automobile Co., Ltd.

- Zhejiang Sanli Suspension Co., Ltd.

Frequently Asked Questions

What is a leaf spring and its primary function?

A leaf spring is a type of spring used in vehicle suspension systems, typically consisting of several layers of metal (leaves) curved in an arc. Its primary function is to support the axle, bear the load, absorb road shocks, and provide damping, ensuring a stable and comfortable ride, especially in heavy-duty vehicles.

What are the key advantages of composite leaf springs over traditional steel leaf springs?

Composite leaf springs offer significant advantages including substantial weight reduction (up to 70%), which leads to improved fuel efficiency and reduced emissions. They also provide enhanced ride comfort, superior corrosion resistance, higher fatigue life, and better NVH (Noise, Vibration, and Harshness) characteristics compared to traditional steel counterparts.

Which vehicle types primarily utilize leaf springs?

Leaf springs are predominantly utilized in commercial vehicles such as heavy-duty trucks, light commercial vehicles (LCVs), buses, and trailers due to their robust load-carrying capacity and durability. They are also common in off-highway vehicles like agricultural machinery and construction equipment, with some applications in certain passenger cars and utility vehicles.

How do innovations in material science impact the leaf spring market?

Innovations in material science are profoundly impacting the leaf spring market by enabling the development of lighter and stronger alternatives to traditional steel. The rise of advanced composite materials like fiberglass and carbon fiber allows for superior performance, reduced vehicle weight, improved fuel economy, and extended component lifespan, driving market growth and technological advancements.

What regions are driving the growth of the global leaf spring market?

The Asia Pacific region is a primary driver of global leaf spring market growth, fueled by rapid industrialization, burgeoning automotive production, and extensive infrastructure development in countries like China and India. North America and Europe also contribute significantly, driven by replacement demand, technological advancements, and stringent regulatory landscapes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Automotive Leaf Spring Assembly Market Size Report By Type (Multi-leaf Spring, Mono-leaf Spring), By Application (Bus, Truck, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Automotive Leaf Spring Assembly Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Mono-leaf Spring, Multi-leaf Spring), By Application (Truck, Bus, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

- Automotive Leaf Spring Suspension Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Passenger Car, Light Commercial Vehicle, Medium- & Heavy-Duty Vehicle, Others), By Application (OEM, Replacement), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager