Leak Test Apparatus Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440681 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Leak Test Apparatus Market Size

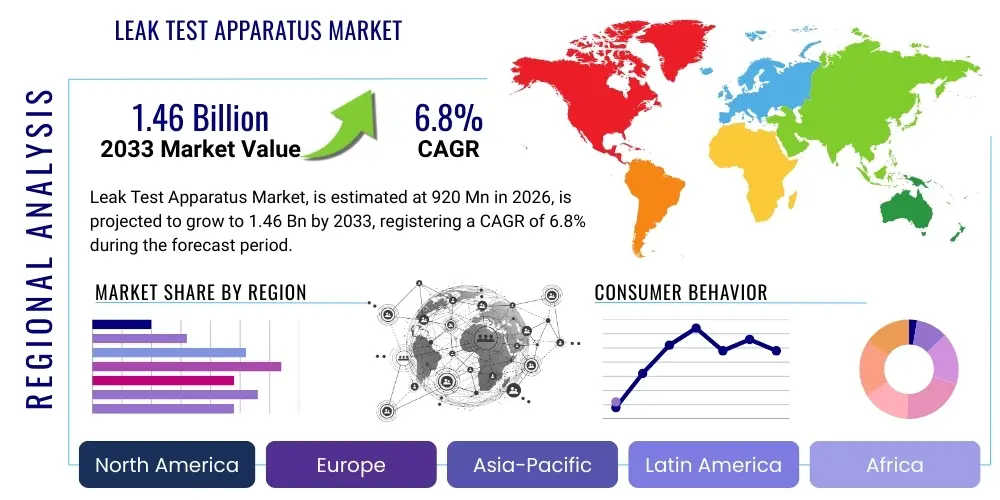

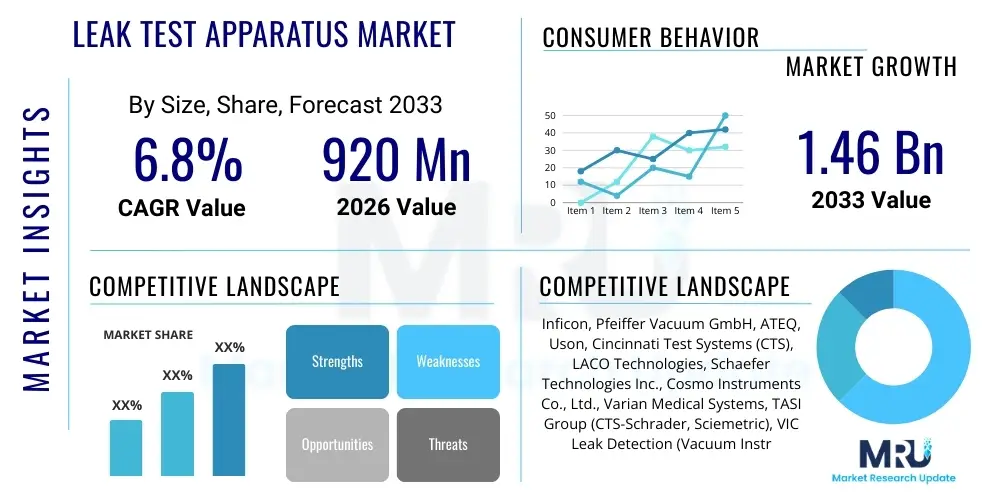

The Leak Test Apparatus Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 920 million in 2026 and is projected to reach USD 1.46 billion by the end of the forecast period in 2033. This robust growth is primarily driven by escalating demand for quality control across diverse industries, increasing regulatory scrutiny, and the imperative for enhancing product reliability and safety in critical applications. The market expansion is further fueled by technological advancements in leak detection methods, including more precise and automated systems that cater to the evolving needs of modern manufacturing processes and sophisticated product designs.

The consistent upward trajectory of the market size reflects a global commitment to superior manufacturing standards and a proactive approach to mitigate potential product failures or environmental hazards associated with leaks. Industries such as automotive, medical devices, and consumer electronics, which are highly sensitive to quality defects, are significant contributors to this growth. Moreover, the integration of smart technologies and data analytics into leak test apparatus is not only improving accuracy and efficiency but also expanding the addressable market by enabling predictive maintenance capabilities and real-time process optimization, thus creating new avenues for market penetration and sustained growth.

Leak Test Apparatus Market introduction

The Leak Test Apparatus Market encompasses the global industry dedicated to the development, manufacturing, and distribution of specialized instruments and systems designed to detect and quantify leaks in products, components, and sealed systems. These devices range from simple bubble test equipment to highly sophisticated mass spectrometer-based helium leak detectors, utilizing various principles to identify breaches in hermetic seals or material integrity. The primary objective of leak testing is to ensure product quality, operational safety, and compliance with stringent industry standards and environmental regulations, preventing product recalls, financial losses, and potential harm to end-users or the environment.

Major applications of leak test apparatus span across a broad spectrum of industries, including automotive for fuel systems and airbags, medical devices for sterile packaging and implant integrity, electronics for hermetically sealed components, and HVAC/refrigeration for refrigerant containment. Furthermore, these systems are indispensable in the aerospace sector for ensuring the structural integrity of critical components, in the pharmaceutical industry for sterile drug packaging, and in general manufacturing for quality assurance of various consumer goods. The benefits of employing advanced leak test apparatus are multifaceted, including enhanced product reliability and longevity, significant improvements in operational safety, reduction in material waste, and optimization of manufacturing processes by identifying defects early in the production cycle.

Key driving factors propelling the growth of this market include the increasing complexity of manufactured products demanding higher precision in quality control, the global push towards automation and Industry 4.0 paradigms necessitating integrated leak detection solutions, and the ever-tightening regulatory landscape across various sectors. For instance, regulations governing emissions in the automotive industry or sterility in medical devices mandate rigorous leak testing, making these apparatus essential investments for manufacturers. The growing consumer expectation for defect-free and durable products further reinforces the adoption of sophisticated leak testing technologies, as companies strive to maintain brand reputation and customer loyalty.

Leak Test Apparatus Market Executive Summary

The Leak Test Apparatus Market is experiencing significant momentum, driven by a confluence of evolving business trends, distinct regional growth patterns, and dynamic segment shifts. Globally, business trends indicate a strong move towards automation, digitalization, and the integration of artificial intelligence (AI) and machine learning (ML) into leak detection processes. Manufacturers are increasingly seeking solutions that offer higher precision, faster test cycles, and comprehensive data logging capabilities, reflecting a broader industry shift towards smart manufacturing and predictive quality control. There is also a notable trend towards customization and modular designs, allowing apparatus to be tailored to specific application requirements and integrated seamlessly into existing production lines, thereby enhancing operational flexibility and efficiency for end-users.

From a regional perspective, the market demonstrates diverse growth trajectories. The Asia Pacific (APAC) region is emerging as a dominant force, characterized by rapid industrialization, expansion of manufacturing bases, and increasing adoption of advanced quality control measures across countries like China, India, Japan, and South Korea. North America and Europe, while representing mature markets, continue to drive innovation and demand for high-precision, advanced leak testing solutions, particularly in regulated industries such as aerospace, medical devices, and automotive, propelled by stringent quality standards and a focus on advanced R&D. Latin America, the Middle East, and Africa are showing nascent but accelerating growth, fueled by infrastructure development and increasing foreign direct investment in manufacturing sectors.

Segmentation trends highlight particular areas of accelerated growth. Technology-wise, mass flow and helium leak detection methods are experiencing robust demand due to their high sensitivity and accuracy, critical for complex applications. However, pressure decay remains a widely adopted and cost-effective solution for many general industrial applications. End-use industry analysis reveals strong growth in the automotive sector, driven by electric vehicle battery and fuel cell testing, and in the medical and pharmaceutical sectors, where product safety and sterility are paramount. The increasing complexity and miniaturization of electronic components are also bolstering demand for highly sensitive leak testing, underscoring a consistent drive for enhanced quality and reliability across all major industry verticals.

AI Impact Analysis on Leak Test Apparatus Market

User questions regarding AI's impact on the Leak Test Apparatus Market frequently revolve around how artificial intelligence can enhance accuracy, speed, and automation, reduce human error, and enable predictive maintenance. Users are keen to understand if AI can make leak detection more precise by analyzing complex data patterns, thereby identifying leaks that might be missed by conventional methods. There is also a strong interest in AI's role in optimizing test parameters, streamlining quality control processes, and integrating leak testing into broader smart factory ecosystems. Concerns often include the cost of implementation, the complexity of integration, and the need for specialized skills to manage AI-driven systems. Overall, the expectation is for AI to transform leak testing from a reactive quality check to a proactive, intelligent, and fully integrated component of advanced manufacturing, delivering unprecedented levels of efficiency and reliability.

The integration of AI in leak test apparatus is poised to revolutionize the industry by addressing several long-standing challenges and unlocking new capabilities. AI algorithms can process vast amounts of sensor data from leak detection equipment, identifying subtle anomalies and trends that human operators or simpler analytical tools might overlook. This leads to significantly enhanced accuracy in pinpointing leak locations and quantifying leak rates, particularly in complex assemblies or highly sensitive applications. Moreover, AI-driven systems can learn from historical data to optimize test parameters in real-time, adapting to variations in material properties or environmental conditions, thereby reducing setup times and minimizing false positives or negatives, which directly translates into improved operational efficiency and reduced waste.

Beyond precision and efficiency, AI's predictive capabilities are a game-changer for equipment maintenance and quality assurance. By continuously monitoring the performance of leak test apparatus and correlating it with historical data, AI can predict potential equipment failures before they occur, enabling proactive maintenance and reducing costly downtime. Furthermore, AI can contribute to process optimization by analyzing leak data across entire production lines, identifying systemic issues, and suggesting adjustments to manufacturing processes to prevent leaks from occurring in the first place. This transition from defect detection to defect prevention, facilitated by AI, offers substantial long-term benefits in terms of cost savings, product quality consistency, and overall operational excellence within manufacturing environments.

- Enhanced Accuracy and Sensitivity: AI algorithms analyze complex sensor data to detect minute leaks and subtle patterns often missed by traditional methods, significantly improving detection reliability and precision.

- Automated Test Optimization: AI-driven systems autonomously adjust test parameters (e.g., pressure, time) in real-time based on product variations and historical data, optimizing test cycles for speed and accuracy.

- Predictive Maintenance: AI monitors apparatus performance, predicts potential failures, and schedules proactive maintenance, minimizing downtime and extending equipment lifespan.

- Data-Driven Quality Control: AI processes large datasets from leak tests to identify root causes of leaks in production lines, suggesting process improvements to prevent defects.

- Reduced Human Error: Automation and intelligent decision-making by AI systems reduce reliance on manual interpretation and intervention, leading to more consistent and objective results.

- Integration with Industry 4.0: AI facilitates seamless integration of leak testing into broader smart factory ecosystems, enabling real-time data exchange, centralized monitoring, and remote diagnostics.

- Advanced Anomaly Detection: AI can identify unusual leak signatures or deviations from normal patterns, helping to flag novel types of defects or emerging quality issues.

DRO & Impact Forces Of Leak Test Apparatus Market

The Leak Test Apparatus Market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and various impact forces shaping its trajectory. The primary drivers include the escalating global demand for high-quality, defect-free products across all manufacturing sectors, coupled with increasingly stringent regulatory standards for product safety, environmental protection, and public health. Industries like automotive, medical devices, and aerospace face intense scrutiny, mandating rigorous leak testing to ensure compliance and prevent costly recalls. Furthermore, the relentless pursuit of automation and integration into Industry 4.0 paradigms pushes manufacturers to adopt advanced, high-speed, and data-driven leak testing solutions that seamlessly fit into smart factory environments, thereby boosting efficiency and productivity.

Despite these compelling drivers, the market faces several notable restraints. High initial investment costs associated with advanced leak test apparatus, particularly for highly sensitive and automated systems, can be a significant barrier for small and medium-sized enterprises (SMEs). The technical complexity of operating and maintaining sophisticated leak detection equipment often requires specialized technical expertise, which can be scarce and expensive to train or hire. Moreover, the lack of standardized testing protocols across all industries and applications can lead to fragmentation in demand and create challenges for manufacturers of leak test apparatus in developing universally applicable solutions, thereby complicating market penetration and adoption rates.

Opportunities for growth are abundant and strategically vital for market players. The burgeoning electric vehicle (EV) market presents a substantial opportunity for leak testing of battery packs, cooling systems, and fuel cells, requiring highly specialized and sensitive equipment. Similarly, the expanding market for advanced medical devices, including implants and diagnostic instruments, necessitates ultra-precise leak detection for ensuring patient safety and product efficacy. Furthermore, the ongoing digitalization trend and advancements in sensor technology offer avenues for developing more intelligent, connected, and user-friendly leak test apparatus with enhanced diagnostic capabilities. The shift towards sustainable manufacturing also creates demand for leak detection solutions that prevent waste of valuable resources and reduce environmental impact.

The market is also shaped by several impact forces, including competitive rivalry, which is moderately intense due to the presence of both large, established players and niche specialists. Supplier power is moderate, as key components like sensors and vacuum pumps are critical but sourced from a competitive market. Buyer power is high, especially for large industrial clients, who often demand customized, high-performance solutions at competitive prices. The threat of new entrants is moderate, as developing advanced leak testing technology requires significant R&D investment and technical know-how. Finally, the threat of substitutes, while present from alternative quality control methods, is generally low for critical applications where specific leak detection sensitivity is paramount and non-negotiable for product integrity and safety.

Segmentation Analysis

The Leak Test Apparatus Market is meticulously segmented across various dimensions, providing a granular understanding of its structure and growth dynamics. These segmentations are crucial for identifying specific market niches, understanding customer preferences, and formulating targeted business strategies. The primary segmentation categories include technology type, which categorizes apparatus based on the physical principles used for leak detection; end-use industry, distinguishing between diverse application sectors; automation level, differentiating between manual, semi-automatic, and fully automated systems; and portability, classifying equipment as benchtop, portable, or in-line integrated solutions. Each of these segments exhibits unique growth drivers, technological requirements, and market characteristics, reflecting the diverse demands of the global manufacturing landscape.

Analyzing these segments allows for a comprehensive assessment of market trends and future growth potential. For instance, the demand for helium leak detection, under the technology segment, is particularly strong in high-precision industries like aerospace and medical devices where even minute leaks can have catastrophic consequences. Conversely, pressure decay testing, known for its cost-effectiveness and versatility, continues to dominate general industrial applications. The growth in the automotive sector for leak testing of EV components represents a significant shift in end-use demand, moving beyond traditional internal combustion engine applications. Understanding these interdependencies and specific segment dynamics is vital for market players to innovate and allocate resources effectively, ensuring their product offerings align with evolving customer needs and industry benchmarks.

- By Technology

- Pressure Decay Leak Testing: Measures pressure drop over time in a sealed part, indicating a leak. Cost-effective and widely used.

- Mass Flow Leak Testing: Detects leaks by measuring the amount of air or gas flowing into or out of a test part, offering higher sensitivity than pressure decay for certain applications.

- Helium Leak Detection (Mass Spectrometer): Utilizes helium as a tracer gas and a mass spectrometer to detect extremely small leaks, highly sensitive and precise for critical applications.

- Bubble Test Leak Testing: Involves submerging a pressurized part in water and observing bubbles, a simple and visual method for gross leak detection.

- Vacuum Decay Leak Testing: Measures a pressure rise in an evacuated chamber surrounding a test part, effective for detecting leaks in flexible packaging.

- Other Technologies: Includes ultrasonic leak detection, tracer gas (e.g., hydrogen, SF6) sniffers, and thermal conductivity methods.

- By End-Use Industry

- Automotive: Testing of fuel systems, brake lines, engines, transmissions, HVAC, airbags, and increasingly EV battery packs and fuel cells.

- Medical & Pharmaceutical: Ensures sterility and integrity of medical devices, drug packaging, IV bags, catheters, and implants.

- Industrial (General Manufacturing, Aerospace & Defense, HVAC): Covers a wide range of components, from industrial valves and fittings to aircraft parts and refrigeration systems.

- Packaging: Verifies integrity of food, beverage, and consumer goods packaging to prevent spoilage and ensure shelf life.

- Electronics: Tests hermetically sealed components, sensors, and electronic housings for environmental protection.

- Food & Beverage: Ensures integrity of sealed containers and flexible packaging to maintain product freshness and prevent contamination.

- Research & Development: Used in laboratories for material testing, product development, and quality assurance protocols.

- By Automation Level

- Manual: Operator-dependent systems requiring manual loading, testing, and interpretation.

- Semi-Automatic: Some automated functions (e.g., test cycle), but still requiring operator intervention for loading/unloading.

- Automatic: Fully integrated into production lines with automated loading, testing, and sorting, often incorporating robotics.

- By Portability

- Benchtop: Compact units designed for laboratory or small-scale production environments.

- Portable: Handheld or mobile units for on-site testing and field applications.

- Integrated/In-line Systems: Custom-built solutions integrated directly into high-volume manufacturing lines.

Value Chain Analysis For Leak Test Apparatus Market

The value chain for the Leak Test Apparatus Market is a comprehensive network of activities that spans from raw material sourcing and component manufacturing to the final deployment and post-sales support of leak testing solutions. The upstream segment of this value chain involves critical suppliers providing specialized components such as highly sensitive pressure sensors, precise flow meters, sophisticated vacuum pumps, mass spectrometer components, and advanced software for data acquisition and analysis. These suppliers are integral to the performance and accuracy of the final leak test apparatus. Strong relationships with reliable component providers are essential for manufacturers to ensure the quality, innovation, and cost-effectiveness of their products, as the accuracy and reliability of the apparatus are directly tied to the quality of its constituent parts. Innovations in sensor technology and materials science at this upstream level can significantly influence the capabilities and competitive edge of the entire market.

Moving downstream, the value chain encompasses the manufacturing, assembly, and integration of these components into complete leak test systems. This stage involves significant research and development efforts to design apparatus that meet diverse industry-specific requirements, comply with international standards, and incorporate advanced features like automation, data logging, and connectivity. Following manufacturing, the distribution channel plays a crucial role in bringing these complex systems to end-users. Distribution can occur through direct sales channels, where manufacturers engage directly with large industrial clients, often providing customized solutions and extensive technical support. This direct approach allows for closer client relationships and deeper understanding of specific application needs, which is particularly valuable for high-value or highly specialized apparatus.

Alternatively, indirect distribution channels involve leveraging a network of authorized distributors, resellers, and system integrators. These partners often have established regional presence, local market expertise, and the capability to provide localized sales, installation, and first-line support. System integrators, in particular, are vital as they often combine leak test apparatus with other manufacturing equipment, robotics, and automation systems to deliver complete turnkey solutions for complex production lines. The final stage of the value chain involves comprehensive after-sales services, including installation, calibration, maintenance, repair, and ongoing technical support and training. Given the precision and critical nature of leak testing, robust service and support are paramount for customer satisfaction and ensuring the long-term operational efficiency and accuracy of the apparatus, thereby securing recurring revenue streams and fostering long-term customer loyalty.

Leak Test Apparatus Market Potential Customers

The Leak Test Apparatus Market caters to a diverse and expanding base of potential customers, primarily comprised of various end-user industries that prioritize product quality, safety, and regulatory compliance. The automotive industry represents a substantial segment of buyers, requiring leak testing for a vast array of components including engine blocks, fuel tanks, brake lines, airbag inflation systems, and increasingly, battery packs and cooling systems for electric vehicles. Manufacturers in this sector are driven by stringent safety standards and the demand for durable, high-performance vehicles, making precise leak detection an indispensable part of their production processes. The shift towards EVs is introducing new and complex leak testing challenges, further expanding this customer segment's demand for advanced solutions.

Another critical customer base resides within the medical device and pharmaceutical industries. Here, leak test apparatus is essential for ensuring the sterility and integrity of drug packaging, medical implants, catheters, syringes, and various diagnostic instruments. The non-negotiable requirements for patient safety and efficacy, coupled with strict regulatory oversight from bodies like the FDA, compel manufacturers to invest in the most accurate and reliable leak detection systems. Any failure in these products due to leaks can have severe consequences, making quality assurance through advanced leak testing a top priority. This segment often demands highly sensitive and validated testing methods to meet extreme precision requirements and compliance mandates.

Beyond these primary sectors, potential customers include a broad spectrum of general manufacturing companies, particularly those involved in industrial equipment, HVAC/refrigeration, and consumer electronics. Manufacturers of industrial valves, pipes, fittings, heat exchangers, and compressed gas systems rely on leak testing to ensure the safety and efficiency of their products. In the HVAC and refrigeration sector, leak detection is crucial for preventing refrigerant loss and ensuring system performance and environmental compliance. Furthermore, companies in the food and beverage industry utilize leak test apparatus to verify the hermetic seals of packaging, preventing spoilage and maintaining product freshness, while the electronics industry employs these systems to protect sensitive components from environmental ingress. Research and development laboratories also serve as key buyers, using these systems for material characterization, product development, and quality validation in innovative applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 920 million |

| Market Forecast in 2033 | USD 1.46 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Inficon, Pfeiffer Vacuum GmbH, ATEQ, Uson, Cincinnati Test Systems (CTS), LACO Technologies, Schaefer Technologies Inc., Cosmo Instruments Co., Ltd., Varian Medical Systems, TASI Group (CTS-Schrader, Sciemetric), VIC Leak Detection (Vacuum Instrument Corporation), CETA Testsysteme GmbH, InterTech Development Company, Edwards Vacuum, Rotarex, Dürr AG, Furness Controls Limited, Gagemaker, Technifor |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Leak Test Apparatus Market Key Technology Landscape

The Leak Test Apparatus Market is characterized by a dynamic and continuously evolving technology landscape, driven by the relentless pursuit of higher accuracy, speed, and versatility in leak detection. Historically, methods like bubble testing and simple pressure decay have formed the bedrock of the industry, offering cost-effective solutions for gross and medium leak detection. However, modern manufacturing demands, particularly from high-precision industries, have propelled the development and adoption of more sophisticated techniques. Key among these are mass flow leak testing, which offers enhanced sensitivity by measuring volumetric flow rates, and helium mass spectrometer leak detection, which stands as the gold standard for detecting extremely minute leaks, crucial in applications where even picogram-level leakage rates are critical. These advanced technologies are continually refined to improve detection limits, reduce test times, and broaden their applicability across various material types and product geometries.

Beyond the core detection principles, the technology landscape is heavily influenced by the integration of automation, digital control systems, and advanced data analytics. Modern leak test apparatus often incorporate programmable logic controllers (PLCs) and human-machine interfaces (HMIs) for precise control over test parameters, automated cycle execution, and user-friendly operation. The development of advanced sensors with improved resolution and stability is also a significant trend, contributing directly to the overall accuracy and reliability of the equipment. Furthermore, the increasing connectivity enabled by the Industrial Internet of Things (IIoT) is transforming leak testers into smart devices that can communicate with other factory systems, facilitate remote monitoring, and integrate into comprehensive quality management platforms, providing real-time process feedback.

The most impactful technological advancements currently shaping the market revolve around the incorporation of artificial intelligence (AI) and machine learning (ML). AI algorithms are being deployed to analyze complex leak test data, identify subtle patterns, optimize test parameters autonomously, and even predict potential equipment failures, moving from reactive quality control to proactive process optimization. This includes adaptive testing algorithms that learn from historical data to fine-tune test settings for different product batches or component variations. Moreover, the development of non-destructive testing (NDT) methods that integrate leak detection with other quality checks, alongside advancements in robotics for automated loading, unloading, and part handling, are significantly enhancing the efficiency and throughput of leak testing processes. These technological strides are not only improving the performance of leak test apparatus but also making them more adaptable to the increasingly complex and diversified demands of modern manufacturing environments.

Regional Highlights

The Leak Test Apparatus Market exhibits distinct regional dynamics, each influenced by varying levels of industrialization, regulatory frameworks, technological adoption rates, and economic conditions. North America, encompassing the United States and Canada, is a mature market characterized by high adoption of advanced leak testing technologies, particularly in the automotive, aerospace, medical device, and electronics sectors. Stringent regulatory standards for product quality and safety, coupled with a strong emphasis on R&D and manufacturing innovation, drive continuous demand for high-precision, automated, and often customized leak detection solutions. The region benefits from significant investments in smart manufacturing initiatives and a robust industrial infrastructure, positioning it as a key market for technological advancements and early adoption of AI-integrated systems.

Europe, including Germany, the UK, France, Italy, and other member states, also represents a significant market, largely driven by its robust automotive industry, pharmaceutical sector, and stringent environmental regulations. Countries like Germany are at the forefront of industrial automation and Industry 4.0, leading to a strong demand for highly integrated and efficient leak testing solutions. The region's focus on sustainability and emissions control further fuels the adoption of precise leak detection in industries like HVAC and refrigeration. While growth may be slower compared to emerging economies, the demand for advanced, high-quality, and compliant solutions ensures a stable and innovation-driven market in Europe.

- Asia Pacific (APAC): This region is projected to be the fastest-growing market, primarily due to rapid industrialization, expanding manufacturing capabilities, and increasing foreign direct investments in countries like China, India, Japan, and South Korea. The automotive, electronics, and general manufacturing sectors are booming, leading to a surge in demand for leak test apparatus. Growing awareness of quality control and rising disposable incomes fueling demand for high-quality consumer goods also contribute significantly to market expansion.

- North America: A technologically advanced and mature market, driven by strict regulatory frameworks and high-value manufacturing industries such as aerospace, medical devices, and automotive. High demand for automated, high-precision, and AI-integrated leak testing solutions.

- Europe: Characterized by strong automotive and pharmaceutical industries, coupled with stringent environmental regulations. Focus on Industry 4.0 and sustainable manufacturing drives the adoption of advanced and efficient leak detection systems.

- Latin America: An emerging market with growing industrialization and manufacturing activities, particularly in automotive and packaging sectors. Increasing investments in infrastructure and manufacturing facilities are expected to boost demand for leak test apparatus.

- Middle East & Africa (MEA): Showing nascent growth, driven by investments in manufacturing diversification, infrastructure development, and growing emphasis on quality control in oil & gas, automotive assembly, and packaging industries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Leak Test Apparatus Market.- Inficon

- Pfeiffer Vacuum GmbH

- ATEQ

- Uson

- Cincinnati Test Systems (CTS)

- LACO Technologies

- Schaefer Technologies Inc.

- Cosmo Instruments Co., Ltd.

- Varian Medical Systems (part of Siemens Healthineers)

- TASI Group (including brand names like Cincinnati Test Systems, Sciemetric, and CTS-Schrader)

- VIC Leak Detection (Vacuum Instrument Corporation)

- CETA Testsysteme GmbH

- InterTech Development Company

- Edwards Vacuum

- Rotarex

- Dürr AG (through its Industrial Automation division)

- Furness Controls Limited

- Gagemaker

- Technifor

Frequently Asked Questions

What is a leak test apparatus and why is it important?

A leak test apparatus is a specialized instrument or system used to detect and quantify the presence of unintended openings or flaws (leaks) in products, components, or sealed systems. It is critically important for ensuring product quality, operational safety, and regulatory compliance across various industries. By identifying leaks, these devices prevent product failures, reduce waste, enhance reliability, and protect both consumers and the environment from potential hazards, thereby safeguarding brand reputation and reducing warranty claims.

What are the primary technologies used in leak testing?

The primary technologies include Pressure Decay, Mass Flow, Helium Leak Detection (using mass spectrometers), Bubble Testing, and Vacuum Decay. Pressure decay measures pressure drops in a sealed part; mass flow gauges air or gas flow. Helium leak detection offers ultra-high sensitivity using a tracer gas. Bubble testing is a visual method, while vacuum decay detects leaks in flexible packaging by monitoring pressure rise in an evacuated chamber. Each technology is selected based on the required sensitivity, product type, and application demands.

Which industries are the biggest users of leak test apparatus?

The automotive industry is a major user for testing fuel systems, engines, and EV components. The medical and pharmaceutical sectors extensively use them for sterile packaging, implants, and devices. Other significant users include general manufacturing (valves, fittings, aerospace parts), packaging (food, beverage, consumer goods), electronics (hermetically sealed components), and HVAC/refrigeration for refrigerant containment. These industries require precise leak detection to meet stringent quality, safety, and regulatory standards.

How is AI impacting the leak test apparatus market?

AI is significantly impacting the market by enhancing accuracy, speed, and automation. AI algorithms analyze complex data for minute leak detection, optimize test parameters in real-time, and enable predictive maintenance for apparatus. This leads to reduced human error, improved efficiency, and deeper insights into manufacturing processes for proactive quality control. AI-driven systems integrate seamlessly into Industry 4.0 environments, transforming leak testing into an intelligent, data-driven, and preventive quality assurance function.

What are the key growth drivers and challenges for the market?

Key growth drivers include increasing global demand for high-quality products, stringent regulatory mandates across industries, and the widespread adoption of automation and Industry 4.0 principles. Challenges include the high initial investment costs for advanced systems, the technical complexity requiring specialized expertise, and a lack of universal standardization across diverse applications. Addressing these challenges while capitalizing on opportunities in emerging sectors like electric vehicles and advanced medical devices will be crucial for market players.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager